- DL manuals

- Accuprint

- Printer

- AP30CL - 6000

- Service Manual

Accuprint AP30CL - 6000 Service Manual

Summary of AP30CL - 6000

Page 1

P p ap30cl - 6000 closed loop cooling high resolution printer service manual 94ms41 rev. C1 s/w ver 2.06 o.

Page 2

94ms41 rev. C1 s/w ver 2.06 this manual is designed for technical personnel and should only be used by authorized dealer service personnel. This manual is written to provide an understanding of the equipment, as well as a plan for troubleshooting..

Page 3: Contents

94ms41 rev. C1 s/w ver 2.06 0-1 0. Contents 1. Specifications crated dimensions ...................................................................... 1-1 shipping weight .......................................................................... 1-1 actual dimensions ...................................

Page 4

0-2 94ms41 rev. C1 s/w ver 2.06 type mode ................................................................................... 4-8 exposure statistics (elapsed hours) ............................................ 4-9 exposure statistics (total exposures) ......................................... 4-9 s...

Page 5

94ms41 rev. C1 s/w ver 2.06 0-3 10. Exposure trays mylar® replacement ................................................................ 10-1 if mylar® pulls out of the frame ............................................. 10-1 outer frame replacement .......................................................

Page 6

0-4 94ms41 rev. C1 s/w ver 2.06 blown fuse on pc board ........................................................ 13-14 lamp head signals .................................................................. 13-15 light function states ............................................................... 13-17...

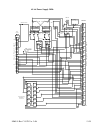

Page 7: Specifications

94ms41 rev. C1 s/w ver 2.06 1-1 1. Specifications 10.5" 92.5" 35" 38" 72" 45.5" 48.5" 45" crated dimensions length width height 102" 60" 80" 259 cm 152 cm 203 cm shipping weight crated 1760 lbs. 800 kg. Uncrated 1450 lbs. 659 kg. Actual dimensions cabinet welded heavy gauge steel construction with a...

Page 8

1-2 94ms41 rev. C1 s/w ver 2.06 intensity lamps can be operated at 6kw, 4kw and 2kw for the ap30cl-6000 typical room requirements 36" 36" 36" top view top view rear front electrical connections the printer operates on 208/240v 60hz, 3-phase, 3 wires and ground; 480v 60hz, single-phase, 2 wires and g...

Page 9

94ms41 rev. C1 s/w ver 2.06 1-3 • connect the main leads to the 4 position or 6 position terminal block and connect the ground lead to the single ground terminal (see next page for hook up). • reinstall the lower side door. • energize the main power circuit. You should hear the lamp head and power s...

Page 10

1-4 94ms41 rev. C1 s/w ver 2.06 cooling requirements minimum pressure and flow rate of the chilled water depends on input temperature. For proper cooling system selection, contact olec. ! Cl if water temperature and water flow do not meet the following specifications the unit will overheat, one or b...

Page 11: Cooling System

94ms41 rev. C1 s/w ver. 2.06 2-1 2. Cooling system connecting power to and checking the evaporator • place the evaporator flat on the floor. • connect the hose from the evaporator to the bottom of the rear panel drain. ! Cl make sure the hose end on the evaporator is lower than the bottom of the rea...

Page 12

2-2 94ms41 rev. C1 s/w ver. 2.06 connecting the chiller connecting chiller to printer: • mount the flow meter and temperature gauge assembly on a wall in the upright position. ! Cl the flow meter and temperature gauge assembly must be mounted level or the flow meter will not function properly. Inlet...

Page 13

94ms41 rev. C1 s/w ver. 2.06 2-3 connecting chiller to printer (cont.) upper heat-exchanger lower heat-exchanger 1 7 16 24 to system from chiller outlet 6 pl 3 pl 3 pl 20 19 air vent 2 pl 2 pl 1 to secure flow meter (item 24) to nipple (item 10) use hose clamps supplied with flowmeter. 2 cut tubing ...

Page 14

2-4 94ms41 rev. C1 s/w ver. 2.06 filling the closed loop system ! Cl if the closed loop system is not filled properly the unit will overheat, one or both lights sources will shut themselves off randomly under heavy usage and damage to the unit will be the result. • hook a hose to the bleed valve and...

