- DL manuals

- AC Tech

- Inverter

- ESV112N02TXB

- Operating Instructions Manual

AC Tech ESV112N02TXB Operating Instructions Manual

Summary of ESV112N02TXB

Page 1

V0100 sv01b operating instructions smvector - frequency inverter 0.5 … 10 hp (0.37 kw… 7.5 kw).

Page 2: Contents

English copyright © 2006 ac technology corporation all rights reserved. No part of this manual may be reproduced or transmitted in any form without written permission from ac technology corporation. The information and technical data in this manual are subject to change without notice. Ac technology...

Page 3: About These Instructions

English this documentation applies to the smv frequency inverter, and contains important technical data and describes installation, operation, and commissioning. These instructions are only valid for smv frequency inverters with software rev 20 (see drive nameplate). Please read the instructions bef...

Page 4: Safety Information

English 1 safety information general some parts of lenze / ac tech controllers can be electrically live and some surfaces can be hot. Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation creates the risk of severe injury to personnel or damage to e...

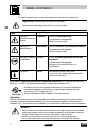

Page 5: Safety Information

English 4 safety information all safety information given in these operating instructions have the same layout: signal word! (characterizes the severity of the danger) note (describes the danger and informs on how to proceed) icon signal words warning of hazardous electrical voltage danger! Warns of...

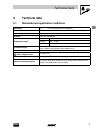

Page 6: Technical Data

English 5 technical data 2 technical data 2.1 standards and application conditions conformity ce low voltage directive (7/2/eec) approvals ul 508c underwriters laboratories - power conversion equipment input voltage phase imbalance humidity temperature range transport -25 … +70°c storage -20 … +70°c...

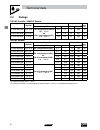

Page 7: Technical Data

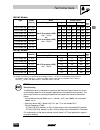

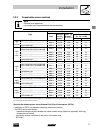

English esv25n0sxb esv7n0sxb esv75n0sxb esv25n02sxb esv7n02yxb esv75n02yxb esv2n02yxb esv52n02yxb esv222n02yxb esv2n02txb esv52n02txb esv222n02txb esv402n02txb esv552n02txb esv752n02txb technical data 2.2 ratings 120vac doubler / 240vac models type power [hp/kw] mains output current watts loss volta...

Page 8: Technical Data

English esv7n04txb esv75n04txb esv2n04txb esv52n04txb esv222n04txb esv402n04txb esv552n04txb esv752n04txb esv75n0txb esv52n0txb esv222n0txb esv402n0txb esv552n0txb esv752n0txb the smvector drive is designed to operate at the nominal output current (i n ) shown in the ratings tables for most standard...

Page 9: Installation

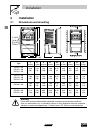

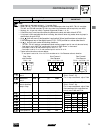

English esv25…xb esv7…xb esv75…xb esv2…xb esv52…xb esv222…xb esv402…xb esv552…xb esv752…xb drives must not be installed where subjected to adverse environmental conditions such as: combustible, oily, or hazardous vapors or dust; excessive moisture; excessive vibration or excessive temperatures. Cont...

Page 10: Installation

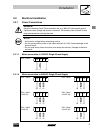

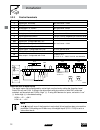

English esv…n0s… esv…n0s… esv…n0s… esv…n02y… (2/pe ac) esv…n02y… (/n/pe ac) esv…n02s… (2/pe ac) esv…n02s… (/n/pe ac) 9 installation 3.2 electrical installation 3.2.1 power connections danger! Hazard of electrical shock! Circuit potentials are up to 00 vac above earth ground. Capacitors retain charge...

Page 11: Installation

English esv…n02y… esv…n02t… esv…n04t… esv…n0t… (/pe ac) 0 installation 3.2.1.3 mains connection to three-phase supply pe l1 l2 l3 pe l1 l2 l3 3.2.1.4 motor connection u / t1 v / t2 w / t3 pe pes pes m 3~ pe pes pes pes pe pes = protective earth shielding mains and motor terminations 2 lb-in (. Nm) 0...

