- DL manuals

- ABB

- Inverter

- PVS300

- Product Manual

ABB PVS300 Product Manual - Features

Operation basics and hardware description 29

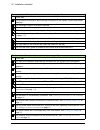

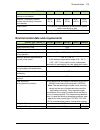

Features

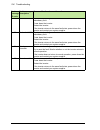

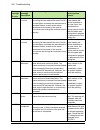

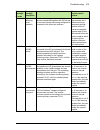

Operation and protection features

Feature

Description/Operation

Automatic operation

The inverter wakes up and goes to sleep automatically depending

on the solar radiation conditions. It connects and disconnects to

the electrical grid automatically according to country

requirements. The inverter studies the system operations; it

generates messages and production data information to the user.

DC string fuses,

monitored

String fuses provide protection for solar modules and string

cabling against earth faults originating from solar side installation

errors or faulty components.

DC surge protection

device, monitored

A surge protection device (SPD) protects the inverter from

induced voltage spikes, for example caused by thunderstorms

close to the installation location. The inverter monitors SPD

cartridges and informs the user when the cartridge must be

replaced.

DC switch

The manually-operated DC power switch which can disconnect

the inverter from solar modules under full load conditions. When

turned on, the DC switch interlocks the inverter’s bottom cover

and front cover so that they cannot be removed.

DC reverse polarity,

monitored

The inverter has a short circuit diode between the DC terminals to

protect the internal electronics from reverse voltages. In case of

reversed –dc and +dc connection the full short circuit current will

flow through the diode, setting the DC voltage to zero. The

inverter informs the user about reversed DC connection.

DC ground fault

monitoring

In accordance with VDE0126-1-1; the inverter monitors the

impedance between ground and DC terminals before grid

connection can be established.

MPPT

Maximum power point tracking. Inverter software function that

automatically operates the solar generator, array, string or module

at its maximum power point. PVS300-TL inverters have one

MPPT.

Residual current detection In accordance with VDE0126-1-1; the inverter has a DC and AC

sensitive residual current monitoring unit (RCMU) which

measures and sums the currents of L and N conductors. If

residual currents (DC or AC) are detected, the inverter

disconnects from the grid.

AC Grid monitoring with

anti-islanding

In accordance with VDE0126-1-1; the inverter monitors the

voltage and frequency of the electrical grid and can detect if the

grid is operating with tolerances. The inverter also stops power

conversion and disconnects from grid when missing electrical grid

is detected (anti-islanding).

AC Over current trip,

monitored

The inverter hardware has an over current trip function. The

inverter informs the user if over current trip is performed.

Summary of PVS300

Page 1

Abb solar inverters product manual pvs300 string inverters.

Page 2

List of related manuals all manuals are available in pdf format on the internet. See further information on the inside of the back cover. Pvs300 manuals code (english) pvs300 string inverters user’s guide 3aua0000100680 option manuals and guides pvs-apk-f control unit wall mounting kit for pvs300 st...

Page 3: Product Manual

Product manual pvs300 string inverters 3aua0000096321 rev b en effective: 2013-03-14 2013 abb oy. All rights reserved. 1. Safety table of contents 4. Mechanical installation 5. Electrical installation 7. Start-up.

Page 5: Table of Contents

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

6 table of contents rj45 data connector x6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 additional pe terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 4. Planning the installati...

Page 7

Table of contents 7 general rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 inverter . . . . . ....

Page 8

8 table of contents 10. Maintenance what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 general about maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 sel...

Page 9

Table of contents 9 further information.

Page 10

10 table of contents.

Page 11: Safety

Safety 11 1 safety what this chapter contains this chapter presents the safety instructions which you must follow when installing, operating and servicing the inverter. Read these safety instructions carefully before working with the product. Failure to observe these instructions can result in physi...

Page 12

12 safety the following warning label is attached to the secondary cover of the inverter. The following warning label is attached on the right side of the inverter..

Page 13: Intended Use

Safety 13 intended use the inverter can only be used as part of a photovoltaic (pv) system when it is permanently connected to the electrical grid. Safety during installation and maintenance these warnings are intended for everyone who works with the inverter, its input and output cabling, or the as...

