- DL manuals

- ABB

- Valve Positioners

- TZIDC-110

- Operating Instructions Manual

ABB TZIDC-110 Operating Instructions Manual - Manufacturer'S Information

10

Electro-pneumatic positioner TZIDC-110

41/18-77 EN

2

Manufacturer's information

2.1 Delivery

When receiving the delivery please immediately check items and scope for intactness

and completeness. The scope of delivery is stated in the shipping documents. If ordered,

the accessories (e.g. mounting material, pressure gauge block, filter regulator) are added

to the delivery as individual items. Check items and scope of the delivery by means of

the catalog numbers to see if types and quantities are in accordance with your order. If

the positioner is delivered already mounted to the actuator, the positioner, accessories

and actuator or final control element are considered as a common delivery item. A list of

catalog numbers and details of the different versions and accessories can be found in

data sheet 18-0.23 EN.

2.2 CE compliance information

We declare that we are the manufacturer of the TZIDC-110 positioner and that the pro-

duct conforms with the EMC Directive 89/336/CEE as of May 1989 and meets the

requirements of the following standards:

•

EN 55022:1998 “Information technology equipment, Radio disturbance

characteristics, Limits and methods of measurement”

•

EN 61000-6-2:8/2002 ”Electromagnetic compatibility (EMC)

Part 6-2: Generic standards - Immunity for industrial environments

•

EN 61000-6-3:3/2000 “Electromagnetic compatibility (EMC)

Part 6-3: Generic standards - Emission standard for residential,

commercial and light-industrial environments

The TZIDC-110 positioner complies with the EC directive for CE conformity certification.

Summary of TZIDC-110

Page 1

P r o f i b u s process field bus ® operating instructions 41/1877 en electro-pneumatic positioner tzidc-110 for profibus pa.

Page 2

2 electro-pneumatic positioner tzidc-110 41/18-77 en electropneumatic positioner tzidc110 for profibus pa operating instructions document no.: 41/18-77 en issued: 04.05 manufacturer abb automation products gmbh schillerstr. 72 32425 minden germany tel: +49 551 905-534 fax: +49 551 905-555 ccc-suppor...

Page 3: Table of Contents

41/18-77 en electro-pneumatic positioner tzidc-110 3 table of contents important information ....................................................................................................... 5 1 safety summary .......................................................................................

Page 4: 4 Technical Data

4 electro-pneumatic positioner tzidc-110 41/18-77 en 3.3 electrical connection..............................................................................................22 3.3.1 safety instructions ........................................................................................ 22 3.3.2 g...

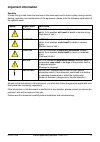

Page 5: Important Information

41/18-77 en electro-pneumatic positioner tzidc-110 5 important information symbols in order that you can make the best use of this document and to ensure safety during commis- sioning, operation and maintenance of the equipment, please note the following explanation of the symbols used: as well as t...

Page 6: Safety Summary

6 electro-pneumatic positioner tzidc-110 41/18-77 en 1 safety summary 1.1 general safety instructions this chapter provides important instructions for your safety. Thoroughly read and follow these instructions. Proper and safe operation of the tzidc-110 positioner requires: • proper transportation a...

Page 7

41/18-77 en electro-pneumatic positioner tzidc-110 7 1.2 device-specific safety instructions 1.2.1 general 1.2.2 pneumatic safety ! Warning • any user-made changes or manipulations of the device are prohibited! Only the manufacturer or an expert for explosion protection are authori- zed to modify th...

Page 8

8 electro-pneumatic positioner tzidc-110 41/18-77 en 1.2.3 electrical safety ! Warning • observe the common vde safety regulations and the accident preven- tion rules of the employers liability insurance association. • observe the common standards and safety regulations for the installa- tion and op...

Page 9: 1.3 Explosion Protection

41/18-77 en electro-pneumatic positioner tzidc-110 9 1.3 explosion protection one of the type plates seen below is attached to the positioner to the left of the main type plate, depending on the positioner’s explosion protection. It indicates the degree of explo- sion protection and the certificate ...

Page 10: Manufacturer'S Information

10 electro-pneumatic positioner tzidc-110 41/18-77 en 2 manufacturer's information 2.1 delivery when receiving the delivery please immediately check items and scope for intactness and completeness. The scope of delivery is stated in the shipping documents. If ordered, the accessories (e.G. Mounting ...

