- DL manuals

- Accom

- Switch

- ASWR8150

- Technical Manual

Accom ASWR8150 Technical Manual

Summary of ASWR8150

Page 1

Aswr8150 component digital switcher technical guide pn 9100-0212-04 copyright© may 2000 accom, inc. 1490 o’brien drive menlo park, california 94025.

Page 2

Copyright 2000 accom, inc. All rights reserved. No part of this publication may be reproduced or used in any form by any means without written permission of the publisher. Many of the designations used by manufacturers and sellers to distinguish their products are claimed as trademarks. Where those ...

Page 3

Table of contents introduction features and options................................................... 1-1 system components .................................................... 1-2 video processing functional description .................. 1-4 video input modules [1]...................................

Page 4

Component analog monitor outputs ..................1-20 program outputs......................................................1-20 preview output ........................................................1-20 auxiliary 3 and 4 outputs (optional)...................1-22 control functional description ......

Page 5

Back view ....................................................................2-6 left/side view ...........................................................2-6 right/side view.........................................................2-6 control panel cutout dimensions...........................2-6 ex...

Page 6

Using multiple control panels.................................... 2-24 physical connections......................................................2-24 acquiring and de-acquiring control .........................2-24 troubleshooting hints ...................................................2-25 signal ...

Page 7

Standard or advanced wipe generator .....................3-19 color corrector/color corrector bypass ...................3-21 input modules .................................................................3-24 extended memory ..........................................................3-25 hard disk dr...

Page 8

Introduction................................................................... 5-1 engineering menu ........................................................ 5-2 communications submenu ............................................5-3 input submenu.........................................................

Page 9

Current selection .....................................................5-29 name ..........................................................................5-29 input assign submenu .................................................5-30 assigning sources to crosspoints .........................5-30 us...

Page 10

The disk menu ............................................................ 5-56 save recall submenu .....................................................5-57 drive ...........................................................................5-57 comment ...................................................

Page 11

Digital betacam vtr settings ................................5-75 d5 vtr settings........................................................5-76 effects loop processing ............................................ 5-77 conceptual background information..........................5-77 effects loop re-entr...

Page 12

Table of contents 8150 technical guide x contents 9100-0212-04 - may 2000

Page 13: Features And Options

Section 1 introduction features and options the aswr8150 offers a unique combination of small physical size and features traditionally associated with large, expensive post production switchers. The 8150 is the result of an aggressive asic (application specific integrated circuit) development progra...

Page 14: System Components

Supershadow – a full bandwidth drop shadow. Surfacefx – combines the powerful texture and light source modeling tools with the advanced ultrawarp feature. You can use any 8150 source, including video and key inputs, the supermatte generator, or the framestores, as the source for a texture. Four inde...

Page 15

The main power switch is in the lower right corner of the signal chassis front panel, under a cover. The switch has a standard label: 0 = off, 1 = on. Numeric menus dve key misc wipe color crctr color crctr f1 f2 f3 ch a freeze save keyframe save keyframe recall keyframe recall keyframe field acquir...

Page 16: Video Processing Functional

Video processing functional description video input modules [1] the 8150 can accept 16 video inputs with two auxiliary outputs, or 14 video inputs with four auxiliary outputs. (two of the four aux output paths are used for 16-input configurations.) inputs can be any combination of video or key sourc...

Page 17

1 2 2 figure 1-2 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-5.

Page 18

M/e pgm – mix/effect main program output; crosspoint input number 30. M/e pvw – mix/effect look-ahead preview output; crosspoint input number 31. M/e loop vid send – processed fill video feed for effects looping; crosspoint input number 29. M/e loop key send – processed key feed for effects looping;...

Page 19

2 2 figure 1-3 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-7.

Page 20

Internal dve video return combined channel a and b video output of the internal dve option; crosspoint input number 21. Internal dve key return combined channel a and b key output of the internal dve option; crosspoint input number 22. Crosspoint matrix outputs 8150 outputs aux 1, 2 – auxiliary bus ...

Page 21

2 2 figure 1-4 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-9.

Page 22

Dsk border fill – the fill source for a pgm/pst wipe border or dsk border. Pgm (program) – the source selected on the program bus. Pst (preset) – the source selected on the preset bus. Dsk fill – the 4:2:2 fill source selected for the dsk. Dsk aux – the 0:2:2 part of a 4:4:4 fill source selected for...

Page 23

3 3 figure 1-5 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-11.

Page 24

The main key input for the 4:2:2 part and the external mask input for the 0:2:2 part. After you complete the color correction, the video is downsampled and output as 4:2:2 video. Key/border processor [4] inputs the key/border processors have a primary key extraction input (key 1, key 2, and dsk key)...

Page 25

4 4 figure 1-7 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-13.

Page 26

In figure 1-6. Dual patch mode discriminates and combines two phase vectors; each patch has controls for adjusting the chroma key settings precisely. Luminance key extraction advanced clip and gain controls support fully linear luminance key extraction. The low clip and low gain pushknobs are like t...

Page 27

5 figure 1-8 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-15.

Page 28

Wipe pattern generators [8] two independent wipe pattern generators provide wipe transitions for the mix/effects processor and the pgm/pst/dsk processor. Either wipe generator can be fed to the routing switcher and output for use as a mask source. The standard wipe generators offer 28 patterns. Wipe...

Page 29

7 8 9 6 figure 1-9 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-17.

Page 30

The processing flow consists of a pgm/pst mixer, a downstream keyer, and a master fade-to-black mixer. Like the m/e processor, the pgm/pst/dsk processor lets you to break out processed key and fill signals, route them to external devices for further manipulation, then return them before the final co...

Page 31

10 12 13 11 figure 1-10 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-19.

Page 32

Enhanced (frame delay) output module [13] the enhanced output module may be installed in some 8100s and is installed in all 8150s, with the possible exception of those 8150s that were upgraded from 8100s. It processes signal outputs as follows. Auxiliary outputs (optional) aux 1, 2 the frame delay o...

Page 33

13 figure 1-11 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-21.

Page 34

Auxiliary 3 and 4 outputs (optional) aux 3, 4 the aux 3 and 4 output module, if present, is installed in the lower right input slot at the rear of the chassis. This module has two additional serial digital auxiliary bus outputs for external processing feeds or for isolated feeds. These outputs are a...

Page 35

13 figure 1-12 8150 video functional diagram 8150 technical guide video processing functional description 9100-0212-04 - may 2000 introduction 1-23.

Page 36

Control functional description signal chassis serial 1, 2, 3 three serial remote control ports provide interfaces to external devices, primarily edit controllers. Figure 1-13, on the facing page, shows the typical configuration for connecting the 8150 to an edit controller. Use ports 1 and 2 for edi...

Page 37

Figure 1-13 8150 control functional diagram 8150 technical guide control functional description 9100-0212-04 - may 2000 introduction 1-25.

Page 38

Rs-232 this serial port connects a mouse, mouse pen, or trackball for fine control of wipe pattern position and other joystick functions. Rs-422 this serial port is not currently supported. Keyboard you can connect an off-the-shelf, pc at keyboard to this port for naming crosspoints and disk files. ...