Page 14

14 safety isolating the inverter from external power sources notes: warning! Do not use excessive force to remove or replace the front or bottom covers. The dc switch must be turned off before the covers can be removed. Covers must be replaced before the dc switch can be turned on. • the dc connecti...

Page 15: Safe Start-Up and Operation

Safety 15 grounding safety rules for electricians • comply with all relevant electrical safety regulations of the installation country or region. • always connect protective earth (pe) to the inverter and associated equipment to ensure personal safety and electromagnetic compatibility. • ensure that...

Page 16

16 safety general safety warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. Before turning on the inverter and putting it into service: • take care of any permits and approvals required by local authorities. • inform the respective utility co...

Page 17: Introduction to The Manual

Introduction to the manual 17 2 introduction to the manual what this chapter contains this chapter describes the intended audience and contents of the manual. It includes a flowchart, covering delivery to commissioning, with references to where detailed instructions can be found. Applicability the m...

Page 18: Related Documents

18 introduction to the manual planning the installation describes the steps which must be completed prior to actual installation. Mechanical installation describes the mechanical installation. Electrical installation describes the electrical installation. Installation checklist contains a list for f...

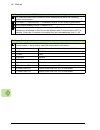

Page 19

Introduction to the manual 19 quick installation and start-up flowchart task see: plan the installation: check ambient conditions, inverter ratings, cabling requirements, required cooling air flow, installation location, prepare equipment layout, compatibility with solar arrays and other system equi...

Page 20

20 introduction to the manual commission the inverter. Start-up , page 77 accessory manuals (if applicable): pvs-apk-f control unit wall mounting kit for pvs300 string inverters installation guide (3aua0000108440 [english]) pvs-apk-m control unit table stand and wireless communication kit for pvs300...

Page 21: Terms and Abbreviations

Introduction to the manual 21 terms and abbreviations term/abbreviation explanation ac alternating current. Cable lug a connector which is crimped onto the end of cable. Also known as a crimp connector or cable anchor. Circuit breaker automatic switch which will trip to off and protect the load circ...

Page 22

22 introduction to the manual solar array group of parallel-connected solar strings. Solar array junction box device that connects outputs of multiple solar source circuits (strings) into a combined output circuit or circuits. Solar cell solar cell or photovoltaic cell is an electronic device that c...

Page 23: Operation Basics and

Operation basics and hardware description 23 3 operation basics and hardware description what this chapter contains this chapter briefly describes the construction, operation and control principle of the pvs300 string inverter. Overview the pvs300 transformerless string inverter converts direct curr...

Page 24

24 operation basics and hardware description 1. As the sun rises, the inverter wakes up when there is enough daylight for the solar modules to generate dc voltage in excess of the minimum inverter operating limit. 2. After waking up, the inverter verifies the status of the power line and then switch...

Page 25: Layout Drawing

Operation basics and hardware description 25 layout drawing no. Description no. Description 1 front cover 1) 12 inlet conduits for control cables, 3 pcs 2 control area: display, leds, keypad 13 cooling fan and holder 2) 3 dc switch handle 0=off, 1=on 14 dc connectors 4 main enclosure 15 ac and pe co...

Page 26

26 operation basics and hardware description 1) interlocked. The front cover and the bottom cover can be removed and replaced only when the dc switch is in position 0 (switched off). The covers can be removed separately. 2) the cooling fan cools the heat sink and main circuit components. The stirrin...

Page 27

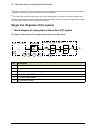

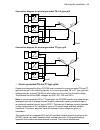

Operation basics and hardware description 27 block diagram of three-phase photovoltaic (pv) system the figure below shows the three-phase system configuration. Note: depending on the local grid code requirements, the circuit breaker at the ac distribution board can be either a single 3 pole circuit ...

Page 28: Pvs300 Block Diagram

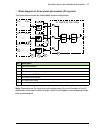

28 operation basics and hardware description pvs300 block diagram no. Component description 1 dc terminals connection of dc cabling from solar arrays 2 main board integrated circuit board onto which the main circuit components are attached 3 string fuses short circuit protection for string circuits ...

