- DL manuals

- ABB

- Inverter

- PVS800-57-0100kW-A

- Hardware Manual

ABB PVS800-57-0100kW-A Hardware Manual

Summary of PVS800-57-0100kW-A

Page 1

Abb solar inverters hardware manual pvs800-57 central inverters (100 to 1000 kw).

Page 2: List Of Related Manuals

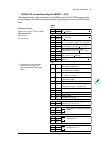

List of related manuals 1) delivered as a printed copy with the inverter. Inverter hardware manual code (english) pvs800-57 hardware manual 3aua0000053689 1) inverter firmware manual pvs800 central inverters firmware manual 3aua0000058422 1) and adaptive program application guide 3aua0000091276 opti...

Page 3: Hardware Manual

Hardware manual pvs800-57 central inverters (100 to 1000 kw) 3aua0000053689 rev h en effective: 2014-07-09 2014 abb oy. All rights reserved. 1. Safety instructions 4. Mechanical installation table of contents 6. Electrical installation 8. Start-up.

Page 5: Update Notice

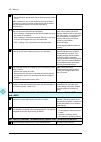

Update notice 1 update notice safety updated bullet points (page 11): safety in installation and maintenance precautions before electrical work these precautions are for all personnel who do work on the inverter, its input and output cables, the transformer or the photovoltaic generator. The notice ...

Page 6: Start-Up

Update notice 2 new bullet point (page 14): safety in installation and maintenance electrical safety these warning are for all personnel who do work on the inverter, its input and output cables, the transformer or the photovoltaic generator. Warning! Obey these instructions to prevent injury or deat...

Page 7: Table Of Contents

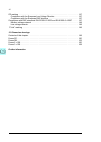

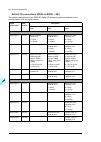

5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety instructions contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 use...

Page 8

6 door devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 inverter module (r7i) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 inverter module (r8i) . . . . . . . . . ....

Page 9

7 protecting the photovoltaic generator and dc input cable in short-circuit situations . 79 protecting the inverter and the ac output cable against thermal overload . . . . . . . . 79 supplying power for the auxiliary circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8...

Page 10

8 7. Installation checklist contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 8. Start-up c...

Page 11

9 replacing the lcl filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 reforming the capacitors . . . . . . ....

Page 12

10 ce marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 compliance with the european low voltage directive . . . . . . . . . . . . . . . . . . . . . . 147 compliance with the european emc directive . . . . . . . . . . . . . ...

Page 13: Safety Instructions

Safety instructions 11 1 safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install and operate the inverter and do maintenance on the inverter. If you ignore the safety instructions, injury or death can occur, or damage can occur ...

Page 14: Maintenance

12 safety instructions safety in installation and maintenance precautions before electrical work these precautions are for all personnel who do work on the inverter, its input and output cables, the transformer or photovoltaic generator. Warning! Obey these instructions. If you ignore them, injury o...

Page 15

Safety instructions 13 7. Ask the person in control of the electrical installation work for a permit to work. 6. Install temporary grounding as required by the local regulations. Connect the ac and dc busbars to the pe using an appropriate temporary grounding tool. View of ac busbars grounding diame...

Page 16

14 safety instructions electrical safety these warnings are for all personnel who do work on the inverter, its input and output cables, the transformer or photovoltaic generator. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • if you are...

Page 17

Safety instructions 15 • when the photovoltaic generator cells are exposed to light (even if it is dim), the generator supplies dc voltage to the inverter. Grounding these instructions are for all personnel who are responsible for the grounding of the inverter. Warning! Obey these instructions. If y...

Page 18

16 safety instructions general safety these instructions are for all personnel who install the inverter and do maintenance work on it. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • standard iec/en 62109-2 (section 4.8.3.6) requires tha...

Page 19

Safety instructions 17 • when removing a module which is equipped with wheels, pull the module carefully out of the cubicle along the ramp. Make sure the wires do not catch. While pulling on the handle, keep a constant pressure with one foot on the base of the module to prevent the module from tippi...

Page 20

18 safety instructions • beware of the cooling fan blades. The fans may continue to rotate for a while after disconnection of the electrical supply. • beware of hot surfaces. Some parts inside the inverter cabinet, such as heatsinks of power semiconductors, remain hot for a while after disconnection...

Page 21: Start-Up And Operation

Safety instructions 19 start-up and operation these warnings are for all personnel who commission, plan the operation or operate the inverter. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • close the inverter ac and dc main switches and...

Page 22

20 safety instructions.

Page 23: Introduction To The Manual

Introduction to the manual 21 2 introduction to the manual contents of this chapter this chapter describes the intended audience and contents of the manual. It contains a flowchart of the steps in checking the delivery, installing and commissioning the inverter. The flowchart refers to chapters/sect...

Page 24: Related Documents

22 introduction to the manual electrical installation describes the electrical installation process of the inverter. Installation checklist contains a list for checking the mechanical and electrical installation of the inverter. Start-up describes the start-up procedure of the inverter. Fault tracin...

Page 25: Terms And Abbreviations

Introduction to the manual 23 terms and abbreviations install the inverter. Connect the power cables. Connect the control and the auxiliary control cables. Mechanical installation (page 63 ) , electrical installation (page 83 ) check the installation. Installation checklist (page 97 ) commission the...

Page 26

24 introduction to the manual plc programmable logic controller ppcs power plate communication system; a protocol used in the optical fiber link that controls the output semiconductors of an inverter module raio analog i/o extension module rdco ddcs communication module that can be snapped on the rm...

Page 27: Operation Principle And

Operation principle and hardware description 25 3 operation principle and hardware description contents of this chapter this chapter gives a short description of the inverter’s operation principle and construction..