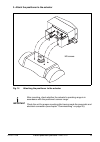

Page 11: Installing and Commissioning

41/18-77 en electro-pneumatic positioner tzidc-110 11 3 installing and commissioning 3.1 mechanical mounting 3.1.1 general the arrow (1) on the feedback shaft (and thus the lever) must travel within the area marked with the small arrows (2). When mounting the positioner, ensure that the transfer of ...

Page 12

12 electro-pneumatic positioner tzidc-110 41/18-77 en 3.1.2 operating conditions at the installation site ambient temperature: -40 °c ... +85 °c (-25 °c ... + 85 °c when using proximity switches of type sj2-s1n (no)) relative humidity: 95 % (mean annual value), condensation permissible. Observe the ...

Page 13

41/18-77 en electro-pneumatic positioner tzidc-110 13 follow the procedure (steps 1 - 5) below to attach the positioner to a linear actuator: 1. Mount the follower guide to the actuator 2. Assemble the lever (if not yet pre-assembled) • fasten the follower guide (1) and the clamp plates (2) with scr...

Page 14

14 electro-pneumatic positioner tzidc-110 41/18-77 en 3. Mount the lever and the angle bracket to the positioner • attach the lever (1) to the positioner’s feedback shaft (2) (can only be mounted in one position due to the flat on the side of the feedback shaft). • check whether the lever travels wi...

Page 15

41/18-77 en electro-pneumatic positioner tzidc-110 15 4.A mount the positioner to a cast iron yoke or 4.B mount the positioner to a columnar yoke • fasten the angle bracket (1) with screw (2), plain washer (3) to the cast iron yoke (4). • hold the angle bracket (1) in the appropriate position agains...

Page 16

16 electro-pneumatic positioner tzidc-110 41/18-77 en 5. Adjust the stroke the scale on the lever indicates the relevant points for the various valve stroke ranges. You can adapt the valve stroke range to the operating range of the position sensor by shifting the bolt with follower pin in the oblong...

Page 17

41/18-77 en electro-pneumatic positioner tzidc-110 17 3.1.4 mounting the positioner to rotary actuators the following mounting kit is available for mounting to a rotary actuator according to vdi/ vde 3845: tools required: wrench 10 mm /13 mm allen key 3 mm • adapter (1.0) with spring (1.4) • four sc...

Page 18

18 electro-pneumatic positioner tzidc-110 41/18-77 en follow the procedure (steps 1 - 3) below to attach the positioner to a rotary actuator: 1. Mount the adapter to the positioner 2. Attach the mounting bracket (1) to the positioner • determine the mounting position (in paral- lel to the actuator o...

Page 19

41/18-77 en electro-pneumatic positioner tzidc-110 19 3. Attach the positioner to the actuator important after mounting, check whether the actuator’s operating range is in accordance with the positioner’s sensor range. Check the unit for proper mounting after having made the pneumatic and electrical...

Page 20: 3.2 Pneumatic Connection

20 electro-pneumatic positioner tzidc-110 41/18-77 en 3.2 pneumatic connection 3.2.1 safety instructions 3.2.2 making the pneumatic connections all pneumatic piping connections are located on the right-hand side of the positioner. Threaded bores g 1/4 or 1/4-18 npt, respectively, are provided. The p...

Page 21

41/18-77 en electro-pneumatic positioner tzidc-110 21 the connections have to be arranged, according to their marks, in the following way: 3.2.3 mounting the splash guard cap screw the splash guard cap delivered with your positioner into the appropriate hole in the bottom plate of the case, as seen ...

Page 22: 3.3 Electrical Connection

22 electro-pneumatic positioner tzidc-110 41/18-77 en 3.3 electrical connection 3.3.1 safety instructions 3.3.2 general installation instructions ! Warning • observe the common vde safety regulations and the accident preven- tion rules of the employers liability insurance association • observe the c...

Page 23

41/18-77 en electro-pneumatic positioner tzidc-110 23 3.3.3 overview two threaded bore holes 1/2 - 14 npt or m20 x 1.5 are available on the left hand side as the cable entry into the case. One is equipped with a cable gland and in the other a pipe plug is mounted. The screw terminals inside the case...

Page 24

24 electro-pneumatic positioner tzidc-110 41/18-77 en 2. Connect the wires to the terminals • remove approximately 6 mm of the insulation. • when connecting the bus lines, shutdown module, proximity switches or microswit- ches, insert the wire ends from the left into the appropriate screw terminal a...

