- DL manuals

- ABB

- Remote Starter

- PST105

- Installation And Commissioning Manual

ABB PST105 Installation And Commissioning Manual - Operation

Functions

Chapter 10

144

1SFC132003M0201

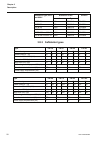

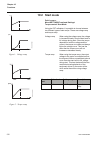

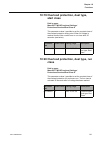

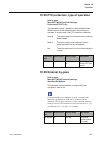

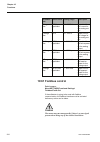

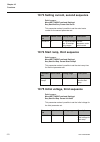

10:24 Locked rotor protection time

Path in menu:

Menu/SETTINGS/Functional Settings/

Protections/Locked Rotor/Lock R Time

This parameter makes it possible to set the delay time from

detection until activation of the protection.

It is active only if Locked rotor protection is selected.

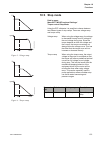

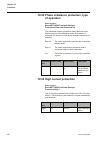

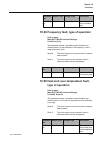

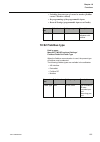

10:25 Locked rotor protection, type of

operation

Path in menu:

Menu/SETTINGS/Functional Settings/

Protections/Locked Rotor/Lock R Op

This parameter makes it possible to select between three

different actions of the softstarter when the protection is

activated. It is active only if the Locked rotor protection is

selected.

Stop–M

The motor stops and a manual reset is required

before restart.

Stop–A

The motor stops and an automatic reset is

performed when the fault disappears.

Ind

The motor continues to run but a fault indication

is given.

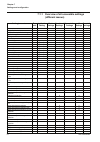

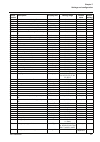

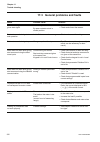

Parameter

text

Default value Setting range

Description

Lock R

Time

1.0 s

0.2...10.0 s

Trip time for

locked rotor pro-

tection

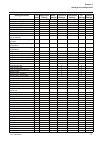

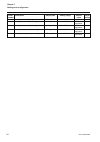

Parameter

text

Default value Setting range

Description

Lock R Op Stop–M

Stop–M, Stop–A,

Ind

Type of opera-

tion for locked

rotor protection

Summary of PST105

Page 1

Power on protection fault power on protection fault power on protection fault power on protection fault power on protection fault softstarters type pst30...Pstb1050 installation and commissioning manual manual 1sfc132003m0201 june 2007.

Page 2: This Manual Belongs To:

This manual belongs to:.

Page 3: Softstarters

Softstarters type pst30...Pstb1050 installation and commissioning manual manual 1sfc132003m0201 june 2007.

Page 5: Pst30...Pstb1050

5 1sfc132003m0201 installation and commissioning manual pst30...Pstb1050 1 general this is the installation and commissioning manual for softstarters pst30...Pstb1050 based on software version cu 05.02.Xx (see status information menu) document number: 1sfc132003m0201 edition: 04 revision: 03 issue d...

Page 6: Safety

6 1sfc132003m0201 2 safety this chapter describes warning and information signs used in this manual, which the user should pay attention to. The softstarter shall be installed by authorized personnel only. This manual is a part of the softstarter and should always be accessible to personnel working ...

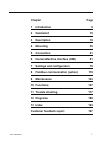

Page 7: Chapter

7 1sfc132003m0201 chapter page 1 introduction 9 2 quickstart 15 3 description 19 4 mounting 35 5 connection 41 6 human-machine interface (hmi) 61 7 settings and configuration 75 8 fieldbus communication (option) 119 9 maintenance 123 10 functions 127 11 trouble shooting 177 12 diagrams 189 13 index ...

Page 8: Notes

Chapter 8 1sfc132003m0201 notes .................................................................................................................................. .................................................................................................................................. .........

Page 9: Chapter 1 Introduction

9 1sfc132003m0201 chapter 1 introduction about the complete set of documentation for a softstarter................................ 11 about the installation and commissioning manual ............................................ 11 intended audience .......................................................

Page 10: Introduction

Introduction 10 1sfc132003m0201.

Page 11: Chapter 1 Introduction

Introduction chapter 1 11 1sfc132003m0201 chapter 1 introduction 1:1 about the complete set of documentation for a softstarter for the softstarter, the following documents are available: pst30...Pstb1050 softstarters installation and commissioning manual document id: 1sfc132003m0201 1sfc132003m2001 ...

Page 12: 1:2.2 Chapters Included

Introduction chapter 1 12 1sfc132003m0201 1:2.1.2 requirements the installation personnel must have a basic knowledge in handling electric equipment. The commissioning and maintenance personnel must be well experienced in using this kind of equipment. 1:2.2 chapters included • introduction introduce...

Page 13

Introduction chapter 1 13 1sfc132003m0201 1:2.4 acronyms and abbreviations the following acronyms and abbreviations are used in this manual. Acronym/ abbreviation description bp by-pass dol direct-on-line fb fieldbus fbp fieldbusplug hmi human-machine interface it information technology lcd liquid c...

Page 14

Introduction chapter 1 14 1sfc132003m0201.

Page 15: Chapter 2 Quickstart

15 1sfc132003m0201 chapter 2 quickstart connection ........................................................................................................ 17 configuration..................................................................................................... 18 start of the motor .......

Page 16: Quickstart

Quickstart 16 1sfc132003m0201.

Page 17: Chapter 2 Quickstart

Quickstart chapter 2 17 1sfc132003m0201 chapter 2 quickstart this chapter is a short guide to how to connect, do the configuration and start the softstarter in the easiest way. Warning! Mounting, electrical connection and settings of the softstarter shall be made in accordance with existing laws and...

Page 18: 2:2

Quickstart chapter 2 18 1sfc132003m0201 2:2 configuration 1. Enter the application setting by pressing left selection key twice. Press select using the left selection key. Figure 4. 2. Select the appropriate type of load using navigation keys. Figure 5. 3. Press store set and next to continue or bac...

Page 19: Chapter 3 Description

19 1sfc132003m0201 chapter 3 description overview ........................................................................................................... 21 functions .......................................................................................................... 22 markings and connec...

Page 20: Description

Description 20 1sfc132003m0201.

Page 21: Chapter 3 Description

Description chapter 3 21 1sfc132003m0201 chapter 3 description this chapter describes the softstarter in general, specifications as well as available accessories and spare parts. 3:1 overview the pst softstarter is a microprocessor-based softstarter designed with the latest technology for soft start...

Page 22: 3:2

Description chapter 3 22 1sfc132003m0201 3:2 functions the pst softstarter has several integrated protection and warning functions. Almost any type of fault can also be detected and displayed. All available protections, warnings, and fault indications are listed below. Start/stop functions • start r...

Page 23

Description chapter 3 23 1sfc132003m0201 fault supervision functions • phase loss • fieldbus communication • frequency out of range • heat sink over-temperature • thyristor short circuit • by-pass doesn’t open • by-pass doesn’t close • connection fault • non conducting thyristor • line side fault • ...

