- DL manuals

- ABB

- Measuring Instruments

- Sensyflow iG

- Operating Manual

ABB Sensyflow iG Operating Manual

Summary of Sensyflow iG

Page 1

Sensyflow ig intelligent gas-mass flowmeter profibus dpv1 pa profile 3.0 version 1.00 preliminary operating manual 42/14-39 en rev. 00

Page 2

2 sensyflow ig, version 1.00 42/14-39 en gas-mass flowmeter sensyflow ig profibus dpv1 pa profile 3.0 version 1.00 operating manual document no. 42/14-39 en issue date 02.02 revision 00 manufacturer: abb automation products gmbh borsigstraße 2 63755 alzenau germany phone: +49 6023- fax: +49 6023-321...

Page 3

Contents 42/14-39 en sensyflow ig, version 1.00 3 contents sensyflow ig 1 correct use, general safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.1 range of applications, proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

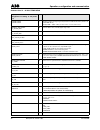

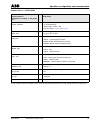

Page 4

4 sensyflow ig, version 1.00 42/14-39 en 7.4 display, operation, and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 7.4.1 operating structure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 7.4.2 di...

Page 5

Correct use, general safety instructions 42/14-39 en sensyflow ig, version 1.00 5 1 correct use, general safety instructions 1.1 range of applications, proper use sensyflow ig has been designed for mass flow measurement of gases and gas conglomerates in closed pipe circuits. These operating instruct...

Page 6

Correct use, general safety instructions 6 sensyflow ig, version 1.00 42/14-39 en a copy of the operating instructions must be stored in a suitable place at the usage location of the device at all times. Read these operating instructions prior to commissioning, decommissioning, maintaining, or repai...

Page 7

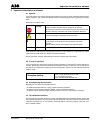

Important information in advance 42/14-39 en sensyflow ig, version 1.00 7 2 important information in advance 2.1 symbols to ensure optimum use of these operating instructions and a safe use of the assemblies during commis- sioning, operation, and maintenance please observe the following explanations...

Page 8

Important information in advance 8 sensyflow ig, version 1.00 42/14-39 en fig. 2-1 calibration certificate sample calibration subject: sensor data and serial (fabrication) number customer data regarding the application calibration data: data regarding test bench and boundary conditions calibration r...

Page 9

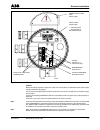

System description 42/14-39 en sensyflow ig, version 1.00 9 3 system description the mass flow meters of the sensyflow ig family operate according to the hot-film anenometer principle. An exact description can be found in section 9, "measuring principle" the compact version of the metering system co...

Page 10

System description 10 sensyflow ig, version 1.00 42/14-39 en 3.1 pipe components the pipe components and weld-on adapters guarantee the defined installation of the transducer in the pipeline. Moreover, they allow simple installation and removal of the transducer for inspection and/or cle- aning. By ...

Page 11

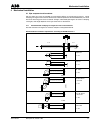

Mechanical installation 42/14-39 en sensyflow ig, version 1.00 11 4 mechanical installation 4.1 pipe component and transducer inlet and outlet runs must be provided to avoid negative effects on the measuring accuracy, these steadying run lengths make sure that disturbances of the flow profile are el...

Page 12

Mechanical installation 12 sensyflow ig, version 1.00 42/14-39 en • components that influence the flow (e. G. Valves, shut-off fittings and similar components) should pos- sibly be mounted at the outlet run length, i. E. Behind the measuring point . • the sealings used must not change the cross-sect...

Page 13

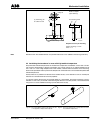

Mechanical installation 42/14-39 en sensyflow ig, version 1.00 13 fig. 4-1 adaption by using a weld-on adapter note deviations from the stated dimension and position tolerances cause additional measuring uncertainty. 4.2 installating the transducer in areas with high ambient temperature the permissi...

Page 14

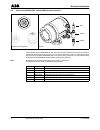

Mechanical installation 14 sensyflow ig, version 1.00 42/14-39 en 4.3 aligning housing head and display in the compact and remote version the housing of the evaluation electronics has been pivot-mounted for enhanced readability. From the center position it can be rotated by approximately 170° to the...

Page 15

Mechanical installation 42/14-39 en sensyflow ig, version 1.00 15 4.4 mounting the evaluation electronics (remote version) in the remote version you can use cables with a length up to 25 m between sensor (transducer) and eva- luation electronics. The transducer is installed as described before in th...

