- DL manuals

- ABB

- Relays

- REU 610

- Operator's Manual

ABB REU 610 Operator's Manual

Summary of REU 610

Page 1

Voltage protection relay reu 610 reu 610 operator's manual.

Page 3

3 contents copyrights ................................................................................. 5 1. Introduction ..............................................................7 1.1. This manual .............................................................. 7 1.2. Use of symbols ...............

Page 4

4.2.2.1. Menu system of parameters ............ 30 4.2.2.2. How to change settings .................. 31 4.2.2.3. Configuration ................................ 34 4.2.2.4. How to acknowledge and reset indications, output contacts and memorized values ......................... 37 4.3. Protection rel...

Page 5

5 copyrights the information in this document is subject to change without notice and should not be construed as a commitment by abb oy. Abb oy assumes no responsibility for any errors that may appear in this document. In no event shall abb oy be liable for direct, indirect, special, incidental or c...

Page 6

6.

Page 7

7 1. Introduction 1.1. This manual this manual provides basic information on the voltage relay reu 610 and presents detailed instructions on how to use the human-machine interface (hmi) of the relay. In addition to the instructive part, a short chapter on commissioning and maintenance of the relay i...

Page 8

1.4. Product documentation in addition to the relay and this manual, the delivery contains the following relay- specific documentation: table 1.4.-1 reu 610 product documentation name document id certificate of verification 1mrs081662 installation manual 1mrs752265-mum technical reference manual 1mr...

Page 9

9 1.6. Document revisions version ied revision date history a a 01.02.2006 document created b c 30.11.2006 content updated c c 06.07.2007 content updated voltage protection relay operator's manual reu 610 reu 610 1mrs755770

Page 10

10

Page 11

11 2. Safety information dangerous voltages can occur on the connectors, even though the auxiliary voltage has been disconnected. Non-observance can result in death, personal injury or substantial property damage. Only a competent electrician is allowed to carry out the electrical installation. Nati...

Page 12

12.

Page 13

13 3. Product overview 3.1. Use of the relay the voltage relay reu 610 is a versatile multifunction protection relay mainly designed for overvoltage and undervoltage protection and for supervision of medium voltage distribution networks. The relay can also be used for protecting generators, motors a...

Page 14

* two galvanically isolated digital inputs and three additional galvanically isolated digital inputs on the optional i/o module * disturbance recorder: * recording time up to 80 seconds * triggering by one or several internal or digital input signals * records four analog channels and up to eight us...

Page 15

15 4. Operation 4.1. Hmi features 4.1.1. Front panel the front panel of the relay contains: * alphanumeric 2 × 16 characters ’ lcd with backlight and automatic contrast control * threeindicator leds (green, yellow, red) with fixed functionality * eight programmable indicator leds (red) * hmi push-bu...

Page 16

Left up down right enter clear/ cancel clear/ cancel a040225 fig. 4.1.2.-1 navigation push buttons use the navigation buttons to view, select and edit the wanted menu items. * activate the main menu by pressing an arrow button. * move between the menu levels and menu items by using the arrow buttons...

Page 17

17 1. The backlight is turned on after the relay has performed the internal power-up tests and entered into the protection mode. 2. The display is tested by inverting it for approximately three seconds, see fig. 4.1.3.1.-1. 3. The display is returned to the idle mode and the backlight is turned off ...

Page 18

* turn the backlight on by pressing an arrow button on the hmi. If the hmi panel is not used for approximately five minutes, the backlight is turned off automatically. * activating the power-saving built-in feature by pressing turns the backlight off within 20 seconds. 4.1.3.4. How to adjust the dis...

Page 19

19 u12 un:0.00 measurements a051435 fig. 4.1.5.-1 display showing the first submenu * enter a submenu by pressing ; exit by pressing . * navigate between the main levels in the submenus by using or . * press to return the display to the idle mode. 4.1.6. Hmi passwords the hmi passwords are used to p...

Page 20

Change the hmi setting password as follows: 1. Press an arrow button to access the main menu. 2. Use the arrow buttons to select configuration\hmi passwords \setting password and press . 3. Press to enter the setting mode and give the current hmi password if required. If the default password 999 is ...

Page 21

21 1. Press an arrow button to access the main menu 2. Use the arrow buttons to select configuration\communication\spa settings\password spa and press . 3. Press to enter the setting mode and give the current hmi password if required. If the default password 999 is still valid, no password is requir...

Page 22

5. Press to confirm the selection. The selected language is shown on the display. 6. Press to return the display to the idle mode. By pressing before confirming the selection, the former language remains active and the display is returned to the view mode. Pressing again returns the display to the i...

Page 23

23 5. The first digit of the setting value of the parameter to be edited starts to flash. Use and to move the cursor and and to increase or decrease the value. The setting range (for example year or minutes) is shown on the right- hand side of the second line of the display. 6. To store a new value ...