Page 24: 3:3

Description chapter 3 24 1sfc132003m0201 3:3 markings and connections figure 1: markings and connections 1sfa 894 007 r1002 ie: 37-72a ul 508 uc: 100-250v ac/dc fla: 37-68a made in sweden ue 208 220-240 440-480 v in line 20 20 50 hp caution fuse 250a typower zilox max short circuit current 65ka at 4...

Page 25: 3:4

Description chapter 3 25 1sfc132003m0201 3:4 type designation 3:5 industrial it thanks to abb's broad program of product standardization, today's industrial it components are - whether they are products or systems, hardware or software - the building blocks of larger solutions, incorporating functio...

Page 26: 3:6

Description chapter 3 26 1sfc132003m0201 3:6 environmental influence the product is designed to minimize the environmental affects during manufacturing and use of the product. Most of the materials used, are of recycle type and shall be handled and recycled according to existing laws. Further inform...

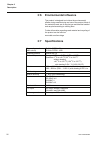

Page 27: 3:8

Description chapter 3 27 1sfc132003m0201 3:8 technical data 3:8.1 general 3:8.2 semi-conductor fuses general data rated insulation voltage, u i 690 v rated operational voltage, u e 208 - 600 v / 400 - 690 v rated supply voltage, u s 100 - 250 v 50/60 hz rated frequency 50 / 60 hz voltage tolerances ...

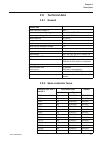

Page 28: 3:8.3 Softstarter Types

Description chapter 3 28 1sfc132003m0201 3:8.3 softstarter types pstb470 900 170m5015 170h3004 pstb570 900 170m5015 170h3004 pstb720 1250 170m5018 170h3004 pstb840 1500 170m6018 170h3004 pstb1050 xxx-600-70 1800 170m6020 170h3004 pstb1050 xxx-690-70 1600 170m6019 170h3004 softstarter type, 600 v and...

Page 29

Description chapter 3 29 1sfc132003m0201 type pst142 pst175 pst210 pst250 connection type line delta line delta line delta line delta rated current i e (a) 142 245 175 300 210 360 250 430 motor size 380 - 415v (kw) 75 132 90 160 110 184 132 220 motor size 480v (hp) 100 150 125 200 150 250 200 300 mo...

Page 30: 3:8.4 Weights

Description chapter 3 30 1sfc132003m0201 3:8.4 weights 3:8.5 ul information equipment suitable for use in a circuit with maximum available fault current as shown when protected by devices indicated. Suitable for use on a circuit capable of delivering not more than 1) rms symmetrical amperes, 2) volt...

Page 31: 3:8.6 Dimensions

Description chapter 3 31 1sfc132003m0201 3:8.6 dimensions pst30...72 figure 2: dimensions pst30...72 (mm) (1 mm = 0.0394 in) pst85...142 figure 3: dimensions pst85...142 (mm) (1 mm = 0.0394 in) 1sfc132038f0001 1sfc132039f0001.

Page 32

Description chapter 3 32 1sfc132003m0201 pst85...142 with marine pack figure 4: dimensions pst85..142 with marine kit (mm) (1 mm = 0.0394 in) pst175...300 figure 5: dimensions pst175..300 (mm) (1 mm = 0.0394 in) 12 7 46,5 262 52,5 251 64,5 390 46,5 155 270 1 s f c 132 130f 02 01 1s f c 1321 31f 020 ...

Page 33

Description chapter 3 33 1sfc132003m0201 pstb370...470 figure 6: dimensions pstb370...470 (mm) (1 mm = 0.0394 in) pstb570...1050 figure 7: dimensions pstb570...1050 (mm) (1 mm = 0.0394 in) 1sfc132041f0001 243 162 1sfc132042f0001.

Page 34

Description chapter 3 34 1sfc132003m0201.

Page 35: Chapter 4 Mounting

35 1sfc132003m0201 chapter 4 mounting receiving, unpacking and checking.................................................................. 37 intermediate storage .................................................................................... 37 mounting ............................................

Page 36: Mounting

Mounting 36 1sfc132003m0201.

Page 37: Chapter 4 Mounting

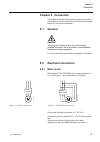

Mounting chapter 4 37 1sfc132003m0201 chapter 4 mounting this chapter describes instructions on how to receive the softstarter and how to mount it in a proper way. 4:1 receiving, unpacking and checking • check that the package is turned with the correct side up, figure 1. • check for transport damag...

Page 38: 4:2.2 Requirements

Mounting chapter 4 38 1sfc132003m0201 4:2.2 requirements see chapter 3 “description” for environmental requirements. 4:2.3 minimum distance to wall/front to have a suitable cooling, the softstarter has to be mounted vertically, and in such a way that the airways are not blocked, see figure 2. Follow...

Page 39

Mounting chapter 4 39 1sfc132003m0201 4:2.4 minimum enclosure sizes in applications where the softstarter is installed in an enclosure, the following minimum enclosure sizes and fan capacities are recommended. (1mm = 0.0394 in) dimensions and drilling plan see chapter 3 “description” . 4:2.5 addings...

Page 40

Mounting chapter 4 40 1sfc132003m0201.

Page 41: Chapter 5 Connection

41 1sfc132003m0201 chapter 5 connection general ............................................................................................................. 43 electrical connection ......................................................................................... 43 main circuit...............

Page 42: Connection

Connection 42 1sfc132003m0201.

Page 43: Chapter 5 Connection

Connection chapter 5 43 1sfc132003m0201 chapter 5 connection this chapter describes the electrical connections as well as connections for communication devices that have to be made before you can use the softstarter. 5:1 general caution! All wiring and connection must be carried out by a qualified e...

Page 44

Connection chapter 5 44 1sfc132003m0201 when used for marine applications, please use standard installation cables with concentric conductors for earth. This earth conductor shall be 360 degree connected to earth in the cable glands or in the near of the gland. Warning! Capacitors for power factor c...

Page 45

Connection chapter 5 45 1sfc132003m0201 5:2.1.1 external by-pass contactor an external by-pass contactor can be used for softstarters size pst30...300 (built in for size pstb370...1050). Connect the contactor to terminals b1, b2, and b3 on the line side and terminals 2t1, 4t2, and 6t3 on the motor s...

Page 46

Connection chapter 5 46 1sfc132003m0201 m8 m8 m10 m12 9 nm - 80 lb.In m8 6 nm - 53 lb.In 1 x 6 ...... 70 mm 2 x 6 ...... 35 mm 1 x 6 ...... 70 mm 2 x 6 ...... 35 mm a wg 1...8 2 2 2 2 4 mm 18 nm - 160 lb.In pst 30...72 pst 85...142 pst 175...300 14 14 1l1 2t1 4t2 6t3 b1 b2 b3 3l2 5l3 40 nm - 354 lb....