Page 15

94ms41 rev. C1 s/w ver. 2.06 2-5 by a spring clip and should pull off easily, do not remove the spring clip from coils. Set the thermostat on the inside of the unit to 100°f (20°c) and turn the unit on. The flow meter should read no flow. Turn the unit off and reconnect one of the coils and turn the...

Page 16

2-6 94ms41 rev. C1 s/w ver. 2.06 closed loop cooling assembly (cont.) c 21 e 3 15 5 16 14 8 7 25 1 22 j d 2 17 a b 1 6 f h 11 17 14 13 17 18 10 18 20 1 g k 3 1 18 20 4 3 20 19 ref. 27 27 1 9 20 11 20 6 11 12 23 17 24 19 3 26 l 12 3 30 31 32 ref. Ref. Ref. 6 5 1 4 3 qty 2 1 item description weldment,...

Page 17

94ms41 rev. C1 s/w ver. 2.06 3-1 3. Integrator functions and features microprocessor-controlled light integrator with led display, 40 memories, battery backup, single button control, lamp statistics and self- diagnostics. The operator control panel is composed of two sections, the display board and ...

Page 18

3-2 94ms41 rev. C1 s/w ver. 2.06 u menu this key is used as the autostep indicator and for the continuous vacuum feature. Note: u menu special function the u key has the optional function to be used to set auto-step and continuous vacuum per memory in normal operating mode. The frame control switch ...

Page 19

94ms41 rev. C1 s/w ver. 2.06 3-3 feature quick reference the following feature descriptions appear in the exposure window while setting each feature. In order to select or setup the following features you must first be in the setup mode. [lock] lock level feature [code] lock code feature [2ual] 2 (t...

Page 20

3-4 94ms41 rev. C1 s/w ver. 2.06 operator control panel p the ap 30 heavy duty exposure system has a power key on the integrator. • press the p key to turn on the unit. • press the p key again after use, and the system will run through a 2 minute cool down cycle and then turn off all blowers. S stop...

Page 21

94ms41 rev. C1 s/w ver. 2.06 3-5 • press the p key on the integrator to power up the lights, the front switches, and the printer's computer system. Note: allow the printer a 5 minute warm-up period before any calibration procedures. This will allow for complete and accurate light level stabilization...

Page 22

3-6 94ms41 rev. C1 s/w ver. 2.06 example: let's say our 500 unit exposure gave us 600 mj. That means we got 1.2 mj per unit or a 1.2:1 ratio. The objective is to get a 1:1 ratio. To get that we would multiply our current calibration number of 500 by 1.2, 500 x 1.2 = 600. • since we are working with ...

Page 23

94ms41 rev. C1 s/w ver. 2.06 3-7 matching exposure surfaces • do a test exposure in the frame being calibrated to the reference frame. • determine the correction necessary to make each surface the same at the reference surface. If this is done with a step scale the correction is as follows. .15 dens...

Page 24

3-8 94ms41 rev. C1 s/w ver. 2.06 splitting steps a densitometer can be used to assist in determining a fractional difference in step scales. When measuring density, make several measurements to avoid being influenced by pinholes. Example original reference second scale a b • pick a step from the ref...

Page 25: Integrator Program Set Up

94ms41 rev. C1 s/w ver 2.06 4-1 4. Integrator program set up to enter the select mode note: this step must be followed in several of the program set ups. • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1,2,3t...

Page 26

4-2 94ms41 rev. C1 s/w ver 2.06 dim. Enter the lock level desired. • press the v key to set entry. • if the lock level is set for 2, 3 or 4, the exposure window will read [code] . Enter your 3 digit code. • press the v key. • press the 0 key. • press the v key. Note: if you want a higher lock level ...

Page 27

94ms41 rev. C1 s/w ver 2.06 4-3 setting or changing your lock code feature note: if you are setting the code you must know the existing code. Note: lock level must be set to 0 to program this step and reset when finished see lock level feature. • press the p key on the integrator to power up the lig...

Page 28

4-4 94ms41 rev. C1 s/w ver 2.06 • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1,2,3t 4 in sequence. The vacuum window will read [sel_] . This places you in the select mode. • press the 9 key five (5) times....

Page 29

94ms41 rev. C1 s/w ver 2.06 4-5 [spgt] press and release the e key until [spgt] appears in the exposure window. This places you in the split exposure option. • press the v key to cycle the split exposure mode on or off. • press the 0 key twice to exit this mode. Single surface mode the printer may b...