Page 25: 3.4 Commissioning

41/18-77 en electro-pneumatic positioner tzidc-110 25 3.4 commissioning 3.4.1 procedure 1. Turn on the air supply to the positioner. 2. Connect the bus with arbitrary polarity (or auxiliary power 9 v dc ... 32 v dc) to the bus terminals. Is displayed. 3. Check for proper mounting: - press and hold m...

Page 26

26 electro-pneumatic positioner tzidc-110 41/18-77 en 5. Run the standard autoadjustment function. - make sure that the remote level is activated. For linear actuators 1 : - press and hold mode . Wait until the countdown has run down from 5 to 0, then release mode . - press and hold mode again until...

Page 27

41/18-77 en electro-pneumatic positioner tzidc-110 27 3.4.2 setting the bus address • switch the positioner over from the remote level to the operating level: press and hold mode and enter simultaneously until the countdown has run down from 3 to 0. Release mode and enter . • switch the positioner o...

Page 28

28 electro-pneumatic positioner tzidc-110 41/18-77 en 3.4.3 requesting information additional information can be called up for display by briefly pressing the buttons shown in the table when the bus mode is active (i.E. The following display is seen): 3.4.4 local operation (bus device) procedure for...

Page 29

41/18-77 en electro-pneumatic positioner tzidc-110 29 3.4.5 parameter setting example "changing zero position (of the lcd) from clockwise to counter-clockwise" starting situation: the positioner is operating remote-controlled. 1. Cange over from the remote level to the operating level: - press and h...

Page 30

30 electro-pneumatic positioner tzidc-110 41/18-77 en 5. Change parameter setting: - briefly press to select "ctclockw". 6. Change over to parameter 3.3 "exit" and save the new setting: - press and hold mode . - in addition, 1 x briefly press . - is displayed. - release mode . - briefly press to sel...

Page 31

41/18-77 en electro-pneumatic positioner tzidc-110 31 if the optionally installed filter regulator is installed, it has to be checked regularly as well. Additionally, the control position should be checked periodically for conformity with the tolerance limit. 3.5.1 functional test of the shutdown mo...

Page 32: Technical Data

32 electro-pneumatic positioner tzidc-110 41/18-77 en 4 technical data 4.1 basic model communication profiles profibus pa profile for process control devices electro pneumatic actuator v3.0 block types 1 ao function block, 1 transducer block,1 function block physical layer compliant to the standard ...

Page 33

41/18-77 en electro-pneumatic positioner tzidc-110 33 shut-off values end position 0 % =0...45 % end position 100 % =55...100 % travel angle of rotation used range 25...120 ° (rotary actuators, optionally 270°) 25...60 °(linear actuators) travel time prolongation range of 0...200 seconds, separately...

Page 34

34 electro-pneumatic positioner tzidc-110 41/18-77 en influence of vibration ≤ +/-1 % up to 10 g and 80 hz seismic requirements meets requirements of din/iec 68-3-3 class iii for strong and strongest earthquakes influence of mounting orientation no effect meets the requirements of the following dire...

Page 35

41/18-77 en electro-pneumatic positioner tzidc-110 35 explosion protection fm and csa pending atex ii 2g eex ia ii c t6 examination certificate tÜv 02 atex 1831 x type: intrinsically safe device group: ii 2g (eex ia iic) temperature class: t4, t5, t6 perm. Amb. Temperature: t4: -40 °c ≤ t amb ≤ 85 °...

Page 36: 4.2 Options

36 electro-pneumatic positioner tzidc-110 41/18-77 en 4.2 options module for the shutdown function supply voltage 24 v dc (20...30 v dc) (electrically isolated from the input signal) safe position is activated when voltage ak approval ak 4 to din v 19250 test report no. 101/s01/148 explosion protect...

Page 37

41/18-77 en electro-pneumatic positioner tzidc-110 37 digital position feedback with 24 v microswitches 1 2 microswitches for independent position signaling. Switching points adjustable between 0 and 100 % voltage max. 24 v ac / dc current load max. 2 a contact surface 10 µm gold (au) mechanical pos...

Page 38: Certificates

38 electro-pneumatic positioner tzidc-110 41/18-77 en 5 certificates.

Page 39

41/18-77 en electro-pneumatic positioner tzidc-110 39.

Page 40

40 electro-pneumatic positioner tzidc-110 41/18-77 en.

Page 41

41/18-77 en electro-pneumatic positioner tzidc-110 41.

Page 42

42 electro-pneumatic positioner tzidc-110 41/18-77 en.

Page 43

41/18-77 en electro-pneumatic positioner tzidc-110 43.

Page 44

44 electro-pneumatic positioner tzidc-110 41/18-77 en.

