- DL manuals

- Accu

- Chiller

- EQ Series

- Installation, Operation And Maintenance Manual

Accu EQ Series Installation, Operation And Maintenance Manual

Summary of EQ Series

Page 1

Copyright thermal care inc. 2010 eq series portable chillers installation, operation and maintenance manual.

Page 2

Table of contents foreword ............................................................................................................................................................................. 1 installation .......................................................................................

Page 3

Chiller construction ........................................................................................................................................................... 15 compressor ................................................................................................................

Page 4: Foreword

1 foreword the intent of this manual is to serve as a guide for placing your portable chiller in service and operating and maintaining it properly. This manual is supplemented as required to accommodate any special items that may have been provided for a specific application. The written information...

Page 5

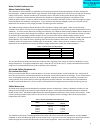

2 specific electrical schematic is shipped with the unit. Measure each leg of the main power supply voltage at the main power source. Voltage must be within the voltage utilization range given in table 1. Table 1 - voltage utilization range rated voltage utilization range 230 208 to 254 460 414 to 5...

Page 6

3 water cooled condenser lines (water cooled units only) the performance of the condenser is dependent on maintaining the proper flow and temperature of water through the heat exchanger. Insufficient water flow or high condenser water supply temperatures will result in the reduction of cooling capac...

Page 7: Start-Up

4 unsatisfactory chiller performance is poorly designed piping. Avoid unnecessarily long lengths of hoses or quick disconnect fittings that offer high resistance to water flow. When manifolds are required for water distribution, they should be installed as close to the use point as possible. Provide...

Page 8

5 1. Assure the main power source is connected properly, that it matches the voltage shown on the nameplate of the unit, and that it is within the voltage utilization range given in table 1. Electrical phase sequence must be checked at installation and prior to start-up for three-phase systems. Oper...

Page 9

6 8. (eq2 series only) make sure the freezestat is set appropriately for the operating conditions of the chiller. The freezestat is located inside the main electrical control panel. It should be set at 10°f (5°c) below the minimum chilled water temperature setting that the chiller will be operating....

Page 10: Controller Operation

7 once proper flow and temperature are achieved, press the stop button. The unit is now ready to be placed into service. Controller operation the chiller includes a microprocessor controller designed to perform all control functions directly from the front panel. When a button is depressed, a click ...

Page 11

8 power depressing the power button will switch the control power on or off. Control power must be initiated before either the start button or remote on/off contacts can start the chiller. Start depressing the start button will start the pump and enable the compressor. The compressor (and condenser ...

Page 12

9 high refrigerant pressure if the compressor discharge refrigerant pressure exceeds the setting on the high refrigerant pressure safety, the compressor and pump will shut off and the high refrigerant pressure led will be illuminated. Pressing the alarm reset button will reset the high refrigerant p...

Page 13

10 note: during normal operation, the compressor may cycle on and off. An internal anti-cycle time delay will not allow the compressor to restart for 2.5 minutes after it has cycled off. For air cooled units the fans will cycle off with the compressor. Partial load the partial load led will be illum...

Page 14

11 5. Press and release the start button to store the new selection into the controller memory. 6. Press and release the power button once to exit the function. Press and release the power button again to restore controller power..

Page 15

12 diagnostic error codes several different error codes may be displayed on the digital readouts labeled to process and set point. Most of the possible error codes indicate some type of failure in the microprocessor controller. Below is a list of the error codes. If there are any error codes other t...

Page 16: Control Options

13 control options return water temperature display this option allows the to process digital display to indicate to process or return water temperatures. To view the return water temperature, hold down the lower set point temperature and raise set point temperature buttons simultaneously. Once the ...

Page 17: Chiller Operation

14 when the spi option is purchased, there is a second set of dip switches included on the back of the main control panel. This set of dip switches is labeled "comm". All dip switch adjustments that follow are to be made on the comm set. Do not adjust any dip switches on the config set. Note: all di...

Page 18: Chiller Construction

15 the compressor is the heart of the refrigeration circuit. It takes the cool, low-pressure gas entering the compressor and compresses it, which creates the hot, high-pressure gas that exits the compressor. Since the compressor is not 100% efficient, some extra heat is added to the refrigerant as i...