Page 28: Product Overview

26 operation principle and hardware description product overview the pvs800-57 is a central inverter for converting, adjusting and conveying power generated by a solar generator to the electrical power system. The inverter is built in an air-cooled cabinet for indoor use. Cooling air is let in throu...

Page 29

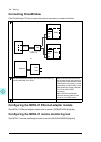

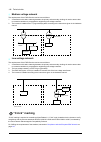

Operation principle and hardware description 27 block diagram of solar generator system a block diagram of a solar generator system where the solar module string arrays are connected to the electrical power system through an inverter is shown below. Pvs 800- 57 1…20 1 2 3 5 1 solar module (photovolt...

Page 30

28 operation principle and hardware description example main circuit diagram of the inverter system (r7i) 1 2 4 3 5 option +e216 grid it network only auxiliary power supply junction box power supply max. 6 a. Fault current protected. Option +g410..

Page 31

Operation principle and hardware description 29 symbol terminal/component description/operation 1 dc input terminals the solar generator is connected to the inverter dc input terminals with busbars or through miniature circuit breakers (option +h377). 2 ac output the ac output terminals connect the ...

Page 32

30 operation principle and hardware description u1 inverter module converts the dc voltage to ac voltage. The operation is controlled by switching the igbts. U3 lcl filter smooths the current and voltage waveform. Z1.1-3 common mode filter reduces common mode voltages and currents in the solar gener...

Page 33

Operation principle and hardware description 31 example main circuit diagram of the inverter system (r8i) 1 2 4 3 5 grid option +e216 1 auxiliary power supply junction box power supply max. 6 a. Fault current protected. Option +g410. It network only.

Page 34

32 operation principle and hardware description symbol terminal/component description/operation 1 dc input terminals the solar generator is connected to the inverter dc input terminals with busbars and fuse links. 2 ac output the ac output terminals connect the inverter to the low-voltage ac power s...

Page 35

Operation principle and hardware description 33 q10 auxiliary control voltage switch hand-operated switch which connects the auxiliary control voltage to the inverter. U1 inverter module converts the dc voltage to ac voltage. The operation is controlled by switching the igbts. U3 lcl filter smooths ...

Page 36: (2 × R8I)

34 operation principle and hardware description example main circuit diagram of the inverter system (2 × r8i) 1 2 4 3 5 option +e216 it network only 1 1 1 1 1 1 1 grid auxiliary power supply.

Page 37

Operation principle and hardware description 35 external 100 v ac, 115 v ac or 200 v ac auxiliary power supply (options +g396, +g397 and +g398) auxiliary power supply from the inverter main circuit (option +g415) 3 5 300 v ac / 350 v ac / 400 v ac.

Page 38

36 operation principle and hardware description descriptions of symbols symbol terminal/component description/operation 1 dc input terminals the solar generator is connected to the inverter dc input terminals with busbars and fuse links. 2 ac output the ac output terminals connect the inverter to th...

Page 39

Operation principle and hardware description 37 q1 ac main switch- disconnector hand-operated switch which connects the inverter to the electrical power system. The ac main switch-disconnector can be operated at all times. If it is operated during operation, the inverter will trip as the grid disapp...

Page 40: (3 × R8I)

38 operation principle and hardware description example main circuit diagram of the inverter system (3 × r8i) 1 2 3 4 5 grid option +e216 it network only 1 1 1 1 1 1 1 auxiliary power supply.

Page 41

Operation principle and hardware description 39 external 100 v ac, 115 v ac or 200 v ac auxiliary power supply (options +g396, +g397 and +g398) auxiliary power supply from the inverter main circuit (option +g415) 3 5 300 v ac / 350 v ac / 400 v ac.

Page 42

40 operation principle and hardware description descriptions of symbols symbol terminal/component description/operation 1 dc input terminals the solar generator is connected to the inverter dc input terminals with busbars and fuse links. 2 ac output the ac output terminals connect the inverter to th...

Page 43

Operation principle and hardware description 41 electrical power network supervision functions the inverter control program includes electrical power network supervision functions. The inverter monitors, for example, overvoltage, undervoltage, overfrequency, underfrequency and frequency change rate ...

Page 44: +F283)

42 operation principle and hardware description positive or negative pole grounding (options +f282 and +f283) the positive and negative pole grounding options can be used when solar modules require grounding of inverter dc poles. The grounding of the poles complies with standard iec 62109-2. One dc ...

Page 45: Layout Drawings

Operation principle and hardware description 43 see pvs800 central inverters firmware manual (3aua0000058422 [english]) for detailed instructions on how to enable the reduce run operation. Layout drawings the figures below show examples of cabinet layout for different frame sizes. Depending on the s...

Page 46

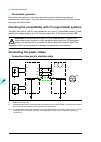

44 operation principle and hardware description cabinet layout of frame r7i a cabinet of frame r7i is shown below with doors open and shrouds removed. Description a incoming cubicle b inverter module cubicle 1 dc cable lead-throughs 2 photovoltaic generator connection terminals 3 auxiliary control v...

Page 47

Operation principle and hardware description 45 cabinet layout of frame r8i a cabinet of frame r8i is shown below with doors open and shrouds removed. 8 13 18 5 2 1 14 15 16 17 19 a b c d description 1 dc cable lead-throughs 2 dc input terminals (fuse protected) 3 input dc fuses 4 connecting knobs f...

Page 48

46 operation principle and hardware description cabinet layout of frame 2 × r8i a cabinet of frame 2 × r8i is shown below with doors open and shrouds removed. D 2 1 4 3 a b c d c 8 6 12 5 1 14 15 18 13 9 7 8 9 7 12 13 16 17 21 20 20 20 20 4 3 10 11 11 10 2 17 17 22 4 14 19 6 17 20 external control i...

