- DL manuals

- Absolute

- Boiler

- ABS-1500

- Installation And Operating Manual

Absolute ABS-1500 Installation And Operating Manual

Gas-Fired Condensing Hot Water Boiler

Installation and Operating Manual

Innovative Industrial Inc.

ABS 1500-2000-2500-3000-4000/V.01/4/2016

ABS - 1500

ABS - 2000

ABS - 2500

ABS - 3000

ABS - 4000

CAUTION

Please read this manual and retain a copy for future

reference. Improper Installation, adjustment, alterations,

service or maintainer can cause serious injury, property

damage or death. Refer to this manual for assistances

or additional information or consult a qualified installer,

service agent.

Innovative Industrial Inc.

122 Burton Street

Hamilton, Ontario, Canada L8l 3R5

- Cast Aluminum Sectional Heat Exchanger

- 10 to 1 Turndown

- Honeywell Sola Boiler Control System

- Compact Light Weight Packaged Boiler

- Five Models from 1,500 to 4,000 MBH

- Low NO

x

Standard

- Fully Packaged CSA/ASME Boilers

Document # 2050-20

Summary of ABS-1500

Page 1

Gas-fired condensing hot water boiler installation and operating manual innovative industrial inc. Abs 1500-2000-2500-3000-4000/v.01/4/2016 abs - 1500 abs - 2000 abs - 2500 abs - 3000 abs - 4000 caution please read this manual and retain a copy for future reference. Improper installation, adjustment...

Page 2

Absolute boilers abs 1500-2000-2500-3000-4000 2 cation before you install and operate this boiler, please read this manual carefully in its entirety. If for whatever reason you are not clear of any details, please do not hesitate to contact us as shown below. Please read all safety and warnings symb...

Page 3

Absolute boilers abs 1500-2000-2500-3000-4000 3 contents 1. Safety instructions 6 1.2 symbols 6 1.2 general safety notes 7 1.3 lighting instructions 8 2.2 operational principal of boiler 11 2.3 view of boiler for service connections 11 3. Technical data 12 3.1 boiler version 13 3.2 technical data sh...

Page 4

Absolute boilers abs 1500-2000-2500-3000-4000 4 4.5 condensate drain connection and trap 30 4.6 water connection 31 4.6.1 water pressure 32 4.6.2 safety valve 32 4.6.3 water treatment 33 4.6.4 water flow 34 4.6.5 typical water system layout 35 4.6.6 frost protection 36 5. Electrical 36 5.1 general 3...

Page 5

Absolute boilers abs 1500-2000-2500-3000-4000 5 8. Operator interface display 63 8.1 honeywell sola control programming/configuration 64 8.2 programming access: 64 9. Commissioning 66 9.1 pre operational checks 66 9.2 safety checks and lighting instructions 66 9.3 commissioning steps 67 9.4 importan...

Page 7

Absolute boilers abs 1500-2000-2500-3000-4000 7 1. Safety instructions 1.2 symbols the following symbols are used in this document to emphasize certain instructions. This is in order to increase your personal safety and to safeguard the technical reliability of the boiler. Caution indicates a potent...

Page 8

Absolute boilers abs 1500-2000-2500-3000-4000 8 1.2 general safety notes installers and operational personnel must at all times observe all safety regulations. The following warnings and cautions are general and must be given the same attention as specific precautions included in these instructions....

Page 9

Absolute boilers abs 1500-2000-2500-3000-4000 9 to turn off gas to appliance operating instructions for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life 1- stop! Read th...

Page 10

Absolute boilers abs 1500-2000-2500-3000-4000 10 the absolute “abs series” of hydronic heating condensing boilers is a combination of more than 35 years of north american and european engineering experience in condensing boiler technology. The absolute “abs series” utilizes a durable sectional cast ...

Page 11

The standard control package allows for external on/off, local-remote switch. The built in digital display shows normal operating fault indications and allows actual and set values to be read and adjusted. The intelligent, advanced boiler control continuously monitors the boiler operating conditions...

Page 12

2.2 operational principal of boiler combustion air is drawn into the inlet connection from the plant room (room ventilated version) or from outside via the air inlet pipe. On the inlet side of the fan is a specially designed chamber which takes gas from the multi-block and mixes it in the correct pr...