Page 16

Electrical installation 16 sensyflow ig, version 1.00 42/14-39 en 5 electrical installation 5.1 general information about profibus profibus is a vendor-independent, standardized field bus for applications in manufacturing, process, and building automation. The profibus technology has been defined as...

Page 17

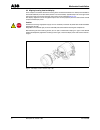

Electrical installation 42/14-39 en sensyflow ig, version 1.00 17 fig. 5-2 sensyflow ig terminal box with direct profibus connection caution before connecting the power supply lines make sure that the device is operated with the correct supply voltage (see device rating plate)! First you connect the...

Page 18

Electrical installation 18 sensyflow ig, version 1.00 42/14-39 en 5.4 connecting profibus dp via profibus m12 bus connector fig. 5-3 profibus dp m12 bus connector for this device version a profibus dp m12 bus connector with complete internal wiring is supplied in- stead of the central screw terminal...

Page 19

Electrical installation 42/14-39 en sensyflow ig, version 1.00 19 5.5 profibus bus terminator and cable to minimize line reflections and to ensure a defined steady level on the transmission line, the transmis- sion line must be fitted with the following termination resistor combination at both ends....

Page 20

Commissioning 20 sensyflow ig, version 1.00 42/14-39 en 6 commissioning after completion of the installation procedure (see previous section) sensyflow ig can be commissioned. Follow the instructions below: caution before connecting the power lines make sure that the device is operated with the corr...

Page 21

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 21 7 operation, configuration and communication 7.1 profibus communication bus communication of the "sensyflow ig" thermal gas-mass flow meter with profibus interface is ba- sed on the "profile for process control devi...

Page 22

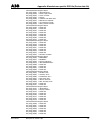

Operation, configuration and communication 22 sensyflow ig, version 1.00 42/14-39 en 7.1.2 module configuration for cyclic data communication (dp) sensyflow ig provides cyclic data communication for the following modules, which are described in the vendor-specific gsd file. Four modules must be sele...

Page 23

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 23 note the configuration of the individual slots is supported by gsd file revision 3.0. If the pcs does not support gsd file revision 3.0, the corresponding configuration alternatives are to be considered (see above)....

Page 24

Operation, configuration and communication 24 sensyflow ig, version 1.00 42/14-39 en • quality = good (not cascade) ) • limits 7.1.2.3 hexadecimal status byte messages status byte messages for gas flow, temperature and integrator (totalizer) are shown in hexadecimal no- tation on the display. The st...

Page 25

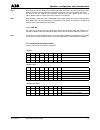

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 25 7.1.2.4 diagnosis • device diagnosis diagnostic byte bit type 1 0 hardware failure of electronic 1 hardware failure of mechanics 2 motor temp. Too high 3 electronic temp. Too high 4 memory error 5 failure sensor 6 d...

Page 26

Operation, configuration and communication 26 sensyflow ig, version 1.00 42/14-39 en diagnostic byte bit type 5 0 com module 1 mt module 2 internal can error 3 serial eeprom error 4 reserved 5 reserved 6 reserved 7 reserved diagnostic byte bit type 6 0 cal data error 1 gas temp. Error 2 heater temp....

Page 27

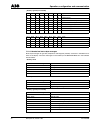

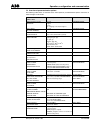

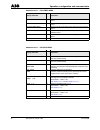

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 27 7.1.3 acyclic data communication (dpv1) 7.1.3.1 device management block * device-dependant 7.1.3.2 physical block slot index relative index parameter object data type store size acc. Transport type default value man...

Page 28

Operation, configuration and communication 28 sensyflow ig, version 1.00 42/14-39 en 7.1.3.3 flow transducer block flow (tb flow) 0 68 52 manufacturer language uint8 s 1 r/w a 0 0 .. 3 o 0 69 53 manufacturer operating hour meter string s 4 r a - years, days, hours, minutes o 0 70 54 manufacturer cal...

Page 29

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 29 function block flow analog input (ai) 4 74 23 mass_flow_lo_lim float s 4 r,w a - m 4 75 24 mass_flow_hi_lim float s 4 r,w a - m 4 4 4 43..52 pno reserved m 4 104 53 manufacturer parameter characteristic selection un...

Page 30

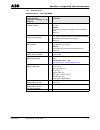

Operation, configuration and communication 30 sensyflow ig, version 1.00 42/14-39 en 7.1.3.4 gas temperature transducer block gas temperature (tb temp.) 1 41 25 lo_lim float s 4 r/w a - m 1 42 1 43 27 lo_lo_lim float s 4 r/w a - m 1 44 1 45 1 46 30 hi_hi_alm ds-39 16 r a - o 1 47 31 hi_alm ds-39 16 ...

