- DL manuals

- ABB

- Switch

- VD4 Series

- Operating Manual

ABB VD4 Series Operating Manual

Summary of VD4 Series

Page 1

Vd4 vacuum circuit-breaker – high duty instruction manual ba 359/10 e medium voltage products.

Page 3

Your safety first – always! • only install switchgear and switchboards in enclosed rooms suitable for electrical equipment. • ensure that installation, operation and maintenance are carried out by specialist electricians only. • comply in full with the legally recognized standards (din vde / iec), t...

Page 4

4 contents page 4.3 transport 16 4.4 delivery 16 4.5 intermediate storage 16 5 installation 17 6 commissioning / operation 18 6.1 note on safety at work 18 6.2 preparatory activities 18 6.3 operation of the circuit-breaker 18 6.3.1 charging the spring energy store 18 6.3.2 closing and opening 18 6.3...

Page 5

5 1 summary 1.1 general (figures 2/1 and 2/2) the vacuum circuit-breakers of type vd4 are intended for indoor installation in air-insulated switchgear systems. Their switching capacity is sufficient to handle any conditions arising from switch- ing of equipment and system components under normal ope...

Page 6

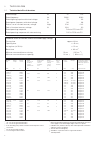

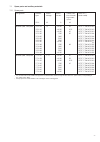

6 rated voltage kv 12 17.5 rated frequency hz 50/60 50/60 rated lightning impulse withstand voltage kv 75 95 rated power frequency withstand voltage kv 28 38 rate of rise of transient recovery voltage kv/ μ s 0.34 0.42 peak of transient recovery voltage kv 20.6 30 rated operating sequence o-3 min-co...

Page 7

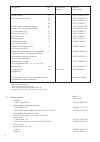

7 2.2 technical data releases and blocking magnet equipment power consumption 1) ac dc va w shunt release off -y2 3) , -y9 3) 250 250 -y2 5) , -y9 5) 310 310 shunt release on -y3 3) 250 250 -y3 5) 310 310 blocking magnet -y1 3) 5) 10 10 undervoltage release: -y4 • undelayed 3) 5) 11 10 • delayed 4) ...

Page 8

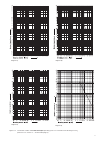

8 diagram a) diagram b) figure 2/1: vacuum circuit-breaker, type vd4, for 12 kv, 275 mm pole centres, mechanism side figure 2/2: vacuum circuit-breaker, type vd4, for 12 kv, 210 mm pole centres, pole side 2.4 permissible number of vacuum interrupter switching operations in relation to breaking curre...

Page 9

9 figure 2/3: permissible number of vacuum interrupter operating cycles n as a function of the breaking current i a (reference see section 2.1 – technical data page 6) diagram d) diagram c) diagram e) diagram f).

Page 10

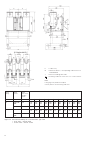

10 figure 2/4: dimensional drawing of a circuit-breaker, type vd4, • 12 kv, 1250 ... 2500 a, 50 ka • 17.5 kv, 1250 ... 2500 a, 40 ka k = cable entry m = minimum distance, corresponding to dimension a to din vde 0101 t = bore for handling, both sides = earthing conductor connection - use contact wash...

Page 11

11 figure 2/5: dimensional drawing of a circuit-breaker, type vd4, • 12 kv, 3150/4000 a 1) , ...63 ka • 12 kv, 1250 ...2500 a, 63 ka • 17.5 kv, 3150/4000 a 1) , ...40 ka 1) with fan cooling k = cable entry m = minimum distance, corresponding to dimension a to din vde 0101 t = bore for handling, both...

Page 12

12 • mechanical off push-button 3 • mechanical position indicator 4 • charging condition indicator 8 for the spring energy store • mechanical operating cycle counter 5 the following additional equipment can be installed: • blocking magnet -y1 with auxiliary switch -s2 • shunt release on -y3 • second...

Page 13

13 five nocs to five nccs. Its contacts are availa- ble for any required control, annunciation or in- terlock functions. The auxiliary switch is normally configured as shown in figure 7/5. • the single pole auxiliary switch -s7 (fleeting con- tact time ≥ 30 ms) serves to provide a fault signal ("bre...

Page 14

14 figure 3/3: partial section of a vacuum interrupter, simplified schematic diagram (details vary according to the specified switching duties) 15.1 insulator 15.2 fixed contact 15.3 movable contact 15.4 metal bellows 15.5 screen 15.6 guide 15.7 interrupter lid figure 3/2: sectional view of a vacuum...

