- DL manuals

- Abloy

- Door Opening System

- DA400

- User Manual

Abloy DA400 User Manual

Summary of DA400

Page 1

Abloy ® da400 swing door operator program version 1.5 picomed.

Page 2: Contents

Contents general installation adjusting door movements control points connections battery operation fire door system programming handset connection examples technical data construction & operation removal of housing function switches installation electrical connections adjusting door movements contr...

Page 3: Dear Customer

Dear customer you have acquired an electro-mechanical automatic swing door operator, the safety of which has been proven through our research and development and field tests. The modern scandinavian design available in three different colour alternatives will ensure its acceptabily in the various en...

Page 4: General Information

General information approvals warnings low voltage directive (finland, sweden, norway, denmark) emc directive (european community) ul (united states of america) csa and ulc (canada) fire door use (finland, usa, canada) closing force must not exeed 178 n (40 lb) for a pedestrian application. Closing ...

Page 5: Technical Data

1 technical data the automatic swing door operator is intended for both new and existing swing door applications, internal and opening out external doors. The automatic swing door operator can be used in residential units, institutions, shops, public buildings, warehouses and offices. Operating cond...

Page 6: Construction & Operation

Construction & operation 2 control unit direct current - motor pulse counter pulse disk safety clutch the operation of the automatic swing door operator is controlled by a microprocessor. Abloy the body and the housing of the operator are manufactured from aluminium. The body is secured to the wall ...

Page 7: Removal Of Housing

Removal of housing 3 switches program selector: 2 - position switch = automatic: the impulse device connected to the door operator will open the door and close it after a preset door open time. The hold open time can be adjusted between 0...60 s (control points 7 or 17). Power-assisted manual openin...

Page 8: Installation

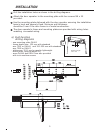

Installation 4 extension piece note! 6 inspect the swing door operator against transport damage. Test the free swinging of the door, which should open and close smoothly. The automatic swing door operator is to be installed on the transom, with the mains switch located towards the hinge. For , the d...

Page 9: Installation

Installation drill the installation holes as shown in the drilling diagrams. Attach the door operator to the mounting plate with four screws m8 x 25 provided. Use the mounting plate delivered with the door operator ensuring the installation base is level and securely fixed. Minimum wall thickness sh...

Page 10: Installation

6 installation drill the installation holes as shown in the drilling diagrams. Attach the door operator to the mounting plate with four screws m8 x 25 provided. Use the mounting plate delivered with the door operator ensuring the installation base is level and securely fixed. Minimum wall thickness ...

Page 11: Electrical Connections

7 electrical connections abloy 2 1 3 115/230v ac 3x 1,5mm 2 4x 0,22mm 2 3x 0,22mm 2 2x 0,22mm 2 2x 0,22mm 2 4x 0,22mm 2 5x 0,22mm 2 2x 0,22mm 2 safety sensor remote control push-button/elbow switch/pull switch card reader radars or photocells motor locks microswitch keep ca r d mains connections: if...

Page 12: Adjustment of Door Movements

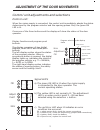

8 adjustment of door movements pulse counter the counter has three sensors. Two count the pulses and the disk direction, the other senses the perimeter of the disk. Pulse disk a pulse disk fitted to the drive shaft is used to determine the door closed position. This is achieved by the pulse counter ...

Page 13

9 adjustment of the door movements selection+ s/a- adjustment+ error adjustment ok ok adjust- ment error control unit adjustments and selections control unit: : when the mains supply is connected, the control unit immediately adopts the status determined by the program selector and the opening pulse...

Page 14: Adjustment of Door Movements

10 adjustment of door movements selection+ a) s/a- b) adjustment+ c) buttons: a) selection+ button this button is used to call 0...28 onto the display. With the light on the digital display, press the selection+ button for at least 3 seconds enabling yellow adjustment led to light. With a appears on...

Page 15: Control Points

11 control points max. 100 o control points and control values control points are presented in numerical order 0...28. Study all the control points to ensure the optimum possible operation of the door. Adjust the functions ensuring the safety clutch does not slip. Control point n:o control value des...

Page 16: Control Points

Control point n:o control value description 12 control points 1...8 1 or 0 0...2 0...2 0...60 0...60 1 or 0 1 or 0 0...10 0...10 1...10 0...3 1 or 0 1 or 0 0... 6553559 0...60 safety feature sensitivity (sealed) power-assisted manual opening power-assisted manual opening: hold open time selection of...

Page 17: Control Points

13 the opening angle, where the operator changes from initial speed to final speed. (1 digit = approx. 2°) ensure adequate angle for final speed! The closing angle where the operator changes from initial speed to final speed. (1 digit = approx. 2°) the operator's force requires adjustment to suit do...

Page 18: Control Points

14 the operator keeps the door closed at preset force for 1 second following which this reduced to half of the preset value. Value 0 = no lock-up force. 1= standard arm, 0= sliding arm 2= restoring the factory settings 0= off 1= fire door use (closes only) 2= full battery backup (opening & closing) ...

Page 19: Control Points

15 the operator drives the door against the closed position for a preset value of 1 second. Fire doors - adjust the lock control relay hold time to a minimum. Sequencing 1 = opening and closing sequencing for pair of rebated doors the master door opens first and then the slave. The slave door closes...