Page 31

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 31 function block gas temperature analog input (ai) 5 74 5 75 24 input_fault_gen uint8 d 1 r a - m 5 76 25 input_fault_1 uint8 d 1 r a - m 5 77 26 input_fault_2 uint8 d 1 r a - o 5 78 27 sensor_wire_check_1 uint8 d 1 r...

Page 32

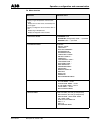

Operation, configuration and communication 32 sensyflow ig, version 1.00 42/14-39 en 2 40 2 41 25 lo_lim float s 4 r/w a - m 2 42 2 43 27 lo_lo_lim float s 4 r/w a - m 2 44 2 45 2 46 30 hi_hi_alm ds-39 16 r a - o 2 47 31 hi_alm ds-39 16 r a - o 2 48 32 lo_alm ds-39 16 r a - o 2 49 33 lo_lo_alm ds-39...

Page 33

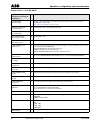

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 33 7.1.3.5 totalizer function block totalizer (tot) slot index relative index parameter object data type store size access transport type default value/ allowed range mandatory (m) / optional (o) 3 16 0 block object ds...

Page 34

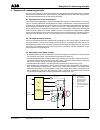

Operation, configuration and communication 34 sensyflow ig, version 1.00 42/14-39 en 7.2 description of function blocks in profibus devices the primary sensor signals are processed in the transducer blocks. For sensyflow ig these are the flow and temp transducer blocks. Further signal processing is ...

Page 35

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 35 fig. 7-3 analog input function block (identical for flow and temp signals) fig. 7-4 totalizer function block 7.3 smart vision dtm configuration detailed information about smart vision can be found in the correspondi...

Page 36

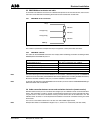

Operation, configuration and communication 36 sensyflow ig, version 1.00 42/14-39 en the context-sensitive button functions are shown in the display. This allows easy operation and configu- ration of the sensyflow ig. The display modes show symbols in the lower right corner of the display, indicatin...

Page 37

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 37 7.4.1 operating structure overview the operating structure represents the arrangement scheme of the dialog boxes. Within a menu level you can navigate with the up/down arrow buttons. The submenus can be accessed by ...

Page 38

Operation, configuration and communication 38 sensyflow ig, version 1.00 42/14-39 en 7.4.2 display modes 7.4.3 operating modes display of gas temperature, flow rate, and characteristic curve. Use the up/down arrow buttons to toggle the individual display modes. Flow rate display, numerically and as ...

Page 39

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 39 7.4.4 entering and changing data 7.4.5 status signals the examples measuring point no. And dp slave address are used to demonstrate entering and chan- ging data. Both entry masks are found in the parameter menu that...

Page 40

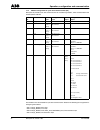

Operation, configuration and communication 40 sensyflow ig, version 1.00 42/14-39 en 7.5 overview of parameterization options the following table shows an overview of the most important parameterization options and menus in which changes can be made. Parameter menu item selection/possible entry wher...

Page 41

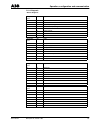

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 41 7.6 menu structure main menu submenu level 1 • display of gas temperature and mass flow • value • display of mass flow value, numerically and • as bar graph • display of integrator value and mass flow va- lue • disp...

Page 42

Operation, configuration and communication 42 sensyflow ig, version 1.00 42/14-39 en submenu level 2 tb flow menu • calibration factor ** • low flow cut-off * • zero point correct** • zero point on/off ** • mass flow state • flow unit * • mass flow lo lim ** • mass flow hi lim** • end tb flow ai flo...

Page 43

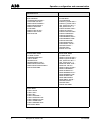

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 43 7.7 parameterization in service mode all menu items marked with */sp can be configured. In specialist mode all menu items marked with */sp and **/se can be configured. All other items can only be displayed (d) 7.7.1...

Page 44

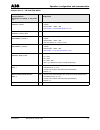

Operation, configuration and communication 44 sensyflow ig, version 1.00 42/14-39 en submenu level 1 → profibus menu submenu level 1 → service menu display indication explanation tb flow menu access to the transducer block flow (mass flow) in submenu level 2 ai flow menu access to the analog input b...

Page 45

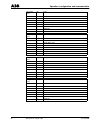

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 45 7.7.2 submenu level 2 submenu level 2 → tb flow menu display indication designation according to pa profile 3.0 explanation calibration factor calibr_factor se input of calibration factor that acts as multiplier on ...

