- DL manuals

- ABB

- Inverter

- UNO-7.6-TL-OUTD-S-US-A

- Product Manual

ABB UNO-7.6-TL-OUTD-S-US-A Product Manual - Ppropriate Usage

- 11 -

004CC1

1- Introduction and safety

A

ppropriate usage

The UNO Inverter is a photovoltaic inverter that converts direct current of a connected PV array into alternating

current and feeds that power into the AC utility grid.

This inverter is designed for outdoor use, but can be used indoors if installed to specified environmental and

mounting parameters stated in this manual, and adherence to the National Electric Code. See environmental

conditions below and environmental check in section 2.

C

onditions of use

This inverter utilizes a transformerless design and requires connected arrays to be

floating with respect to ground; it can be used only with photovoltaic modules that do

not require one of the terminals to be grounded.

•

The DC and AC operating currents MUST NOT exceed the limits documented in the

technical specifications found in the data table in the appendix, section 7.

• The inverter is certified for use only with photovoltaic arrays connected to its input

channel(s). Do not connect batteries or other types of power sources.

E

nvironmental conditions

Adverse environmental conditions can lead to a reduction in performance. The equipment

should be installed outdoors, but only in environmental conditions indicated in this manual.

Care must be taken to provide adequate ventilation if installed indoors.

I

mproper or prohibited use

The following actions are dangerous and not consistent with acceptable practice under the

terms of the warranty:

• Installing the equipment in environments with flammable conditions.

•

Using the equipment with safety devices not working or disabled.

•

Using the equipment or parts of the equipment by connecting it to other machines or

equipment, unless otherwise expressed.

•

Modifying areas that are operator restricted and/or altering parts of the equipment in

order to vary the performance or change its protection.

•

Cleaning with corrosive products that may corrode parts of the equipment or with products

that might generate electrostatic charges.

•

Using or installing the equipment or parts of it without having read and correctly interpreted

the contents of this manual.

• Blocking airflow to the cooling fins (e.g., warming or drying rags) on the unit or accessory

parts is dangerous and could compromise the inverter operation.

Summary of UNO-7.6-TL-OUTD-S-US-A

Page 1

Abb solar inverters product manual uno-7.6-8.6-tl-outd-s-us-a (7.6 to 8.6 kw).

Page 2

- 2 - 001cv important safety instructions this manual contains important safety instructions that must be followed during installation and maintenance of the inverter. Save these instructions! Keep this document in a safe place near the inverter for easy access during installation and maintenance. T...

Page 3

- 3 - 001cv product manual uno-7.6-8.6 string inverters 1 - introduction and safety 2 - installation location 3 - mounting and wiring 4 - operations 5 - troubleshooting 6 - maintenance 7 - appendix uno-7.6-8.6-tl-outd-s-us-a product manual bcg.00751.0_aa rev 1.1 © copyright 2014 abb. All rights rese...

Page 4: Ontents

- 4 - 002tc c ontents i ntroduction and safety ...................................................................................................................... 7 warnings in this document .............................................................................................................

Page 5

- 5 - 002tc o perations ........................................................................................................................................43 monitoring and data transmission .....................................................................................................43 ...

Page 6

- 6 - 002tc.

Page 7: Arnings In This Document

- 7 - 003ch1 w arnings in this document this is a list of special safety symbols used in this manual that highlight potential safety risks and/or useful information. The symbol usage is described below: caution the reader should stop, use caution and fully understand the operations explained before ...

Page 8: Eneral Installation Warnings

- 8 - 004cc1 1- introduction and safety g eneral installation warnings the uno transformerless inverter is designed and tested according to international safety requirements (ul1741/ieee1547); however, certain safety precautions must be observed when installing and operating this inverter. All opera...

Page 9: Afety Instructions

- 9 - 004cc1 1- introduction and safety s afety instructions these servicing instructions are for use by qualified personnel only. To reduce the risk of electric shock, do not perform any servicing other than that specified in the operating instructions. Be sure all flammable materials including con...