Page 13

Absolute boilers abs 1500-2000-2500-3000-4000 13 3. Technical data ref. Abs1500 abs2000 abs2500 abs3000 abs4000 l 50” 50” 58 1/4 ” 58 1/4 ” 69 1/4 ” l1 70 11/16 ” 70 11/16 ” 77 7/8 ” 77 7/8 ” 88 7/8 ” q 22 1/2 ” 22 1/2 ” 22 5/8 ” 22 5/8 ” 22 5/8 ” h* 30” 30” 30” 30” 30” h1* 38 1/2 ” 38 1/2 ” 48” 48”...

Page 14

Absolute boilers abs 1500-2000-2500-3000-4000 14 3.1 boiler version 26 24 6 5 7 8 9 11 12 14 15 23 17 18 25 16 10 2 3 4 1 20 21 19 28 22 27 13 29.

Page 15

Absolute boilers abs 1500-2000-2500-3000-4000 15 the service side of the boiler (with the heat exchanger inspection cover) is the front. 1. Pressure relief valve. 2. Air vent. 3. Spare 3/4” 4. Flow switch (optional) 5. Boiler supply 6. Ntc temperature sensor (supply water) 7. Low water cut off (manu...

Page 16

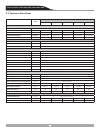

Absolute boilers abs 1500-2000-2500-3000-4000 16 3.2 technical data sheet unit specifications abs 1500 abs 2000 abs 2500 abs 3000 abs 4000 general firing sequence operation full modulation minimum fuel input mbh[kw] 150 [43.9] 200 [58.6] 250 [73.2] 300 [87.9] 400 [117.2] maximum fuel input mbh[kw] 1...

Page 17

Absolute boilers abs 1500-2000-2500-3000-4000 17 3.3 absolute boiler specifications: - fully assembled cast aluminum floor standing sectional hot water boilers. - premix burner with stainless steel cylinder with perforated holes for precise air-fuel mixture and velocity with a stainless tube with wo...

Page 18

Absolute boilers abs 1500-2000-2500-3000-4000 18 3.4 ordering options: - available in inputs from 1500, 2000, 2500, 3000 and 4000 mbh, 5 models - control options: - honeywell sola control with touch screen control - bms- available with sola control/touch screen - service kits for heat exchanger - co...

Page 19

Absolute boilers abs 1500-2000-2500-3000-4000 19 4. Installation: 4.1. General installation instructions notes: by law, this boiler must be installed by a competent trained and or licensed gas-heating technician, or gas supplier. It is in your own interest and that of safety to ensure that the local...

Page 20

Absolute boilers abs 1500-2000-2500-3000-4000 20 4.2.1 site preparation ensure that the site selected for the installation has the following: - access to ac input power of 120 vac for abs 1500, abs 2000 and abs 2500. - access to ac input power of 230 vac 3 phase for two models abs 3000 and abs 4000 ...

Page 21

Absolute boilers abs 1500-2000-2500-3000-4000 21 4.2.3 multiply boiler arrangements front 36” 6” minimum between boilers front 36” side 18” side 18” front 36” back 24” back 24” side 18” front 36” side 18”.

Page 22

Absolute boilers abs 1500-2000-2500-3000-4000 22 4.2.4 setting the boiler in place it is recommended that a house keeping pad 4 to 6 inches high be installed to ensure proper condensate drainage. If anchoring the boiler is required due to local codes for seismic activities potential, ensure 4 holes ...

Page 23

Absolute boilers abs 1500-2000-2500-3000-4000 23 4.3 flue gas discharge and air supply 4.3.1 general the absolute boiler is suitable for both conventional room-supplied or sealed combustion. It is listed as a 100% sealed combustion boiler. Sealed combustion terminals should comply with the local and...

Page 24

Absolute boilers abs 1500-2000-2500-3000-4000 24 4.4.1 venting options the standard delivery of the absolute boiler can be installed with any of the venting options listed above. See each respective section for details; discard the air intake grill when using sealed combustion vent systems. 4.4.2 ve...