Page 19

16 condenser water regulating valve (water cooled units only) a condenser water regulating valve is provided as standard. This valve is located in the condenser water piping at the outlet of the condenser. It regulates the flow of water through the condenser in order to maintain the high-pressure si...

Page 20

17 microprocessor controller controls the amount of hot gas used. Eliminating cycling of the compressor is extremely desirable as it significantly extends its lifetime expectancy. Reservoir the reservoir is mounted to the inside of the cabinet. The reservoir is made of polyethylene and is fully insu...

Page 21: Preventive Maintenance

18 coolant pressure switch this switch is located in the water piping at the inlet of the evaporator. It is designed to shut the unit down if there is insufficient coolant pressure at the evaporator and hence coolant flow through the evaporator. The switch is adjustable; however, no adjustments shou...

Page 22

19 7. With the main disconnect shut off and locked out, check the condition of electrical connections at all contactors, starters and controls. Check for loose or frayed wires. 8. Check the incoming voltage to make sure it is within 10% of the design voltage for the chiller. 9. Check the amp draws t...

Page 23

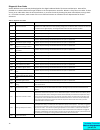

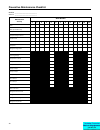

20 preventive maintenance checklist model # ___________________________ serial # ___________________________ maintenance activity week number 1 2 3 4 5 6 7 8 9 10 11 12 13 date clean condenser coil and inlet filter (air cooled units) temperature control pump discharge pressure coolant level glycol c...

Page 24: Troubleshooting

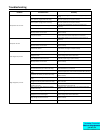

21 troubleshooting problem possible cause remedy compressor will not start compressor overload check supply voltage, start components (single phase), and wiring run capacitor (single phase units only) measure capacitance and replace if faulty start capacitor (single phase units only) measure capacit...

Page 25

22 problem possible cause remedy freezestat low flow through evaporator adjust flow to proper level freezestat control module check for proper setting, replace if faulty microprocessor control board replace if faulty freezestat sensor replace if faulty low pump discharge pressure pump running backwa...

Page 26: Charts And Drawings

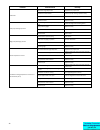

23 charts and drawings table 8 - eq air cooled chiller electrical specifications model voltage compressor pump condenser fan control circuit unit mca 2 rla 1 power (hp) fla power (hp) fla fla eq3a01 208/1/60 5.9 ¼ (.186 kw) 2.7 1 / 4 (.186 kw) 1.7 0.24 12.8 230/1/60 5.4 2.4 1.6 0.22 11.8 eq2a02 208/...

Page 27

24 table 9 - eq water cooled chiller electrical specifications model voltage compressor pump control circuit unit mca 2 rla 1 power (hp) fla fla eq2w02 208/3/60 9.5 1 (.745 kw) 3.9 0.24 16.8 230/3/60 8.6 3.6 0.22 15.4 460/3/60 4.3 1.8 0.11 8.2 208/3/60 9.5 2 (1.49 kw) 7.5 0.24 20.4 230/3/60 8.6 6.8 ...

Page 28: Pump Curves (60 Hz)

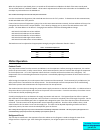

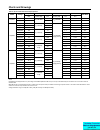

25 figure 2 - 60 hz pump curves (water) pump curves (60 hz) 0 10 20 30 40 50 60 70 80 90 100 0 5 10 15 20 25 30 pump flow (gpm) pump pressu re (psi) 0 20 40 60 80 100 120 140 160 180 200 220 0 10 20 30 40 50 60 70 80 90 100 110 pump flow (l/min) pump pressu re (ft ) ¼ hp positive discplacement pump ...

Page 29: Pump Curves (50 Hz)

26 figure 3 - 50 hz pump curves (water) pump curves (50 hz) 0 10 20 30 40 50 60 70 0 5 10 15 20 25 pump flow (gpm) pu mp pr es su r e (ps i) 0 20 40 60 80 100 120 140 160 0 20 40 60 80 pump flow (l/min) pu mp pr es su r e (ft) ¼ hp positive discplacement pump (eq3a01 ) 2 hp 2-stage 3 hp 2 hp 1 hp.