Page 10

- 10 - 004cc1 1- introduction and safety l ocation of safety notices and labels note the location of safety notices on the inverter for notification and protection. Labels must not be hidden with external objects or parts such as rags, boxes, or other such equipment. They should be cleaned periodica...

Page 11: Ppropriate Usage

- 11 - 004cc1 1- introduction and safety a ppropriate usage the uno inverter is a photovoltaic inverter that converts direct current of a connected pv array into alternating current and feeds that power into the ac utility grid. This inverter is designed for outdoor use, but can be used indoors if i...

Page 12: Rc Fault Detection (Afd)

- 12 - 004cc1 1- introduction and safety a rc fault detection (afd) the 2011 national electric code (nec) and 2013 canadian electric code (cec) include a condition that requires a photovoltaic system with a dc voltage greater than 80v, and which is on a building or whose dc conductors enter a buildi...

Page 13: Egulatory Nameplate

- 13 - 004cc1 1- introduction and safety power alarm gfi esc up down enter uno r egulatory nameplate technical data in this manual does not supersede the data on the labels affixed to the equipment. The product nameplate is affixed to the inverter chassis and provides the following information: 1) p...

Page 14

- 14 - 004cc1 1- introduction and safety.

Page 15: Ransportation and Handling

- 15 - 005ch2 t ransportation and handling when being transported, the inverter and electronic components must be protected from vibration, mechanical shocks, humidity, etc. I ncoming inspection it is the customer’s responsibility to examine the condition of the unit. Upon receipt of the inverter ch...

Page 16

- 16 - u006cc2 2 - installation components for all models description qty/part# 3 pin connector for configurable relay 2 82000005907-g 8 pin connector for communication signals 2 82000005908-g l-key tool; torx wrench;90° 1 81510000077 mounting kit includes items below xak.P0101.0 1 wall bracket for ...

Page 17: Nvironmental Check

- 17 - u006cc2 2 - installation s elect the installation location the inverter must be installed by qualified installers and/or licensed electricians ac - cording to the applicable local code regulations (nec, cec, and other). Once physically mounted, the wiring must be carried out with the equipmen...

Page 18: Nstallation Position

- 18 - u006cc2 2 - installation i nstallation position when planning the installation, maintain clearance distances illustrated below to allow normal control functions and easy maintenance operations. When choosing the location and position, comply with the following conditions: • install on a wall ...

Page 19: 25” Handle to Handle

- 19 - u006cc2 2 - installation when installing multiple inverters side-by-side, mounting handles must be considered in measurements. Recommended clearance of 2” between inverters is not required, but a reasonable clearance must be maintained to allow easy access to handles for mounting/dismounting,...

Page 20

- 20 - u006cc2 2 - installation.

Page 21: Mounting and Wiring

- 21 - 007ch3 labeled illustration of uno inverter label description label description 01 mounting bracket 05 wiring box cover 02 upper mounting slots 06 dc disconnect switch 03 lower mounting slots 07 lifting handle (1 each side) 04 inverter cover 08 bottom locking point for securing wiring box to ...

Page 22

- 22 - 008cc3 3 - wiring label description label description 06 dc disconnect switch 11 signal cable openings with plastic threaded plug, 1/2“ 09 dc cable opening with plastic threaded plug , 1”* 17 gore vent pressure equalizer 10 ac cable opening with plastic threaded plug, 1“ * 18 3/4 “, 1” concen...

Page 23: All Mounting

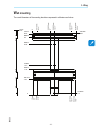

- 23 - 008cc3 3 - wiring w all mounting the overall dimensions of the mounting bracket are expressed in millimeters and inches. 516.70m m 20.34” 0 55.15mm 2.17” 258.35mm 10.17” 461.55mm 18.17” 208.35mm 8” 13mm 0.5” 55mm 2.16” 461.5mm 18.17” 503.7mm 19.8” 17mm 0.67” 734.8mm 28.9” 0 17.84mm 0.7” 184.7...