Page 40

Good practices electronic equipment requires special handling. When maintaining the equipment covered in this manual, observe the standard procedures listed below: unless it’s terminated internally, use the correct termination resistor at the input of any monitoring device when connecting it to a hi...

Page 41: Unpacking

Section 2 installation unpacking remove the 8150 signal chassis, control panel, and other equipment from the shipping boxes. Inspect all articles for shipping damage. If you find any, notify the shipping carrier immediately for claims adjustments. Compare the contents against the packing list. Conta...

Page 42

Control panel the 8150 control panel consumes less than 55 watts. An external modular power supply provides control panel operating voltages. Plug the control panel power supply into a standard ac mains outlet, then connect the dc power cable to the control panel "power" connector. The dc power cabl...

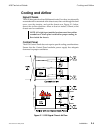

Page 43: Cooling And Airflow

Cooling and airflow signal chassis the 8150 dissipates less than 900 thermal watts. Four fans, two internally mounted and two mounted at the chassis rear, draw air through the front cover, over the circuitry, and out the chassis rear. Figure 2-1, below, shows the air flow direction. Allow at least s...

Page 44

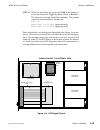

Dimensions and physical installation signal chassis figure 2-2, on the facing page, shows the 8150 signal chassis dimensions. Front view this view shows the overall width of the signal chassis. The chassis fits in a standard rack (19.00 inches or 483mm wide). Top view this view shows the chassis dep...

Page 45

Figure 2-2 signal chassis dimensions 8150 technical guide dimensions and physical installation 9100-0212-04 - may 2000 installation 2-5.

Page 46

Control panel figure 2-3, on the facing page, shows the dimensions of the 8150 control panel for desk top installation. Top view the top view shows overall control panel dimensions. Back view the back view shows the control panel height from the base to the highest point. Left/side view the left/sid...

Page 47

22.84" 580mm 12.30" 312mm 16.30" 414mm 5.50" 140mm 32.5 o 10 o 3.12" 79mm figure 2-3 8150 control panel dimensions 8150 technical guide dimensions and physical installation 9100-0212-04 - may 2000 installation 2-7.

Page 48

External disk drive mounting the control panel in a console blocks access to the internal disk drive. You must install the optional external floppy drive to save and recall switcher files. The figure below shows the dimensions for console mounting the optional external disk drive. 4.8" 122mm 8.0" 20...

Page 49: Signal Chassis Connections

Signal chassis connections video inputs inputs 1 - 14 a standard 8150 comes with four serial digital inputs (two input modules). You can customize your video inputs by installing up to 12 more inputs (six more input modules) to meet your requirements. Input modules plug into the chassis as shown in ...

Page 50

Module options figure 2-6, below, shows the available input and output modules. The digital input modules are full 10-bit compatible, with 8-bit paths for the digital inputs selectable in the engineering menu. The digital input modules also have one color matte generator per input that you can use a...

Page 51

Dual component analog input this optional module supports several component analog formats, including smpte/ebu n10, betacam ® , mii ® , rgb, and monochrome key signals. Input "a" connectors are odd numbered inputs, input "b" are even number inputs. Input horizontal retiming is automatic, with a ran...

Page 52

The 10-bit component analog input module has dual color leds that light green to indicate that the video or key input is present and genlocked. Yellow indicates that the video or key sync input is present but not genlocked, or does not match the system line standard. Red indicates that there is no v...

Page 53

Output modules output module configurations because different systems have different characteristics, you can modify certain 8150 output settings to suit your requirements. You can change these settings: output blanking width (both horizontal and vertical), output bit resolution, and output horizont...

Page 54

However, the rise times of the blanking-to-active video transitions are unfiltered and may be subject to ringing. You may wish to turn h blanking to on to properly filter these transitions. Use the following pushknobs to set horizontal blanking as needed: main left – adjusts the blanking width of th...

Page 55

Supermatte and framestore test patterns) may be present in any unblanked active lines when these signals are included in the 8150 video output. Step 1: turn the signal chassis power off. Remove the four screws that secure the output module to the rear of the chassis and pull the module out slightly....

Page 56

On the program bus. Observe the program output on a waveform monitor, and verify that the correct lines are blanked or unblanked as needed. Vertical blanking – frame delay output module there is a control for vertical output blanking in the engineering menu output submenu. You can individually blank...

Page 57

Or up if the binary value of the lsbs is 10. 8 truncated simply removes the two lsbs from the 10-bit signal. This mode is recommended for troubleshooting only, and should not be used during normal operations. With the standard output module, there is one bit resolution setting for all digital output...

Page 58

Advance the output horizontal phase of all digital outputs by up to 9.25 microseconds, in 18.5 nanosecond (1/4 pixel) steps. Output module connections the following describes all output module connectors. Reference (ref, ref loop) two 75 Ω bnc connectors provide a passive looping system reference co...

Page 59

Program outputs (pgm 1, pgm 2) two ccir 601/smpte 259m serial digital program outputs are provided on 75 Ω bnc connectors. With the standard output module, both outputs are delayed approximately 34 lines from reference. With the frame delay output module only, the program 1 output is selectable betw...

Page 60

Remote ports: serial 1, serial 2, serial 3 (linc) there are three serial rs-422 ports on 9-pin female sub-miniature d connectors. These ports provide the control interface for peripheral linc devices and computer editing systems. A variety of remote protocols are supported, and you can select the po...

Page 61

Control panel this serial rs-422 port provides the control panel interface on a 9-pin female sub-miniature d connector. Gpi this connector provides eight general purpose interface (gpi) inputs and eight gpi outputs on a 25-pin female sub-miniature d connector. Tally this connector provides 16 input ...

Page 62: Control Panel Connections

Control panel connections keyboard this connector lets you use an off-the-shelf pc at keyboard with a 5- pin din connector. You can use the keyboard to name inputs and disk files. Rs-232 / rs-422 this serial port connects a mouse, mouse pen, or trackball to let you draw masks in the framestore. Note...

Page 63

External floppy this port connects to an external 3.5" 1.44mb or 720kb floppy disk drive with a 25-pin female sub-miniature d connector. This option is required if you install the control panel in a console that prevents access to the internal floppy disk drive. Power the control panel receives dc o...

Page 64

Using multiple control panels the 8150 signal chassis can connect to and communicate with multiple control panels. All control panels connected to a signal chassis are in communication with that chassis, but only one panel has control of that chassis. Control panels that are not transmitting to the ...

Page 65

Troubleshooting hints if the control panel does not appear to have control of the signal chassis, check the acquire button led to verify that it is on. If not, press acquire once to regain control. If it is part of a multiple control panel system, check the other control panels to see if one is acqu...

Page 66

Signal chassis connector detail serial 1, 2, 3 connectors the serial connectors can be configured for rs-422 master or slave operation (rs-232 format is not supported). See figure 2-8 for configuration details. Note: only serial 3 supports linc (locally integrated node control). It is set as an rs-4...

Page 67

Control panel connector the control panel connector is wired as an rs-422 master port. (the control panel "control in" connector is wired as an rs-422 slave port.) you can use a generic rs-422 cable wired pin-to-pin for the control panel connection. Table 2-2 control panel connector pin functions 81...