Page 49

Operation principle and hardware description 47 description 1 dc cable lead-throughs 2 dc input terminals (fuse protected) 3 input dc fuses 4 connecting knobs for temporary grounding of the dc busbars for work 5 dc main switch 6 ground fault monitoring device (options +q954, +q976 and +q981) 7 dc co...

Page 50

48 operation principle and hardware description cabinet layout of frame 3 × r8i a cabinet of frame 3 × r8i is shown below with doors open and shrouds removed. A b c d c 7 1 9 7 9 c 2 3 4 5 6 8 9 7 11 12 13 15 16 17 18 19 10 11 11 12 12 13 13 14 20 20 10 10 6 3 20 20 4 2 20 d d 2 1 1 3 4 17 21 17 17 ...

Page 51: Door Devices

Operation principle and hardware description 49 door devices the cabinet doors are equipped with: • an inverter control panel • ac and dc main switch operating handles • an emergency stop push button in frames 2 × r8i and 3 × r8i (option +q951 in r7i and r8i) • an emergency stop reset button (with o...

Page 52: Inverter Module (R7I)

50 operation principle and hardware description inverter module (r7i) the cooling fan at the base of the inverter module is fed from the auxiliary voltage supply. Inverter module (r8i) the modules run on wheels, which, along with the quick connector at the ac output, enable quick replacement of a mo...

Page 53

Operation principle and hardware description 51 item explanation 1 dc (input) connections 2 ac output busbars. They match the quick connector socket mounted in the cubicle. 3 fiber optic connectors of the aint board. Connected to the rdcu control unit. 4 retractable support legs 5 handle 6 cooling f...

Page 54

52 operation principle and hardware description connections and interfaces overview the diagram below shows the power connections and control interfaces of the pvs800-57 inverters. 1) monitoring and/or controlling of the inverter; 2) grid monitoring relay (option +q969, +q974, +q975 or +q980); 3) se...

Page 55

Operation principle and hardware description 53 see chapter electrical installation for the wiring instructions and section control unit (rdcu/rmio) connection data on page 138 for the control unit specifications. For more information on the connections, see the circuit diagrams delivered with the i...

Page 56

54 operation principle and hardware description connection examples the diagram below shows a connection example for scada, plc or data logger when a modbus/rtu connection is used. Scada / data logger / plc slot 1 slot 2 rdcu (a43) rmba-01 slot 1 slot 2 rmba-01 rdcu (a43) • • • inverter 1 inverter n.

Page 57

Operation principle and hardware description 55 the diagram below shows a connection example for scada, plc or data logger when a modbus/tcp connection is used. Cdp-312r control panel the cdp-312r is the user interface of the inverter unit, providing the essential controls such as start/stop/reset/r...

Page 58: Type Designation Labels

56 operation principle and hardware description type designation labels inverter label the type designation label of the inverter includes the ratings, valid markings, a type designation and a serial number, which allow individual recognition of each inverter. The type designation label is located o...

Page 59

Operation principle and hardware description 57 inverter module label the type designation label of the inverter module includes the ratings, valid markings, a type designation and a serial number. The module label is attached to the front panel of the inverter module. Example labels are shown below...

Page 60: Type Designation Key

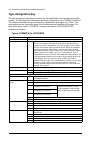

58 operation principle and hardware description type designation key the type designation contains information on the specifications and configuration of the inverter. The first digits from left express the basic configuration, eg, pvs800-57-250kw-a. The optional selections are given thereafter, sep...

Page 61

Operation principle and hardware description 59 fieldbus k454 rpba-01 profibus dp adapter module slot 1: only one of options k454, k458, k466, k467 can be selected. K458 rmba-01 modbus adapter module (slot 1) k464 neta-01 intelligent ethernet adapter module k466 reta-01 ethernet/ip™ and modbus/tcp a...

Page 62

60 operation principle and hardware description types -0500kw-a to -1000kw-c selection alternatives product series pvs800 product series (abb central inverters) type 57 cabinet-built central inverter. When no options are selected: ip42 (ul type 2), ac main contactor, gpv fuses, ac side switch discon...

Page 63

Operation principle and hardware description 61 fieldbus k454 rpba-01 profibus dp adapter module slot 1: only one of options k454, k458, k466, k467 can be selected. K458 rmba-01 modbus adapter module k464 neta-01 intelligent ethernet adapter module k466 reta-01 ethernet/ip™ and modbus/tcp adapter mo...

Page 64

62 operation principle and hardware description.

Page 65: Mechanical Installation

Mechanical installation 63 4 mechanical installation contents of this chapter this chapter describes the mechanical installation procedure of the inverter. Checking the installation site see section ambient conditions on page 144 for allowable operating conditions, and section dimensions, weights an...

Page 66: Required Tools

64 mechanical installation note: for easy maintenance, do not install the inverter on a higher level than the floor in front of it. If the inverter is placed higher, the ramp supplied with the inverter cannot be used when replacing an inverter module. The wall behind the unit must be of non-flammabl...

Page 67: Moving The Unit

Mechanical installation 65 moving the unit move the unit by crane (a), fork-lift or pallet truck (b), or on rollers (c) as shown below. If the cabinet needs to be laid on its back, it must be supported from below beside the cubicle seams as shown below. A) support, b) cabinet back panel. Note: trans...

Page 68: Placing The Unit

66 mechanical installation placing the unit move the cabinet into its final position with an iron bar and a piece of wood at the bottom edge of the cabinet. Place the wooden piece properly in order not to damage the cabinet frame! Overview of the installation process the unit must be installed in an...