Page 24

- 24 - 008cc3 3 - wiring • using a level, position the mounting bracket 01 on the wall and use it as a drilling template. • drill the required holes using a 10mm/0.39” bit; holes must be about 70mm/2.75” deep. • attach the bracket to the wall with the screws and wall anchors supplied in the mounting...

Page 25: Iring Details

- 25 - 008cc3 3 - wiring w iring details always respect the nominal ratings of voltage, current, and power defined in the appendix, part 7, when designing your system. Observe the following considerations in design: to reduce the risk of fire, connect only to a circuit provided with 40a/50a maximum ...

Page 26: Iring Box Components

- 26 - 008cc3 3 - wiring w iring box components to access the wiring terminals in the switchbox, the cover 05 must be removed by loosening the six captive screws using the torx screwdriver provided. When connection operations are complete, re-install the cover 05 and tighten the cover screws with at...

Page 27

- 27 - 008cc3 3 - wiring e lectrical connection to the pv field - dc side verify that the dc voltage in the wiring box has the correct polarity and is within the operational range prior to terminating. To prevent electrocution hazards, all the connection operations must be carried out with the dc di...

Page 28

- 28 - 008cc3 3 - wiring i nstalling jumpers for parallel configuration the uno is configured in the independent mode as default . Parallel configuration is made by using the two jumpers provided to short the positive and negative inputs on the dc disconnect switch. In addition, the parallel input m...

Page 29: Jumper 2

- 29 - 008cc3 3 - wiring insert jumpers on positive and negative inputs • gently loosen 2 screws in positive input until jumper can fit in same slot as wire. • insert jumper 1 in slots of +vin1 and +vin2, along with wires. • push wires firmly in slot and tighten both screws to 2nm torque. • gently l...

Page 30

- 30 - 008cc3 3 - wiring u no 8.6kw - external string combiner with single mppt input when using an external string combiner with a single input for the uno 8.6kw, it is not possible to use the 10awg wire with the 48a power level in the switchbox. In this case, the wires of channel 2 terminal block ...

Page 31: Ptional Dc Fused Inputs

- 31 - 008cc3 3 - wiring o ptional dc fused inputs the wiring box is designed with room to accommodate three fused dc inputs per mppt channel resulting in a total of six fused inputs (12 fuses and 12 fuse holders, considering positive and negative inputs). An optional kit is available for addition o...

Page 32

- 32 - 008cc3 3 - wiring dc terminal blocks place 6 fuse holders on dc side, in two groups of 3 each. Attach by hooking fuse holder at top of din rail and snapping onto bottom of din rail. Fit 1 terminal feeder atop each group. Insert one 3 pin bus bar feeder on each terminal block grouping. Tighten...

Page 33

- 33 - 008cc3 3 - wiring ac terminal blocks use a small, flat head screw driver to loosen and move end blocks, ac terminal block, and ac ground terminal on the din rail by pushing screw driver into space at top of block and lifting up and off of din rail. Move ac terminal block and ac ground termina...

Page 34

- 34 - 008cc3 3 - wiring reconnect dc wiring wires removed from dc terminal block in step 1 are labeled, +vin1, +vin2, -vin1, -vin2. Connect wires in terminal feeders of respective fuse holder groupings as illustrated below. Insert the 12 fuses provided in fuse holders. G rid output connection (ac s...

Page 35

- 35 - 008cc3 3 - wiring c onnection to ac terminal block ac grid wiring is based on the grid standard shown in the utility configuration table below. • run an approved raceway between inverter and external ac ocpd. • remove the threaded plastic plug and nut from the ac cable opening 10 . • insert t...

Page 36

- 36 - 008cc3 3 - wiring c ommunication card connections wiring for the rs-485 communication system and hardwired control options must be routed through the switchbox and into the main inverter chassis for termination. Communication and signal wiring connections are described on the following pages....

Page 37

- 37 - 008cc3 3 - wiring communication and signal wiring connections are located on the main inverter board and illustrated below. Label description a01 multi-function relay a02 remote control, rs-485, ethernet a03 connection of rs-485 line on rj45 connector a04 switch s3 for termination resistance ...