Page 25

Absolute boilers abs 1500-2000-2500-3000-4000 25 warning the flue gas vent pipe must be airtight and watertight. Horizontal sections of the venting must slope downward towards the boiler ½” per linear foot [12mm] and adequate vent support must be provided. 4.4.4 room combustion air supply requiremen...

Page 26

Absolute boilers abs 1500-2000-2500-3000-4000 26 warning the boiler should never be operated in a negative building pressure. Caution should be exercised with exhaust fans, air handling & other devices, that could affect the buildings air pressure or combustion air supply. All venting must be arrang...

Page 27

Absolute boilers abs 1500-2000-2500-3000-4000 27 runs of the venting must slope towards the boiler ¼ to½” per linear foot chimney applications: this venting system uses a single vent to discharge all flue gases to the outside vertically, combustion air provided with the boiler room, the air source m...

Page 28

Absolute boilers abs 1500-2000-2500-3000-4000 28 application note: in all applications the venting must be between the minimum and maximum equivalent vent lengths shown in table 5a-b. For values not shown in the chart, consult your local sales representative 4.4.6 co-venting – retrofitting: danger a...

Page 29

Absolute boilers abs 1500-2000-2500-3000-4000 29 instructions: adjust thermostat so appliance will operate continuously. - test for spillage near and around the each of the gas appliances after 5 minutes of main burner operation. - after determining that each appliance remaining connected to the com...

Page 30

Absolute boilers abs 1500-2000-2500-3000-4000 30 4.4.7 vent terminations installation precautions: [consult national & local codes for other requirements] all exhaust terminations for conventional chimney must be finished with a finishing cone with tapered end, with a bird/ rodent screen. All sidewa...

Page 31

Absolute boilers abs 1500-2000-2500-3000-4000 31 according to the national gas codes [csa b149 & ansi z223.1/nfpa 54] a vent shall not terminate: - directly above a paved walkway or driveway which serves two or more buildings or where the flue gas condensation or vapor could create a hazard or impro...

Page 32

Absolute boilers abs 1500-2000-2500-3000-4000 32 4.6 water connection the absolute boiler is supplied with 4 inch # 150 ansi flanges for both the inlet and outlet manifolds. It is advisable to install a shut off valve for the both the supply and return to allow removal of the boiler in the future. A...

Page 33

Absolute boilers abs 1500-2000-2500-3000-4000 33 4.6.1 water pressure the boiler is suitable for a maximum working pressure of 160 psi [10.8 bar], the system pressure shall be at least 12 psi [0.8 bar] 4.6.2 safety valve a safety relief valve nb certified with v or hv symbol as supplied must be inst...

Page 34

Absolute boilers abs 1500-2000-2500-3000-4000 34 4.6.3 water treatment the heat exchanger is manufactured from aluminum alloys which will provide many years of excellent service, if maintained properly. All heat exchangers require proper water conditions to remain efficient and function properly. Fa...

Page 35

Absolute boilers abs 1500-2000-2500-3000-4000 35 4.6.4 water flow see the chart below for proper water flow requirements. Incorrect flow may cause eventual damage or premature boiler failure that may not be covered under the warranty proper flow rates may be achieved through a combination of primary...

Page 36

Absolute boilers abs 1500-2000-2500-3000-4000 36 4.6.5 typical water system layout - the piping diagram illustrates the minimum boiler system controls needed, the by-pass system is not necessary, but can be used in multiple heating temperature circuits. - consult all national, local and building cod...

Page 37

Absolute boilers abs 1500-2000-2500-3000-4000 37 4.6.6 frost protection the boiler must be installed in a frost free area to prevent freezing of the condensate drain pan and pipe. If the temperature of the heating water drops to much, the built in unit protection activates. If the boiler is decommis...

Page 38

Absolute boilers abs 1500-2000-2500-3000-4000 38 model voltage/phase fuse sizes abs1500 120/60/1 15a fused disconnect abs2000 120/60/1 15a fused disconnect abs2500 abs3000 abs4000 120/60/1 15a fused disconnect 230/60/3 10a fused disconnect 5.2.1 sola main control voltage: 120v ac 60 hz +10% -15% saf...