Page 46

Operation, configuration and communication 46 sensyflow ig, version 1.00 42/14-39 en submenu level 2 → ai flow menu display indication designation according to pa profile 3.0 explanation ai flow state ai flow state d display of status message for mass flow in hexadecimal notation (status to ai flow ...

Page 47

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 47 submenu level 2 → tb gas temp menu display indication designation according to pa profile 3.0 explanation tb temp state primary_value d display of status message for the gas temperature in hexadecimal notation displ...

Page 48

Operation, configuration and communication 48 sensyflow ig, version 1.00 42/14-39 en submenu level 2 → ai gas temp menu display indication designation according to pa profile 3.0 explanation ai temp state ai temp state d display of status message for gas temperature in hexadecimal notation (status t...

Page 49

Operation, configuration and communication 42/14-39 en sensyflow ig, version 1.00 49 submenu level 2 → total menu in case of power failure the integrator value is retained. After switching the device on again, adding continuous automatically. Display indication designation according to pa profile 3....

Page 50

Maintenance and service 50 sensyflow ig, version 1.00 42/14-39 en 8 maintenance and service all sensyflow measuring systems are precisely calibrated for the respective application with our own ca- libration equipment, for which abb automation is associated with the german calibration service. Exten-...

Page 51

Sensyflow ig: measuring principle 42/14-39 en sensyflow ig, version 1.00 51 9 sensyflow ig: measuring principle for many years, thermal gas-mass flow meters with analog design have been established as complete process measuring devices in the chemical industry.The digital sensyflow ig represents a l...

Page 52

Sensyflow ig: measuring principle 52 sensyflow ig, version 1.00 42/14-39 en the increased application and cost advantage results from the diagnostic possibilities of the digital sen- syflow. The functions provided allow for preventive maintenance of the measuring system and the equip- ment, as opera...

Page 53

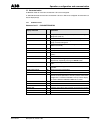

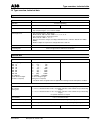

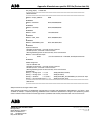

Type overview, technical data 42/14-39 en sensyflow ig, version 1.00 53 10 type overview, technical data type sensyflow ig sensyflow ig-ex application process engineering explosion protection zone 2 optional atex version under preparation components – ig transducer as compact or remote version – pip...

Page 54

Type overview, technical data 54 sensyflow ig, version 1.00 42/14-39 en type sensyflow ig sensyflow ig-ex operating pressure 4 × 10 6 pa (40 bar) operating temperature of medium (transducer) standard range: -25...+150 °c extended range: -25...+300 °c in preparation ambient temperature: evaluation el...

Page 55

Abbreviations 42/14-39 en sensyflow ig, version 1.00 55 11 abbreviations dtm device tool manager emc electromagnetic compatibility fdt field device tool fms field message specification gsd geräte stamm datei (device data file) dp decentral periphery dpv1protocol cyclic and acyclic communication dvgw...

Page 56

Decommissioning and packaging 56 sensyflow ig, version 1.00 42/14-39 en 12 decommissioning and packaging packaging for transport or return to the manufacturer if the original packaging material is no longer available, wrap the device in a padded plastic film or cor- rugated paper board and place it ...

Page 57

Appendix: manufacturer-specific gsd file (device data file) 42/14-39 en sensyflow ig, version 1.00 57 13 appendix: manufacturer-specific gsd file (device data file) ;=================================================================== ; gsd file for profibus dp (en 50170) ;===========================...

Page 58

Appendix: manufacturer-specific gsd file (device data file) 58 sensyflow ig, version 1.00 42/14-39 en maxtsdr_500 = 100 maxtsdr_1.5m = 150 maxtsdr_3m = 250 maxtsdr_6m = 450 maxtsdr_12m = 800 redundancy = 0 ; no redundancy transmission repeater_ctrl_sig = 0 24v_pins = 0 ;=============================...

Page 59

Appendix: manufacturer-specific gsd file (device data file) 42/14-39 en sensyflow ig, version 1.00 59 ;gerätespezifische diagnose byte 2 unit_diag_bit(32) = "zero point error" unit_diag_bit(33) = "power supply failed" unit_diag_bit(34) = "confi. Not valid" unit_diag_bit(35) = "restart" unit_diag_bit...

Page 60

Appendix: manufacturer-specific gsd file (device data file) abb automation products gmbh borsigstraße 2 63755 alzenau, germany phone +49 6023 92- 0 fax +49 6023 92-3210 http://www.Abb.Com subject to technical changes. Printed in the fed. R. Of germany 42/14-39 en rev. 00 issue 02.02 subject to techn...