Page 12: Installation

English esv25n0sxb esv7n0sxb esv75n0sxb esv25n0sxb, esv25n02sxb, esv7n0sxb, esv7n02yxb esv75n0sxb, esv75n02yxb esv2n02yxb esv52n02yxb esv222n02yxb esv7n02yxb, esv75n02yxb esv2n02yxb, esv52n02yxb, esv2n02txb, esv52n02txb esv222n02yxb, esv222n02txb esv402n02txb esv552n02txb esv752n02txb esv7n04txb...E...

Page 13: Installation

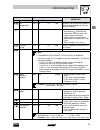

English 2 installation 3.2.3 control terminals terminal data for control connections 1 digital input: start/stop input resistance = 4.K Ω 2 analog common 5 analog input: 0...0 vdc input resistance: >50 k Ω 6 internal dc supply for speed pot +0 vdc, max. 0 ma 25 analog input: 4...20 ma input resistan...

Page 14: Commissioning

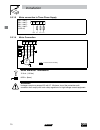

English commissioning 4 commissioning 4.1 local keypad & display fwd auto rev stop run v005 run start button: in local mode (p00 = 0, 4), this button will start the drive. Stop stop button: stops the drive, regardless of which mode the drive is in. Warning! When jog is active, the stop button will n...

Page 15: Commissioning

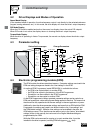

English 4 commissioning 4.2 drive displays and modes of operation speed mode display in the standard mode of operation, the drive frequency output is set directly by the selected reference (keypad, analog reference, etc.). In this mode, the drive display will show the drive’s output frequency. Pid m...

Page 16: Commissioning

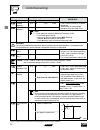

English 5 commissioning 4.5 parameter menu 4.5.1 basic setup parameters code possible settings important no. Name default selection start control source 0 0 local keypad use run button on front of drive to start terminal strip use start/stop circuit wired into the terminal strip. See section .2. 2 r...

Page 17: Commissioning

English motor current rating p08 = smv output rating x 00 example: motor = amps; smv = 4 amps; p08 = 75% note do not set above the rated motor current as listed on the motor dataplate. The motor thermal overload function of the smv is ul approved as a motor protection device. If line power is cycled...

Page 18: Commissioning

English 7 commissioning code possible settings important no. Name default selection start method 0 0 normal start on power-up drive will automatically start when power is applied. 2 start with dc brake when start command is applied, drive will apply dc braking according to p74, p75 prior to starting...

Page 19: Commissioning

English 8 commissioning 4.5.2 i/o setup parameters code possible settings important no. Name default selection assertion level 2 low p20 and the assertion level switch must both match the desired assertion level unless p00, p2…p2 are all set to 0. Otherwise an f.Al fault will occur. 2 high tb-a inpu...

Page 20: Commissioning

English 9 commissioning code possible settings important no. Name default selection note • when input is activated, settings ...7 override p0 • when tb-a...Tb-c are configured for auto references other than mop, tb-c overrides tb-b, and tb-b overrides tb-a. Any other auto reference will have priorit...

Page 21: Commissioning

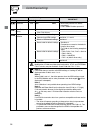

English 20 commissioning code possible settings important no. Name default selection relay output tb-, 7 0 0 none disables the output run energizes when the drive is running 2 reverse energizes when reverse rotation is active fault de-energizes when the drive trips, or power is removed 4 inverse fau...

Page 22: Commissioning

English 2 commissioning code possible settings important no. Name default selection tb-4 output 0 0...2 (same as p40) 24 dynamic braking for use with dynamic braking option 25 network activated requires optional communication module (refer to the network module documentation). Loss of load threshold...

Page 23: Commissioning

English 22 commissioning 4.5.3 advanced setup parameters code possible settings important no. Name default selection speed at minimum signal 0.0 -999.0 {hz} 000 f p161 p160 ref 10v (20ma) 0v (4ma) v0 speed at maximum signal 0.0 -999.0 {hz} 000 note • p0 sets the output frequency at 0% analog input •...