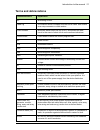

Page 29: Features

Operation basics and hardware description 29 features operation and protection features feature description/operation automatic operation the inverter wakes up and goes to sleep automatically depending on the solar radiation conditions. It connects and disconnects to the electrical grid automaticall...

Page 30

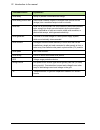

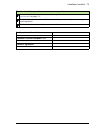

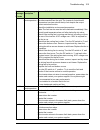

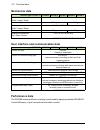

30 operation basics and hardware description user interface and communication features ac short circuit protection in case of external ac side short circuit, the inverter trips to protect its electronics. Over temperature protection if the inverter detects potentially harmful internal temperatures, ...

Page 31: Type Designation Label

Operation basics and hardware description 31 type designation label the type designation label is located on the right hand side of the inverter. Type designation key the type designation contains information on the specifications and configuration of the inverter. You find the type designation on t...

Page 32: Optional Accessories

32 operation basics and hardware description optional accessories connections and control interfaces see the connection diagram on page 60 . Dc input connectors dc input connectors are the connection point for solar panels. The inverter has four pairs of dc+ and dc- connectors to attach up to four s...

Page 33

Operation basics and hardware description 33 nut inserts for clamp connections nut inserts are the connection points for control cable shields and clamp connectors to protective earth. Rj45 data connector x6 rj45 (8p8c) connector is used for connecting the control unit or wireless communication (par...

Page 34

34 operation basics and hardware description.

Page 35: Planning The Installation

Planning the installation 35 4 planning the installation what this chapter contains this chapter instructs in planning the mechanical and electrical installation. Selecting the location for the inverter warning! Do not install the inverter in a location where: • corrosive, explosive or flammable mat...

Page 36

36 planning the installation the installation location must be accessible in emergencies and for maintenance. The installation location must be out of reach of children, pets and pests. During operation, the inverter can produce a slight noise or vibration which could disturb people. Consider this w...

Page 37: Selecting The Power Cables

Planning the installation 37 selecting the power cables general rules dimension the dc input power and ac output power cables according to the local regulations and the following rules: • select cables rated for at least 70 °c maximum permissible temperature of conductor in continuous use. • select ...

Page 38

38 planning the installation recommended ac output power cable types the power cable types that can be used for the inverter ac output are shown below. Shielded cable with line and neutral conductors and a concentric pe conductor as shield. The shield must meet the pe conductor cross section require...

Page 39: Selecting The Control Cables

Planning the installation 39 selecting the control cables general rules it is recommended to use halogen free, shielded control and data cables. A double-shielded cable is the best alternative for low-voltage digital signals but a single-shielded twisted pair cable is also usable. Signals in separat...

Page 40

40 planning the installation recommended cable type for remote control unit and i2i interfaces over eia/rs-485 shielded twisted pair (stp) cable (for example lapp kabel unitronic ® lihch (tp) or equivalent) is recommended. These interfaces do not require termination resistors. The cabling distance i...

Page 41

Planning the installation 41 tools needed during installation depending on the system size, selected mounting location and materials used, mechanical and electrical installers could need the following equipment and tools: general tools • personal safety equipment such as gloves, helmet, goggles, ear...

Page 42

42 planning the installation checking solar array and inverter compatibility check that: • solar modules and dc cables used in the system are protection class ii certified (double insulated). • solar modules used in the system do not require grounding of dc+ or dc- terminals. • solar modules used in...

Page 43

Planning the installation 43 protecting the solar array and dc input cables from short-circuits the inverter dc string fuses and short-circuit diode protect the inverter dc circuit, the dc input cables and solar modules from short-circuit situations provided that the dc cables and solar array are di...

Page 44

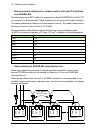

44 planning the installation the following table shows the common line-to-neutral and line-to-line voltages in tn and tt type grids. Connection diagram for neutral grounded tn-s type grid connection diagram for neutral grounded tn-c type grid line-to-neutral voltage (v rms ) line-to-line voltage (v ...

Page 45

Planning the installation 45 connection diagram for neutral grounded tn-c-s type grid connection diagram for neutral grounded tt type grid corner grounded tn and tt type grids connection diagrams for three pvs300 solar inverters to corner grounded tn and tt grids are shown in the following figures. ...