Page 68

Gpi connector gpi inputs all gpi inputs work as switch closures through an opto-isolator. Figure 2-10, below, shows a typical interface. See table 2-3 for the connector pinout. Electrical specifications the following specifications are for the opto-isolator (device # h11l1) used in the 8150. Input l...

Page 69

Table 2-3 gpi connector pin functions 8150 technical guide signal chassis connector detail 9100-0212-04 - may 2000 installation 2-29.

Page 70

Gpi outputs all gpi outputs work as solid state opto-isolated switch closures. Opto-isolators have limited drive current capability, so some form of external drive interface is needed for applications that need greater current than that supplied by the opto-isolator output. Figure 2-11, below, shows...

Page 71

Tally connector all tally outputs are opto-isolated open-collector outputs. Opto-isolators have limited current capability to drive some relays or tally lamps. An external drive interface is needed for applications that need greater current than that supplied by the opto-isolator output. (see figure...

Page 72

Table 2-4 tally connector pin functions signal chassis connector detail 8150 technical guide 2-32 installation 9100-0212-04 - may 2000

Page 73

Parallel digital connector table 2-5, below, gives the pin functions for the ccir 656/smpte 125m parallel digital connectors on the dual parallel input modules. Table 2-5 parallel digital connector pin functions 8150 technical guide signal chassis connector detail 9100-0212-04 - may 2000 installatio...

Page 74

Control panel connector detail keyboard connector this connector supports an off-the-shelf pc at keyboard. See table 2-6, below, for standard ibm pc at pin functions. Table 2-6 keyboard connector pin functions control panel connector detail 8150 technical guide 2-34 installation 9100-0212-04 - may 2...

Page 75

Rs-232 connector the rs-232 and rs-422 ports support several pointing devices for fine control of wipe patterns when drawing masks in the framestore. Table 2-7, below, gives the pin function details for the rs-232 port. Table 2-7 rs-232 connector pin functions 8150 technical guide control panel conn...

Page 76

Rs-422 connector the rs-422 and rs-232 ports support several pointing devices for fine control of wipe patterns when drawing masks in the framestore. Table 2-8, below, gives the pin function details for the rs-422 port. Table 2-8 rs-422 connector pin functions control panel connector detail 8150 tec...

Page 77

Control in, out connectors use the control in connector to connect to the signal chassis "control panel" connector. Use the control out connector to loop control to the next control panel (you can loop up to four control panels). Both ports are wired as rs-422 slave ports. See table 2-9 below for pi...

Page 78

External floppy connector use this connector to install the optional external floppy disk drive. Table 2-10, below, shows the external floppy connector pin functions. Table 2-10 external floppy connector pin functions control panel connector detail 8150 technical guide 2-38 installation 9100-0212-04...

Page 79

Power connector table 2-11, below, gives the power connector pin functions. Table 2-11 power connector pin functions 8150 technical guide control panel connector detail 9100-0212-04 - may 2000 installation 2-39.

Page 80

Control panel connector detail 8150 technical guide 2-40 installation 9100-0212-04 - may 2000

Page 81

Section 3 option installation this section explains how to identify and install 8150 options and sub-assemblies. The 8150 is configured at the factory, but you may upgrade your system later, or you may need to identify installed options. Some option sub-boards plug into the 8150 main board with stan...

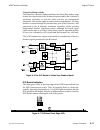

Page 82

Power switch power supply hard drive hard drive cooling fan rear board card cage ram battery backup power supply unit (psu) psu mounting tray rear board card cage signal chassis - top internal view signal chassis - front internal view framestore sub-board wipe pattern dve board sub-board color corre...

Page 83: Option Identification

Option identification figure 3-2, on the following page, shows option board locations for the main board. Figure 3-3 shows drawings of the various input option boards. To identify the options installed in your 8150, examine figures 3-2 and 3-3, and see the text below. Aux 1, 2 aux buses 1 and 2 are ...

Page 84

444 chroma key aux 3, 4 aux 1, 2 framestore: j7 and surrounding area framestore: j7 and surrounding area wipe generator: j6 and surrounding area wipe generator: j6 and surrounding area color corrector: j5 and surrounding area color corrector: j5 and surrounding area dram memory super charger sub-boa...

Page 85

Wipe generator a wipe generator sub-board is required in the 8150 and is factory installed at location j6. Two versions are available: standard and advanced. You have the standard wipe generator if some ics are not installed on the sub-board; advanced wipe generator boards are fully populated. In ei...

Page 86

Sync on g or y. The component video + key module supports one analog video input in any of the above formats (as well as wide band rgb, which it can sample at the 4:4:4 rate), plus one analog key input, both sampled at 10-bit resolution, plus a composite sync input if needed. The composite video + k...

Page 87: Option Installation

Option installation aux bus 1, 2 before proceeding, ensure that you have two accom simm type delaystiks, accom p/n 9400-0706. Warning: removing the switcher board disconnects the ram battery backup. Save all effects, timelines, personality files, and engineering setups to disk before extracting the ...

Page 88

Aux bus #1 delaystik location (aux0) aux bus #2 delaystik location (aux1) figure 3-5 aux bus 1, 2 delaystik locations option installation 8150 technical guide 3-8 option installation 9100-0212-04 - may 2000

Page 89

Aux bus 3, 4 before proceeding, ensure that you have the following items: two accom simm type delaystiks, accom p/n 9400-0706 one aux 3, 4 output module, accom p/n 9400-0748 warning: removing the switcher board disconnects the ram battery backup. Save all effects, timelines, personality files, and e...

Page 90

Aux bus #3 delaystik location (aux2) aux bus #4 delaystik location (aux3) figure 3-6 aux bus 3, 4 delaystik locations option installation 8150 technical guide 3-10 option installation 9100-0212-04 - may 2000

Page 91

Dve board before proceeding, ensure that you have a twin channel dve assembly, p/n 9400-0656, a super charger sub-board assembly, p/n 9400-0762, and a new boot prom, p/n 8700-5078-02. This procedure is for 8150s containing switcher board assemblies at or above revision 2.P, which began shipping in m...

Page 92

Step 7: install the dve board into the topmost slot in the chassis. There will be an empty board slot between the switcher and dve boards. Step 8: from this point, update the software by following the instructions that came with the dve option installation kit. Super charger sub-board u1 figure 3-7 ...

Page 93

4:4:4 chroma key before proceeding, ensure that you have three accom simm type delaystiks, accom p/n 9400-0706. Warning: removing the switcher board disconnects the ram battery backup. Save all effects, timelines, personality files, and engineering setups to disk before extracting the board. Step 1:...

Page 94

M/e a fill delaystik location (mefilla444) m/e b fill delaystik location (mefillb444) dsk fill delaystik location (dkyfilla444) figure 3-8 4:4:4 chroma key delaystik locations option installation 8150 technical guide 3-14 option installation 9100-0212-04 - may 2000

Page 95

Step 5: smpte proposed recommended practice rp 175 (digital interface for 4:4:4:4 component video signals [dual link]) specifies de-multiplexing wide band digital 4:4:4 or 4:4:4:4 video signals into 4:2:2:0 and 0:2:2:4 pairs. This is for interconnecting to other devices using standard 4:2:2 connecti...

Page 96

Dual framestores before proceeding, ensure that you have the framestore sub-board, accom p/n 9400-0649. The mounting hardware should already be present on the switcher board. Figure 3-9, below, shows the major components on the framestore sub-board and the assembly number for identification. Warning...