Page 47

Connection chapter 5 47 1sfc132003m0201 5:2.2 supply voltage and control circuit when used for marine applications, and if feeding from the outside of the enclosure, then please use a standard cable for feeding the supply voltage and for the control circuit, with an auxiliary bare conductor (earth c...

Page 48

Connection chapter 5 48 1sfc132003m0201 5:2.2.3 start and stop, terminals 4, 5, 8, 9, 10, 11 internal control voltage the softstarter has a built-in holding circuit which does not require any external power source for start and stop, see figure 11. A conventional circuit with auxiliary relay is also...

Page 49

Connection chapter 5 49 1sfc132003m0201 external control voltage the softstarter can, if required, also be used with an external 24 v dc source from a plc or similar. Connect the cables according to figure 14 or figure 15 depending on which type of control method is used. Warning! Terminal 4, 5, 6, ...

Page 50

Connection chapter 5 50 1sfc132003m0201 5:2.2.4 programmable inputs, terminals 6 and 7 the softstarter has two programmable inputs. In0, default reset event. In1, default reset event. See chapter 7 “settings and configuration” for programming. 1. Connect the cables according to figure 18 or figure 1...

Page 51

Connection chapter 5 51 1sfc132003m0201 programmable inputs (sequence start) when sequence start is going to be used, the wiring should be according to figure 21 or figure 22. The start command (terminal 5, 6, and 7) must be maintained during the complete start sequence and run otherwise a direct st...

Page 52

Connection chapter 5 52 1sfc132003m0201 5:2.2.5 programmable output relay k4, terminals 12, 13, and 14 the output relay gives signal depending on the selected function. Default: run see chapter 7 “settings and configuration” for programming. 1. Connect the cables to terminal 12, 13, and 14. 5:2.2.6 ...

Page 53

Connection chapter 5 53 1sfc132003m0201 5:2.2.7 programmable output relay k6, terminals 18, 19, and 20 the output relay gives signal depending on the selected function. Default: event see chapter 7 “settings and configuration” for programming. 1. Connect the cables to terminal 18, 19, and 20. 5:2.2....

Page 54: (Pstb370...1050 Only)

Connection chapter 5 54 1sfc132003m0201 5:2.2.9 analog output if the analog output is used, the cables shall be connected to terminals 23 and 24, see figure 30. See chapter 7 “settings and configuration” for programming. The ptc input uses the same terminals as the analog output and only one of thes...

Page 55

Connection chapter 5 55 1sfc132003m0201 figure 34: tightening torques and cable dimensions (1 mm=0.0394 in) x9 x9 100-250v 50/60 hz figure 32: connection when the contactor is operated from the keypad (factory wiring) figure 33: connection when the by-pass contactor is operated separately (emergency...

Page 56: 5:3

Connection chapter 5 56 1sfc132003m0201 5:3 connection of communication devices (optional) 5:3.1 fieldbus communication the fieldbus communication plug shall be connected to the communication interface on the front of the pst, see figure 35. Make sure that the plug is in correct position and tighten...

Page 57: 5:3.2 External Keypad

Connection chapter 5 57 1sfc132003m0201 5:3.2 external keypad an external keypad for door mounting can be connected to the softstarter. A 3-meter cable including both the serial communication and the power supply to the keypad makes the connection. The cable shall be connected to the external keypad...

Page 58

Connection chapter 5 58 1sfc132003m0201 5:3.3 transferring of parameters to transfer(copy) parameters from one softstarter to another, connect the keypad to the chosen softstarter and follow the sequence below. 5:3.3.1 uploading of parameters enter the menu transfer par. Select to keypad and confirm...

Page 59

Connection chapter 5 59 1sfc132003m0201 5:3.3.3 technical data general data display lcd type signal indication leds power on: green protection: yellow fault: red ambient temperature storage: -25 ° c to +70 ° c (-13 ° f to 158 ° f) operation: 0 ° c to +50 ° c (32 ° f to 122 ° f) degree of protection ...

Page 60

Connection chapter 5 60 1sfc132003m0201.

Page 61

61 1sfc132003m0201 chapter 6 human-machine interface (hmi) overview ........................................................................................................... 63 application ................................................................................................... 63 design...

Page 62

Human-machine interface (hmi) 62 1sfc132003m0201.

Page 63: (Hmi)

Human-machine interface (hmi) chapter 6 63 1sfc132003m0201 chapter 6 human-machine interface (hmi) this chapter describes how the human-machine interface (keypad and display) works. 6:1 overview 6:1.1 application the human-machine interface is used for several purposes such as programming the softst...

Page 64: 6:1.2 Design

Human-machine interface (hmi) chapter 6 64 1sfc132003m0201 6:1.2 design the hmi consists of: • status indication led indicators • lcd display • selection and navigation keys the led indicators work as follows: the keypad is based on the same user concept as today’s mobile phones. The lcd display con...

Page 65

Human-machine interface (hmi) chapter 6 65 1sfc132003m0201 the functionality of the keypad is illustrated by the following example: changing the rated motor current (setting i e ). 1. You will find the setting as well as a short explanation and the path to it in chapter 10 “functions” . Path in menu...

Page 66: 6:1.3 Password

Human-machine interface (hmi) chapter 6 66 1sfc132003m0201 6:1.3 password to lock the keypad from control and change of settings, a password can be set. When the keypad is locked, all menus are available but no changes can be done nor any actions can be taken. 6:1.3.1 setting password the password a...

Page 67

Human-machine interface (hmi) chapter 6 67 1sfc132003m0201 6:1.4 locking/unlocking the keypad 1. Press the upper navigation key twice to enter the param- eter keypad is, figure 16. 2. The keypad is unlocked if the display is indicating active in the upper right corner. 3. Lock the keypad. 4. Select ...

Page 68: 6:2

Human-machine interface (hmi) chapter 6 68 1sfc132003m0201 6:2 menu tree 6:2.1 overview the menu tree includes menus for • settings • local control • event log • status information • reset events figure 18: menu tree top level settings local control event log status information reset events start/st...

Page 69: 6:2.2 Top Level

Human-machine interface (hmi) chapter 6 69 1sfc132003m0201 6:2.2 top level top level contains general softstarter information, and the menus can be reached from here. The selections are presented one by one on the top row. Use navigation keys to present all selections. Press select to enter a functi...

Page 70: 6:2.4 Local Control Menu

Human-machine interface (hmi) chapter 6 70 1sfc132003m0201 6:2.4 local control menu the local control menu is used to start or stop the motor from the keypad. When a type of local control is selected the softstarter can only be controlled by the keypad. The softstarter operation state (stopped/runni...

Page 71

Human-machine interface (hmi) chapter 6 71 1sfc132003m0201 6:2.4.2 jog enter the jog menu, figure 23. Select jog. The motor will start and accelerate to rated speed according to the set parameters as long as the jog command is activated. The motor stops immediately as soon as the command is released...

Page 72: 6:2.5 Event Log Menu

Human-machine interface (hmi) chapter 6 72 1sfc132003m0201 6:2.5 event log menu the event log menu is used to check the event log in the softstarter. When entering this menu the 21 latest events in the log are presented, in chronological order with the latest event as no. 1, the second latest as no....

