- DL manuals

- Abloy

- Garage Door Opener

- DA461

- Installation And Commissioning Manual

Abloy DA461 Installation And Commissioning Manual

Summary of DA461

Page 1

Abloy ® da461 swing door operator installation and commissioning manual.

Page 2: Approvals / Standards

2 approvals / standards ------------------ this manual contains important safety instructions ------------------ warning - it is important for safety of persons to follow these instructions. ------------------------------------ save these instructions ----------------------------------------- this a...

Page 3: Contents

3 contents 1 revision .............................................................................................................................. 4 2 content of delivery ........................................................................................................ 5 3 general informatio...

Page 4: 1 Revision

4 1 revision following pages have been revised: page revision 16 safetysensor-unit added into connections. 17-18 settings updated. 19 added a note about safety sensors. 20-25 all connections drawings updated. 27 safety sensor diagnistics added. 29 safetysensor-unit info added. As at 21.05.2015..

Page 5: Content of Delivery

5 2 content of delivery da461 swing door operator - screws 6 pcs m6x14 - adapter - spanner wrench da104 mounting plate - screws 6 pcs 5,5x32 - ordered separately da147 standard arm - screws 2 pcs 5,5x32 and 1 pcs m8x20 + m8x30 - ordered separately da148 extended arm - screws 2 pcs 5,5x32 and 1 pcs m...

Page 6: 3 General

6 3 general information technical data measures • 721 (l) x 85 (h) x 107 (w) mm • weight 9 kg • supply voltage 100/230 vac (±10 %) 50...60 hz • rated output 120 w • enclosure class ip20 temperature range • storage -20...50 °c (in dry premises) • operation -15...50 °c (in dry premises) • the automati...

Page 7: 4 Operation

7 4 operation 5 main switch and mode switch the abloy ® da461 electromechanical swing door operator is especially suited to external and fi re resisting doors. The door is opened by motor force, and closed with the on board door closer. The motor and door closer are connected via clutch mechanism, w...

Page 8: 6 Door

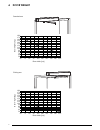

8 6 door weight standard arm door w eight [k g] 180 170 160 150 140 130 120 110 100 90 80 70 60 50 60 70 80 90 100 110 120 130 140 150 door width [cm] door w eight [k g] 180 170 160 150 140 130 120 110 100 90 80 70 60 50 60 70 80 90 100 110 120 130 140 150 door width [cm] sliding arm.

Page 9: 7 Installation

9 7 installation tools required - drill - set of ball ended allen wrenches - # 2 phillips head screwdriver - flat blade screwdrivers, 2 pcs steps of installation - preparing installation - installing the mounting plate - mounting the operator and the arm - connecting the operator to mains - commissi...

Page 10

10 7.1 installing the mounting plate da104 the operator is installed on the transom, with the main switch located towards the hinge side of the door. Use the mounting plate da104 with the door operator ensuring the installation base is level. Securely fi x the mounting plate to the transom. Minimum ...

Page 11

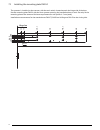

11 y min 21 320* 45 da104 7.2 assembly of the operator and standard arm da147, da148 to the closing side mounting of the operator: m6x14 and washer 11°-22 ° 90 ° pre-setting of the spring force frame depth 42 y 332 - after installation, ensure that the arm and door are properly adjusted. - mount a d...

Page 12

12 y 34 y min 38 m l 585 da104 frame depth 44°-55° frame depth pre-setting of the spring force - after installation, ensure that the arm and door are properly adjusted. - mount a door stop to the door open position so that wind will not drive the door against the wall, resulting in damage. - tighten...

Page 13

13 m y min 14 max 20 l 585 da104 44°-55° frame depth pre-setting of the spring force y 34 frame depth - after installation, ensure that the arm and door are properly adjusted. - mount a door stop to the door open position so that wind will not drive the door against the wall, resulting in damage. - ...

Page 14

14 7.5 removing of the position sensor 7.5 removing of the position sensor the position sensor must be removed, if the clutch or closing force need adjustment. This prevents possible damage of the sensor during adjustment. Fixing screw for position sensor position sensor removed 7.6 door closer adju...