Page 38

- 38 - 008cc3 3 - wiring if conduit is used, run the appropriate raceway and terminate it to the wiring box chassis using a conduit connector that matches the raceway. The conduit must be terminated at one of the two ½” signal openings 11 . If the terminal blocks are used, the signals rtn, +t/r and ...

Page 39

- 39 - 008cc3 3 - wiring the two rj45 connectors available for the rs-485 communication are equivalent to each other and can be used interchangeably for the input or output of the line when creating a daisy chain connection of the inverters. D aisy chain units for connection to a monitoring system t...

Page 40: Ddressing Each Inverter

- 40 - 008cc3 3 - wiring a ddressing each inverter when multiple inverters are connected on a single rs-485 bus, it is necessary to assign a different rs-485 address to each unit. The address on the inverter is set through the user interface on the display panel (section 4). Address values are assig...

Page 41: Emote Control Connection

- 41 - 008cc3 3 - wiring alarm nc no c c onfigurable relay connection (alarm) the inverter has a multi-function relay accessible at terminal block a01 and it is provisioned with a removable screw-terminal mating connector to simplify connections to the terminal block. The relay output can be configu...

Page 42

- 42 - 008cc3 3 - wiring.

Page 43: Ypes of Data Available

- 43 - 009ch4 m onitoring and data transmission one of the first rules for preventing damage to the equipment and injury to the opera - tor is to have a thorough knowledge of the user interface operations. Abb cannot be held responsible for damage to the equipment or the operator if caused by incomp...

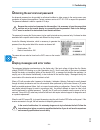

Page 44: Isplay and Keypad

- 44 - 010cc4 4 - operations d isplay and keypad there are three indicators on the led panel and four buttons on the keypad. Leds indicate the operating state of the inverter. The keypad is used to review data on the cyclical display area b10 and access the data logged internally on the uno, using t...

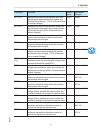

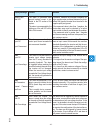

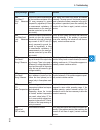

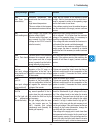

Page 45: Ed Indicators

- 45 - 010cc4 4 - operations l ed indicators in their various combinations, the leds can indicate conditions that are different from the single one. The table below shows the possible combinations of activation of the leds in relation to the operating state of the inverter. Warning and error message...

Page 46

- 46 - 010cc4 4 - operations d escriptions of symbols and display fields b1 -indicates the transmission and reception of data through the rs-485 line b2 - indicates the presence of the rs-485 communication line b3- reports the presence of a line of radio communication (radiomodule card installed) b6...

Page 47

- 47 - 010cc4 4 - operations c yclical display of general information the graphic display area b10 consists of 2 lines with 16 characters per line. When moving through the menu using the buttons of the keypad, area b10 is used to: • display the operating state of the inverter and the statistical dat...

Page 48: Tatistics Menu

- 48 - 010cc4 4 - operations s tatistics menu the statistics menu is a view only display of internally logged inverter data. Lifetime partial today last xxx user period statistics last 365 days last 30 days last month last 7 days start xxxxxxxx end xxxxxxxxx lifetime - displays the total statistics ...

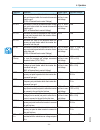

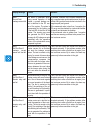

Page 49: Ettings Menu

- 49 - 010cc4 4 - operations once the start and end dates for the user periods have been selected, the following data is available: • e-use: energy produced during the selected period • val. : value of production for the selected period calculated with the currency and conver- sion coefficient set i...

Page 50

- 50 - 010cc4 4 - operations address - used to set the address for the serial communication of inverters connected to the rs-485 line. The addresses that can be assigned are 2 to 63. Use the up and down buttons to scroll the numerical scale. “auto” address is equivalent to address=1 and can be used ...

Page 51

- 51 - 010cc4 4 - operations parameter definition default value adjustable ranges set u>> indicates the value of the absolute over volt- age set point beyond which the inverter dis- connects from the grid. [115% of nominal line to neutral voltage] 319 v fixed set u indicates the value of the absolut...