Page 73: 6:2.7 Reset Events Menu

Human-machine interface (hmi) chapter 6 73 1sfc132003m0201 6:2.7 reset events menu the reset events menu is entered automatically when a fault has occurred or a protection is activated. It can also be entered via the main menu. Use navigation keys to view if there are several events to reset. Figure...

Page 74

Human-machine interface (hmi) chapter 6 74 1sfc132003m0201.

Page 75: Setting and Configuration

75 1sfc132003m0201 chapter 7 settings and configuration settings ............................................................................................................. 77 overview of all accessible settings (different menus) .................................. 78 parameter list...................

Page 76: Setting and Configuration

Setting and configuration 76 1sfc132003m0201.

Page 77: 7:1

Settings and configuration chapter 7 77 1sfc132003m0201 chapter 7 settings and configuration 7:1 settings settings can be done in three different ways: • keypad • fieldbus communication • external keypad (option) with the keypad, settings can be done as individual parameter setting or selection of p...

Page 78: (Different Menus)

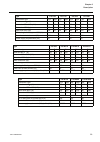

Settings and configuration chapter 7 78 1sfc132003m0201 7:1.1 overview of all accessible settings (different menus) setting/parameter top level application setting basic settings functional settings presentation settings all settings reset all settings password x keypad lock/unlock x reset to factor...

Page 79

Settings and configuration chapter 7 79 1sfc132003m0201 low current warning x x low current warning level x x overload warning x x overload warning level x x thyristor (scr) overload warning x x phase loss fault, type of operation x x fieldbus fault, type of operation x x frequency fault, type of op...

Page 80

Settings and configuration chapter 7 80 1sfc132003m0201 dual current limit time x dual current limit level x setting/parameter top level application setting basic settings functional settings presentation settings all settings reset all settings.

Page 81: 7:1.2 Parameter List

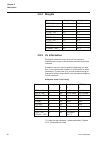

Settings and configuration chapter 7 81 1sfc132003m0201 7:1.2 parameter list param. Number description display text setting range default value actual setting 1 setting current setting ie 9.0...1207a individual 2 start ramp start ramp 1...30s, 1...120s 10s 3 stop ramp stop ramp 0...30s, 0...120s 0s ...

Page 82

Settings and configuration chapter 7 82 1sfc132003m0201 50 function of programmable input in1 in1 none, reset, enable jog, dol, start 3, fb- dis reset 51 function of programmable output relay k4 relay k4 run, tor, event run 52 function of programmable output relay k5 relay k5 run, tor, event tor 53 ...

Page 83

Settings and configuration chapter 7 83 1sfc132003m0201 58(4) locked rotor event of relay v7 v7 lock rot yes, no no 58(5) underload event of relay v7 v7 underload yes, no no 58(6) phase imbalance event of relay v7 v7 phase imb yes, no no 58(7) ptc event of relay v7 v7 ptc yes, no no 58(8) phase reve...

Page 84

Settings and configuration chapter 7 84 1sfc132003m0201 127 analog output, voltage range max u range max 10...1000v 600v 128 analog output, active power range max kw kw range max 1...3000kw pst(b) size dependent 129 analog output, active power range max hp hp range max 1...4000hp pst(b) size depende...

Page 85: 7:2 Description of Menus

Settings and configuration chapter 7 85 1sfc132003m0201 7:2 description of menus for detailed description of each function, see chapter 10 “functions” . 7:2.1 top level this level contains information about output voltage and current, heat sink temperature, real time clock and more. From this menu, ...

Page 86

Settings and configuration chapter 7 86 1sfc132003m0201 start mode the start mode of the motor is displayed. The possible options are: • volt • torque stop mode the stop mode of the motor is displayed. The possible options are: • volt • torque status of inputs/outputs the status of the programmable ...

Page 87: 7:2.2 Application Setting

Settings and configuration chapter 7 87 1sfc132003m0201 7:2.2 application setting the application setting menu consists of predefined parameters for the selected application and should be used if an easy and quick set-up is required. Only a few parameters have to be set before start of the motor is ...

Page 88

Settings and configuration chapter 7 88 1sfc132003m0201 setting i e set the current that the softstarter will be exposed to i.E. Rated motor current if the unit is connected in line. For units connected inside delta the setting i e must be set according to the current in the delta circuit = 58% ( ) ...

Page 89

Settings and configuration chapter 7 89 1sfc132003m0201 tuning parameters nine parameters can be tuned individually if a more specific adjustment is required. Each parameter is described in chapter 10 “functions” . • start mode • stop mode • start ramp • stop ramp • initial voltage • end voltage • s...

Page 90: 7:2.3 Basic Settings

Settings and configuration chapter 7 90 1sfc132003m0201 7:2.3 basic settings the basic settings menu consists of the most common start/ stop parameters required for the set-up. Each parameter can be adjusted separately. For a deep description of each parameter, see chapter 10 “functions” . Enter the...

Page 91

Settings and configuration chapter 7 91 1sfc132003m0201 start ramp set the ramp time for start. Press store to save the time for the start ramp. Stop ramp set the ramp time for stop (softstop). Note that this function shall only be used for applications with small flywheel masses, for example pumps ...

Page 92: 7:2.4 Functional Settings

Settings and configuration chapter 7 92 1sfc132003m0201 7:2.4 functional settings the functional setting menu consists of groups with parameters arranged by function such as protection, warning, fault, fieldbus communication etc. This menu should be used if a more advanced set-up is required. For a ...

Page 93

Settings and configuration chapter 7 93 1sfc132003m0201 kick start activate the kick start function by entering this menu. Press store to save the selection. Kick level set the required level of the kick start. Press store to save the data. This menu will only be visual if kick start is activated. K...

Page 94

Settings and configuration chapter 7 94 1sfc132003m0201 7:2.4.2 torque control to set parameters related to torque control, enter the torque control group. Start mode select which type of ramp that shall be used during start. The possible options are: • volt • torque press store to save the selected...

Page 95

Settings and configuration chapter 7 95 1sfc132003m0201 7:2.4.3 protections to set parameters related to the protections, enter the protections group. Caution! The motor may start unexpectedly if there is a start signal present when the softstarter has tripped for a protection and a reset is perform...

Page 96

Settings and configuration chapter 7 96 1sfc132003m0201 if overload “dual” is selected, the following settings will be available: overload start class (ol class s) select the required class for overload relay during start condition. Following classes are available: • 10a • 10 • 20 • 30 press store t...

Page 97

Settings and configuration chapter 7 97 1sfc132003m0201 locked rotor protection (locked rotor) activate the protection if required by changing to yes. If “yes” is selected, the following settings will be available: locked rotor level (lock r lev) set the level of the locked rotor protection. Availab...

Page 98

Settings and configuration chapter 7 98 1sfc132003m0201 underload protection (underload) activate the protection if required by changing to yes. If “yes” is selected, the following settings will be available: underload level (underl lev) set the level of the underload protection. Available only if t...