Page 69

Mechanical installation 67 fastening the cabinet to the floor the cabinet must be fastened to the floor by using clamps along the edge of the cabinet bottom, or by bolting the cabinet to the floor through the holes inside. Alternative 1 – clamping insert the clamps into the twin slots along the fron...

Page 70

68 mechanical installation alternative 2 – using the holes inside the cabinet the cabinet can be fastened to the floor using the fastening holes inside the cabinet, if they are accessible. The recommended maximum distance between the fastening points is 800 mm (31.5”). If the back fastening holes ar...

Page 71: Miscellaneous

Mechanical installation 69 miscellaneous preventing the recirculation of hot air prevent hot air circulation outside the inverter by leading the outcoming hot air away from the area where the inlet air to the inverter is taken. Also, ensure that the hot air from the inverter module cubicle cannot en...

Page 72

70 mechanical installation calculating the required static pressure difference the required static pressure difference between the exit air duct and the inverter installation room can be calculated as follows: where p d dynamic pressure air density (kg/m 3 ) v m average air velocity in the exit duct...

Page 73

Mechanical installation 71 cable duct in the floor below the cabinet a cable duct can be constructed below the middle part of the cabinet. The duct width may not exceed 450 mm. The cabinet weight lies on the 100 mm wide section in front and 50 mm wide section on the back which the floor must carry. ...

Page 74

72 mechanical installation.

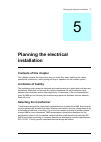

Page 75: Planning The Electrical

Planning the electrical installation 73 5 planning the electrical installation contents of this chapter this chapter contains the instructions that you must obey when selecting the cables, transformer, protections, cable routing and way of operation for the inverter system. Limitation of liability t...

Page 76

74 planning the electrical installation requirements for the transformer • suitable for the network and inverter ac voltage, current and power • suitable for use with igbt inverters • degree of protection, temperature limits and lifetime are appropriate for the environment • equipped with a static g...

Page 77: Inverter

Planning the electrical installation 75 selecting the grid disconnecting device the inverter is equipped with a hand-operated disconnecting device which isolates the inverter and the solar generator from the electrical power system. The disconnecting device does not, however, isolate the inverter ac...

Page 78

76 planning the electrical installation symmetrical shielded cable is recommended for the ac output cabling; see section recommended ac output power cable types below. Compared to a four-conductor system, the use of symmetrical shielded cable reduces electromagnetic emission of the whole inverter sy...

Page 79

Planning the electrical installation 77 recommended ac output power cable types the power cable types that can be used for the inverter ac output are represented below not allowed power cable types selecting the control cables general rules all control cables must be shielded. Use a double-shielded ...

Page 80: Routing The Cables

78 planning the electrical installation signals in separate cables run analog and digital signals in separate, shielded cables. Never mix 24 v dc and 115/230 v ac signals in the same cable. Signals allowed to be run in the same cable relay-controlled signals, providing their voltage does not exceed ...

Page 81: Protection

Planning the electrical installation 79 separate control cable ducts implementing short-circuit and thermal overload protection protecting the inverter and ac output cable in short-circuit situations the inverter is equipped with internal ac fuses which restrict inverter damage in case of a short-ci...

Page 82

80 planning the electrical installation supplying power for the auxiliary circuits supply the inverter with rated auxiliary voltage. Protect the supply according to local regulations with, eg, fuses and/or fault current breakers. Do not connect any additional appliances to the inverter without consu...

Page 83: Systems

Planning the electrical installation 81 implementing ground fault monitoring in it (ungrounded) systems the internal ground fault monitoring of the inverter is based on total sum of the phase current measurements. The monitoring will detect severe ground faults in it (ungrounded) systems. However, o...

Page 84: (Options +F282 And +F283)

82 planning the electrical installation customer wiring the insulation monitoring device can be connected to external systems. See the circuit diagrams delivered with the inverter. Start-up see chapter start-up . More information • circuit diagrams delivered with the inverter • manufacturer’s operat...

Page 85: Electrical Installation

Electrical installation 83 6 electrical installation contents of this chapter this chapter describes the electrical installation process of the inverter. Warnings warning! Only qualified electricians are allowed to do the work described in this chapter. Obey the safety instructions on the first page...

Page 86: . .

84 electrical installation photovoltaic generator ensure that the insulation of the solar generator has been checked according to manufacturer’s instructions. The solar generator must be disconnected from the inverter during the insulation check. Checking the compatibility with it (ungrounded) syste...

Page 87

Electrical installation 85 connection diagram of a four-conductor system arrange the cables as shown below to get an as equal current distribution as possible. Connect single-core cables without concentric protective shield (armor) as shown below. Warning! Ground all conductive cable supports, cable...

Page 88

86 electrical installation dc input cable connection procedure 1. Remove the shroud covering the input power terminals. 2. Lead the cable(s) into the inside of the cabinet. If a shielded cable is used, connect the shield to the cabinet grounding busbar with a cable lug. 3. Connect the dc- conductor ...

Page 89

Electrical installation 87 ac output cable connection procedure 1. Remove the shroud covering the output power terminals. 2. Lead the cable(s) into the inside of the cabinet. If a shielded cable is used, prepare the cable ends and make the 360° grounding arrangements at the cabinet entry as shown on...

Page 90

88 electrical installation pe pe pe.

Page 91: Auxiliary Circuit

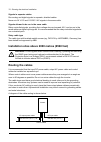

Electrical installation 89 connecting the external power supply cable for the auxiliary circuit connect the external power supply cable conductors to the terminals of auxiliary control voltage switch q10 as shown below. For the location of the switch inside the cabinet, see the cabinet layout photos...