Page 46

46 planning the installation automatically from the grid if a residual current >300 ma or quick rise >30 ma is detected. Connection diagram for corner grounded tn type grid connection diagram for corner grounded tt type grid l1 l n pe l n pe l n pe l3 l2 earth 230 v 23 0 v 23 0 v l1 l n pe l n pe l ...

Page 47

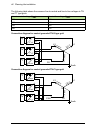

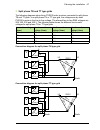

Planning the installation 47 split phase tn and tt type grids the following diagrams show three pvs300 solar inverters connected to split phase tn and tt grids. In a split phase tn or tt type grid, the voltage seen by each pvs300 inverter is the line-to-line voltage. The allowed line-to-line rms vol...

Page 48

48 planning the installation.

Page 49: Mechanical Installation

Mechanical installation 49 5 mechanical installation what this chapter contains this chapter describes how to check the installation location and inverter delivery, the installation tools required and the mechanical installation procedure for the inverter. Warning! Ignoring the following instruction...

Page 50

50 mechanical installation 1. Check that the package is not damaged. 2. Before opening the package, check the sales package labels to verify that the delivery is of the correct type. 3. Transport the inverter in its packaging to the installation site. 4. Avoid removing items from the sales package u...

Page 51

Mechanical installation 51 removing and replacing the front cover and bottom cover the front and bottom covers can only be removed and replaced when the dc switch (1) is set to the off position. It is not possible to turn the dc switch, or operate the inverter, when either of the covers is removed. ...

Page 52

52 mechanical installation removing and replacing the bottom cover to remove the bottom cover, turn the dc switch (1) to the off position and then gently pull the bottom cover (4) downwards. To replace the bottom cover, ensure that the dc switch is in the off position and gently push the over upward...

Page 53

Mechanical installation 53 installing the mounting plate onto the supporting structure see section dimension drawing on page 121 for details of dimensions, weights and free space requirements. No. Description 1 cantilever support for inverter hanging 2 pilot securing point, 6.5 mm 3 wall securing p...

Page 54

54 mechanical installation installation sequence note: ensure that dust from drilling will not enter the inverter during the installation. Note: when a self-carrying wall surface, such as a brick wall, is not available: mounting dimensions clearances h h1 h2 h3 w w1 w2 w3 w4 cb cs ct mm 411 200 239 ...

Page 55

Mechanical installation 55 • if stud work can be located behind the wall surface and the mounting plate holes can be aligned with it, the mounting plate can be fastened to the stud work. • if suitable stud work cannot be located, a strong supporting structure (for example, stud work, boards, railing...

Page 56

56 mechanical installation installing the inverter onto the mounting plate installation sequence 1. Remove the bottom cover from the inverter. See removing and replacing the front cover and bottom cover on page 51 . 2. With the top of the inverter tilted slightly towards you, lift it up so that the ...

Page 57: Electrical Installation

Electrical installation 57 6 electrical installation what this chapter contains this chapter describes the electrical installation process for the inverter. It explains how to fit connectors and to perform cabling. It also presents the purpose and pinout of each connector. See section safety during ...

Page 58: Routing The Cables

58 electrical installation routing the cables general rules ideally, the input, output and control cables should be installed on separate trays. If control cables must cross over power cables, arrange them at an angle as near to 90 degrees as possible. Try to ensure that control cables and power cab...

Page 59

Electrical installation 59 fault message is generated and grid connection is prevented. The inverter is also equipped with overvoltage protection devices on both the dc and ac sides. Inverter the inverter has been tested for insulation between the main circuit and the chassis (1500 v rms 50 hz for 1...

Page 60: Connection Diagram

60 electrical installation connection diagram description description 1 relay output terminal (optional) 6 rj45 data type 8p8c plug 2 remote control unit terminal 7 rj45 data type 8p8c jack 3 i2i link terminal 8 ac cable connector 4 rs-485 embedded fieldbus interface 9 additional pe terminal* 5 clam...

Page 61: Connecting The Power Cables

Electrical installation 61 connecting the power cables see section selecting the power cables on page 37 . Connection area layout description 1 negative dc inputs, female panel receptacles, 4 in parallel 2 positive dc inputs, male panel receptacles, 4 in parallel 3 feed through rubber grommets for c...