Page 20: Control Points

16 control points the counter indicates number of openings. The fixed obsticles in safety sensor zone can be excluded by adjusting the area smaller than the door open position. Dispalys the program version. 0= da400 europe 1= da400 ul (north america) version.

Page 21: Control Points

17 control points programming examples a safe door: the safety of the door operator is controlled by basic adjustments; operator force, speeds, safety feature sensitivity, operator's force and hold open time. - the operator force is an important adjustment. A high control value affects to the safety...

Page 22: Internal Connections

18 control unit 27 26 25 24 23 22 21 20 19 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 x3 x4 open auto resistor 1000 ohm pulse counter led blue red red red red black black black black locking circuit sequencing motor battery t 800ma mains switch remove connections, when using separate program switc...

Page 23: Internal Connections

19 internal connections power-supply cord through the end of housing power-supply cord through the base plate abloy max 200 mm max 200 mm the power supply cord shall not be - routed through doorways, window openings, walls, ceilings, floors or the like. - attached or otherwise secured to the buildin...

Page 24: External Connections

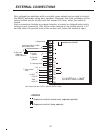

20 control unit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 6) resistor 1000 ohm safety detector 3) locking circuit 7) lock control relay no nc c 8) gnd +12v dc gnd +24v dc max. Output current 12vdc / 0.5a or 24vdc / 0.8a 4) outside impulse 5) inside impulse 1) sequencing sequence control sequence ...

Page 25: External Connections

21 1) to program operators to function together, namely the correct closing sequence for pair doors, sequential opening or interlock. The operators are connected to a current loop (connectors 1 and 2) the jumpers on the control unit will determine the master operator. Only one operator can be master...

Page 26: Battery Operation

22 battery operation is possible by addition of a battery or batteries and battery adapter to the operator. During a power failure the operator will revert to the chosen battery operation mode. See control point 15. ; when there is a smoke alarm fitted the operator reverts to manual mode, following ...

Page 27: Battery Operation

23 battery operation when fire door use is chosen, the battery is checked by the operator and the following should be noted: during power failure.... When power failure ends.... National requirements the test made by the operator: the battery is loaded with 0.4 a test load for a 30 second period. If...

Page 28: Battery Operation

24 battery operation during power failure.... The operator and devices connected will operate normally. The red led starts to blink. 8.0 v 10.5 v when battery voltage drops under the operator stops low-energy state: the door is opened manually and the operator closes door. 12 v full battery backup; ...

Page 29: Battery Operation

25 battery operation during power failure.... The operator and devices connected will operate normally. The red led starts to blink. 17 v 20 v when battery voltage drops under the operator halts low-energy state: the door is opened manually and the operator closes door. 24 v full battery backup; the...

Page 30: Battery Adapter

26 battery adapter power alarm control unit 27 26 25 24 23 22 21 20 19 battery adapter 950596 1 2 3 4 5 6 no c yellow white red black blue red black blue in the adapter there is two relay outputs and one input. The outputs are power alarm and battery alarm. The input is for connecting smoke detector...

Page 31

27 fire door system according ul requirements battery adapter is used in the fire doors when there is a need to meet e.G the ul requirements. In the adapter there is two relay outputs and one input. The outputs are power alarm and battery alarm. The input is for connecting smoke detectors. The power...

Page 32: Abloy Fire Door System

28 abloy fire door system (not according ul regulations) the abloy da400 for fire doors with abloy smoke detectors and relays max two smoke detectors please note, lock the detector y ell owt y ell ow black black gray locking circuit gray gray white blue black red green set the following control poin...

Page 33: Programming Handset

29 programming handset ok ok abloy ok abl oy ok control values change control point decrease power switch increase set value reset error 4-digit display transmitter 1. Switch power on 2. Enter master code and press 2. Find control point and adjust value 3. Press errors: err 1: wrong master code err ...

Page 34: Connection Examples

30 connection examples 15 16 1 2 8 9 15 16 1 2 8 9 8 9 8 9 1 2 9 8 1 2 radar radar remember sequence control jumpers note! Disconnect mains supply and remove the battery cable before making any connections! Tandem doors; stepwise opening - the example is for tandem doors with two-way traffic. - the ...

Page 35

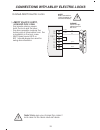

31 connections with abloy electric locks note! Before connections switch the power off and remove battery. Note! Make sure you choose the correct lock case for fire doors and exit doors. 1) - the impulse device opens both the lock and the door. - the door operator receives the locking circuit inform...

Page 36

32 connections with abloy electric locks note! Before connections switch the power off and remove battery. Note! Make sure you choose the correct lock case for fire doors and exit doors. 1) - the impulse device opens both the lock and the door. - abloy lead cover 8810 or 8811 should always be used f...

Page 37

33 connections with abloy electric locks note! Before connections switch the power off and remove battery. Note! Make sure you choose the correct lock case for fire doors and exit doors. 1) - the impulse device opens both the lock and the door. - the door operator receives the locking circuit inform...

Page 38

Tero nuutinen/29.6.2000/norja_engl anti_1_5/c+fh8 r abloy oy wahlforssinkatu 20 80100 joensuu tel.+(358) 013-2501 fax +(358) 13-2502 209 abloy oy is an assa abloy group company. The assa abloy group is the wordls leading manufacturer and supplier of locks and associated products, dedicated to satis...