Page 92

90 electrical installation connecting the dc current measurement signals to an external controller (option +g416) this table shows the terminals for connecting the dc current measurement signals (0…4 v) to an external controller. The terminals for connecting the grounding wires are x50:9 and x50:29....

Page 93: (Option +G410)

Electrical installation 91 connecting the junction box power supply (option +g410) the maximum allowed current that can be connected to the power supply is 6 a. Connecting the emc filter (option +e216) connect the emc filter on the network side of the low voltage transformer. Connecting the control ...

Page 94

92 electrical installation default i/o connection diagram (rdcu – a43) the external control cable connections to the rmio board for the pvs800 solar inverter master control program with default settings are shown below (program version gsxr7360 and later). Rmio x20 1 vref- reference voltage -10 v dc...

Page 95

Electrical installation 93 default i/o connection diagram (rdcu – a41) the external control cable connections to the rmio board for the pvs800 solar inverter control program with default settings are shown below (program version isxr7360 and later). Rmio x20 1 vref- by default, not in use. -10 v dc,...

Page 96

94 electrical installation default i/o connections (rdio on rdcu – a41) the default connections of the rdio-01 digital i/o extension modules inserted on the inverter control unit are shown below. Digital input/output rdio terminal description 100 kw and 250 kw units 500 kw and 630 kw units 875 kw an...

Page 97

Electrical installation 95 connection procedure making 360 degrees grounding at the cabinet lead-through for the control cables 1. Loosen the emi conductive cushions. 2. Cut adequate holes to the rubber grommets in the lead-through plate and lead the cables through the grommets and the cushions into...

Page 98: Connecting A Pc

96 electrical installation note: if the outer surface of the shield is non-conductive: • cut the shield at the midpoint of the bare part. Be careful not to cut the conductors or the grounding wire (if present). • turn the shield inside out to expose its conductive surface. • cover the turned shield ...

Page 99: Installation Checklist

Installation checklist 97 7 installation checklist contents of this chapter this chapter contains a list for checking the mechanical and electrical installation of the inverter. Checklist go through the checks below with another person. Obey the safety instructions given on the first pages of this m...

Page 100

98 installation checklist the ac transformer is suitable for use with the inverter. (see section selecting the transformer , page 73 .) the insulation of the assembly is sufficient. (see section checking the insulation of the assembly , page 83 .) the ac power system is an it (ungrounded) system. Th...

Page 101: Start-Up

Start-up 99 8 start-up contents of this chapter this chapter describes the start-up procedure of the inverter. It also gives some advice for operation. Start-up procedure the functioning of the inverter is first tested in the local control mode with the control panel (cdp312r). Thereafter, the contr...

Page 102

100 start-up set up the cabinet heater (option +g300): • set the maximum temperature with the t65 thermostat (default 10 °c). Note: especially in very humid conditions when the inverter is installed on the site for a longer period without grid connection keep the cabinet heaters on for several days ...

Page 103

Start-up 101 adjusting grounding resistance for positive or negative pole grounding (options +f282 and +f283) by default, the grounding resistance is set to 3 kohm. If needed, modify the resistor configuration on the pgnd-02 (a20) board as follows: • warning! Make sure that the voltage is disconnect...

Page 104

102 start-up check that the inverter is in local control mode, ie, letter l is at the top row of the control panel display. If not, press the control panel key . Start the inverter by pressing the control panel key . Description of the events in a normal starting procedure after receiving the start ...

Page 105

Start-up 103 set parameter 98.08 auto line id run to no. This parameter setting prevents an unnecessary id run in case of auxiliary power loss of the control board. Note: if the phase order changes, set 99.07 line side id run to yes to run the id run once. See the firmware manual. Setting up fieldbu...

Page 106: Connecting Drivewindow

104 start-up connecting drivewindow if the drivewindow pc tool is used in the start-up procedure, proceed as follows. Configuring the neta-01 ethernet adapter module see neta-01 ethernet adapter module user’s manual (3afe64605062 [english]). Configuring the neta-21 remote monitoring tool see neta-21...

Page 107: Fault Tracing

Fault tracing 105 9 fault tracing contents of this chapter this chapter describes the fault tracing possibilities of the inverter. Leds this table describes leds of the inverter. Where led when the led is lit rmio board (a41) red inverter in fault state green the power supply on the board is ok. Rmi...

Page 108: Control Panel

106 fault tracing warning and fault messages displayed by the cdp-312r control panel the control panel displays the warnings and faults of the inverter control unit that it is currently controlling. Flashing messages warning, id:2 or fault, id:2 on the control panel display indicate a warning or fau...

Page 109: Maintenance

Maintenance 107 10 maintenance contents of this chapter this chapter contains preventive maintenance instructions of the inverter. Maintenance intervals if installed in an appropriate environment, the inverter requires very little maintenance. The tables below lists the routine maintenance intervals...

Page 110

108 maintenance recommended annual maintenance actions by the user abb recommends these annual inspections to ensure the highest reliability and optimum performance. Recommended maintenance intervals after start-up 1) if the inverter is continuously used for reactive power compensation during the ni...

Page 111: Replacing The Air Filters

Maintenance 109 cleaning the interior of the cabinet warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. Warning! Use a vacuum cleaner with an antistatic hose and nozzle. Using a normal vacuum cleaner create...

Page 112: Cleaning The Heatsink

110 maintenance cleaning the heatsink the inverter module heatsink fins pick up dust from the cooling air. Check the cleanliness of the heatsink regularly. The inverter runs into overtemperature warnings and faults if the heatsink is not clean. When necessary, clean the heatsink as follows. Warning!...

Page 113: 2 × R8I, 3 × R8I)

Maintenance 111 checking and cleaning the power connections (r8i, 2 × r8i, 3 × r8i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions before ele...