Page 99

Settings and configuration chapter 7 99 1sfc132003m0201 phase imbalance protection (phase imb) activate the protection if required by changing to yes. If “yes” is selected, the following settings will be available: phase imbalance level (ph imb lev) set the level of the phase imbalance protection. A...

Page 100

Settings and configuration chapter 7 100 1sfc132003m0201 phase reversal protection (phase rev) activate the phase reversal protection if required by changing to yes. If “yes” is selected, the following setting will be available: phase reversal type of operation (ph rev op) select what operation shal...

Page 101

Settings and configuration chapter 7 101 1sfc132003m0201 7:2.4.4 warnings to set parameters related to the warnings, enter the warnings group: high current warning (warn i=high) activate the warning function if required by changing to yes. Press store to save the selected operation high current warn...

Page 102

Settings and configuration chapter 7 102 1sfc132003m0201 7:2.4.5 faults caution! The motor may start unexpectedly if there is a start signal present when the softstarter has tripped for a fault and a reset is performed. This reset can be either manual (stop- m) or automatic (stop-a). Phase loss faul...

Page 103

Settings and configuration chapter 7 103 1sfc132003m0201 stop–a the motor will stop and an automatic reset is performed. Press store to save the selected operation. Thyristor short circuit fault, type of operation (scr sc op) select what operation shall be asserted if a fault occurs with shorted thy...

Page 104

Settings and configuration chapter 7 104 1sfc132003m0201 7:2.4.6 inputs to set parameters related to the programmable inputs, enter the inputs group. First programmable input (in0) select the required function for the input in0. Press store to save/activate the selected function. One of the followin...

Page 105

Settings and configuration chapter 7 105 1sfc132003m0201 second programmable input (in1) select the required function for the input in1. One of the following functions can be selected: none no specific function (not activated). Reset reset of an event. Enable when the in1=0 the softstarter stops imm...

Page 106

Settings and configuration chapter 7 106 1sfc132003m0201 7:2.4.7 outputs to set parameters related to the programmable outputs, enter the outputs group. Output relay k4 (relay k4) select the required function for the output relay k4. One of the following functions can be selected: run run indication...

Page 107

Settings and configuration chapter 7 107 1sfc132003m0201 output relay k6 (relay k6) select the required function for the output relay k6. One of the following functions can be selected: run run indication. Tor top of ramp indication. Event indication of selected event(s), see relay k4. Press store t...

Page 108

Settings and configuration chapter 7 108 1sfc132003m0201 7:2.4.8 analog output to set parameters related to the analog output, enter the analog output group. Analog output (analog out) activate the analog output by changing to yes. Since the analog output uses the same terminals as the ptc protectio...

Page 109

Settings and configuration chapter 7 109 1sfc132003m0201 • current of the motor (i amp) • main voltage (u volt) • active power kw (p kw) • active power hp (p hp) • reactive power (q kvar) • apparent power (s kva) • calculated temperature of the motor (tmpmot) • calculated temperature of the scr (tmp...

Page 110

Settings and configuration chapter 7 110 1sfc132003m0201 7:2.4.9 fieldbus to set parameters related to the fieldbus communication, enter the fieldbus group. Fieldbus control (fieldb ctrl) activate the fieldbus control of the softstarter by changing to yes. Press store to save the selected function. ...

Page 111

Settings and configuration chapter 7 111 1sfc132003m0201 7:2.4.10sequence start the sequence start function can be used for starting several motors or multiple speed motors with different parameter sets such as individual ramp times, initial voltages, current limits etc. Up to three individual param...

Page 112

Settings and configuration chapter 7 112 1sfc132003m0201 third sequence setting current (3rd set ie) set the current for the third parameter group. Press store to save the value. This parameter will only be displayed if parameter no of seq is set to 3. Function of first programmable input (in0) this...

Page 113

Settings and configuration chapter 7 113 1sfc132003m0201 second sequence parameters (2nd seq .Param.) to set parameters related to the second sequence, enter the 2nd seq. Param. Group. Following parameters can be adjusted: 2nd set ie setting current. Start ramp2 ramp time for start. Init volt2 initi...

Page 114: 7:2.5 Presentation Settings

Settings and configuration chapter 7 114 1sfc132003m0201 7:2.5 presentation settings the presentation setting menu consists of parameters for the lcd set-up. The presentation language can be chosen among 13 different languages. The real-time clock for the softstarter can be set in this menu. Enter t...

Page 115

Settings and configuration chapter 7 115 1sfc132003m0201 lcd auto off the lcd will be switched off automatically by a pre-set time between 1 - 255 minutes. If the display has switched off, a touch on any of the keys will switch it on again. Date type the date can be presented in three different ways...

Page 116: 7:2.6 Service Settings

Settings and configuration chapter 7 116 1sfc132003m0201 7:2.6 service settings the service setting menu consists of parameters used for maintenance and repair. This menu shall never be used by anybody but authorized service personnel. Warning! If parameters are changed the consequences can be malfu...

Page 117

Settings and configuration chapter 7 117 1sfc132003m0201 7:2.7.1 changed settings the changed settings menu consists of the parameters that have been changed in contrast to the factory default setting. If no parameters have been changed, the lcd will display no changed settings. 7:2.7.2 reset all se...

Page 118

Settings and configuration chapter 7 118 1sfc132003m0201 7:2.7.3 operation mode the operation mode makes it possible to switch between two different modes in the softstarter, a demo mode and the regular operation mode. By entering the demo mode, programmable inputs/outputs, start and stop circuits, ...

Page 119: (Option)

119 1sfc132003m0201 chapter 8 fieldbus communication (option) overview ......................................................................................................... 121 required accessories ................................................................................ 121 instructions....

Page 120

Fieldbus communication (option) 120 1sfc132003m0201.

Page 121: (Option)

Fieldbus communication (option) chapter 8 121 1sfc132003m0201 chapter 8 fieldbus communication (option) 8:1 overview the pst softstarter has an interface on the front for connecting the abb fieldbus plug used for fieldbus communication. Through this interface it is possible to control the softstarte...

Page 122: 8:1.2 Instructions

Fieldbus communication (option) chapter 8 122 1sfc132003m0201 8:1.2 instructions to do the set-up of input/output telegrams, parameter settings etc. Following instructions are available at www.Abb.Com/lowvoltage: • as-interface 1sfc132011m0201 • devicenet 1sfc132045m0201 • profibus dp 1sfc132044m020...

Page 123: Chapter 9 Maintenance

123 1sfc132003m0201 chapter 9 maintenance regular maintenance ...................................................................................... 125 service and repair ........................................................................................... 125 maintenance.

Page 124: Maintenance

Maintenance 124 1sfc132003m0201.

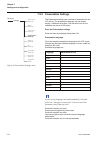

Page 125: Chapter 9 Maintenance

Maintenance chapter 9 125 1sfc132003m0201 chapter 9 maintenance this chapter describes the maintenance required for the softstarter. In principle, the product is maintenance free but some items should be checked regularly. Caution! Do not open the softstarter or touch any live parts when the main an...