Page 97

Framestore sub-board location (j7 and surrounding area) figure 3-10 framestore sub-board location 8150 technical guide option installation 9100-0212-04 - may 2000 option installation 3-17.

Page 98

Step 2: see figure 3-10, on the previous page, to locate the framestore sub-board (j7 and surrounding shaded area). Note the orientation notch in j7 and orient the framestore sub-board to match. Seat the sub-board on the connector and press gently but firmly directly over the connector area so as no...

Page 99

Standard or advanced wipe generator before proceeding, ensure that you have the correct sub-board; the standard wipe generator board is accom p/n 9400-0708; the advanced wipe generator board is accom p/n 9400-0681. Figure 3-11, below, shows the major components on both wipe generator sub-boards and ...

Page 100

Wipe sub-board location (j6 and surrounding area) figure 3-12 wipe generator sub-board location option installation 8150 technical guide 3-20 option installation 9100-0212-04 - may 2000

Page 101

Step 3: note the orientation notch in j6 and orient the replacement wipe generator sub-board to match. Seat the sub-board on the connector and press gently but firmly directly over the connector area so as not to unduly flex the switcher board. Fix the standoff fastening screws to secure the sub-boa...

Page 102

Ccr or ccr bypass sub-board location (j5 and surrounding area) figure 3-14 color corrector sub-board location 8150 technical guide option installation 9100-0212-04 - may 2000 option installation 3-23.

Page 103

Input modules before proceeding, ensure that you have the necessary input module(s) and/or blank plate(s) to install in all empty slots. These are the accom part numbers: dual serial digital input, accom p/n 9400-0675 dual parallel digital input, accom p/n 9400-0669 dual component analog input, acco...

Page 104

Extended memory before proceeding, ensure that you have an 8mb dram simm, accom p/n 3119-0005. Warning: removing the switcher board disconnects the ram battery backup. Save all effects, timelines, personality files, and engineering setups to disk before extracting the board. Step 1: power down the 8...

Page 105

Dram memory figure 3-15 dram memory location option installation 8150 technical guide 3-26 option installation 9100-0212-04 - may 2000

Page 106

Hard disk drive installing this option requires access to the bottom side of the signal chassis. If it is installed in a rack that does not allow screwdriver access to the chassis bottom, remove it from the rack and place it on a suitable workbench. Before proceeding, ensure that you have the follow...

Page 107

Note: the scsi update involves inverting the voltage regulator and changing two surface-mount resistors. If you do not feel comfortable making these modifications yourself, contact accom customer service to arrange an exchange or on-site service call. Step 4 connect the 4-way power harness to mother...

Page 108

Step 11: when the unit boots up, press the disk menu button to access the disk menu. Toggle the drive softkey to hard drv. The status box message should be . The prompt under the central status box should read: path: c: disk size: 1079736800 [approximately] disk free: 1079736800 [approximately] sinc...

Page 109

Option installation 8150 technical guide 3-30 option installation 9100-0212-04 - may 2000

Page 110

Section 4 system overview this section describes the major signal chassis physical assemblies and the led indicators for the 8150 main circuit board, the optional dve board, and the input and output modules. You will also find a brief discussion of the control panel buttons and their locations. 8150...

Page 111: Signal Chassis

Signal chassis see figure 4-1, on the facing page, in reference to the descriptions below. Major assembly locations the signal chassis front internal view shows the locations of the 8150 main circuit board, the optional dve board, and the subboards. Note that there may not be a dve board or framesto...

Page 112

Rear board card cage ram battery backup power supply unit (psu) psu mounting tray rear board card cage signal chassis - top internal view power switch power supply hard drive cooling fan signal chassis - front internal view framestore sub-board wipe pattern dve board sub-board color corrector sub-bo...

Page 113

Main board indicators see the drawing on the facing page in reference to the descriptions below. D1 - d8 yellow address bus activity these leds show activity on the eight msbs of the address bus. D9 green video standard when this led is lit, 525-line operation is selected. If it is off, 625-line ope...

Page 114

Signal chassis - front internal view framestore sub-board wipe pattern sub-board color corrector sub-board 8150 main board d 24 d 23 green d 22 d 21 d 20 d 19 d 18 d 17 d 16 d 15 d 14 d 13 d 12 d 11 d 10 d 9 d 8 d 7 d 6 d 5 d 4 d 3 d 2 d 1 green green green green green green green green green green ...

Page 115

D18 green editor port 1 tx this led normally flashes to indicate that serial port 1 is transmitting data. D19 yellow editor port 1 rx this led normally flashes to indicate that serial port 1 is receiving data. D20 green editor port 2 tx this led normally flashes to indicate that serial port 2 is tra...

Page 116

Input module indicators the input modules have dual color leds that indicate the input signal status. See the following table. Led color digital input module status analog input module status off no input signal present (does not apply) red (does not apply) no input sync present yellow input signal ...

Page 117

Output module indicators the standard and optional frame delay output modules each have a dual color led that indicates the reference status. Led color reference status red no reference present yellow reference present but does not match selected line standard green reference present at selected lin...

Page 118

Dve board (option) overview the optional dve board provides frame-based, 10-bit video processing. This processing includes image sizing, positioning, rotation, warps, light sourcing, textures, and drop shadows. One of the unique features of the 8150 dve option is its flexible channel configuration. ...

Page 119

The video for each channel is read out of the transform framestores, with addresses generated by that channel’s transform controller, and sent to the output interpolators. The transformed video and generated key information from each channel passes to the combiner, which composites the two channels ...

Page 120

Video-key/shadow mode the video-key/shadow mode is similar to the video/key mode, except that the key signal input to the b channel is processed by the a channel’s transform controller, so that the video and key are transformed identically. Also, the key input is used to create a drop shadow. The dr...

Page 121

Dve board jumpers and modules the dve board has several jumpers and plug-in modules. Some modules are small printed circuit boards that install parallel to the primary board, and attach with standoffs and phillips screws. Others are simms (single in-line memory modules), and plug in perpendicular to...

Page 122

There are four delay simms. They are identical, and support a video or key component path: sm3e3 a channel y delay sm2e4 a channel c delay sm2e1 b channel key/y delay sm1e2 b channel shadow/c delay figure 4-8 dve board locations 8150 technical guide signal chassis 9100-0212-04 - may 2000 system over...

Page 123

There are four interpolator coefficient #2 simms. They are identical, and support a video or key component path. Sm8b4 a channel y interpolator sm8b3 a channel c interpolator sm8b2 b channel key/y interpolator sm8b1 b channel shadow/c interpolator there are eight transform framestore simms. They are...

Page 124: Control Panel

Control panel a brief description of all control panel button groups and where they are located follows. Note: there are high voltages present inside the control panel. Never operate the control panel unless the case is securely closed. Menu buttons the menu buttons are the group of green buttons to...

Page 125

Menu screen layout & controls menu display you can adjust the menu display lcd brightness and contrast with the two thumbwheels set into the left side of the control panel. Submenu labels and controls a top level menu can have up to six submenu labels, shown on the right side of the menu screen. Bri...