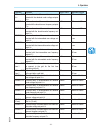

Page 52

- 52 - 010cc4 4 - operations parameter definition default value adjustable ranges set u>> indicates the value of the absolute over voltage set point beyond which the inverter disconnects from the grid [115% of nominal line to neutral voltage] 115% of nomi- nal line to neu- tral voltage fixed set u i...

Page 53

- 53 - 010cc4 4 - operations parameter definition default value adjustable ranges set time u indicates the value of the countdown timer asso- ciated with the absolute under voltage setpoint u 0.16 sec 160 msec to 300 sec set time f>> indicates the value of the countdown timer asso- ciated with the a...

Page 54

- 54 - 010cc4 4 - operations parameter definition default value adjustable ranges u>(10 min) der. Provides ability to limit the power for 10 minutes due to the high aver- age voltage value set by the parameter set u>(10 min) disable disable or enable slow ramp enable/disable the gradual feeding of p...

Page 55

- 55 - 010cc4 4 - operations w) chosen by the user from a list (the list may also show choices that are not available for the specific model). • crepuscular: the relay switches only when the input voltage exceeds the input voltage set for connection to the grid. The operating modes are described in ...

Page 56

- 56 - 010cc4 4 - operations menu allows programming of a time interval for which the inverter stays connected to the grid in a situation where the input voltage has dropped below the undervoltage limit (set at 70% of vstart). The default time is set at 60 sec. The user can set it from 1 to 3600 sec...

Page 57

- 57 - 010cc4 4 - operations standard curve for mode 3, cos(phi) in f(p) • mode 4 - q = f(u) : reactive power as a function of the grid voltage measured by the inverter. To enable this mode, select enable and then ok (using the up / down arrows). When enabled, use def curve will appear on the displa...

Page 58: Nformation Menu

- 58 - 010cc4 4 - operations mppt - this section of the menu allows setting the parameters of the maximum power point tracking (mppt) function. This function is useful when there are shaded areas on the pv array that can create several maximum power points in the work curve. • mppt amplitude: the am...

Page 59: Igbee Menu

- 59 - 010cc4 4 - operations part no. - displays the uno part number. Serial no. - displays the uno serial number and the week (from 1 to 52) and year of manufacture. Firmware - displays the revision of the firmware installed in the equipment. Country selector - display and configuration menu for gr...

Page 60: Ommissioning

- 60 - 010cc4 4 - operations c ommissioning do not place any items on the inverter during operation. Do not touch the heat sink when the inverter is operating, as some parts may be hot and cause burns. C onfigure inverter settings the following settings can be configured before or after commissionin...

Page 61: Ower On The Inverter

- 61 - 010cc4 4 - operations p ower on the inverter 1. Turn the dc disconnect switch in the on position. If there are two separate external disconnect switches (one for dc and the other for ac), first close the ac disconnect switch and then the dc disconnect switch. 2. Once the inverter is powered, ...

Page 62

- 62 - 010cc4 4 - operations once the connection sequence is complete, the inverter starts to operate and indicates correct operation by the green led lighting steady on the led panel. This means there is sufficient sunlight to feed power into the grid. If there is not sufficient sunlight, the unit ...

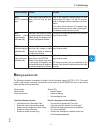

Page 63: Troubleshooting

- 63 - 01 1c5 a rc fault detection self-test errors an autotest circuit is included in the module design of the dc arc fault detector and interruptor (afdi) solution. The afdi performs a self-test when the system is started, (i.E. Every morning when sunlight is sufficient for grid connection). The i...

Page 64

- 64 - 01 1c5 5 - troubleshooting o btaining the service level password an advanced password can be provided to authorized installers to allow access to the service menu upon completion of required documentation. Contact customer service at 877-261-1374 to request this password. The password obtaine...

Page 65

- 65 - 01 1c5 5 - troubleshooting display message causes solution ground fault red led the alarm is generated when ground leakage current is de- tected in the dc section of the system. The alarm is accompanied by the lighting up of the red led on the front of the inverter. If possible, measure the i...