Page 126

Maintenance chapter 9 126 1sfc132003m0201.

Page 127: Chapter 10 Functions

127 1sfc132003m0201 chapter 10 functions setting current................................................................................................. 131 start mode ...................................................................................................... 132 stop mode..................

Page 128: Function

Function 128 1sfc132003m0201 external by-pass ............................................................................................. 151 high current warning ....................................................................................... 152 high current warning level....................

Page 129

Chapter 129 1sfc132003m0201 lcd automatic switch-off ................................................................................ 172 password ........................................................................................................ 173 date type......................................

Page 130

Chapter 130 1sfc132003m0201.

Page 131: Chapter 10 Functions

Functions chapter 10 131 1sfc132003m0201 chapter 10 functions this chapter describes all settings and functions possible in the softstarter, as well as the easiest way of finding them. The respective default values, setting ranges and parameter texts shown in the display are also stated. 10:1 settin...

Page 132: 10:2 Start Mode

Functions chapter 10 132 1sfc132003m0201 10:2 start mode path in menu: menu/settings/functional settings/ torque control/ start mode using the pst softstarter it is possible to choose between two different types of start ramps. These are voltage ramp and torque ramp. Voltage ramp when using the volt...

Page 133: 10:3 Stop Mode

Functions chapter 10 133 1sfc132003m0201 10:3 stop mode path in menu: menu/settings/functional settings/ torque control/ stop mode using the pst softstarter it is possible to choose between two different types of stop ramps. These are voltage ramp and torque ramp. Voltage ramp when using the voltage...

Page 134: 10:4 Tune Torque Control

Functions chapter 10 134 1sfc132003m0201 10:4 tune torque control path in menu: menu/settings/functional settings/torque control/ tune t-ctrl with this parameter it is possible to change the speed of the regulator that regulates the voltage so that the torque will follow a predefined torque curve. I...

Page 135: 10:6 Stop Ramp

Functions chapter 10 135 1sfc132003m0201 10:6 stop ramp path in menu: menu/settings/functional settings/ start/stop / stop ramp when a stop signal is given, the softstarter performs a stop ramp by controlling the output voltage to the motor so that either the voltage or the torque decreases from ful...

Page 136: 10:8 End Voltage

Functions chapter 10 136 1sfc132003m0201 10:8 end voltage path in menu: menu/settings/functional settings/ start/stop / end volt this parameter makes it possible to set the voltage level where the stop ramp ends. The voltage or the torque will decrease from full voltage to this level and then cut th...

Page 137: 10:10 Current Limit

Functions chapter 10 137 1sfc132003m0201 10:10 current limit path in menu: menu/settings/functional settings/ start/stop / current lim it is possible to limit the starting current by using this function. When the current limit is reached, the output voltage stays stable until the current level falls...

Page 138: 10:12 Kick Start

Functions chapter 10 138 1sfc132003m0201 10:12 kick start path in menu: menu/settings/functional settings/ start/stop / kick start in some applications it can be necessary to kick loose the motor i.E. Initial friction, and therefore a kick start can be used. With this function a selectable fix volta...

Page 139: 10:15 Start Ramp Range

Functions chapter 10 139 1sfc132003m0201 10:15 start ramp range path in menu: menu/settings/functional settings/ start/stop / start range the time of the start ramp is settable up to 30 seconds as default, but if required the range could be extended up to 120 seconds by this parameter. A too long ra...

Page 140

Functions chapter 10 140 1sfc132003m0201 10:17 overload protection type path in menu: menu/settings/functional settings/ protections/overload this parameter makes it possible to set the required function of the integrated motor overload protection. Too high motor temperature causes a stop of the mot...

Page 141: Start Class

Functions chapter 10 141 1sfc132003m0201 10:19 overload protection, dual type, start class path in menu: menu/settings/functional settings/ protections/overload/dual class s this parameter makes it possible to set the required class of the overload protection during start. When full voltage is reach...

Page 142: Operation

Functions chapter 10 142 1sfc132003m0201 10:21 overload protection, type of operation path in menu: menu/settings/functional settings/ protections/overload/ol op this parameter makes it possible to select between three different actions by the softstarter when the protection is activated. It is acti...

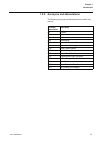

Page 143

Functions chapter 10 143 1sfc132003m0201 10:22 locked rotor protection path in menu: menu/settings/functional settings/ protections/locked rotor if the motor current exceeds the set level and the set time when the motor is running at full voltage, this protection is activated. The protection starts ...

Page 144: Operation

Functions chapter 10 144 1sfc132003m0201 10:24 locked rotor protection time path in menu: menu/settings/functional settings/ protections/locked rotor/lock r time this parameter makes it possible to set the delay time from detection until activation of the protection. It is active only if locked roto...

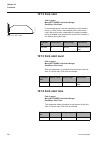

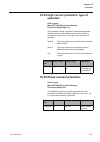

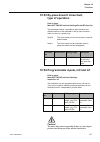

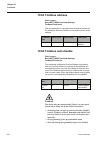

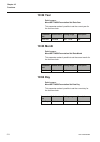

Page 145: 10:26 Underload Protection

Functions chapter 10 145 1sfc132003m0201 10:26 underload protection path in menu: menu/settings/functional settings/ protections/underload if the motor current falls below the set level and the set time when the motor is running at full voltage, the protection is activated. The protection starts mon...

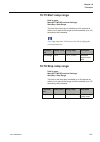

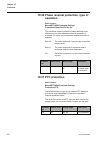

Page 146: Operation

Functions chapter 10 146 1sfc132003m0201 10:28 underload protection time path in menu: menu/settings/functional settings/ protections/underload/underl time this parameter makes it possible to set the delay time from detection until the protection is activated. It is active only if underload protecti...

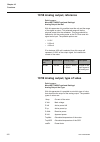

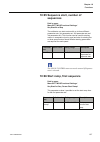

Page 147

Functions chapter 10 147 1sfc132003m0201 10:30 phase imbalance protection path in menu: menu/settings/functional settings/ protections/phase imb if the current in one phase differs from another phase with more than the set level the protection is activated. The protection starts monitoring 30 second...

Page 148: Of Operation

Functions chapter 10 148 1sfc132003m0201 10:32 phase imbalance protection, type of operation path in menu: menu/settings/functional settings/ protections/phase imb/phase imb op this parameter makes it possible to select between three different actions of the softstarter when the protection is activa...

Page 149: Operation

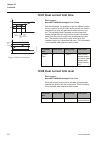

Functions chapter 10 149 1sfc132003m0201 10:34 high current protection, type of operation path in menu: menu/settings/functional settings/ protections/high i/high i op this parameter makes it possible to select between three different actions of the softstarter when the protection is activated. It i...

Page 150: Operation

Functions chapter 10 150 1sfc132003m0201 10:36 phase reversal protection, type of operation path in menu: menu/settings/functional settings/ protections/phase rev/ph rev op this parameter makes it possible to select between three different actions of the softstarter when the protection is activated....