Page 62

62 electrical installation dc cabling connection procedure assembling the dc connectors to the cables warning! For protection against electric shock, the dc connectors must be completely isolated from the power supply during assembly. Description 1 turn off the dc switch on the inverter front panel ...

Page 63

Electrical installation 63 2 use connector type pv-kbt4 for the dc+ connection and connector type pv-kst4 for the dc- connection. 3 check that the cables are of the right type and diameter. Check that the conductor diameter corresponds to the internal diameter of the metal contact. Mc4 cable coupler...

Page 64

64 electrical installation 7 pull lightly to check that the contact has properly engaged. 8 insert the test pin with the corresponding side into the socket or plug. If the contact is properly assembled, the white marking on the test pin must still be visible. 9 screw on the cable gland hand-tight an...

Page 65

Electrical installation 65 ac cabling connection procedure description 1 isolate the inverter from all possible power sources. See isolating the inverter from external power sources on page 14 . 2 insert ac cable through ac connector body and multilayer rubber grommet. Discard unused parts of the ru...

Page 66

66 electrical installation connecting the control cables see section recommended ac output power cable types on page 38 . Connection area layout description 1 x1 spring terminal, programmable output relay interface for external control equipment. 2 x2 spring terminal, rs-485 interface for remotely i...

Page 67

Electrical installation 67 note: grounding the cable shield: • do not connect the cable shield to the isolated functional ground of terminals x2, x3 or x4. • connect the cable shield with the provided clamp connectors to the grounded nut insert [item 9]. • ground only one end of the cable shield to ...

Page 68

68 electrical installation output relay, terminal x1 control unit remote installation, terminal x2 pin name description x1:1 ro_com relay output, common x1:2 ro_nc relay output, normally closed x1:3 ro_no relay output, normally open pin name description x2:1 data + inverter rs-485 transmit data x2:2...

Page 69

Electrical installation 69 for further information about remotely installing the control unit, see pvs-apk-f control unit wall mounting kit for pvs300 string inverters installation guide (3aua0000108440 [english]) and pvs-apk-m control unit table stand and wireless communication kit for pvs300 strin...

Page 70

70 electrical installation inverter to inverter link, terminal x3 (i2i) pin name description x3:1 data + inverter rs-485 transmit data x3:2 data - inverter rs-485 receive data x3:3 gnd_a functional ground, isolated inverter 1 1(+) 2(-) 3 x3 inverter 2 1(+) 2(-) 3 x3 inverter 3 1(+) 2(-) 3 x3 pe n l ...

Page 71

Electrical installation 71 embedded fieldbus interface, terminal x4 embedded fieldbus interface, termination resistor switch pin name description x4:1 data + inverter rs-485 transmit data x4:2 data - inverter rs-485 receive data x4:3 gnd_a functional ground, isolated switch name description s1:1 bia...

Page 72

72 electrical installation connection procedure 1. Remove the front and bottom covers. See removing and replacing the front cover and bottom cover on page 51 . 2. If necessary, fit dc connectors to the ends of the cables coming from the solar strings. See dc cabling connection procedure on page 62 ....

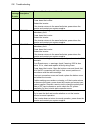

Page 73: Installation Checklist

Installation checklist 73 7 installation checklist what this chapter contains this chapter contains an inspection list for checking the mechanical and electrical installation of the inverter before start-up. Checklist go through the checklist with another person. Follow the instructions given in cha...

Page 74

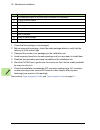

74 installation checklist mechanical installation (see mechanical installation on page 49 ) check that: the mechanical installation and markings correspond to the system’s layout and design drawings. The installation location is properly selected. There is sufficient free space around the unit (see ...

Page 75

Installation checklist 75 the external line circuit breakers are adequately sized. See ac output data and grid requirements on page 114 . The ac distribution board is installed, wired and inspected correctly and according to local regulations. All shrouds and covers are in place and secured. Serial ...

Page 76

76 installation checklist.

Page 77: Start-Up

Start-up 77 8 start-up what this chapter contains this chapter describes the start-up procedure of the inverter. Warning! Only qualified electricians are allowed to perform installation, cabling or testing work on the inverter! The safety instructions in chapter safety on page 11 must be followed du...