Page 39

Absolute boilers abs 1500-2000-2500-3000-4000 39 p w m m oto r d c b a 4 3 2 1 d c b a 4 3 2 1 co m nc no co m no nc hg p lg p co m l n no nc lwc o no conn ect ions on j11 co nnect or 12 j4 11 9 8 7 6 5 4 3 2 1 10 j5 7 6 5 4 3 2 1 j6 8 7 6 5 4 3 2 1 j7 7 6 5 4 3 2 1 j9 1 2 3 4 5 6 7 1 j8 2 3 4 5 6 7...

Page 40

Absolute boilers abs 1500-2000-2500-3000-4000 40 od od (+ ) (-) tt 24v- n 24v + s uppl y/ o ut let te m p. S ens or d hw d hw d hw re tu rn/ inl et te m p. S en sor tt fl fl fl f3 h g f e d c b a 8 7 6 5 4 3 2 1 h g f e d c b a 8 7 6 5 4 3 2 1 abs ol ut e a bs s er ies m odel (s ) 3000 & 4000 int er...

Page 41

Absolute boilers abs 1500-2000-2500-3000-4000 41 a bs ol ut e ab s s er ies (a ll m odel s) s afe ty & l im it w iri ng d eta il size dr awn b y: d wg n o re v 11x 17 cr aig h . 4- a bs -s o l- 001 0 sc ale n ts 4/ 6/ 2016 sh eet 8 of 1 5 c o m no nc ia s c o m no nc c om no nc hg p lg p j6 8 7 6 5 ...

Page 42

Absolute boilers abs 1500-2000-2500-3000-4000 42 d c b a 4 3 2 1 d c b a 4 3 2 1 d c b a 4 3 2 1 d c b a 4 3 2 1 a bs ol ut e ab s s er ies (a ll m odel s) sol a r 7910a j 3 det ai ls c om m uni cat ion to h m i opt ions size dr awn b y: d wg n o re v 11x 17 cr aig h . 4- e pa -s o l- 001 0 sc ale n...

Page 43

Absolute boilers abs 1500-2000-2500-3000-4000 43 a bs ol ut e ab s s er ies m od el (s ) 750- 2500 ty pic al fie ld w irin g b m s a ppl ic at ion size dr awn b y: dw g no re v 11x 17 cr aig h . 4- e pa -s o l- 001 0 sc ale n ts 4/ 6/ 2016 sh eet 11 of 1 5 h g f e d c b a 8 7 6 5 4 3 2 1 h g f e d c...

Page 44

Absolute boilers abs 1500-2000-2500-3000-4000 44 a bs ol ut e a bs s er ies 3000- 4000 ty pic al fie ld w irin g o ut door r es et a ppl ic at ion size dr awn b y: d wg n o re v 11 x17 cr aig h . 4- e pa -s o l- 001 0 sc ale n ts 4/ 6/ 2016 sh eet 12 of 1 5 h g f e d c b a 8 7 6 5 4 3 2 1 h g f e d ...

Page 45

Absolute boilers abs 1500-2000-2500-3000-4000 45 abs ol ut e a bs s er ies m odel (s ) 3000 & 4000 ty pic al fie ld w irin g o ut door r es et a ppl ic at ion size dr awn b y: dw g no re v 11 x17 cr aig h . 4- e pa -s o l- 001 0 sc ale n ts 4/ 6/ 2016 sh eet 14 of 1 5 h g f e d c b a 8 7 6 5 4 3 2 1...

Page 46

Absolute boilers abs 1500-2000-2500-3000-4000 46 a bs ol ut e a bs s er ies 3000- 4000 ty pic al fie ld w irin g o ut door r es et a ppl ic at ion size dr awn b y: dw g no re v 11x 17 cr aig h . 4- e pa -s o l- 001 0 sc ale n ts 4/ 6/ 2016 sh eet 13 of 1 5 h g f e d c b a 8 7 6 5 4 3 2 1 h g f e d c...