Page 30

4-6 94ms41 rev. C1 s/w ver 2.06 [sel_] press 1,2,3t 4 in sequence. The vacuum window will read [sel_] . This places you in the select mode. • press the y key once. The memory window will read [su] . [bcnt] press and release the e key until [bcnt] appears in the exposure window. This places you in th...

Page 31

94ms41 rev. C1 s/w ver 2.06 4-7 [auac] press and release the e key until [auac] appears in the exposure window. This places you in the automatic vacuum option. • press the v key to cycle the automatic vacuum mode on or off. • press the 0 key twice to exit this mode. Auto step mode note: this feature...

Page 32

4-8 94ms41 rev. C1 s/w ver 2.06 tray mode ! C the default tray speed is set at the factory to 5 seconds. Olec does not recommend changing this setting without consulting the olec factory. Damage to the transport can occur. • press the p key on the integrator to power up the light, the front remote s...

Page 33

94ms41 rev. C1 s/w ver 2.06 4-9 exposure statistics (elapsed hours) note: the exposure statistics should be reset to zero when the lamps are changed. Note: this provides the operating hours on the lamps in total and at each intensity since the last reset. This function should be used whenever the ex...

Page 34

4-10 94ms41 rev. C1 s/w ver 2.06 [ehi_] press the 2 key. The letters [ehi_] will appear in the vacuum window. The exposure window will display the number of exposures made at high power. [elo_] press the 2 key a second time. The letters [elo_] will appear in the vacuum window. The exposure window wi...

Page 35

94ms41 rev. C1 s/w ver 2.06 4-11 setting the light intensity low • press the i key to set intensity. Press i for the first time. The first led on the left indicates the intensity is set to low ( 1kw on 5kw units, 2kw on 8kw units). Medium • press: i for the second time. The first two leds light to i...

Page 36

4-12 94ms41 rev. C1 s/w ver 2.06 error handling system if an error occurs, the machine displays an error code to aid in troubleshooting. The error codes defined are: [err_] the message [err_] will appear in the vacuum window, and a number in the exposure window. Look up the number below for a descri...

Page 37: Diagnostics

94ms41 rev. C1 s/w ver. 2.06 5-1 5. Diagnostics output diagnostics one of the many advancements olec has introduced to the field is the ability of its equipment to run a self-diagnostic check. All computer- activated functions and all internal and external switches can be checked out on the integrat...

Page 38

5-2 94ms41 rev. C1 s/w ver. 2.06 functions table e function value 1 heat exchanger solenoids [0001] 2 blower on/off [0002] 3 upper vacuum pump o n/off [0004] 4 lower vacuum pump on/off [0008] 5 work light and nose section fans o n/off [0016] 6 motor direction control [0032] 7 frame motor o n/off [00...

Page 39

94ms41 rev. C1 s/w ver. 2.06 5-3 input diagnostics • switch check the switch check can be done while in the select mode. • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1 , 2 , 3 , then 4 in sequence. The vac...

Page 40

5-4 94ms41 rev. C1 s/w ver. 2.06 • lower tray in, frame switch closed, door and emergency switches closed. [0044] the exposure window should read [0044] . [0172] when the g button is pushed the value should change to [0172] . [0060] when the s button is pushed the value should change to [0060] . Typ...

Page 41: Lamp Changing Instructions

94ms41 rev. C1 s/w ver 2.06 6-1 6. Lamp changing instructions ! W the lamps and safety glass may be very hot and cause burns. Prior to changing the lamp, ensure the lamp head is turned off and allowed to complete its cooldown cycle. Olec recomends that every year you unplug your light, remove the sa...

Page 42

6-2 94ms41 rev. C1 s/w ver 2.06 reflectors and glass can substantially reduce light output. • wear the white lightweight fabric gloves that are provided and unpack the new lamp. Clean the lamp with the alcohol wipe included. • place each end of the new olite lamp (one end at a time) on the holders. ...

Page 43: Preventive Maintenance

94ms41 rev. C1 s/w ver 2.06 7-1 7. Preventive maintenance preventive maintenance daily (approximately 15 minutes required) • clean exposure frame glass and mylar. The exposure frame glass and mylar should be kept meticulously clean. Dirt and resist flakes on these surfaces will cause exposure defect...