Page 151: 10:39 External By-Pass

Functions chapter 10 151 1sfc132003m0201 10:38 ptc protection, type of operation path in menu: menu/settings/functional settings/ protections/ptc/ptc op this parameter makes it possible to select between three different actions of the softstarter when the protection is activated. It is active only i...

Page 152: 10:40 High Current Warning

Functions chapter 10 152 1sfc132003m0201 10:40 high current warning path in menu: menu/settings/functional settings/ warnings/warn i=high if the function is selected, a warning signal will be given provided that the current during full voltage is higher than the set value. The measurement starts 30 ...

Page 153: 10:44 Overload Warning

Functions chapter 10 153 1sfc132003m0201 10:43 low current warning level path in menu: menu/settings/functional settings/ warnings/warn i=low/wa i=l lev this parameter makes it possible to set the indication level of the low current warning function. 10:44 overload warning path in menu: menu/setting...

Page 154

Functions chapter 10 154 1sfc132003m0201 10:46 thyristor (scr) overload warning path in menu: menu/settings/functional settings/ warnings/warn scr ol if this function is selected, a warning signal will be given that the thyristor overload protection will be activated, if the current does not decreas...

Page 155: Type of Operation

Functions chapter 10 155 1sfc132003m0201 10:49 frequency fault, type of operation path in menu: menu/settings/functional settings/ faults/freq f op this parameter makes it possible to select between two different actions of the softstarter if the frequency is out of range (frequency fault). Stop–m t...

Page 156: Operation

Functions chapter 10 156 1sfc132003m0201 10:51 thyristor short circuit fault, type of operation path in menu: menu/settings/functional settings/ faults/scr sc op if one or several thyristors are shorted, this parameter makes it possible to select between two different actions of the softstarter. Sto...

Page 157: Type of Operation

Functions chapter 10 157 1sfc132003m0201 10:53 by-pass doesn't close fault, type of operation path in menu: menu/settings/functional settings/faults/bp open op this parameter makes it possible to select between two different actions of the softstarter if the by-pass contactor does not close in a pro...

Page 158

Functions chapter 10 158 1sfc132003m0201 • switching from one type of control to another (fieldbus control / hardwire control) • re-programming of the programmable inputs • reset all settings (programmable input set to enable) warning! Terminal 4, 5, 6, 7, 8, 9, 10, and 11 should be connected using ...

Page 159: K5, and K6

Functions chapter 10 159 1sfc132003m0201 10:55 programmable output relays, k4, k5, and k6 path in menu: menu/settings/functional settings/ outputs/relay k4 / k5 / k6 switch over relays the softstarter has three programmable output relays that can be used for different purposes depending on the selec...

Page 160

Functions chapter 10 160 1sfc132003m0201 description 2 fault groups can be selected. If any of the faults in a fault group occurs, a fault signal is given. Fault group consists of: • phase loss fault • fieldbus fault • frequency fault • heat sink over-temperature fault • by-pass doesn’t open fault •...

Page 161: 10:57 Analog Output

Functions chapter 10 161 1sfc132003m0201 10:56 programmable software output v7 path in menu: menu/settings/functional settings/ outputs/sw outp v7 if the softstarter is used with fieldbus communication, a fourth output is available. This is a software output only and the signal can be taken only thr...

Page 162

Functions chapter 10 162 1sfc132003m0201 10:58 analog output, reference path in menu: menu/settings/functional settings/ analog output /anl ref with this parameter it is possible to set the unit and the range of the signal to output. This selected range will be the physical output from the softstart...

Page 163

Functions chapter 10 163 1sfc132003m0201 10:60 analog output, range max path in menu: menu/settings/functional settings/ analog output/ i/u/p/q/s range max with this parameter it is possible to set the value that will be represented as the maximum value by an analog meter or by a plc. If for instanc...

Page 164: 10:61 Fieldbus Control

Functions chapter 10 164 1sfc132003m0201 10:61 fieldbus control path in menu: menu/settings/functional settings/ fieldbus/fieldb ctrl if the softstarter is going to be used with fieldbus communication, the fieldbus interface must be activated before any action can be taken. Caution! The motor may st...

Page 165: 10:62 Fieldbus Type

Functions chapter 10 165 1sfc132003m0201 • switching from one type of control to another (fieldbus control / hardwire control) • re-programming of the programmable inputs • reset all settings (programmable input set to enable) 10:62 fieldbus type path in menu: menu/settings/functional settings/ fiel...

Page 166: 10:63 Fieldbus Address

Functions chapter 10 166 1sfc132003m0201 10:63 fieldbus address path in menu: menu/settings/functional settings/ fieldbus/fieldb addr with this parameter it is possible to set a fieldbus address for the softstarter. Select a suitable, not occupied number as the address. 10:64 fieldbus auto disable p...

Page 167: Sequences

Functions chapter 10 167 1sfc132003m0201 10:65 sequence start, number of sequences path in menu: menu/settings/functional settings/ seq start/no of seq the softstarter can start motors with up to three different parameter sets (1st parameter set, 2nd parameter set and 3rd parameter set). This functi...

Page 168

Functions chapter 10 168 1sfc132003m0201 10:67 initial voltage, first sequence path in menu: menu/settings/functional settings/ seq start/1st seq. Param./init volt1 this parameter makes it possible to set the initial voltage for the first parameter set 10:68 current limit, first sequence path in men...

Page 169

Functions chapter 10 169 1sfc132003m0201 10:70 start ramp, second sequence path in menu: menu/settings/functional settings/ seq start/2nd seq. Param./start ramp2 this parameter makes it possible to set the start ramp time for the second parameter set. 10:71 initial voltage, second sequence path in m...

Page 170

Functions chapter 10 170 1sfc132003m0201 10:73 setting current, second sequence path in menu: menu/settings/functional settings/ seq start/2nd seq. Param./2nd set ie this parameter makes it possible to set the rated motor current for the second parameter set. 10:74 start ramp, third sequence path in...

Page 171

Functions chapter 10 171 1sfc132003m0201 10:76 current limit, third sequence path in menu: menu/settings/functional settings/ seq start/3rd seq. Param./curr lim3 this parameter makes it possible to set the current limit level for the third parameter set. 10:77 setting current, third sequence path in...

Page 172: 10:78 Language

Functions chapter 10 172 1sfc132003m0201 10:78 language path in menu: menu/settings/presentation set./language the text on the lcd display can be presented in 13 different languages. This parameter makes it possible to select among the following languages: • english • polish • turkish • russian • ch...

Page 173: 10:80 Password

Functions chapter 10 173 1sfc132003m0201 10:80 password path in menu: top level press upper navigation key once. This parameter makes it possible to set a password when locking the keypad from controlling and changing the settings. All menus are available when the keypad is locked but no changes or ...