Page 15

15 37 31 38 6 35 33 34 36 figure 3/4: basic structure of the stored-energy spring mechanism 6 recess 9 charging lever 15 vacuum interrupter 15.3 movable contact 16.2 roller contact 17 contact force spring 18 insulated coupling rod 19 opening spring 20 shift lever pair 21 cam disk 30 drive shaft 31 r...

Page 16

16 4.5 intermediate storage intermediate storage of the switchgear in the switch position off and the stored-energy spring mechanisms discharged (indicator discharged: ). Conditions for optimum intermediate storage: 1. Devices with basic packaging or unpacked: • a dry and well ventilated storeroom w...

Page 17

17 5 installation careful and professional installation of the switch- gear is one of the fundamental conditions of trouble-free circuit-breaker operation. • install the mechanism enclosure in the panel without tension or distortion, inserting dished washers below the nuts or bolt heads at each of t...

Page 18

18 6 commissioning / operation 6.1 note on safety at work • this switchgear may only be operated by specially trained personnel who are familiar with the characteristics of the particular device. • observe the relevant instructions in section 1.2. 6.2 preparatory activities (prior to application of ...

Page 19

19 6.3.3 run-on block when any irregularities occur in the internal control mechanism or with the charging function of the spring energy store, the run-on stop blocks the next closing operation. This is a protective function to prevent damage to the circuit-breaker. Release of the run-on block is de...

Page 20

20 7 maintenance maintenance serves to ensure trouble-free operation and achieve the longest possible work- ing life of the switchgear. In accordance with din 31 051 / iec 61208 it comprises the following closely related activities: inspection: determination of the actual condition servicing: preser...

Page 21

21 note: use only halogen free cleansers, and in no case 1.1.1-trichloroethane, trichloroethylene or carbon tetrachloride! 7.3.2 stored-energy spring mechanism (figures 7/1 to 7/4) servicing of the operating mechanism is to be performed after the following number of operating cycles: • breakers with...

Page 22

22 7.3.3 breaker pole the breaker pole with the vacuum interrupter is maintenance-free up to reaching the permissible number of vacuum interrupter operating cycles in accordance with section 2.4. Checking of the vacuum is only necessary when there is good cause to suspect that force applied external...

Page 23

23 1) for circuit-breakers with additional equipment in withdrawable module design another ident nos. (order codes) corresponding to the cubicle types apply. 2) always quote the serial number of the switchgear when ordering parts. 7.5 spare parts and auxiliary materials 7.5.1 spare parts breaker pol...

Page 24

24 designation item rated supply ident no. No. Voltage (order code) auxiliary switch -s1 gce7002397r0122 (with clamp-type terminal) -s3 gce7002397r0121 -s4 gce7002397r0122 -s5 gce7002397r01.. 1) auxiliary switch on blocking magnet -s2 gce7003022p0101 auxiliary switch for fault annunciation -s7 gce09...

Page 25

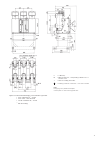

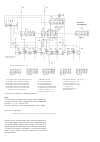

25 45 41.1 43 41.1 43 41.2 42.1 41.2 42 41 figure 7/1: auxiliary switch block, equipment example 41 mounting plate 41.1 upper (plug-in) fixing point 41.2 lower fixing point 42 auxiliary shaft 42.1 crank 43 fastening screw 45 magnet holder, complete figure 7/4: charging motor, charging system and spr...

Page 26

26 – s1 auxiliary switch on operating mechanism – s2 auxiliary switch on blocking magnet – s3 auxiliary switch on the breaker shaft – s4 auxiliary switch on the breaker shaft – s5 auxiliary switch on the breaker shaft – s7 auxiliary switch for fault annunciation (fleeting contact, time ≥ 30 ms) figu...

Page 27: Vde

27 8 application of the x-ray regulations one of the physical properties of vacuum insulation is the possibility of x-ray emissions when the con- tact gap is open. The specified test performed by the physikalisch-technische bundesanstalt (ptb) in braunschweig demonstrates that the local dos- age out...

Page 28

Ma_vd4-hd(en)-_1vcd601410 - 1601 (gs) abb s.P.A. Electrification products division medium voltage products via friuli, 4 i-24044 dalmine tel.: +39 035 6952 111 fax: +39 035 6952 874 e-mail: info.Mv@it.Abb.Com abb ag calor emag medium voltage products oberhausener strasse 33 petzower strasse 8 40472 ...