- DL manuals

- AccuLine

- Laser Level

- 40-6640

- Service Manual

AccuLine 40-6640 Service Manual

Prepared By: Peter Brandt Version: 08 – 20080415

Page

1 of 26

40-6640 Service Manual

40-6640

Self Leveling Laser Marker

SERVICE MANUAL

Main Instrument

Bracket

Item

Description

Page(s)

1.0

Overall Instrument Assembly

2 - 8

1.1

Central Unit Assembly

5

2.0

Component Assembly

9 - 15

2.1

Core Module Assembly

9

2.2

Base Plate Module Assembly

10

2.3

Platform Module Assembly

12

2.4

Bracket Assembly

15

3.0

Electrical Connections

17

4.0

Calibration

18 – 23

4.1

Checking Accuracy

18

4.2

Calibration Adjustments

19

4.2.1

Linearity (curvature) error

20

4.2.2

Oblique error

21

4.2.3

Height error

23

5.0

Alarm Adjustment

24

6.0

Troubleshooting Guide

25 - 26

Summary of 40-6640

Page 1

Prepared by: peter brandt version: 08 – 20080415 page 1 of 26 40-6640 service manual 40-6640 self leveling laser marker service manual main instrument bracket item description page(s) 1.0 overall instrument assembly 2 - 8 1.1 central unit assembly 5 2.0 component assembly 9 - 15 2.1 core module asse...

Page 2

Prepared by: peter brandt version: 08 – 20080415 page 2 of 26 40-6640 service manual 1. Overall instrument assembly 9 fig. 1-a item jlt part # description qty 1 ap1682 cross plate screw m2.5x14 4 2 ap1572 cross plate screw m2.5x10 4 3 ap1681 back housing 1 4 ap1683 front housing 1 5 ap1684 central u...

Page 3

Prepared by: peter brandt version: 08 – 20080415 page 3 of 26 40-6640 service manual general assembly instructions [note: refer to section 3.0 for information on electrical connections.] 1. Connect the battery compartment plug from the back housing (3) to the main circuit board. (see fig. 1 main cir...

Page 4

Prepared by: peter brandt version: 08 – 20080415 page 4 of 26 40-6640 service manual 3. Before moving the front and back housing units in place, position the rubber jacket (8) over the instrument so that the matching hole is located over the crank shaft and the on-off indicator light (from the power...

Page 5

Prepared by: peter brandt version: 08 – 20080415 page 5 of 26 40-6640 service manual 1.1 central unit assembly(ap1684) fig. 1-1-a item jlt part # description qty 5-1 ap1513 cross plate screws m3×8 4 5-2 ap1688 support seat ring 1 5-3 ap1689 core module 1 5-4 ap1690 cross plate tapping screws st2.9×1...

Page 6

Prepared by: peter brandt version: 08 – 20080415 page 6 of 26 40-6640 service manual general assembly instructions 1. Attach base plate module (5-5) to platform module (5-6) using the three cross plate tapping screws (5-4). 2. Snap on the support seat ring (5-2) making sure that the inside indentati...

Page 7

Prepared by: peter brandt version: 08 – 20080415 page 7 of 26 40-6640 service manual 4. Now attach the connecting circuit board to the underside of the supporting plate of the core module (5-3). The two bolts on the underside must first be removed and then used to attach the circuit board. See fig. ...

Page 8

Prepared by: peter brandt version: 08 – 20080415 page 8 of 26 40-6640 service manual alarm rod positioned inside alarm loop three screws used to attach circuit board fig. 1-1-g the central unit assembly can be disassembled using the reverse order described above..

Page 9: 2.1 Core Module Assembly

Prepared by: peter brandt version: 08 – 20080415 page 9 of 26 40-6640 service manual 2.0 component assembly 2.1 core module assembly regarding general assembly of core module note of caution this module should not be assembled by anyone other than professional service technicians with appropriate eq...

Page 10

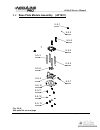

Prepared by: peter brandt version: 08 – 20080415 page 10 of 26 40-6640 service manual 2.2 base plate module assembly (ap1691) fig. 2-2-a see parts list on next page 5- 5- 13 5- 5- 10 5- 5- 11 5- 5- 12 5- 5- 9 5- 5- 8 5- 5- 3 5- 5- 7 5- 5- 6 5- 5- 5 5- 5- 4 5- 5- 2 5- 5- 1.

Page 11

Prepared by: peter brandt version: 08 – 20080415 page 11 of 26 40-6640 service manual item jlt part # description qty 5-5-1 ap1696 cross plate screws m2x10 2 5-5-2 ap1697 m2 lock washers 2 5-5-3 ap1698 support post type a (w. 1 hole through side of post) 2 5-5-4 ap1699 support post type b (w. 2 hole...