Page 126

The keypad buffer the keypad buffer can show one of the following: empty – the keypad buffer is ready for use. You can enter a number or command from the numeric keypad, or press a pushknob to copy that pushknob value into the buffer. A value – pressing a pushknob enters the number in the buffer as ...

Page 127

Entering and modifying parameter values you can change menu values or settings several ways: turn the pushknob below its label. Enter a value in the numeric keypad, then press a pushknob to set the value. This applies to pushknobs that select sources; use the crosspoint number for a source, not its ...

Page 128

Program/preset buttons the program/preset button group includes the pgm pst, dsk, and ftb (fade-to-black) buttons. They are in the lower right corner of the control panel. Pressing the pgm pst or dsk button accesses control of the program, preset, and dsk fill buses. When either or both of these but...

Page 129

Transition control buttons the transition control button group includes four rows of buttons. Lit leds in the buttons indicate the current transition settings. The top row bknd, key 1, and key 2 buttons select the m/e bus(es) for the active transition. Any combination of these buttons can be lit sim...

Page 130

Quick keyframe buttons the quick keyframes button group includes the insert next, delete, modify , and undo kf edit buttons. All are located on the left side of the control panel, below the pushknobs. They only affect the current keyframe (the one that is currently highlighted in the timeline[s]), e...

Page 131

Timeframe effects editor buttons the timeframe effects editor buttons, located below the four pushknobs, include these buttons: insert, delete, remove, copy , modify, clear keyframe, start (rew), to, end (ff), this , all, and enter. Use these buttons to edit and modify effect keyframes. See section ...

Page 132

Delegation buttons the delegation buttons are toggles. Press one or more of the timeline 1 through timeline 4 buttons to activate or deactivate timeline editing in an effect. Double press one of the timeline buttons, or press one of the tl 1 through tl 4 softkeys in the display timelines submenu, to...

Page 133

Timeline buttons the timeline button group includes the previous, next, stop next , rev, and run buttons. All are located in the lower right corner of the control panel. Use these buttons to run effects and park on timeline effect keyframes in the work buffer. The stop next button lights when the ti...

Page 134: The Status Menu

The status menu you can see the current state of every major function in the 8150 at a glance by pressing the blue show status button below the softkeys on the right of the menu display. This menu is continually updated in real time, and shows the current state of all indicated parameters. This menu...

Page 135

Step 1: power down the 8150 signal chassis. Remove the integral front cover/air filter to access the 8150 switcher board. Use the accom supplied tool to extract the switcher board from the chassis and lay it on a clean, static free, grounded work surface. Note: seating the sub-board requires moderat...

Page 136

Autotrans this box shows the current duration values for auto transitions on the m/e bus, pgm/pst bus, and for fade-to-black (ftb) transitions. Fortune press this softkey to display an inspirational message. Press show status while in this menu to clear the fortune display. The status menu 8150 tech...

Page 137: Introduction

Section 5 engineering setup you can set most of the 8150 engineering parameters with the control panel. This makes 8150 setups easier to make and recall, since there is no need for time consuming manual adjustments in the signal chassis. Introduction this section covers the three menus that control ...

Page 138: Engineering Menu

Engineering menu press the green eng menu button to bring up the engineering menu. The softkeys on the right side of the menu display call up submenus that adjust communications, input and output parameters, and miscellaneous settings. Use the software update softkey to install new system software. ...

Page 139

Communications submenu the communications submenu lets you set up the serial communications ports. These ports, are labeled serial 1, serial 2, and serial 3 (linc) on the back of the signal chassis. Each port is independent, and all can communicate simultaneously. See section 3 – installation for mo...

Page 140

Since the gvg model 200 switcher does not support preview switching, some edit controller manufacturers do not support this function in their gvg 200 protocol. If this is the case with your editor, you should use accom a82/a83 protocol or gvg model 1000 protocol to control the 8150. Either of these ...

Page 141

If the internal dve board is not installed, you can have up to two external dves connected to the 8150 for effects looping purposes, although you can perform only one effects loop at a time. For routing purposes, a dve connected to aux 1 and 2 is called dve 1, and a dve connected to aux 3 and 4 is c...

Page 142

Have a different delay than the aux 3 and 4 outputs. Combiner on forces all four aux outputs, and therefore both aux ref outputs, to the timing of the aux outputs used in a dve effects loop. See the discussion later in this section for a step-by-step description of setting up an effects loop. Note: ...

Page 143

The luma pushknob sets a luminance value, in the range 0 percent (black) to 100 percent. The sat pushknob sets the chroma saturation value in the range 0 percent (monochrome) to 100 percent. The hue pushknob adjustment ranges from +/- 720 degrees. Input bits set the bit resolution of the selected in...

Page 144

Use the input number pushknob to select the physical input number. This number corresponds with the input number on the signal chassis, not the crosspoint button assignment. Even numbered inputs have a master/slave pushknob that the odd numbered inputs do not have, as described later. The format pus...

Page 145

Digital signal at the 4:4:4 sample rate for use as a chroma key source with the optional 4:4:4 chroma keyers. This feature is automatically enabled only when both of the following conditions are met: at least one keyer is set as a chroma key in the main submenu with chroma 444 selected as its key ty...

Page 146

Note: these pushknob adjustments should not replace output level adjustments at the source. They are intended only to compensate for minor non-unity gains in a video system. H phase offsets this softkey accesses the h phase pushknob, which lets you make minor corrections to the horizontal picture po...

Page 147

Setting appears identical to the adapt gph mode; in pal systems, there is a noticeable difference between the two. Adapt gph – this is an adaptive combination of notch and comb modes (see below) that has a low noise threshold. Use this for video that comes from computer graphics, character generator...

Page 148

More proc adjust (h phase/ofs) press this softkey to access controls for adjusting the horizontal position of the active picture, as well as adjusting the dc offsets of the chrominance components of the decoded input video. Use h phase to adjust the horizontal position of the active picture relative...

Page 149

Proc adjust (gain/pedstl) press this softkey to access controls for adjusting levels for the analog key input. Use key gain to adjust the level of the key input. The range is –50 to +150 percent of nominal. Use pedestal to adjust the black offset of the key input. The default setting of 0.00 assumes...

Page 150

Output submenu this submenu has adjustments for the 8150 serial digital outputs. The menu display varies depending on the output module installed, as covered in the following discussion. Output delay this softkey appears only if the enhanced (frame delay) output module is installed (some 8100s and a...

Page 151

Output bits press this softkey to set the bit resolution for the serial digital outputs. If the original output module is installed (8100s only), there is one control for the combined main outputs (program 1, program 2, preview, aux 1, and aux 2) and a separate control for the aux 3/4 output pair, i...

Page 152

V blanking this softkey appears only if the enhanced (frame delay) output module is installed (some 8100s and all 8150s). Press v blanking to set the vertical blanking width of the program 1 and 2, preview, and aux 1 and 2 outputs. Dip switches set the vertical blanking widths for the original outpu...

Page 153

All 8150s), some outputs may have no vertical delay, but the horizontal phase control still affects all outputs. Key mode press this softkey to select the type of signal for the preview, aux 2, and aux 4 outputs. Because of the way that the 8150’s m/e and dsk processors perform key compositing, the ...