Page 114: Fans

112 maintenance fans the cooling fan lifespan depends on the inverter usage and ambient temperature. See the firmware manual for an actual signal which indicates the hours of usage of the fan. Fan failure can be predicted by the increasing noise from fan bearings and the gradual rise in the heatsink...

Page 115

Maintenance 113 replacing the lcl filter cooling fan (r8i, 2 × r8i, 3 × r8i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions before electrical...

Page 116

114 maintenance replacing the door fans warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions before electrical work on page 12 before you start the...

Page 117

Maintenance 115 replacing the cabinet roof fans (r8i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions before electrical work on page 12 before...

Page 118

116 maintenance replacing the cooling fan of the inverter module (r7i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions before electrical work ...

Page 119

Maintenance 117 replacing the cooling fan of the inverter module (r8i, 2 × r8i, 3 × r8i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. 1. Stop the inverter and do the steps in section precautions befor...

Page 120: 3 × R8I)

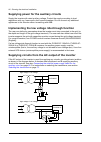

118 maintenance replacing the inverter module (frames r8i, 2 × r8i, 3 × r8i) warning! Obey the safety instructions, page 11 . If you ignore the instructions, physical injury or death, or damage to the equipment can occur. Warning! If you ignore these instructions, physical injury or death, or damage...

Page 121

Maintenance 119 8. Insert the module pull-out ramp under the two bolts at the base of the module and tighten the bolts carefully. 9. Pull the module carefully out of the cubicle along the ramp. Make sure the wires do not catch. While pulling on the handle, keep a constant pressure with one foot on t...

Page 122: Replacing The Lcl Filter

120 maintenance inserting the module into the cubicle 1. Move the new inverter module close to the ramp, then retract the support legs of the module. 2. Push the module up the ramp back into the cubicle. Keep your fingers away from the edge of the module front plate to avoid pinching them between th...

Page 123: Capacitors

Maintenance 121 capacitors the inverter intermediate circuit employs several electrolytic capacitors. Their lifespan depends on the inverter loading and ambient temperature. Capacitor life can be prolonged by lowering the ambient temperature. Capacitor life shortens in high ambient temperatures and ...

Page 124

122 maintenance.

Page 125: Technical Data

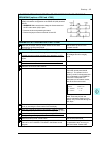

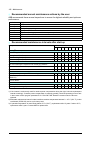

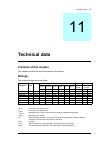

Technical data 123 11 technical data contents of this chapter this chapter contains the technical data for the inverters. Ratings the inverter ratings are given below. Inverter type pvs800-57- … frame size temp nominal ratings i n(ac) i max(dc) u n(ac) p n(ac) p pv i sc pv backfeed current * inrush ...

Page 126

124 technical data altitude derating the inverter load capacity (current and power) decreases if the installation site altitude exceeds 1000 metres (3300 ft). The derating is 1% for every 100 m (328 ft). For the maximum installation site altitude, see section ambient conditions on page 144 . Tempera...

Page 127

Technical data 125 temperature rating of types -0315kw-b and -0630kw-b this curve shows the load capacity of inverter types -0315kw-b and -0630kw-b as a function of ambient temperature. The curve is applicable at altitudes below 1000 m (3300 ft). T 100 90 +40 °c +104 °f +60 °c +140 °f 80 +50 °c +122...

Page 128

126 technical data temperature rating of types-0500kw-a, -0875kw-b and -1000kw-c this curve shows the load capacity of inverter types -0500kw-a, -0875kw-b and - 1000kw-c as a function of ambient temperature. The curve is applicable at altitudes below 1000 m (3300 ft). With temperature compensated al...

Page 129: Type Equivalence Table

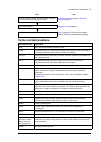

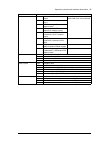

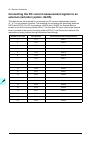

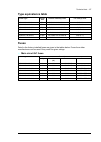

Technical data 127 type equivalence table fuses data for the factory-installed fuses are given in the tables below. Fuses from other manufacturers can be used if they meet the given ratings. Main circuit ac fuses inverter type frame size inverter module(s) used lcl filter(s) used pvs800-57-0100kw-a ...

Page 130

128 technical data inverter dc fuses dc fuses for 2 dc input connections (option +2h382) dc fuses for 4 dc input connections (option +4h382) dc fuses for 5 dc input connections (option +5h382) dc fuses for 8 dc input connections (option +8h382) inverter type fuse information qty rated current (a) bu...

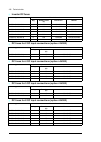

Page 131

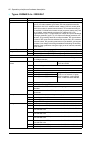

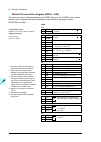

Technical data 129 dc fuses for 10 dc input connections (option +10h382) dc fuses for 12 dc input connections (option +12h382) dc fuses for 15 dc input connections (option +15h382) dc fuses for 16 dc input connections (option +16h382) dc fuses for 20 dc input connections (option +20h382) inverter ty...

Page 132

130 technical data fuses for inverters delivered without input dc fuses (option +0f291) the table below shows the rated dc current for selecting the input dc fuses (see the next table) as per the number of the dc input connections to the solar generator. The table below shows the recommended input d...

Page 133

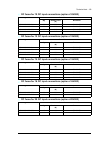

Technical data 131 miniature dc circuit breakers (option +h377) miniature circuit breakers for options +g300 and +g410 dimensions of the recommended fuses (mm). 1 mm = 0.0394 in. Size type code a b d e f g h 2 pv-***af2 81 91 77 61 m10 9.5 24 3 pv-***af3 82 91 92 76 m12 9.5 30 inverter type breaker ...