Page 66

- 66 - 01 1c5 5 - troubleshooting display message causes solution e005 comm.Error internal communi- cation error the alarm occurs when there are communication problems be- tween the control devices inside the inverter. Error inside the inverter that cannot be checked ex- ternally. If the problem per...

Page 67

- 67 - 01 1c5 5 - troubleshooting display message causes solution e013 wrong mode wrong input mode (parallel instead of independent) the alarm is generated only when the inverter is configured with parallel inputs. In this particular configuration, the inverter car - ries out the input voltage check...

Page 68

- 68 - 01 1c5 5 - troubleshooting display message causes solution e018 ground fault leakage current fail the alarm is generated when, during normal operation of the inverter, a ground leakage cur- rent is detected in the dc sec- tion of the system. The alarm is accompanied by the lighting up of the ...

Page 69

- 69 - 01 1c5 5 - troubleshooting display message causes solution e022 self-test error 4 relay self- test timeout time taken to execute the au- totest carried out on the relays of the dc_ac circuit part (inverter) is too long. This may indicate a problem associated with the aforesaid relays. Error i...

Page 70

- 70 - 01 1c5 5 - troubleshooting display message causes solution e025 riso low low insulation resistance before connecting to the grid, the inverter measures the insulation resistance of the pv array com- pared to ground. If the insulation resistance measured by the in- verter is less than 1 mohm, ...

Page 71

- 71 - 01 1c5 5 - troubleshooting display message causes solution e029 error meas z zgrid measures fault error in the internal measurement of the insulation resistance of the pv array compared to ground (imposed by regulations) to have a measurement redundancy (2 measurements on the same pa- rameter...

Page 72

- 72 - 01 1c5 5 - troubleshooting display message causes solution e035 remote off waiting remote on the inverter has been switched off remotely (remote off) and remains in waiting state for the signal that will switch it on again (remote on). Switch on the inverter remotely. If the unit does not swi...

Page 73

- 73 - 01 1c5 5 - troubleshooting display message causes solution e056 over temp. (from external box) excessive temperature mea- sured inside the inverter’s wiring box: high internal temperature. This error relates to the tempera- ture measured on external boxes. Check that the inverter is not expos...

Page 74

- 74 - 01 1c5 5 - troubleshooting display message causes solution w009 table fail na na w010 fan fail (alarm not shown on the display; there is only a flash - ing yellow led) this error appears when there is malfunctioning of the fan(s) in- side the inverter. In this condition, the yellow led on the...

Page 75: Aking A Service Call

- 75 - 01 1c5 5 - troubleshooting display message causes solution w019 spd ac protection open overvoltage surge arresters situ- ated on the ac side are dam- aged. Look at the inspection window present on each surge arrester (ac side). If it is red, the surge ar- rester is damaged and the cartridge m...

Page 76

- 76 - 01 1c5 5 - troubleshooting.

Page 77: Ower-Down Procedure

- 77 - 012c6 maintenance operations must be carried out by specialized staff assigned to perform this work. Do not allow the equipment to be used if problems of any kind are found. Maintenance operations must be carried out with the equipment disconnected from the grid, unless otherwise indicated. F...

Page 78: Outine Maintenance

- 78 - 012c6 6 - maintenance r outine maintenance checking and maintenance operations must be carried out by specialized staff assigned to carry out this work. Do not allow the equipment to be used if problems of any kind are found, and restore the normal conditions correctly or make sure this is do...

Page 79: R2032 Battery Replacement

- 79 - 012c6 6 - maintenance c r2032 battery replacement the replacement of the battery should be performed only by trained personnel. The cr2032 battery housing a05 is located on the inverter connection board and is visible after opening the inverter cover. When this battery is at end-of-life, a me...

Page 80

- 80 - 012c6 6 - maintenance r emoving the old inverter chassis from the switchbox 1. Remove the switchbox cover by loosening the six captive screws using the torx screwdriver provided. 2. Using a phillips head screwdriver, remove the four wires at the top of the dc disconnect switch 06 . 3. Remove ...