Page 154

Miscellaneous submenu press this softkey to bring up the miscellaneous submenu, which lets you select the line standards, aspect ratio, lamp saver delay, and aux output usage if the dve board is installed. Video standard toggle this softkey to select the 525-line or 625-line standard for the system....

Page 155

Display this softkey toggles day and night. Day mode displays the menus in dark text over a light background for legibility in bright environments. Night mode displays the menus in light text over a dark background for reduced glare in dark environments. Set this according to your preference. Timing...

Page 156

8150 is consistently "behind" or "late" relative to other devices in the system. This is a "trial and error" adjustment, but once set, you should not need to change it for a given edit controller. Type the time code offset value first, then the command delay value, then press the edit const pushknob...

Page 157

Use the field ref pushknob to select the field on which the transitions are executed: either – executes a cut or begins a transition at the boundary between the current field and the next, whether it is field 1 or field 2. This is the default setting. F1 – executes a cut or begins a transition only ...

Page 158

Generator, and framestores 1 and 2. A "delayed source" is defined as a source in the 8150 that is delayed by internal processing, i.E., m/e program, m/e preview, wipe pattern, and key monitor. Note that the dve video and key outputs are considered direct sources if both dve video inputs are fed by d...

Page 159

Lamp saver this softkey sets the delay (time out) for the lamp saver feature. If there is no control panel activity (no button presses or fader bar or joystick movement) for the specified duration, the system shuts off the incandescent lamps and leds in the control panel buttons. Set the delay in mi...

Page 160

Software update submenu use this submenu to install a software update from accom. Note: software updates from accom always include installation instructions. Always read the instructions before attempting to install new software. The procedure may require other system changes before the software ins...

Page 161

Note: there are two different versions of chassis software on the update diskette; one version (crate. Bin) is for the 8150 without the dve cpu interface sub-board installed, and the other version (turbo.Bin) is for the 8150 with the dve cpu interface sub-board installed. The 8150 automatically reco...

Page 162

Diagnostics submenu this submenu lets you perform tests on the control panel. Normally, you will not use it, unless you suspect a fault in the control panel. Note that the 8150 "sees" when you press menu and crosspoint buttons while in this menu, just as it does normally. Hold down the lamp test sof...

Page 163

You can add your own mouse or mouse pen for drawing masks and controlling wipes. The 8150 also supports using an external pc at keyboard for naming sources and disk files. The diagnostics submenu lets you verify communications between the 8150 and a mouse and/or keyboard. The "mouse" line lets you v...

Page 164: Personality Menu

Personality menu press the personality menu button to bring up this menu. You can use this menu to name and assign inputs, assign functions to the user keys (function buttons), assign gpi input functions, enable remote ports, and select preview monitor overlays. You can save and recall all settings ...

Page 165

Use the cursor pushknob to move the cursor into the naming box (if you do not have an external pc at keyboard to name the inputs). Turn the cursor pushknob to move the cursor in the naming box (above the pushknob label); push it to backspace (with delete) through the name. Turn the character pushkno...

Page 166

Input assign submenu the input assign submenu displays the bus crosspoint assignments and lets you set which sources appear at which crosspoint buttons. This menu shows two bus rows of nine boxes that represent the crosspoint buttons on the control panel. The top row represents the primary crosspoin...

Page 167

User keys & miscellaneous submenu the user keys & misc submenu lets you record macros (commonly used button-press sequences), select certain menus for automatic recall, and disable or enable the undo menu button. You can assign macros of up to 50 button presses to the blue function buttons (f1, f2, ...

Page 168

Hint: it is often helpful, especially when recording long macros, to create a script to follow, since you cannot edit macros after recording them. Step 3: if the user keys & misc submenu is still active, press the stop softkey to complete the macro recording. If another menu is active, you can press...

Page 169

Toggle this softkey to enable and disable the undo menu button. With this button enabled (the default), pressing undo menu steps backward to the last button pressed and "undoes" button presses and menu settings. You can "undo" all button presses made since you enabled this feature. If you step back ...

Page 170

Gpis submenu the gpis submenu lets you assign functions to the eight input gpis. A gpi (general purpose interface) is simply an active-low ttl pulse or contact closure that is output by one device to trigger a function in another device. See section 2 – installation for information on physically int...

Page 171

The functions available for gpi input triggers appear in the lower list box. Input gpis can trigger the following functions: – no function. Autotrans (current) –executes the currently active transition, just like pressing the auto tran button. Cut (current) – cuts the currently active transition, ju...

Page 172

Freeze/passthru fs #2 switch – toggles the state of framestore 2 to its opposite, just like toggling between the framestore #2 mode and framestore #2 freeze softkeys in the framestore menu. F1 , f2, f3 – executes the macro currently assigned to a user key, just like pressing one of these buttons (f1...

Page 173

Many dves have two video inputs, corresponding to a "front" side and a "back" side. The dve typically performs a switch internally when the transformed picture rotates from its "front" side to its "back" side or vice versa. If you are feeding the dve from a switcher, this would normally require four...

Page 174

In a video combiner, this potential timing discrepancy could cause a problem. For this reason, there is a control in the engineering menu input submenu that forces all four aux bus outputs to be zero timed to each other, again according to the "latest" source assigned to any aux bus. In this submenu...

Page 175

Step 2: to configure the 8150 gpi inputs, press the gpis softkey in the personality menu. Use the gpi list pushknob to scroll the list and highlight the gpi input number to which you want to assign the front/back switch function. Step 3: use the selection list pushknob to scroll the list of gpi func...

Page 176

It. Rotate the dve video so that the front and back sides alternate on screen. The sources you selected for front and back should appear in the dve at the appropriate times. Also, if the dve is equipped with a key channel and it is turned on, you can press the crosspoint button assigned to the dve k...

Page 177

Step 4: press the events softkey. Turn the select gpo pushknob to select gpi 1. Step 5: press the toggle gpo softkey. Note that the gpo select display changes from none to 1– – – – – – –. This indicates that gpi output 1 is selected. Step 6: turn the select gpo pushknob to select the gpi 4 output, a...

Page 178

Remote port enables submenu this submenu lets you enable and disable the remote ports. See the installation section for more information on setting up these ports. Port 1 toggle this softkey to enable/disable the port marked "serial 1" on the back of the signal chassis. On is the default. Port 2 tog...

Page 179

Preview monitor overlays submenu the preview monitor overlays are tools for picture conformation and composition. These overlays appear only in the preview output. Safe action toggle this softkey to enable the safe action area boundary, the safe title area boundary, or both. The safe action boundary...

Page 180

Reference lines toggle this softkey to enable reference lines, which are useful for placing screen objects precisely. The position values default to 0 for the exact center of the screen. Position values align with the grid overlay pattern; integer position values coincide with the fixed lines in the...

Page 181: Disk Drive Operations

Disk drive operations press the disk menu button to access all 8150 floppy disk operations, except software updates. These you can control from the engineering menu, as described earlier in this section. The 8150 uses a 3.5" floppy disk drive built into the right side of the control panel, an option...

Page 182

Step 3: press the time softkey and select the current time with the hour (00-23) and minute pushknobs. The 8150 uses a 24-hour clock, where midnight is 00:00, 6 am is 06:00, noon is 12:00, and 6 pm is 18:00. Step 4: after entering the current date and time, press the date & time softkey. This enters...