Page 44

7-2 94ms41 rev. C1 s/w ver 2.06 ! C do not use silicone spray lubricants in the printer. • lubricate frame drive chain and check tension. • apply a light coat of machine oil to the exposure frame drive chain by rubbing an oil wetted rag along the chain. Do not wet the chain enough to cause the oil t...

Page 45: Vacuum System

94ms41 rev. C1 s/w ver 2.06 8-1 8. Vacuum system vacuum pumps description: the printer uses two 1/4-hp oilless rotary vane vacuum pumps, one for each exposure frame. Pressing the g button on the front nose assembly activates the pump for frame that is out of the cabinet. The vacuum gauge on the fron...

Page 46

8-2 94ms41 rev. C1 s/w ver 2.06 flushing option #1 this option requires two pipe nipples at least 4" (102 mm) long with 3/ 8 " npt threads on one end. • remove the filter elements from the front of the muffler box and screw the nipples into the same holes. • with the pump running, allow about 2 tbsp...

Page 47

94ms41 rev. C1 s/w ver 2.06 8-3 pump replacement vacuum pump replacement is straightforward. The left-hand pump controls the lower frame; the right-hand pump controls the upper frame. (left and right as viewed by the operator.) • open either the left or right side cabinet door, depending on which pu...

Page 48

8-4 94ms41 rev. C1 s/w ver 2.06 vacuum seal replacement a cut, torn or otherwise damaged vacuum frame seal will greatly inhibit, if not prevent, full vacuum. A bad seal can be lifted and peeled off the frame glass. If necessary, use a razor blade or other suitable item to remove any leftover seal ad...

Page 49

94ms41 rev. C1 s/w ver 2.06 8-5 vacuum seal replacement (cont.) • unless otherwise specified dimensions are in inches. Dwg. Per ansiy14.5 tolerances are: angles ±5 deg. .X±1 .Xx±.03 .Xxx±.010 .Xxxx±.0030. • clean glass perimeter. Press transfer tape onto glass. (as shown) trim tape along edge of gla...

Page 50

8-6 94ms41 rev. C1 s/w ver 2.06 glass photo tool (optional) • if the unit is equipped with the glass photo tool option you will have a third vacuum pump installed in the bottom of the unit.. • see section vacuum pumps and section tubing/fitting replacement for vacuum problems. • the vacuum pump used...

Page 51: Nose Assembly

94ms41 rev. C1 s/w ver 2.06 9-1 9. Nose assembly removing the nose • turn unit off, allow the unit to complete its cool down cycle and disconnect power. • while standing in front of the unit locate and disconnect all multi-pin connectors and vacuum lines below the nose on the right side. Nose tower ...

Page 52

9-2 94ms41 rev. C1 s/w ver 2.06 replacing the s and g buttons • slide the nose out (see section removing the nose) but it is not necessary to completely remove it, the nose just needs to be slid out far enough to access the switches. • use a small screw driver inserted between the switch and the she...

Page 53

94ms41 rev. C1 s/w ver 2.06 9-3 work lights note: the work lights are controlled by a rocker switch on the underside of the right front corner of the nose. If the work lights are not turning on check the rocker switch and power to the switch. The work lights receive their power from the autoformer i...

Page 54

9-4 94ms41 rev. C1 s/w ver 2.06 nose assembly drawings bottom view 56 4 pl 46 43 50 11 9 9 11 10 50 43 46 4 pl 2 pl 10 button, green "go" barrier harness, sw, operator ov45 removed emergency pushbutton actuator button, yellow "stop" overlay, rail cover, ap30 autoformer,120/208/240v50/60hz lamp, yell...

Page 55

94ms41 rev. C1 s/w ver 2.06 9-5 nose assembly drawings (cont.) b b a a 18 2 pl 45 1 44 3 pl 3 pl 4 pl 2 pl 35 5 pl 47 41 44 41 33 47 33 41 44 38 55 54 42 45 4 3 16 14 16 51 39 37 4 pl 4 pl 40 48 49 3 pl 2 pl 17 15 2 5 6 7 35 5 pl 4 pl 46 43 36 46 36 43 4 pl ref. 34 6 pl 35 34 14 pl top view continue...