Page 78

78 start-up first start-up switch on the ac line circuit breaker at the ac distribution board. The control board and graphical display wakes up. The boot screen appears with a counterclockwise rotating arrow. After 10 seconds, the splash screen appears for a few seconds. Select the user language wit...

Page 79

Start-up 79 first start assistance appears automatically to the screen if the inverter has been powered up for the first time after factory tests. First start assistance also appears automatically if the unit has been powered up but the first start-up settings have not been confirmed by the user. Pr...

Page 80

80 start-up the time appears in the middle of the soft key bar. Select the installation country with the up or down arrow keys. The correct installation country must be selected otherwise correct grid connection parameters are not activated and the inverter shall not start operation. If the correct ...

Page 81

Start-up 81 note: when i2i link is in use, by default the control unit shows the combined production data of the inverters connected to the same i2i link. This function is called multi unit view and it can be disabled or enabled from the screen menu. When adequate dc voltages are available from the ...

Page 82

82 start-up setting up the embedded fieldbus interface for remote monitoring the node addresses need to match the slave addresses with which the monitoring system communicates. From menu -> communication -> embedded fieldbus, set the following parameters: 58.01 protocol enable. 0=none, 1=modbus rtu....

Page 83: Operation

Operation 83 9 operation what this chapter contains this chapter describes the operating modes, operation of the control unit, the information shown by leds and the graphical display. The inverter user interface the control unit sits behind the front panel. Normally, the inverter is controlled using...

Page 84

84 operation the inverter’s main user interface is a control unit, featuring buttons, leds and an lcd graphical display. Additionally, there are status leds on the inverter control board which can be seen when the control unit is removed. For information on the use of the panel, see chapter navigati...

Page 85

Operation 85 the operating modes of the pvs300 string inverter operating status example graphical display description sleep this is a low power consumption mode in which only essential electronics use power. The inverter enters sleep mode when the dc input voltage is below a threshold value and ther...

Page 86: Control Buttons

86 operation control buttons the buttons on the front panel or control unit are used to navigate the menus. Note that not all buttons are used in all views. • the up and down direction buttons are used to scroll up and down to different items within menu screens and to adjust values. Briefly pushing...

Page 87: Led Indicators

Operation 87 • the left softkey is used to select items shown on the bottom left of the display. This key is usually used for stepping backwards, for example to select cancel, exit, no and back. If held down, the left softkey exits each menu and nested view in turn, finally returning to the output v...

Page 88

88 operation led on control unit led description and behavior 1 operational status, red or green, off, on or flashing. 2 danger of electric shock, red symbol, steady on if inverter has diagnosed an active ground fault. Led description and behavior 1 bi-colour led illuminates red or green. Can be off...

Page 89: Graphical Display

Operation 89 led status indications graphical display the graphical display is used to show: • operational status • menus which can be navigated by the user • performance monitoring • event messages (for example, faults, warnings, maintenance reminders) • help refer to chapter start-up on page 77 fo...

Page 90

90 operation common display zones note: in multi-unit installations, information in the status and softkey bars applies to the whole system. Information about individual devices cannot be viewed with the panel. The status icon shows the current state of the inverter. 1 status bar includes the headin...

Page 91

Operation 91 start up assistant the start up assistant appears automatically when the inverter is first installed. This menu guides the user through the settings for language, date, time and installation country. Note: the installation country is permanent once the setting has been confirmed. If you...

Page 92

92 operation the technical information page shows values that are only of interest to technically oriented users. The sun display shows the current state of the unit and the output power in graphical format. See the operating modes of the pvs300 string inverter on page 85 for examples. Use the up ar...

Page 93

Operation 93 by default, the display backlight is on when the inverter is in operating mode. When the inverter is in sleep mode, the control unit and display switch off completely. The control unit wakes up and the backlight illuminates if the keypad is activated. If the keypad is not used for a pre...

Page 94

94 operation note: the local regulations in italy require that the self test is performed successfully during commissioning. If the self test is unsuccessful in italy, the inverter shall not connect to the grid. For more guidance on the self test function, please see further information on page 129 ...