Page 45: Iecex Certificate

41/18-77 en electro-pneumatic positioner tzidc-110 45 iecex certificate of conformity international electrotechnical commission iec certification scheme for explosive atmospheres for rules and details of the iecex scheme visit www.Iecex.Com certificate no.: iecex tun 04.0015x issue no.: 0 status: cu...

Page 46: Iecex Certificate

46 electro-pneumatic positioner tzidc-110 41/18-77 en iecex certificate of conformity certificate no.: iecex tun 04.0015x date of issue: 2004-07-29 issue no.: 0 page 2 of 4 manufacturer: abb automation products gmbh schillerstraße 72 32425 minden germany manufacturing location(s): abb automation pro...

Page 47: Iecex Certificate

41/18-77 en electro-pneumatic positioner tzidc-110 47 iecex certificate of conformity certificate no.: iecex tun 04.0015x date of issue: 2004-07-29 issue no.: 0 page 3 of 4 schedule equipment: equipment and systems covered by this certificate are as follows: the positioner type tzidc-xxx is used for...

Page 48: Iecex Certificate

48 electro-pneumatic positioner tzidc-110 41/18-77 en iecex certificate of conformity certificate no.: iecex tun 04.0015x date of issue: 2004-07-29 issue no.: 0 page 4 of 4 additional information: pp y.

Page 49

41/18-77 en electro-pneumatic positioner tzidc-110 49 tÜv nord cert gmbh & co. Kg am tÜv 1 d-30519 hannover annexe to iecex tun 04.0015x page 1 of 3 tÜv nord cert electrical data for type tzidc resp. Tzidc-200 with marking ex ib iic t6 signal circuit (terminals 11(+), 12(-)) in type of protection “i...

Page 50

50 electro-pneumatic positioner tzidc-110 41/18-77 en tÜv nord cert gmbh & co. Kg am tÜv 1 d-30519 hannover annexe to iecex tun 04.0015x page 2 of 3 tÜv nord cert electrical data for type tzidc-110, tzidc-210, tzidc-120 resp. Tzidc-220 with marking ex ia iic t6 input circuit (terminals +11, -12 resp...

Page 51

41/18-77 en electro-pneumatic positioner tzidc-110 51 tÜv nord cert gmbh & co. Kg am tÜv 1 d-30519 hannover annexe to iecex tun 04.0015x page 3 of 3 tÜv nord cert electrical data for type tzidc, tzidc-110 resp. Tzidc-120 with marking ex na ii t6 type tzidc resp. Tzidc-200 signal circuit (terminals 1...

Page 52

52 electro-pneumatic positioner tzidc-110 41/18-77 en.

Page 53

41/18-77 en electro-pneumatic positioner tzidc-110 53.

Page 54

54 electro-pneumatic positioner tzidc-110 41/18-77 en.

Page 55

41/18-77 en electro-pneumatic positioner tzidc-110 55.

Page 56: Appendix A: Configuration O

56 electro-pneumatic positioner tzidc-110 41/18-77 en appendix a: configuration o ver vie w p a r. D is p la y f u n ct io n p a ra m et e r se tt in g u n it f a ct o ry s e tt in g p 1 ._ s t and ard p1 .0 a c t u a t o r act uat or t y p e li nea r , r o t a r y - l ine a r p1 .1 a u t o _a d j a...

Page 57

41/18-77 en electro-pneumatic positioner tzidc-110 57 p 6 ._ ma n_ ad j p6 .0 m in _ v r min. V a lv e r ange 0. 0. .. 10 0.0 % 0. 0 p6 .1 m a x _ vr m a x. V a lv e ra ng e 0 .0 .. .1 00 .0 % 1 0 0 .0 p 6 .2 a c tu a t or act uat or type li near, r o t a r y - l ine a r p 6 .3 sprng_y2 sp ri ng act...

Page 58: Rameter O

58 electro-pneumatic positioner tzidc-110 41/18-77 en c onf ma % c° oper ati ng le vel en ter mo de p a ra met e r "e xi t " (n v _ sa ve /c an c e l ) enter (3 ... 0 ) (3 . .. 0) i.2 man ua l i.I ct rl _f ix re m o te le vel mo de + enter (3 ... 0) (lo c a l o per ati on) i.3 m an_ se ns conf igu r...

Page 59

Abb has sales & customer support expertise in over 100 countries worldwide. Www.Abb.Com the company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in the fed. Rep. Of germany (04.05) © abb 2005 42/18 77 e...