Page 56

9-6 94ms41 rev. C1 s/w ver 2.06 nose assembly drawings (cont.) stop go (bot. Pos.) (top pos.) view c c ref. 4 pl 4 pl 1 30 detail b 10 pl 58 22 10 pl 10 pl detail a 8 32 8 32 29 57 53 13 21 view b b view a a 2 pl 2 pl 26 23 25 24 2 pl 2 pl 31 19 20 52 detail a 2 places red blk blk red ref. 27 30 det...

Page 57: 10. Exposure Trays

94ms41 rev. C1 s/w ver 2.06 10-1 10. Exposure trays mylar® replacement • close the mylar® frame and open the six cam latches. • remove the inner mylar® frame and position the pre-cut mylar® sheet into the frame, make sure that the mylar® is overlapping on all side. Closed position open position cam ...

Page 58

10-2 94ms41 rev. C1 s/w ver 2.06 screws through the hinge into the frame make sure the frame is 1 / 32 " to 1 / 16 " above the top of the hinge to avoid the possibility of damaging the glass, then tighten them down. End view bar hinge outer frame allen screw 1/32" to 1/16" • loosen all the allen hea...

Page 59

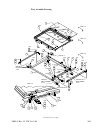

94ms41 rev. C1 s/w ver 2.06 10-3 tray assembly drawing 6 pl 42 20 43 ref. 1 2 pl 19 51 35 33 3 pl 18 9 pl view aa 30 7 ref. Detail b front bearing assy. Detail c front wheel assy. Detail a w/connector see detail d rear wheel assy. 4 pl 9 4 pl 2 pl 2 pl 2 pl 4 pl 20 6 40 37 38 36 2 pl 39 24 2 pl 3 2 ...

Page 60

10-4 94ms41 rev. C1 s/w ver 2.06 tray assembly drawing (cont.) 14 25 34 31 26 32 17 34 25 15 32 16 26 31 detail a detail c detail b detail d qty item description part no. Tray ap30/ov33 1 11d1892a02 1 55sw50-b switch, magnetic inte. 1 2 light block guide mount 12d1737a62 43blb12 linear bearing 1/2" ...

Page 61

94ms41 rev. C1 s/w ver 2.06 10-5 mylar frame assembly outer frame assembly see view a a view add washers as needed to adjust catch to latch latch / handle assembly side view 19 2 pl 32 2 pl 1 3 2 pl 20 8 pl 15 ref. 2 ref. 17 6 2 pl 21 6 pl 7 2 pl 12 8 2 pl 14 2 pl 15 apply gasket all around frame as...

Page 62

10-6 94ms41 rev. C1 s/w ver 2.06 inner frame assembly scale: 1/1 view b 28 nsi 6-32 flexlock nut 41-06nlm 2 2 41-06wls nsi #6 split lock washer 27 screw, shldr ø.187 x 1.25 17 2 41-0bsbl1.25 1 44hdl03 handle, 6 inch mount, magnetic switch 11d2971a71 see viewb 26 nsi 6-32 x 3/8 phil blk 41b06pps.37 2...

Page 63

94ms41 rev. C1 s/w ver 2.06 10-7 gas strut removal each frame assembly has two gas struts to support the top coversheet frame when it is opened. • open the frame with the strut to be replaced. • remove the retainer from both ends of the strut. • pull the strut from the retaining ball mounts. • insta...

Page 64

10-8 94ms41 rev. C1 s/w ver 2.06 frame glass replacement note: wear leather gloves and safety glasses when performing this procedure. • open the frame to be changed. • remove the two glass retaining screws on the front edge of the glass frame. • push up on the glass from under the frame. Hold it up ...

Page 65: 11. Center/drive Assembly

94ms41 rev. C1 s/w ver 2.06 11-1 11. Center/drive assembly center/drive assembly diagram 4 pl drive motor assy. Detail a. 74" 4 pl 2 pl 2 pl chain tensioner assy., detail b. 2 pl 8 pl 2 pl 4 pl 2 pl timing switch assy. Detail c. 18 pl 12 pl 1 32 34 3 40 33 9 8 34 35 47 42 2 15 39 37 36 46 33 8 9 40 ...

Page 66

11-2 94ms41 rev. C1 s/w ver 2.06 center/drive assembly diagram (cont.) 42 43 10 11 12 18 17 16 15 14 13 19 20 21 22 23 24 30 29 28 27 26 25 31 32 33 34 35 36 41 40 39 38 37 9 part no. Description qty item nsi #10 flat washer black ns #10 lock washer split nsi 8-32 5/8 flat head 82 41-10wls 41b10wfr ...