Page 95: Maintenance

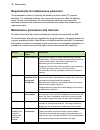

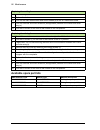

Maintenance 95 10 maintenance what this chapter contains this chapter explains the routine maintenance actions for the inverter. General about maintenance the inverter is a high-quality product which is designed to require very little maintenance and downtime. In the event of a problem or malfunctio...

Page 96

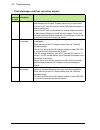

96 maintenance requirements for maintenance personnel the maintenance person is typically the building or photovoltaic (pv) system caretaker. For residential systems, the maintenance person is often the building owner. During commissioning, the commissioning electrician must teach the maintenance pe...

Page 97

Maintenance 97 replacing fans replacing the cooling fan 1 turn off the main disconnector and circuit breaker(s) at the ac distribution board. 2 turn the dc switch (1) on the front of the inverter to the off position. 3 if applicable, turn off disconnecting switches and circuit breakers between the i...

Page 98: Available Spare Part Kits

98 maintenance available spare part kits 8 fit the locking screw to the fan holder. 9 replace the bottom cover. 10 turn on the main disconnector and circuit breaker(s) at the ac distribution board. 11 turn on switches and circuit breakers (as applicable) between the inverter and solar array(s). 12 t...

Page 99: Troubleshooting

Troubleshooting 99 11 troubleshooting what this chapter contains this chapter explains how to replace inverter components. It also presents the possible malfunction indications and symptoms along with the corrective actions. Replacing string fuses 1. Switch off the dc switch on the inverter. 2. Remo...

Page 100

100 troubleshooting 11. Push the fuse holders back into position. 12. Repeat steps 7 to 11 for all string inputs in use. 13. Reconnect all dc cables to the corresponding inputs on the inverter. 14. Replace the front and bottom covers. See section removing and replacing the front cover and bottom cov...

Page 101: Replacing The Inverter

Troubleshooting 101 replacing the inverter if the inverter needs to be replaced, follow the decommissioning and installation procedures. There is no need to transfer components from the old product to the new one. If the inverter is returned and replaced under warranty, there is no need to return th...

Page 102

102 troubleshooting fault messages and their corrective actions fault message id code fault message description causes of fault and corrective actions 1 overcurrent the inverter has performed an overcurrent trip and has disconnected from the grid. Possible causes for an overcurrent peak are an ac si...

Page 103

Troubleshooting 103 16 ground current the inverter’s rcmu has diagnosed leakage current to ground during the inverter’s power feeding operation and has disconnected itself from the electrical grid. Leakage current can be the result of human, animal or another object’s contact between (faulty) cablin...

Page 104

104 troubleshooting 22 redundant ignd the inverter has diagnosed an internal measurements redundancy fault. Power down the inverter. Restart the inverter. If the inverter returns to the same fault state, power down the inverter and contact your system supplier. 23 redundant vac the inverter has diag...

Page 105

Troubleshooting 105 26 inv overtemperature the inverter has performed a control board temperature trip and has disconnected from the grid. The inverter’s control board temperature has risen above the trip limit despite the output current reduction function. Check the installation environment tempera...

Page 106

106 troubleshooting 31 mcu connection the inverter has diagnosed an internal communication error. Power down the inverter. Restart the inverter. If the inverter returns to the same fault state, power down the inverter and contact your system supplier. 32 mcu uac the inverter has diagnosed an interna...

Page 107: Warning Messages

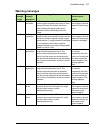

Troubleshooting 107 warning messages warning message id code warning message description cause of warning and inverter’s behavior maintenance or service person actions 1000 dc string fuse blown a dc string fuse has failed. If there are several inputs connected and some of them have good fuses; the i...

Page 108

108 troubleshooting 1006 external fan run time the inverter’s software has calculated that the cooling fan has reached the end of its life. The calculation considers the manufacturer’s estimated lifetime as well as the actual operational environment of the inverter. The inverter and cooling fan cont...

Page 109

Troubleshooting 109 2994 i2i power balancing param. Mismatch 3-phase monitoring: one of the three inverters connected together with i2i link has an incorrect 3-phase monitoring configuration compared to the other two inverters. User should check and compare the 3- phase monitoring parameter settings...