Page 15

15 + - closing force adjustment open the door fully and observe the closing function assuming that the door closes as is required, check the closing function from approximately 15° from the door’s closed position ensuring that there is suffi cient power to close the door fully. Before adjusting the ...

Page 16: 8 Internal

16 white brown white brown i 0 l n red to motor clutch black red black red black main switch to dc supply back-up 7 6 5 4 3 2 1 x4 x1 x2 x5 x6 0 v 1a position sensor mode switch auto: red & black man: nc open: blue & black red black blue auto man open safetysensor-unit cu 8 internal connections - el...

Page 17

17 1 check the free movement of the door. 2 turn mode switch to man. The mode switch is located in the head panel. 3 plug in the mains and turn the switch on. The main switch is located in the head panel. 4 choose the type of the arm. Jumpers are located on the control board. Jumper is connected. Ju...

Page 18

18 9 opening speed and hold open time adjust the opening speed. A slow door is a safe door. The door speed should be set to allow unhindered access but as slow as is possible.. Säädä aukioloaika (0...60 s) hold open -säätimestä. Kun säädin käännetään alueelle ”seq”, joka toinen impulssi avaa oven ja...

Page 19: 10 A Safe Door

19 10 a safe door the safety of an automatic door is achieved with careful basic adjustments. Low speed, higher speeds increase the force applied to any obstruction. The speed should be set so that users are able to pass through the door unhindered, with the speed set as slow is as reasonable possib...

Page 20: 11 External Connections

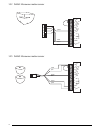

20 +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire de tector 11 external connections connector x2 10 +24 vdc, 500ma output 9 ground 6,7,8 potential free relay output for lock drive 5 impulse input 4 not in use 3 locking circuit inhibits the opening if the lock bol...

Page 21: 12 Connection Examples

21 12 connection examples safety sensor da004 and da005 +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector j1 j2 j3 j4 1 2 3 4 green brown blue, yellow, pink violet white red.

Page 22

22 +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector 1 2 3 4 5 +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector 12.2 da061 microwave motion sensor 12.3 da063 microwave motion sensor yellow white brown green white ...

Page 23

23 com n.O n.C +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector x5 1 3 2 12.4 da033 elbow switch 12.5 da039 and da049 rotary switch red blue black.

Page 24

24 +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector +2 4v o ut gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector 12.6 electric locks el402, el404 and el502 12.7 motor locks el490 ja el590 gray blue green white red black bl...

Page 25

25 12.8 fire door system 4 3 2 1 led nc no c 4 3 2 1 led nc no c +24v out gnd impulse input not in use locking circuit gnd 1 2 3 4 5 6 7 8 9 10 fire detector gray blue green white red operation: when the fi re detection system reacts, it’s relay switches on. Then the gnd (-) is disconnected from the...

Page 26

26 indication possible fault corrective user interventions in defi ned order g not lit y not lit no power. Faulty power supply unit. Faulty control board. 1. Check the mains. 2. Disconnect 10 pin connector from the control board. 3. Measure the voltage of the power supply (7 pin connector, pins 1 an...

Page 27: 14 Maintenance

27 14 maintenance door operators require periodic maintenance. Only trained personel are equiped to work on abloy ® da products. Door leaf is moving sensitively and locking works well. Regular annual services are made: - under 100 openings per day; service once a year - 100 ... 500 openings per day;...

Page 28

28 14.1 adjusting the clearance of the electromagnetic clutch the clearance of the electromagnetic clutch has to be checked during regular service (see timescales on page 28). The clearance should be 0,3 mm. Re-adjust the clutch if needed. Incorrect clearance causes, clutch drag or clutch slip, prev...

Page 29

29 15 spare parts head panel 810174 motor and clutch 812251 position sensor 811339 control unit 811990 transformer 811377 door closer 811702 closing side 811753 opening side mode switch 811456 main switch 807437 adapter 410351 aluminium 410352 white da147/100000 a da147/600000 v da147/800000 e da148...

Page 30

30

Page 31

31.

Page 32

Nimik e: 9312577 päiväys: 05/2015 mjp / 25.5.2015 / indesign manufacturer: abloy secures people, property, and business operations on land, at sea, and in the air – in all circumstances. Assa abloy is the global leader in door opening solutions, dedicated to satisfying end-user needs for security, s...