Page 67

94ms41 rev. C1 s/w ver 2.06 11-3 frame transport system the printer has two aluminum exposure frame assemblies. Vacuum for frame evacuation is drawn through two ports in the glass; one at each of the rear corners. The top coversheet frame is hinged in the back, with a gas strut on each side that hol...

Page 68

11-4 94ms41 rev. C1 s/w ver 2.06 • open the left side sliding door on the printer and locate the drive motor at the left rear corner of the cabinet. • loosen the two set screws which lock the hex nut to the motor shaft. • adjust the hex nut until the minimum setting is found that provides frame move...

Page 69

94ms41 rev. C1 s/w ver 2.06 11-5 [0096] press the 6 key again: upper tray should move in, the vacuum window should read [0096] . • set volt meter for vdc and measure across pins 5 & 6 on motor speed connector. Adjust the 'slow' pot on the control box to read 25 to 32 vdc. Notice that the frame moves...

Page 70

11-6 94ms41 rev. C1 s/w ver 2.06 light block assembly light block assembly drawing 5 9 3 38 28 33 33 26 2 37 34 37 34 26 33 wheel assy. Both sides see detail c 4 pl 8 pl torsion spring assy. Both sides see detail b. Ref. 5 pl 5 pl 26 33 2 9 33 26 21 37 4 33 26 wheel assy. Both sides see detail c 4 p...

Page 71

94ms41 rev. C1 s/w ver 2.06 11-7 light block assembly drawing (cont.) 39 38 37 36 35 34 30 29 28 27 33 32 31 17 6 5 4 3 2 1 14 15 16 8 9 10 11 12 13 7 22 21 20 19 18 23 25 26 24 40 11d2492a06 41-12pps.50 41-f5wfr 41-10wls 41b08wfr 41-14nhx 41bf1shc.37 41-40wfr 41b06pps.37 41-06wls 41-06pps.75 41-06n...

Page 72

11-8 94ms41 rev. C1 s/w ver 2.06 • use the new mounting bracket. • insert two 8-32 x 0.62" screws and secure to mounting bracket with two 8-32 kep nuts. • use the 1 / 2 -13 x 2.0" shoulder screw and large 1 / 2 " washer and insert to the hole in the mounting bracket. Place the mandrel over the shoul...

Page 73: 12. Diagrams

94ms41 rev. C1 s/w ver 2.06 12-1 12. Diagrams control box front view vacuum pumps accessory a/c communication set select switch to line up with led indicator light line voltage selection switch hf1 blower power supply hf1 blower power supply motor l - swt stop in slow out fast motor slow speed 208 2...

Page 74

12-2 94ms41 rev. C1 s/w ver 2.06.

Page 75

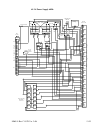

94ms41 rev. C1 s/w ver 2.06 12-3 control box wiring diagram (standard 6kw) j23 (240v) p23 1 2 j20 t9 t8 incoming power gstd power distribution blocks l1 gnd l2 n l3 white f9 1/2asb gtool brown blue blue white 12vdc relay 4 1 -out +out f5 (240v) (240v) r4 220v 120v j17 f8 f7 f6 f5 f10 white orange vi...

Page 76

12-4 94ms41 rev. C1 s/w ver 2.06 unit cabling diagram (old style) b3 b4 b1 b2 b5 b6 xmr l1 l2 p50 p51 p52 p54 p58 p63 p60 p61 p62 p59 p64 p65 j1 j2 j3 sw11 sw12 sw7 sw8 sw1 sw2 p67 12 11 22 21 sw10 sw9 16d2412a00 (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) (red, 18 ga) (black, 18 ga) (bl...

Page 77

94ms41 rev. C1 s/w ver 2.06 12-5 unit cabling diagram (new style) p50 p51 p52 p54 p58 p63 p61 p62 p59 p64 p65 sw5 sw6 sw1 sw2 p67 12 11 22 21 sw7 16d2412a00 (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) 16d2495b00 16d3406a00 (red, 18 ...