Page 24

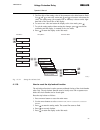

Main menu group menu parameter menu measurements confirm cancel operation lockout reset operation trip lockout recorded data operation settings configuration info a040239 fig. 4.1.10.-1 resetting trip lockout function 4.1.11. How to switch between front and rear connection there are two means of ser...

Page 25

25 when the rear connection is selected, the selected rear protocol is automatically activated. Main menu group menu parameter menu settings configuration measurements recorded data info function test/di communication language frequency configuration memory settings hmi passwords time line-idle stat...

Page 26

1. Press an arrow button to access the main menu. 2. Use the arrow buttons to select configuration\communication\rear protocol and press . The cursor is at the setting currently in use (for example spa). 3. Press to enter the setting mode. The second line starts to flash. 4. Use or to select the wan...

Page 27

27 * stored event values from the protection functions * registered number of starts of protection functions * continuously updated registers of actual values from protection functions * operation * resetting of trip lockout * info * information on the relay, such as device type and relay serial num...

Page 28

1. Press and simultaneously to view the primary phase-to-phase voltages u 12 , u 23 and u 31 and the residual voltage u 0 . 2. Press to return the display to the idle mode. The display has to be in the idle mode to be able to activate the monitoring state. The display is not returned to the idle mod...

Page 29

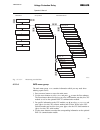

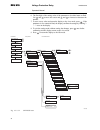

29 main menu group menu parameter menus settings configuration measurements recorded data number of starts 5. Event 4. Event 3. Event recorded data 1. Event 2. Event recorded data recorded data recorded data info 1. U12 un:0.00 1. U23 un:0.00 1. U31 un:0.00 1. Umin un:0.00 1. Umax un:0.00 1. U2s un:...

Page 30

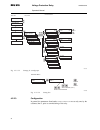

While in the dnp serial number view, press to view the dnp protocol name. 5. To return the display to the idle mode, press . 1mrsxxxxxx x 1mrsxxxxxx x xxxxxxxx xxx xxx xxxxxxxxxxxxxxxxxxxxx xxxxxxxx xxxxxxxx 1 2 3 5 6 7 4 8 main menu parameter menus settings configuration measurements recorded data ...

Page 31

31 the views are used for reading and setting parameters, which are divided into two main groups: * settings * configuration 4.2.2.2. How to change settings the actual settings consist of the settings of group 1 or group 2, depending on which group has been selected to be active (indicated by an ast...

Page 32

6. The first digit of the setting value of the parameter to be edited starts to flash. Use and to move the cursor and and to increase or decrease the number. 7. To store a new value and return the display to the view mode, press . If the parameter is of a numerical kind, the display confirms the sto...

Page 33

33 switchgroups the relay contains the following switchgroups: sgf1 output contacts sgf2 display settings sgf3, sgf4 protection functions sgf5 latching feature for programmable leds sgb1...Sgb5 digital inputs (di1...Di5) sgr1...Sgr8 output contacts (po1, po2, po3, so1, so2, so3, so4, so5) sgl1...Sgl...

Page 34

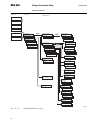

Main menu group menu parameter menus settings configuration measurements recorded data group 1/group 2 new trip ind. Demand settings settings protect. Stages settings settings * grp 1 :000 grp 2 :000 grp 2 :0000 settings * grp 1 :0000 grp 2 :0000 settings * grp 1 :0000 settings settings settings grp...

Page 35

35 to change a parameter: 1. Press an arrow button to access the main menu. 2. Use the arrow buttons to select the main menu group configuration and the wanted group menu, and press . 3. Use or to select the wanted parameter (for example unit address : xxx) or a set of parameters (for example spa se...

Page 36

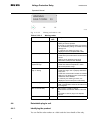

Baud rate :9.6 hmi passwords time line-idle state connection type trip circuit sup main menu group menu parameter menus settings configuration measurements recorded data configuration counter :000 unit address :001 modbus settings spa settings rear protocol configuration di1 status :0 di2 status :0 ...

Page 37

37 hmi passwords time trip circuit sup main menu group menu parameter menus settings configuration measurements recorded data configuration frequency :60 configuration frequency :50 frequency configuration function test/di communication language memory settings setting password configuration hh.Mm;s...

Page 38

Include recorded data, disturbance recorder data and average values (demand values and history data). 4.3. Protection relay indications the operation of the relay can be monitored by means of three different hmi indications: * three indicator leds with fixed functionality: * ready * start/alarm * tr...

Page 39

39 4.3.1.2. Yellow indicator led a040266 fig. 4.3.1.2.-1 yellow indicator led * indicator off: no protection stage has started. * lit indicator: a protection stage has started or generated an alarm. The start and alarm indication can be selected to be either latching or non-latching with the sgf swi...

Page 40

4.3.1.4. Programmable indicator leds in addition to the three fixed leds, the relay contains eight leds which you can program to indicate the status of different type of relay signals. The programmable leds can indicate the following information: * trip signals from protection stages * trip lockout ...