Page 12: 2.3

Prepared by: peter brandt version: 08 – 20080415 page 12 of 26 40-6640 service manual 2.3 platform module assembly (ap1692) the off-center hole needs to match the indentation circle on the bottom of the degree scale. Item jlt part # description qty 5-6-1 ap1706 lock ring 1 5-6-2 ap1707 wave-form gas...

Page 13

Prepared by: peter brandt version: 08 – 20080415 page 13 of 26 40-6640 service manual general assembly instructions 1. Using three cross plate screws, attach the bottom axle (5-6-7) into the bottom of the degree scale (5-6-6). 2. Place the rotation platform (5-6-4) onto the bottom axle (5-6-7). Plac...

Page 14

Prepared by: peter brandt version: 08 – 20080415 page 14 of 26 40-6640 service manual 5. Then push plug receptor down and attach #2 a/c receptor circuit board (5-6-9) using two cross plate screws (5-6-8). (see fig. 2-3-d . ) make sure that wires are fit into inside groove along edge of rotation plat...

Page 15

Prepared by: peter brandt version: 08 – 20080415 page 15 of 26 40-6640 service manual 2.4 bracket assembly (40-6356) fig. 2-4-a see parts list on next page. 9-8 9-10 9-4 9-12 9-6 9-7 9-2 9-1 9-5 9-16 9-11 9-14 9-13 9-15 9-12 9-3 9-9.

Page 16

Prepared by: peter brandt version: 08 – 20080415 page 16 of 26 40-6640 service manual item jlt part # description qty 9-1 ap1717 bracket 1 9-2 ap1718 cover board #1 1 9-3 ap1719 cover board #2 1 9-4 ap1720 cover board #3 1 9-5 ap1721 fastening knob 1 9-6 ap1722 magnet holders 2 9-7 ap1723 rubber pad...

Page 17

Prepared by: peter brandt version: 08 – 20080415 page 17 of 26 40-6640 service manual 3.0 electrical connections fig. 3 a fig. 3-a #1 main circuit board #4 alarm loop circuit board (outside ring) power source (batteries) #3 power switch circuit board #7 connecting circuit board #6 alarm switch circu...

Page 18: 4.0 Calibration

Prepared by: peter brandt version: 08 – 20080415 page 18 of 26 40-6640 service manual 4.0 calibration calibration is a process used to correct for accuracy and/or functional errors above and beyond those stated in published specifications. While manual-leveling, self-leveling, and automatic-leveling...

Page 19

Prepared by: peter brandt version: 08 – 20080415 page 19 of 26 40-6640 service manual a true and correct reference standard must first be established: 1. Use a wall surface 5 meters (16.5 feet) away from the level platform which supports the laser instrument. 2. Establish and mark a level horizontal...

Page 20

Prepared by: peter brandt version: 08 – 20080415 page 20 of 26 40-6640 service manual 4.2.1 linearity (or curvature) error. Either the horizontal or vertical line is not straight (i.E. There is curvature). Adjustment required: adjust the needed screws in the diagram below depending on which laser li...

Page 21

Prepared by: peter brandt version: 08 – 20080415 page 21 of 26 40-6640 service manual 4.2.2 oblique error. Either vertical or horizontal line is not plumb. Adjustment required: if the laser lines are perpendicular to each other and only a small adjustment is needed, adjust the hexagonal nut shown (f...

Page 22

Prepared by: peter brandt version: 08 – 20080415 page 22 of 26 40-6640 service manual fig. 4-2-f fig. 4-2-g remove plastic screw to provide access use 3 mm hexagonal wrench key if the lines are not perpendicular to each other or a larger adjustment is needed, the housing needs to be removed. The mai...

Page 23

Prepared by: peter brandt version: 08 – 20080415 page 23 of 26 40-6640 service manual 4.2.3 height error. Point “o” does share the same height as the laser output source of the instrument, but the height of the laser height needs to be corrected. Adjustment required: first attempt a small error adju...

Page 24: 5.0 Alarm Adjustment

Prepared by: peter brandt version: 08 – 20080415 page 24 of 26 40-6640 service manual 5.0 alarm adjustment after one or more calibrations have been completed, if may be necessary to adjust the alarm range. If the alarm rod is not centered within the alarm loop, make adjustments as follows: 1. Remove...

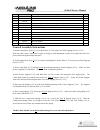

Page 25

Prepared by: peter brandt version: 08 – 20080415 page 25 of 26 40-6640 service manual 6.0 troubleshooting guide (see section 3 for visual display of circuit boards) no. Symptom cause corrective action low batteries. Recharge or replace batteries. On-off switch does not work. Replace on-off switch as...

Page 26

Prepared by: peter brandt version: 08 – 20080415 page 26 of 26 40-6640 service manual hairspring wire is broken replace the hairspring wire connecting wires between circuit boards #1 and #4 are broken repair connecting wires. Core connection wire to laser is cut replace the connection wire #1 main c...