Page 134

132 technical data dimensions, weights and free space requirements the heights and depths of the cabinet are given below. The widths of the cabinet are given below. The weights of the cabinet are given below. Inverter type pvs800-57-… height depth mm in. Mm in. 0100kw-a 2130 83.84 690 27.17 0250kw-a...

Page 135: Cable

Technical data 133 the free space requirements are given below. Losses, cooling data and noise the inverter is cooled by an internal fan, flow direction from front to top. 1) for dimensioning the ventilation of the electric equipment room 2) cooling air flow for a cabinet with one dc input cubicle o...

Page 136

134 technical data the dc input power cable terminal data is given in the table below. Units with fuse-protected dc input connections dc busbars pe busbar inverter type pvs800-57- pcs (plus + minus) bolt size tightening torque bolt size tightening torque +h38 2 +2h382 +4h382 +5h382 +8h382 +10h3 8 2 ...

Page 137: Cable

Technical data 135 terminal and lead-through data for the ac output power cable the ac busbars are tin-plated. Cable lugs suited to tin-plated materials can be used. Inverter type no. Of cable lead-throughs Ø60 mm (2.36”) pvs800-57-0100kw-a 3 pvs800-57-0250kw-a 2 × 3 pvs800-57-0315kw-b 2 × 3 pvs800-...

Page 138

136 technical data ac output connection specification voltage types -0100kw-a, -0250kw-a and -0500kw-a: 300 v ac 3-phase ± 10% types -0315kw-b, -0630kw-b and -0875kw-b: 350 v ac 3-phase ± 10% type -1000kw-c : 400 v ac 3-phase ± 10% allowed electrical system type 3-phase it (ungrounded) system. Galva...

Page 139: Dc Input Connection Data

Technical data 137 power factor (cos phi 1 ) adjustment range 0…1 capacitive or inductive depending on the dimensioning the following graphs illustrate the equipment operation with the nominal ac voltage and nominal ambient temperature. See ratings on page 123 . Current see section ratings . Overvol...

Page 140

138 technical data auxiliary power connection data voltage 230 v ac (115 v ac optional) frequency 50/60 hz allowed electrical system tn-s (grounded) system. If it (ungrounded) system, contact abb for instructions. Overvoltage category (iec 62109, iec 60664-1) 2 control unit (rdcu/rmio) connection da...

Page 141

Technical data 139 insulation test voltage 500 v ac, 1 min logical thresholds “0”, > 12 v dc “1” input current di1 to di 5: 10 ma, di6: 5 ma filtering time constant 1 ms relay outputs rdcu (a43, pvs800 master control program): two programmable relay outputs, or with option +q951 one programmable rel...

Page 142

140 technical data isolation and grounding diagram x20 1 vref- 2 agnd x21 1 vref+ 2 agnd 3 ai1+ 4 ai1- 5 ai2+ 6 ai2- 7 ai3+ 8 ai3- 9 ao1+ 10 ao1- 11 ao2+ 12 ao2- x22 1 di1 2 di2 3 di3 4 di4 9 dgnd1 5 di5 6 di6 7 +24vd 8 +24vd 11 diil 10 dgnd2 x23 1 +24 v 2 gnd x25 1 ro1 2 ro1 3 ro1 x26 1 ro2 2 ro2 3...

Page 143: Efficiency

Technical data 141 efficiency all values below are without auxiliary power consumption. The inverter complies with efficiency standards iec 61683 and en 50530. Maximum efficiency dc voltage 450 v 600 v 800 v pvs800-57-0100kw-a 98.0 97.3 96.6 pvs800-57-0250kw-a 98.0 97.4 96.9 pvs800-57-0500kw-a 98.6 ...

Page 144

142 technical data maximum efficiency dc voltage 525 v 675 v 825 v pvs800-57-0315kw-b 98.6 98.2 97.7 pvs800-57-0630kw-b 98.6 98.2 98.1 pvs800-57-0875kw-b 98.7 98.3 97.9 european (euro-eta) efficiency dc voltage 525 v 675 v 825 v pvs800-57-0315kw-b 98.3 97.7 96.8 pvs800-57-0630kw-b 98.4 97.8 97.3 pvs...

Page 145: Degrees Of Protection

Technical data 143 maximum efficiency dc voltage 600 v 750 v 850 v pvs800-57-1000kw-c 98.8 98.4 98.3 european (euro-eta) efficiency dc voltage 600 v 750 v 850 v pvs800-57-1000kw-c 98.6 97.8 97.4 pvs800-57-1000kw-c efficiency degrees of protection ip42 (ul type 2) protective class class i (iec 62109-...

Page 146: Ambient Conditions

144 technical data ambient conditions environmental limits for the inverter are given below. The inverter is to be used in a heated, indoor, controlled environment. Note : if the installation has ventilation ducts directly to outdoors (eg, a container installation), back flow of moist and dusty air ...

Page 147: Materials

Technical data 145 vibration (iec 60068-2) max. 1 mm (0.04 in.) (5 to 13.2 hz), max. 7 m/s 2 (23 ft/s 2 ) (13.2 to 100 hz) sinusoidal max. 1 mm (0.04 in.) (5 to 13.2 hz), max. 7 m/s 2 (23 ft/s 2 ) (13.2 to 100 hz) sinusoidal max. 3.5 mm (0.14 in.) (2 to 9 hz), max. 15 m/s 2 (49 ft/s 2 ) (9 to 200 hz...

Page 148

146 technical data auxiliary circuit power consumption the auxiliary circuit must be supplied by the customer galvanically separated from inverter output. Inverter type total in running max. (w) total in stand-by (w) additional consumption in stand- by (option +g300) (max. W) pvs800-57-0100kw-a 310 ...