Page 41

41 u>> u12/u23 trip a051581 fig. 4.3.2.1.-2 trip indication latching and non-latching indications a latching operation indication message remains on the display until manually cleared or until replaced by a message of higher priority. However, if the fault is stable and has not disappeared, the oper...

Page 42

Internal relay fault (irf) at permanent internal relay faults, the relay is no longer protecting and has to be sent for repair at an authorized service supplier. When the self-supervision system detects a permanent internal relay fault, the green indicator led starts to flash. The text internal faul...

Page 43

43 table 4.3.2.3.-1 irf codes (continued) fault code type of fault 55 faulty parameter memory, calibration parameters 80 optional i/o module missing 81 optional i/o module unknown 82 optional i/o module configuration error 85 power supply module faulty 86 power supply module unknown 90 hardware conf...

Page 44

Warning fault code: 33 a040280 fig. 4.3.2.3.-3 warning with numeric code table 4.3.2.3.-2 warning codes fault weight value description battery low 1 battery voltage level low * battery should be replaced * if the relay is used without battery, this warning can be disabled by setting non-volatile mem...

Page 45

45 when checking the order number of the relay plug-in unit, be careful not to lift the handle more than 25º (approx. 40 mm). Lifting the handle any further detaches the plug-in unit from the case. A y a040165 fig. 4.4.1.-1 checking the order number of the relay α = 25º y = 40 mm 4.4.2. Detaching an...

Page 46

A040166 fig. 4.4.2.-1 detaching a plug-in unit from the case before fitting a relay plug-in unit into a relay case, check that the unit and the case have the same order number. The order number of the case is printed on the bottom plate inside the case. However, if a substitute plug-in unit has to b...

Page 47

47 a040167 fig. 4.4.2.-2 installing a plug-in unit into the case 4.4.3. Inserting and changing the battery the battery may only be inserted and changed by trained service personnel. To insert or change the battery, first detach the plug-in unit; refer to section 4.4.2. Detaching and installing the p...

Page 48

A b c a040282_2 fig. 4.4.3.-1 inserting and changing the battery a) battery holder b) note! Polarity c) battery 48 reu 610 reu 610 voltage protection relay operator's manual 1mrs755770

Page 49

49 5. Commissioning and maintenance the relay should be subject to regular tests and maintenance in accordance with national regulations and instructions. Prior to commissioning, the functionality of the application-specific relay configuration and settings have to be tested. During relay commission...

Page 50

Polarity checking of voltage transformers should be performed to confirm that the wiring circuitry between the voltage transformers and the relay is correct, which is a prerequisite for the protection functions in the relay to operate correctly. The circuit breaker tripping circuit, interlocking and...

Page 51

51 1. Verifying measurements – can be performed according to the instructions in section 5.3. Measurements verification. 2. Verifying output contacts operation – can be performed according to the instructions in section 5.4. Function test. The circuit breaker tripping circuit should be disconnected ...

Page 52

The internal signals are routed to the output contacts according to the sgr switch groups. The test mode is accessible via function test/di under configuration in the hmi menu. In the test mode, all internal signals from the different protection stages can be activated one by one, the self-supervisi...

Page 53

53 5.5. Digital input test this section describes how the availability of signals connected to the digital inputs can be tested. To monitor the status of the digital inputs, navigate in the hmi menu as follows: 1. Press an arrow button to access the main menu. 2. Use or to select configuration in th...

Page 54

When calculating the voltage to be applied into the phase-to-phase voltage energizing inputs, calculate as follows: * rated voltage, 100, 110, 115 or 120 v, of the relay energizing input to be tested this gives the voltage to be applied during the test as follows: * applied voltage (v) = 2 ×u>>× rat...

Page 55

55 6. Spare parts 6.1. Plug-in unit the relay ’s construction allows a spare part in form of a plug-in unit. The outage time can therefore be reduced to a minimum in case the relay should fail. In case of malfunction, please consult your relay supplier. The spare plug-in unit to be used for a certai...

Page 56

56.

Page 57

57 7. Repair if the relay fails in operation or if the operating values differ remarkably from the specified values, the relay is to be given a proper service. All major measures involving overhaul of electronics are to be taken by the manufacturer. Contact the manufacturer or the nearest representa...

Page 58

58.

Page 59

59 8. Ordering information for ordering information, refer to the technical reference manual. Voltage protection relay operator's manual reu 610 reu 610 1mrs755770

Page 60

60

Page 61

61 9. Abbreviations abbreviation description ascii american standard code for information interchange cbfp circuit-breaker failure protection cpu central processing unit di digital input hmi human-machine interface idmt inverse definite minimum time characteristic iec international electrotechnical ...

Page 64

Abb oy distribution automation p.O. Box 699 fi-65101 vaasa finland tel. +358 10 22 11 fax. +358 10 224 1094 www.Abb.Com/substationautomation 1mrs75577 0 e n 7 /2007.