Page 24: Commissioning

English 2 commissioning code possible settings important no. Name default selection slip compensation 0.0 0.0 {%} 0.0 increase p70 until the motor speed no longer changes between no load and full load conditions. () current limit 200 0 {%} clim max • when the limit is reached, the drive displays , a...

Page 25: Commissioning

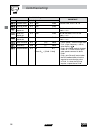

English 24 commissioning code possible settings important no. Name default selection password 225 0000 9999 • must enter password to access parameters • p94 = 0000: disables password clear fault history 0 0 no action clear fault history program selection 0 operate from user settings operate from oem...

Page 26: Commissioning

English 25 commissioning 4.5.4 pid parameters code possible settings important no. Name default selection pid mode 0 0 disabled • normal-acting: as feedback increases, motor speed decreases • reverse-acting: as feedback increases, motor speed increases • pid mode is disabled in vector torque mode (p...

Page 27: Commissioning

English 2 commissioning code possible settings important no. Name default selection minimum alarm 0.0 p204 p205 use with p40, p42 = 8...2 maximum alarm 0.0 p204 p205 preset pid setpoint # 0.0 p204 p205 tb-a activated; p2 = and p200 = or 2 preset pid setpoint #2 0.0 p204 p205 tb-b activated; p22 = an...

Page 28: Commissioning

English 27 commissioning 4.5.5 vector parameters code possible settings important no. Name default selection () drive mode 0 0 constant v/hz constant torque v/hz control for general applications variable v/hz variable torque v/hz control for centrifugal pump and fan applications 2 enhanced constant ...

Page 29: Commissioning

English 28 commissioning code possible settings important no. Name default selection () motor stator resistance 0.00 0.00 { w} 4.00 • will be automatically programmed by p99 • changing these settings can adversely affect performance. Contact factory technical support prior to changing () motor stato...

Page 30: Commissioning

English 29 commissioning 4.5.6 network parameters code possible settings important no. Name default selection network protocol 0 not active this parameter will only display the selection for the module that is installed. Remote keypad 2 modbus rtu canopen 4 devicenet 5 ethernet profibus … module spe...

Page 31: Commissioning

English 0 commissioning code display range (read only) important no. Name analog output 0 {vdc} 0.0 see p50…p55 actual output frequency 0 {hz} 500.0 network speed command 0 {hz} 500.0 command speed if (auto: network) is selected as the speed source terminal and protection status indicates terminal s...

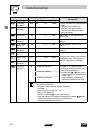

Page 32: 5.1

English troubleshooting and diagnostics 5 troubleshooting and diagnostics 5.1 status/warning messages status / warning cause remedy dc-injection brake active dc-injection brake activated • activation of digital input (p2...P2 = 8) • automatically (p0 = 2, 4...) • automatically (p = , ) deactivate dc...

Page 33: 5.2

English 2 troubleshooting and diagnostics status / warning cause remedy pid mode active drive has been put into pid mode. See p200. Sleep mode is active see p240...P242 start pending the drive has tripped into a fault and will automatically restart (p0 = ...) to disable auto-restart, set p0 = 0...2 ...

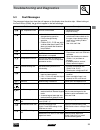

Page 34: 5.3

English troubleshooting and diagnostics 5.3 fault messages the messages below show how they will appear on the display when the drive trips. When looking at the fault history (p500), the . Will not appear in the fault message. Fault cause remedy (1) high temperature fault drive is too hot inside • r...

Page 35

English 4 troubleshooting and diagnostics fault cause remedy (1) digital input configuration fault (p2...P2) more than one digital input set for the same function each setting can only be used once (except settings 0 and ) only one digital input configured for mop function (up, down) one input must ...

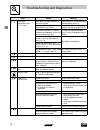

Page 36

English 5 troubleshooting and diagnostics fault cause remedy (1) motor overload fault excessive motor load for too long • verify proper setting of p08 • verify drive and motor are proper size for application flying restart fault controller was unable to synchronize with the motor during restart atte...

Page 37: Notes

Notes.

Page 38

Ac technology corporation • 630 douglas street • uxbridge, ma 01569 • usa +1 (508) 278-9100 (sv01b).