Page 149: Ce Marking

Technical data 147 ce marking a ce mark is attached to the inverter to verify that the unit follows the provisions of the european low voltage and emc directives. Compliance with the european low voltage directive the compliance with the european low voltage directive has been verified according to ...

Page 150: “C-Tick” Marking

148 technical data medium voltage network the requirements of the emc directive can be met as follows: 1. A transformer with static screening between the primary and secondary windings is used to ensure that no excessive emission is propagated to neighboring low-voltage networks. 2. The inverter is ...

Page 151: Dimension Drawings

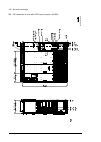

Dimension drawings 149 12 dimension drawings contents of this chapter this chapter contains example dimension drawings of the inverter..

Page 152: Frame R7I

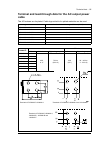

150 dimension drawings frame r7i 3a u a 0000083 128.

Page 153

Dimension drawings 151 ac output: 3a u a 00000 83128.

Page 154

152 dimension drawings 3a u a 00000 83128 one dc in put fo ur dc in pu ts.

Page 155: Frame R8I

Dimension drawings 153 frame r8i r8i – 2 dc inputs (option +2h382) or 4 dc inputs (option +4h382): 3a x d 50 00001 6935.

Page 156

154 dimension drawings r8i – 8 dc inputs (option +8h382): 3a x d 50000 016935.

Page 157

Dimension drawings 155 r8i – ac output terminals: 3a x d 50 00001 6935.

Page 158

156 dimension drawings r8i – dc terminals of units with 2 dc inputs (option +2h382): 3a x d 5000 001693 5.

Page 159

Dimension drawings 157 r8i – dc terminals of units with 4 dc inputs (option +4h382): 3a x d 50000 01693 5.

Page 160

158 dimension drawings r8i – dc terminals of units with 8 dc inputs (option +8h382): 3 a x d 5 00000 16935.

Page 161

Dimension drawings 159 r8i – top view of fastening points: 1) two dc inputs (option +2h382), four dc inputs (option +4h382) 2) eight dc inputs (option +8h382) 1 2 3axd50000016935.

Page 162: Frame 2 × R8I

160 dimension drawings frame 2 × r8i 2 × r8i – 4 dc inputs (option +4h382) or 5 dc inputs (option +5h382): 3 a x d 500000 15007.

Page 163

Dimension drawings 161 2 × r8i – 8 dc inputs (option +8h382) or 10 dc inputs (option +10h382): 3a x d 50000 01500 7.

Page 164

162 dimension drawings 2 × r8i – 12 dc inputs (option +12h382) or 15 dc inputs (option +15h382): 3a x d 50 00001 5007.

Page 165

Dimension drawings 163 2 × r8i – ac output terminals: 3a x d 50 00001 5007.

Page 166

164 dimension drawings 2 × r8i – dc terminals of units with 4 dc input terminals (option +4h382) or 5 dc input terminals (option +5h382): 3a x d 50000 01500 7.

Page 167

Dimension drawings 165 2 × r8i – dc terminals of units with 8 dc input terminals (+8h382) or 10 dc input terminals (+10h382): 3a x d 50000 01500 7.

Page 168

166 dimension drawings 2 × r8i – dc terminals of units with 12 dc input terminals (+12h382) or 15 dc input terminals (+15h382): 3 a x d 5 00000 15007.

Page 169

Dimension drawings 167 2 × r8i – top view of fastening points: 4 dc i n pu ts ( + 4h 382) or 5 dc i n pu ts ( + 5h 382) 8 dc i n pu ts ( + 8h 382) or 10 dc i nput s ( + 10h382) 12 dc i nput s ( + 12h382) or 15 dc i nput s ( + 15h382) 3a x d 50000 01500 7.

Page 170: Frame 3 × R8I

168 dimension drawings frame 3 × r8i 3 × r8i – 8 dc inputs (option +8h382) or 10 dc inputs (option +10h382): 3a x d 50000 01500 6.

Page 171

Dimension drawings 169 3 × r8i – 12 dc inputs (option +12h382) or 15 dc inputs (option +15h382): 3a x d 500 00015 006.

Page 172

170 dimension drawings 3 × r8i – 16 dc inputs (option +16h382) or 20 dc inputs (option +20h382): 3 a x d 500000 15006.

Page 173

Dimension drawings 171 3 × r8i – ac input terminals: 3a x d 50 00001 5006.

Page 174

172 dimension drawings 3 × r8i – dc terminals of units with 8 dc input terminals (option +8h382) or 10 dc input terminals (option +10h382): 3a x d 50000 01500 6.

Page 175

Dimension drawings 173 3 × r8i – dc terminals of units with 12 dc input terminals (option +12h382) or 15 dc input terminals (option +15h382): 3a x d 500 00015 006.

Page 176

174 dimension drawings 3 × r8i – dc terminals of units with 16 dc input terminals (option +16h382) or 20 dc input terminals (option +20h382): 3axd 500 00015006.

Page 177

Dimension drawings 175 3 × r8i – top view of fastening points: 8 dc input s (+ 8h382 ) or 10 dc i nput s ( + 10h3 82) 12 dc i nput s (+ 12 h 382) o r 15 dc inpu ts ( + 15 h382) 16 dc i nput s (+ 16 h 382) o r 20 dc inpu ts ( + 20 h382) 3 a x d 5 00000 15006.

Page 178

176 dimension drawings.

Page 179

Further information more information about abb products for solar applications on the internet: www.Abb.Com/ solar ..

Page 180

Contact us www.Abb.Com/solar 3aua0000053689 rev h (en) effective: 2014-07-09.