Page 47

Absolute boilers abs 1500-2000-2500-3000-4000 47 h g f e d c b a 8 7 6 5 4 3 2 1 h g f e d c b a 8 7 6 5 4 3 2 1 a bs ol ut e ab s s er ies (a ll m odel s) ty pic al fie ld w irin g o pt ional s ens or w iri ng (d h w tank , f lue sens or ) size dr awn b y: dw g no re v 11x 17 cr aig h . 4- e pa -s ...

Page 48

Absolute boilers abs 1500-2000-2500-3000-4000 48 air pressure switch 5.3 power consumption (watts) abs 1500 956 abs 2000 956 abs 2500 1440 abs 3000 1275 abs 4000 1912 5.4 limit controls 5.4.1 temperature control the absolute boiler is equipped with an electronic temperature limit control based on fl...

Page 49

Absolute boilers abs 1500-2000-2500-3000-4000 49 5.4.5 high gas pressure switch (hgp) the boiler is equipped with a gas pressure switch that is mounted directly on the air intake housing. The gas pressure switch is pre set at the factory and should not be adjusted. High gas pressure switch low gas p...

Page 50

Absolute boilers abs 1500-2000-2500-3000-4000 50 6 gas connection 6.1 gas connection the absolute boiler is suitable for use with natural gas only. The gas connection is at the back left side of the boiler . The boiler is fitted with a gas filter which is mounted within the mono block gas valve as s...

Page 51

Absolute boilers abs 1500-2000-2500-3000-4000 51 6.1.3 gas line piping to boiler ensure pipe sizing capability follows the recommend values based on an overall length of pipe from the meter plus the equivalent length of all fittings. Approximate sizing may be based on 1 cubic foot of natural gas sup...

Page 52

Absolute boilers abs 1500-2000-2500-3000-4000 52 6.3 gas / air ratio control the boiler has a pressure differential gas/air ratio control. This gas/air ratio control maintains the correct balance of gas and air quantities to the burner at a constant level under variable loads. This ensures clean and...

Page 53

Absolute boilers abs 1500-2000-2500-3000-4000 53 to adjust low fire: required tools- 2.5 mm hex wrench and combustion analyzer start the boiler and observe proper settings for the system. Set the boiler to low fire, to achieve minimum firing rate of the boiler. A- check the combustion readings on th...

Page 54

Absolute boilers abs 1500-2000-2500-3000-4000 54 1. Electrical din connector 2. Upstream flange 3. G1/8 inlet test port 4. Filter 5. Valve body 6. Coil 7. Test port connection #2, g 1/8 between v1 and v2; both sides. 8. Test port connection #3, g1/8 downstream of v2; both sides. 9. Regulator outlet ...

Page 55

Absolute boilers abs 1500-2000-2500-3000-4000 55 7. Commissioning: danger if you do not follow the commissioning instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. 7.1 pre operational checks 1. Check power supply ensure fused and service di...

Page 56

Absolute boilers abs 1500-2000-2500-3000-4000 56 7.3 combustion setting and adjustment factory combustion readings chart 8 set point high fire abs 1500 abs 2000 abs 2500 abs 3000 abs 4000 co2 9.7 9.58 9.3 9.3 co ppm 65 87 65 54 o2 3.6 9.58 4.3 4.3 factory combustion readings chart 8 set point set po...

Page 57

Absolute boilers abs 1500-2000-2500-3000-4000 57 flue port for combustion analyzer warning the installation of the boiler is not completed until all controls and safety device have been tested and verified for correct function and operation. It is the sole responsibility of the installer to ensure t...

Page 58

Absolute boilers abs 1500-2000-2500-3000-4000 58 warning explosion hazard. Improper configuration can cause fuel buildup and explosion. Operators of this display may move fuel and/ or air actuators to positions that can create hazardous burner conditions. Improper user operation may result in proper...

Page 59

Absolute boilers abs 1500-2000-2500-3000-4000 59 8.1 honeywell sola control programming/configuration the honeywell control has been fully programmed and configured by the factory for most installations, in most installation no adjustments or configurations are required, please note that optional it...

Page 60

Absolute boilers abs 1500-2000-2500-3000-4000 60 step 2: from the configuration window, use the slide bar on the right had side and select the group by touching the group name. Step 3: verify in correct group and view setting, determine the parameter in the group you wish to either view (confirm) or...