Page 183

Creating disk subdirectories step 1: insert a formatted floppy into the internal disk drive or the external drive, if connected. Step 2: press the directory softkey to bring up the directory submenu. Press the make directory softkey on the left side of the display. Step 3: you can use a standard pc ...

Page 184

File type file size in bytes eff 9796 tim varies with number of keyframes wip 660 ccr 664 per 3552 eng 1552 tif varies with image content yuv 699,840 (525) or 829,440 (625) y10 874,800 (525) or 1,036,800 (625) key 708 mat 348 the ability to save full frame images to disk is a powerful feature. The y...

Page 185

Step 2: press the save recall softkey to bring up the save recall submenu. Press the save softkey on the left side of the display. Step 3: if the external floppy disk drive is connected or the hard disk drive is installed, use the drive softkey to the select the drive to which you want to save the f...

Page 186

Step 5: you can use a standard pc at keyboard to assign an 8-character name (dos compatible) to the file. If a pc at keyboard is not available, you can name the file with the cursor and character pushknobs. Use the cursor pushknob to move the cursor in the naming box. Turn the character pushknob to ...

Page 187

Deleting files from disk you can use this function to delete unwanted or unneeded files from a floppy disk. Note: the 8150 does not have an "undelete" function. After deleting a file, you cannot use the 8150 to bring it back. However, the "undelete" facility on many pcs should let you recover delete...

Page 188

Adding comments to a disk file you can add comments of up to 80 characters to each 8150 disk file. The file must already be saved on the disk before you can add comments to it. You cannot save comments to a file that you have not yet saved. You also cannot add comments to an image (tif, yuv, or y10)...

Page 189

Saving multiple disk files with one command to save more than one register of the same type to the disk, you can specify a range of registers to save. All registers in this range are saved with a common file name, to which the 8150 adds a two digit number according to each register’s place in the ra...

Page 190

Name is closings.Tim, the files on disk appear as closin01.Tim, closin02.Tim, etc. Step 5: press the confirm softkey. This saves all registers in the specified range to the disk with the file name that you entered, including the two digit number as described above. The menu prompts when it is done. ...

Page 191

Step 4: turn the file list pushknob to select the first file of the range that you want to recall. That file is highlighted, and in addition, a range of files below the first file is highlighted, indicating which files will be recalled into the specified range of registers. You cannot "mark" or othe...

Page 192: The Disk Menu

The disk menu this section describes each control in the disk menu. You can use this menu to format disks, save, recall, and delete files, add and display file comments, and set the system time and date. Press the green disk menu button to bring up the disk menu. Keypad internal external drive comme...

Page 193

Save recall submenu use the save recall softkey to name, save, recall, and add or read comments on disk files. Drive this softkey selects the built-in disk drive (internal), an optional floppy drive connected to the rear of the control panel (external), or an optional 1gb hard disk drive (hard drv) ...

Page 194

Save press this softkey to name and save a new file to the disk. The register number pushknob selects which register, if applicable, you want to save to disk. You can specify a range of registers by typing the first number in the range, followed by the decimal point, followed by the last number in t...

Page 195

Directory submenu press the directory softkey to create, remove, or change directories on the disk drives. Drive this softkey serves the same function as in the save recall submenu. Make directory this softkey creates a new directory on the floppy disk or optional hard disk. The cursor and character...

Page 196

Delete copy submenu use the delete copy softkey to delete unwanted files from a disk, or to copy files from one disk to another. Drive this softkey serves the same function as in the save recall submenu. From press this softkey to bring up the file type and file list pushknobs. Use the pushknobs to ...

Page 197

Delete press this softkey to access the file type and file list pushknobs, which let you select a file to delete. See the tutorial earlier in this section for a step-by-step procedure. Confirm press this softkey to execute the current command, in this case, a "copy file" or "delete file" command. Wa...

Page 198

Format submenu press the format softkey to format a 720kb or 1.44mb floppy disk with the 8150 floppy disk drive, or to format the optional 1gb scsi hard disk drive. The 8150 automatically senses the floppy disk density (dd = 720kb, hd = 1.44mb) and formats it accordingly. You cannot format a 1.44mb ...

Page 199

Miscellaneous submenu use the misc softkey to set the time and date for the 8150’s real-time clock, which the 8150 uses to time/date "stamp" all files saved on the disk. Date press this softkey to enter the current date. Use the month, day, and year pushknobs to set the real-time clock to today’s da...

Page 200

Assembly removal /replacement this section discusses the procedures for removing and replacing the power supply and backup battery in case of failure, as well as the procedure for disassembling the control panel. Power supply assembly removal/replacement the 8150 uses a todd nmx-504-1205v 500 watt f...

Page 201

Step 4: unplug the two way power fail cable from motherboard connector j20. Step 5: disconnect the 3-way ac harness on the right hand side of the power supply from the ac input harness at the rear of the chassis. Step 6: remove the two m4 flat head screws that secure the power supply tray to the fro...

Page 202

Step 9: remove the four flat head screws that secure the power supply to the tray. Slide the power supply away from the front of the tray, loosen the lugs at the front of the power supply, and remove the ac harness. The harness wires are color-coded as follows: power supply ac terminals wire color a...

Page 203

Step 15: reconnect the two power harnesses and the power fail cable to the motherboard. The 12-way connector mates with j16, the 16-way connector mates with j17, and the two-way connector mates with j20. Warning: the motherboard has male mating connectors for the circuit board assemblies. Though the...

Page 204

Step 1: the main +5vdc output and the -5.2vdc output do not require a minimum load for proper regulation. However, the +/-12vdc outputs require a 20 percent minimum load to regulate properly. Since those outputs are rated at 10 amps, a 20 percent load draws 2 amps. If you need to adjust the +/-12vdc...

Page 205

Backup battery removal/replacement the 8150 uses a sealed 6v lead-acid battery to power and refresh the on-board 8mb dram when the 8150 is not powered. Because of its size, the backup battery is located on the floor of the chassis, not on the switcher board. Change the backup battery, if needed, as ...

Page 206

Step 5: remove the wiring harness from this battery and install it on the replacement battery. You may want to check for continuity of the red lead, as it has a fuse. If there is no continuity, replace the fuse with a 3.5 amp in-line fuse (accom p/n 2000-0023). Connect the black wire (gnd) to the bl...

Page 207

Control panel disassembly and assembly the 8150 control panel requires little or no access to its internal sub assemblies over the course of normal operations and/or maintenance. However, if you need to get inside the control panel for any reason, follow this a step-by-step procedure. The only tool ...

Page 208

Step 5: tilt the top edge of the control panel lcd panel toward you, letting the bottom edge rest on the bottom edge of the control panel. Inside the control panel, there are four cables that you must disconnect from the cpu assembly if you want to completely separate the two control panel sections....

Page 209

Step 5: invert the control panel so that it faces up. You may now reconnect it to the 8150 signal chassis. Make sure the following cables are reconnected: the chassis communications cable the dc power cable the pc keyboard cable (if installed) the mouse cable (if installed) the external floppy disk ...

Page 210: "preread" And The 8150

"preread" and the 8150 some digital vtrs offer a "preread" or "read before write" feature. This function takes advantage of the fact that, in a digital vtr, the "stunt motion" playback heads are physically ahead of the erase and record heads for each video track. In normal play mode, the stunt motio...