Page 81

- 81 - 012c6 6 - maintenance 9. Close the inverter cover and tighten the 8 captive screws. 10. Using two people, lift the inverter up by the handles and pull out to remove from the upper slots on the mounting bracket. I nstalling the replacement inverter chassis 1. Unpack the new inverter chassis an...

Page 82

- 82 - 012c6 6 - maintenance 6. Pass dc wires and ac wires from inverter main board through the cut-out holes into the switchbox. 7. Pull the afd wire from the switchbox through cut-out hole to the inverter and connect at main board, as shown below. 8. Connect any other serial communication and sign...

Page 83: Torage and Dismantling

- 83 - 012c6 6 - maintenance s torage and dismantling if the equipment is not used immediately or is stored for long periods, check that it is packaged correctly and contact customer service for storage instructions. The equipment must be stored in well-ventilated indoor areas in a noncorrosive envi...

Page 84

- 84 - 012c6 6 - maintenance.

Page 85: Ystem Description

- 85 - 013c7 s ystem description uno grid-tied inverters provide the capability to supply the utility grid with energy obtained from photovoltaic panels. To use the dc generated by a photovoltaic field efficiently, it must be transformed into alternating current (ac) via a conversion process known a...

Page 86

- 86 - 013c7 7 - appendix each inverter with multiple strings will work independently of the others and will supply the grid with the maximum power available from its section of photovoltaic panels. Notes on the sizing of the system decisions about how to structure a photovoltaic system depend on a ...

Page 87

- 87 - 013c7 7 - appendix t opographic diagram of the equipment in1.1(+) in1.2(+) in1.1(-) in1.2(-) in1 in2 + - + - in2.1(+) in2.2(+) in2.1(-) in2.2(-) in1 in2 + - + - in1.1(+) in1.1(-) in2.1(+) in2.1(-) in1 + - in2 + - mppt 2 (dc/dc) mppt 1 (dc/dc) b ulk c aps inve r ter (dc/ a c) line fil ter grid...

Page 88: Fficiency Curves

- 88 - 013c7 7 - appendix e fficiency curves the equipment was designed in compliance with energy conservation standards to avoid waste and unnecessary leakage. Graphs of the efficiency curves of the inverters are shown below. The efficiency curves are affected by technical parameters that are conti...

Page 89

- 89 - 013c7 7 - appendix v oltage and temperature derating due to altitude certain conditions should be considered when choosing an installation location at high altitudes. Air pressure decreases as altitude above sea level increases. The reduced air density results in less effective heat dispersal...

Page 90

- 90 - 013c7 7 - appendix example – temperature derating calculation for an uno-7.6/8.6-tl-us installed at 7500 feet: • the maximum rated temperature, for full power operation at sea level, from the uno-7.6/8.6-tl-us series datasheet, is 122of (50oc). • the normalized temperature derating factor, fr...

Page 91: Utomatic Power Reduction

- 91 - 013c7 7 - appendix a utomatic power reduction in order to maintain safe inverter operation under adverse environmental conditions or due to improper input voltages, the unit automatically reduces the amount of power it feeds to the grid. The conditions for power reduction due to environmental...

Page 92

- 92 - 013c7 7 - appendix power reduction due to input voltage the following graphs show the automatic reduction in output power when the input voltage is too high or too low..

Page 93: Echnical Data and Types

- 93 - 013c7 7 - appendix t echnical data and types type code uno-7.6-tl-outd-s-us-a uno-8.6-tl-outd-s-us-a nominal output power 7600w 8600w maximum output power 8300w 9400w rated grid ac voltage 208v 240v 277v 240v 277v input side number of independent mppt channels 2 maximum usable power for each ...

Page 94: Urther Information

F urther information for more information on abb products and services for solar applications, navigate to www.Abb.Com/solarinverters.

Page 95: Ontact Us

C ontact us www.Abb.Com/solarinverters uno-7.6-8.6-tl-outd-us-a product manual bcg.00751.0_aa (na rev 1.1) © copyright 2014 abb. All rights reserved..