Page 61

Absolute boilers abs 1500-2000-2500-3000-4000 61 9. Commissioning warning if you do not follow the commissioning instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. 9.1 pre operational checks 1. Check power supply ensure fused and service di...

Page 62

Absolute boilers abs 1500-2000-2500-3000-4000 62 9.3 commissioning steps note - commissioning can only be performed with the honeywell s7999d 1006 color touch screen display - all units are fully factory tested, due to varying field conditions, boiler must be tested on final site for safety shutdown...

Page 63

Absolute boilers abs 1500-2000-2500-3000-4000 63 3. Touch the diagnostics test button, screen changes to the modulating test window 4. Press the maximum modulation button (high fire position), this will force the boiler into the high fire position. Once in the high fire postion and stable conditions...

Page 64

Absolute boilers abs 1500-2000-2500-3000-4000 64 1. Electrical din connector 2. Upstream flange 3. G1/8 inlet test port 4. Filter 5. Valve body 6. Coil 7. Test port connection #2, g 1/8 between v1 and v2; both sides. 8. Test port connection #3, g1/8 downstream of v2; both sides. 9. Regulator outlet ...

Page 65

Absolute boilers abs 1500-2000-2500-3000-4000 65 a. Local operation via internal set point, the output of the boiler modulates on the basis of the flow temperature. B. Remote operation via external signal (4-20ma) for output or temperature set-point c. Lead/lag (cascade master control) communicates ...

Page 66

Absolute boilers abs 1500-2000-2500-3000-4000 66 8. High gas/vent safety pressure switch calibration and check a. Check for leaks around the piping of high gas pressure switch for gas leaks b. Command boiler on, while starting turn dial to minimum setting or until the boiler shutdown on lci (operati...

Page 67

Absolute boilers abs 1500-2000-2500-3000-4000 67 absolute boilers- abs series boiler start-up form project name address installation & location details city/town prov/state country postal/zip code sart-up date: start-up tech. Equipment installer contact info. Equipment information boiler model seria...

Page 68

Absolute boilers abs 1500-2000-2500-3000-4000 68 11 maintenance 11.1 general maintenance if during the annual inspection combustion results indicate that the boiler is no longer operating at the optimum level additional maintenance should be carried out as follows: - the absolute mini boiler or any ...

Page 69

Absolute boilers abs 1500-2000-2500-3000-4000 69 11.1.3 cleaning the fan use compressed air or a synthetic brush to clean the fan, be careful not to disturb the balance clips on the vanes. 11.1.4 cleaning the heat exchanger release the retaining nuts from heat exchanger cover plate, remove plate, be...

Page 70

Absolute boilers abs 1500-2000-2500-3000-4000 70 max. 70 psi air pressure to clean burner 11.1.5 cleaning the burner assembly caution turn electrical off, then ensure gas has been shut off at the main shut off valve. Next purge all gas in the system as per code. The burner may be hot, allow enough t...

Page 71

Absolute boilers abs 1500-2000-2500-3000-4000 71 11.1.7 cleaning/replacing the ignition/ionization rod caution turn electrical off, then ensure gas has been shut off at the main shut off valve. Next purge all gas in the system as per code. The ignition/ionization rod may be hot, allow enough time to...

Page 72

Absolute boilers abs 1500-2000-2500-3000-4000 72 11.1.9 sight glass cleaning caution turn electrical off, then ensure gas has been shut off at the main shut off valve. Next purge all gas in the system as per code. The ignition/ionization rod may be hot, allow enough time to let boiler cool before re...

Page 73

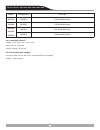

Absolute boilers abs 1500-2000-2500-3000-4000 73 description schedule system pressure monthly control functioning monthly seals or evidence of leaks monthly unobstructed combustion air supply, no chemicals, garbage, gasoline, combustible materials, flammable liquids are stored near the boiler. Month...

Page 74

Innovative industrial inc. Innovative industrial inc. 122 burton street hamilton, ontario, canada l8l 3r5.