Page 110

110 troubleshooting.

Page 111: Decommissioning

Decommissioning 111 12 decommissioning what this chapter contains this chapter explains how to remove the inverter from service and recycle it at the end of its lifetime. Removing the inverter from service 1. Switch off the dc switch on the front panel of inverter. 2. Electrically isolate the invert...

Page 112: Recycling

112 decommissioning 12. If applicable, remove the padlock from underneath the inverter. 13. Remove the locking screw from underneath the inverter. 14. Lift the inverter upwards and tilt it forwards, then lift it off of the mounting plate. 15. Remove the mounting plate from the wall. 16. Recycle the ...

Page 113: Technical Data

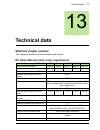

Technical data 113 13 technical data what this chapter contains this chapter presents the technical data for the inverter. Dc input data and solar array requirements inverter type pvs300-tl- 3300w-2 4000w-2 4600w-2 6000w-2 8000w-2 nominal solar array power 3400 w 4200 w 4800 w 6200 w 8300 w maximum ...

Page 114

114 technical data ac output data and grid requirements surge protection device type (spd) abb, ovr pv 40 1000 p ts or phoenix contact, type val-ms 1000dc/2+v-fm-ud solar string fault current protection solar string fuse, 10x38mm, 1000 vdc all input terminals, monitored tested and approved solar str...

Page 115

Technical data 115 environmental data and requirements recommended tripping curve type of external circuit breaker type b minimum / (maximum) allowed nominal current rating of external circuit breaker 20 a / (63 a) 25 a / (63 a) 25 a / (63 a) 32 a / (63 a) 50 a / (63 a) inrush current 0 a (inverter ...

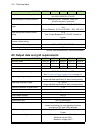

Page 116: Mechanical Data

116 technical data mechanical data user interface and communication data performance data the pvs300 inverters efficiency testing is performed by applying standard en 50530, overall efficiency of grid connected photovoltaic inverter. Inverter type pvs300-tl- 3300w-2 4000w-2 4600w-2 6000w-2 8000w-2 i...

Page 117

Technical data 117 mppt adjustment efficiency conversion efficiency power range of p ac nominal static mppt adjustment efficiency for pvs300 series 99.7% >20% 99.9% pvs300-tl-3300w-2, conversion efficiency 75 80 85 90 95 100 0 10 20 30 40 50 60 70 80 90 100 output power [%] c o nve rsi on ef fi cien...

Page 118

118 technical data pvs300-tl-4600w-2, conversion efficiency 75 80 85 90 95 100 0 10 20 30 40 50 60 70 80 90 100 output power [%] c o nve rsi on ef fi cien cy [% ] 335v 480 v 720 v maximum euro-eta (medium irradiation) cec (high irradiation) 97,0 % 96,4 % 96,8 % pvs300-tl-6000w-2, conversion efficien...

Page 119: Product Compliance

Technical data 119 source: 3axd10000024873, 3axd10000023280 product compliance derating the inverter monitors its internal temperature and derates the power output accordingly to protect the inverter, protection devices and cabling. Derating is fully automatic. While derating is active, if the inver...

Page 120

120 technical data.

Page 121: Dimension Drawing

Dimension drawing 121 14 dimension drawing what this chapter contains this chapter presents the external dimensions of the inverter and also shows the clearance dimensions to ensure that the inverter is properly ventilated. Inverter dimensions 3aua0000094904.

Page 122

122 dimension drawing 3aua0000094904.

Page 123

Dimension drawing 123 required clearances for cooling.

Page 124

124 dimension drawing.

Page 125: Navigation Map

Navigation map 125 15 navigation map what this chapter contains this chapter presents the navigation map in conjunction with instructions for how to read it. How to read the navigation map the top row of the navigation map shows the start-up sequence, from left to right, which is followed when the i...

Page 126: The Navigation Map

126 navigation map the navigation map.

Page 127

Navigation map 127.

Page 128

128 navigation map.

Page 129

Further information for more information on abb products and services for solar applications, navigate to www.Abb.Com/solar..

Page 130

3aua000009632 1 rev b / en eff e ctive: 2013- 03-1 4 contact us www.Abb.Com/solar.