Page 174: 10:82 Year

Functions chapter 10 174 1sfc132003m0201 10:82 year path in menu: menu/settings/presentation set./date year this parameter makes it possible to set the current year for the real time clock. 10:83 month path in menu: menu/settings/presentation set./date month this parameter makes it possible to set t...

Page 175: 10:85 Hour

Functions chapter 10 175 1sfc132003m0201 10:85 hour path in menu: menu/settings/presentation set./time hour this parameter makes it possible to set the current hour for the real time clock. 10:86 minutes path in menu: menu/settings/presentation set./time min this parameter makes it possible to set t...

Page 176

Functions chapter 10 176 1sfc132003m0201 10:87 dual current limit time path in menu: menu/settings/all settings/c lim y time with this softstarter it is possible to use two different current limits: one which is active initially and a second one which is controlled by a timer and goes active when th...

Page 177: Chapter 11 Trouble Shooting

177 1sfc132003m0201 chapter 11 trouble shooting general ........................................................................................................... 179 overview of indications ................................................................................... 179 general problems and...

Page 178: Trouble Shooting

Trouble shooting 178 1sfc132003m0201.

Page 179: Chapter 11 Trouble Shooting

Trouble shooting chapter 11 179 1sfc132003m0201 chapter 11 trouble shooting 11:1 general this chapter is a guide that can be used in case problems should arise with the softstarter or the application. The softstarter normally indicates a fault with led fault, and the lcd displays what type of fault ...

Page 180

Trouble shooting chapter 11 180 1sfc132003m0201 11:3 general problems and faults status possible cause solution motor humming / starts without given start signal. Shorted thyristor. By-pass contactor stuck in closed position. • check and replace. • check and correct the reason. Bad motor sound durin...

Page 181: 11:4 Start Up Faults

Trouble shooting chapter 11 181 1sfc132003m0201 11:4 start up faults 11:5 fault indication status possible cause solution lcd auto shut off the keypad. • touch any key on the keypad. Supply voltage is not connected. • connect the supply voltage according to the circuit diagram. Power on protection f...

Page 182

Trouble shooting chapter 11 182 1sfc132003m0201 frequency fault the frequency is out of range. (47.5 - 52.5hz or 57 - 63hz) • check and correct the frequency. Line side fault the main voltage is not correct on the line side. • check and correct voltage on the line side. Heat sink over-temperature fa...

Page 183

Trouble shooting chapter 11 183 1sfc132003m0201 fieldbus fault the fieldbus communication is not working. • check that the fieldbusplug is connected correctly. • check that correct type of fieldbusplug is used. • check that the parameter fieldbus type is set according to the present fieldbus type. B...

Page 184

Trouble shooting chapter 11 184 1sfc132003m0201 internal faults an internal communication fault of the softstarter has occurred. • disconnect and reconnect the supply voltage (u s ) and make a restart. • if same fault remains, contact your abb sales office. Status possible cause solution power on pr...

Page 185: 11:6 Protection Indication

Trouble shooting chapter 11 185 1sfc132003m0201 11:6 protection indication status possible cause solution overload protection the motor has been exposed to an overload condition because the current over a certain time is too high. (the load on the motor shaft is too high) in line at start • check an...

Page 186

Trouble shooting chapter 11 186 1sfc132003m0201 underload protection the motor current is below set level and time. • check and correct the reason for the underload. • check that the settings are according to the operation conditions. Locked rotor protection the motor is running stiff by some reason...

Page 187

Trouble shooting chapter 11 187 1sfc132003m0201 ptc protection an over-temperature is detected by the ptc thermistors in the motor. • check that the ptc circuit is closed and that the inputs are connected. • check and correct the reason for the overheating. • wait for the motor to cool sufficiently ...

Page 188

Trouble shooting chapter 11 188 1sfc132003m0201.

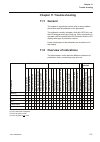

Page 189: Chapter 12 Diagrams

189 1sfc132003m0201 chapter 12 diagrams circuit diagram pst30..Pst300 ..................................................................... 191 circuit diagram pstb370...Pstb1050 ........................................................... 192 diagrams.

Page 190: Diagrams

Diagrams 190 1sfc132003m0201.

Page 191: Chapter 12 Diagrams

Diagrams chapter 12 191 1sfc132003m0201 chapter 12 diagrams 12:1 circuit diagram pst30..Pst300 figure 1: circuit diagram pst30...300 (iec version) terminal 3 is a function earth, it is not a protection earth. It shall be connected to the mounting plate. Figure 2: circuit diagram pst30...300 (ul vers...

Page 192: 12:2 Circuit Diagram

Diagrams chapter 12 192 1sfc132003m0201 12:2 circuit diagram pstb370...Pstb1050 figure 3: circuit diagram pstb370...Pstb1050 (iec version) terminal 3 is a function earth, it is not a protection earth. It shall be connected to the mounting plate. Figure 4: circuit diagram pstb370...1050 (ul version) ...

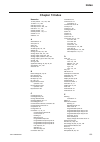

Page 193: Index

193 1sfc132003m0201 index chapter 13 index numerics 1st seq. Param. 112 , 167 , 168 1st set ie 111 , 168 2nd seq .Param. 113 2nd seq. Param. 169 , 170 2nd set ie 111 , 170 3rd seq .Param. 113 3rd seq. Param. 170 , 171 3rd set ie 112 3rdset ie 171 a abbreviations 13 acronyms 13 active 67 airways 38 a...

Page 194: Index

Index 194 1sfc132003m0201 extended start range 22 , 139 extended stop range 22 , 139 external by-pass 18 , 92 , 151 connection 45 contactor 88 , 90 external by-pass contactor 45 external control voltage 49 external keypad 21 f fans 21 fault 64 fault supervision 23 faults 102 , 180 faults indication ...

Page 195: Index

195 1sfc132003m0201 index menu tree 68 menus, description 85 minimum distance to wall/front 38 minimum enclosure sizes 39 minutes 115 , 175 mixer 87 modbus 121 month 174 motor overload protection 22 , 95 , 140 ol class 88 , 140 ol op 95 , 142 overload class 18 , 95 run class 96 start class 96 type o...

Page 196

I n d e x 196 1sfc132003m0201 function of second programmable input 112 number of sequences 111 , 167 second sequence setting current 111 third sequence setting current 112 service settings 69 , 116 setting current 88 , 131 first sequence 112 , 168 second sequence 113 , 170 third sequence 113 , 171 ...

Page 197: Customer Feedback Report

Product: abb would appreciate your comments on this product. Please grade the following questions by selecting one alternative per category. Your answer will enables us to improve our products. How do you grade the quality of the product? Excellent poor total impression usability functionality human...

Page 198

Suggestions for improvements: ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ __________________________________________________________________...

Page 200

Abb a u to mat ion pro ducts ab, cewe-con tro l, se -721 61 v ä ster ås, swed en, tele phon e +4 6 21 32 07 00, t elef a x +46 2 1 1 2 6 0 01 manua l 1 s fc1320 03m02 01 ju ne 200 7 a bb aut o ma tio n techn o log ies a b , cewe- c ont rol.