Page 211

Vtr setups for insert and preread editing this discussion covers the settings needed on certain digital vtrs for proper viewing of editor controlled insert and preread edits. Digital betacam vtr settings if you are using a digital betacam format vtr, for normal insert editing or for preread editing,...

Page 212

Step 7: for normal insert editing, toggle the confidence on/off button on the front control panel to light the led, and toggle the pb.Ee pb button to light the pb led. This forces the vtr to output off-tape video in all modes except standby off. For preread editing, press the preread on/off button t...

Page 213: Effects Loop Processing

Effects loop processing conceptual background information while keying, it is often desirable to manipulate the processed key and fill signals in a dve or other device before combining them with the background. Traditionally, this involved performing the key on one keyer, sending the processed key a...

Page 214

There are two types of 8150 effects loops. The first sends the processed key and fill of keyer 1, keyer 2, or the dsk to the dve, and returns it to the same keyer. The second type lets you perform an m/e background a/background b transition (mix, wipe, or nam), composite keyer 1 over this mix, and s...

Page 215

Note: since the m/e processor and the pgm/pst/dsk processor share the effects loop return path, you can enable only one effects loop at a time. However, if you have four aux outputs installed, you can use them to feed two different dves to create different effects loops, as long as they are not used...

Page 216

The engineering menu input submenu effects loop inputs softkey has two pushknobs that select dve video and key inputs. Note that there are independent settings for dve 1 and dve 2, to support two pairs of aux outputs as described above. Entering the input numbers for the dve(s) here tells the 8150 t...

Page 217

Dve effects loop inputs must be the video and key outputs of the video combiner, and the other pair of dve effects loop inputs must remain set to 0. In any effects loop mode, the dve video and key re-entries are not correctly timed for use as direct sources in the 8150. They are timed properly only ...

Page 218

Note: because the input timing window for an entire input module is changed, the dve video and key inputs must be connected to the same input module for effects looping to work properly. Step 5: this completes the connection and setup for a single external dve (for two external dves, see step 12). T...

Page 219

The background video, which you can select on the keyer 2 fill bus row. Step 10: to change the background video, select a different source on the keyer 2 fill bus. To change the video "inside" the dve, select a different source on the background a bus, or move the fader bar to transition to the back...

Page 220

Encoding the 8150 output (ntsc) the 8150 processes only component video, so does not provide composite outputs. If you are operating in the 525-line standard and need a composite output, you can use the accom a28 digital encoder to output composite digital and analog video for monitoring, recording,...

Page 221

If your 8150 does not have the frame delay output module, modify and connect the a28 for use with the 8150 as follows. If you do have the frame delay output module, you can use the a28 without this modification, as long as the 8150 output connected to the a28 is set to one frame delay. If your a28 w...

Page 222

Step 9: set dip switch u15q position 1 to on. This delays the a28 output sync and burst to match the 8150 delay; turn the switch off if you are feeding a source other than the 8150 to the a28. Step 10: reinstall the main board and option module(s) into the bottom chassis tray and reinstall the tray ...

Page 223

O/p ka and o/p kb (options g and h only): these are identical composite analog key outputs if option g is installed, or identical serial composite digital key outputs if option h is installed. Only use these if you are feeding a key signal to the a28 that matches the timing of the 8150 program or pr...

Page 224

I/p ka and i/p kb: use these inputs only if you are feeding serial component digital key signals to the a28 that are cotimed to the 8150 program or preview output. Note that the a28 encodes only one input key signal at a time. Step 12: connect power to the a28. Verify that a composite version of the...

Page 225

Section 6 system timing general timing considerations introduction using digital processing in a post production switcher lets you implement features that would be difficult, or at least very expensive, with a traditional analog switcher. Because the video is processed digitally, you can use feature...

Page 226

To any source sent to it via an 8150 aux output, provided that the destination device is referenced to the 8150 aux ref signal. Video encoders often require a black burst reference to add correct sync, burst, and blanking to the final composite output. The 8150 does not output a black burst signal, ...

Page 227

Aux output sources delayed by two lines any external input is immediately delayed by approximately two lines from its original timing due to the automatic input timing circuitry (-1/2 to + 2 lines from reference). This means that if an external input to the 8150 is routed directly out an aux output,...

Page 228

The program 1 and preview outputs are always delayed by 34 lines from reference, no matter what source is selected on them, unless set for one frame delay. Also, any aux output with the following sources selected is delayed by 34 lines from reference, as is the aux ref signal associated with that ou...

Page 229

Auxiliary reference the aux bus output is normally used as a router, feeding video and/or key sources out to a dve. The dve then feeds back into the switcher as the video and key source of a linear key. As mentioned above, the minimum delay from reference that an aux bus output can have is two lines...

Page 230

If aux bus outputs 1 and 2 are installed in your 8150, they have one of the three delay values described above, and they are always zero timed to each other. Similarly, if aux bus outputs 3 and 4 are installed, they have one of the three delays, and are always zero timed to each other, but not neces...

Page 231: 8150 Partial Parts List

Appendix a 8150 partial parts list part number description qty. Per system 1000-0009 bat,6v,pe6v6.5,portalac 1 1500-0028 display,14v lamp, v3250-028 44 1500-0033 disp,lcd,640x480 1 1600-0060 disk dr,sony,3.5" 1 1700-0002 fan,12v,42cfm,80mm 2 1700-0031 fan,guard,3 1/8" fan 2 1700-0046 power cord,#c-3...

Page 232

Part number description qty. Per system 8900-0247 fab,a51 disk drive cover 1 (option) 8900-0248 fab,a51 disk drive tray 1 (option) 8900-0904 fab,3u bezel,door power switch 1 8900-0932 fab,8100,top 1 8900-0933 fab,8100,stiffener,pcb 2 8900-0934 fab,8100,battery bracket 1 8900-0935 fab,8100,pcb handle...

Page 233

Part number description qty. Per system 9000-0528 cblassy,8100,a/c input harness 1 9000-0529 cblassy,8100,power fail 1 9000-0561 cblassy,8100,cp to chas 50ft 1 (option) 9000-0563 cblassy,8100,cp,che dispkbd l 1 9000-0571 cblassy,8100,cp to chas 100ft 1 (option) 9000-0572 cblassy,8100,ext fd chas int...

Page 234

Part number description qty. Per system 9400-0659 assy,5100,simm,line delay 1 (dve board subassembly) 9400-0660 assy,5100,simm,dsp ram 1 (dve board subassembly) 9400-0661 assy,5100,simm,coefficient #1 1 (dve board subassembly) 9400-0662 assy,5100,simm,coefficient #2 1 (dve board subassembly) 9400-06...

Page 235

Part number description qty. Per system 9500-0197 mech,8100,front panel 1 9500-0198 mech,8100,control panel 1 9500-0199 mech,8100,c/p, bottom 1 9500-0200 mech,8100,c/p, top 1 9500-0201 mech,8100,joystick assy 1 9500-0202 mech,8100,fader arm 1 9500-0204 mech,8100,ext floppy disk 1 (option) 9500-0241 ...

Page 236

8150 partial parts list 8150 technical guide a-6 appendix 9100-0212-04 - may 2000