Page 78

12-6 94ms41 rev. C1 s/w ver 2.06 unit cabling diagram (ce) blr5 p50 p51 p52 p54 p58 p63 p61 p62 p59 p64 p65 sw9 sw8 sw5 sw6 sw1 sw2 p67 12 11 22 21 sw7 16d2412a00 (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) 16d2495b00 (red, 18 ga) (...

Page 79

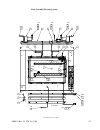

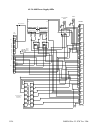

94ms41 rev. C1 s/w ver 2.06 12-7 unit wiring and tubing diagram 18 21 used w/clsd loop only 28 27 15 8 pl 2 pl 36 14 18 15d2067 label , caution 1 47 see b.O.M. Label, ap 30 serial no. 1 46 41-04nhx nsi 4-40 hex nut zinc 2 30 3 pl 10 ref. Evap. Harness (clsd loop only) control/output/input/motor used...

Page 80

12-8 94ms41 rev. C1 s/w ver 2.06 base assembly diagram c e j d a 14 f h g k 14 1 16 15 8 8 32 1 15 16 1 6 20 18 1 21 24 14 15 16 3 2 5 30 29 17 29 22 1 33 5 18 19 33 20 b l 15 5 25 27 13 13 14 32 9 10 1 23 22 12 23 20 5 1 1 4 pl 4 pl 31 26 4 pl 10 6 5 1 4 3 qty 2 1 item description weldment, cabinet...

Page 81: 13. Light Source

94ms41 rev c1 s/w ver. 2.06 13-1 13. Light source component layout lamphead for al 56, al56-480 and al 66 50/60hz 31mot06 shutter motor 39blo14 blower 64mv414 trigger board 55sw02 shutter position switch l1280, l1281 or l1282 replacement lamp 55sw03 safety interlock switch blower 63d0142 lamp suppor...

Page 82

13-2 94ms41 rev c1 s/w ver. 2.06 power supply for al 56-480 60hz l1 t1 t2 l2 power output power input 120 vac coil voltage 33rly04 sealed relays 33rly02 power relay 32bal01 ballast 39blo03 blower 64mv407v04 control board 53jkp01 safety interlock 62d3083a00 capacitor assembly 18 terminal strip 1 powe...

Page 83

94ms41 rev c1 s/w ver. 2.06 13-3 ballast/tap switch wiring al 56 ballast / tap switch wiring com 208 240 cap 240 cap 208 com ballast #1 ballast #2 l1 orange to cap. Pack l2 t1 t2 red blk cap 240 208 com ballast #4 com 208 240 cap ballast #3 1 2 3 4 5 6 10 11 12 voltage selector switch yellow to auto...

Page 84

13-4 94ms41 rev c1 s/w ver. 2.06 al 66 ballast wiring com 120 cap 120 cap com ballast #1 ballast #2 red blk contactor terminal strip cap 120 com ballast #4 com 120 cap ballast #3 no. 29 (violet). No. 20 (orange to cap. Pack). Ac in 6 ga. (blk) (blk) (red) 16 18 17 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1...

Page 85

94ms41 rev c1 s/w ver. 2.06 13-5 • the internal interlock is a loop that travels through the light head, passing through the glass switch and two thermostats. This interlock is in series with the control circuit of the large relays in the power supply. When the interlock is opened, the relays will o...

Page 86

13-6 94ms41 rev c1 s/w ver. 2.06 trigger board a trigger board is provided in the light head to start the lamp. This board operates on demand by sensing the lamp voltage. This board can be heard when it is functioning, although the sound is faint. By turning the unit on and off, the sound can be com...

Page 87

94ms41 rev c1 s/w ver. 2.06 13-7 should be replaced, and the unit should be tested to see that the capacitor did not damage the high or medium relay. To test the unit’s ability to switch power levels, make a manual exposure, then switch between the power levels, noting the change in intensity. When ...

Page 88

13-8 94ms41 rev c1 s/w ver. 2.06 al 66 capacitor assembly 2 1 5 5 5 3 1 4 2 1 2 3 wires to capacitor top front view of pc board 1 2 3 4 wire colors 1) yellow 2) brown 3) blue 4) blue with white stripe 5) orange capacitor assembly part # 62d2723b00 4µƒ swa swb swc 12µƒ 16µƒ 10µƒ 10µƒ opening the lamp...

Page 89

94ms41 rev c1 s/w ver. 2.06 13-9 remove the 6 screws from each side of the lamphead and remove the two endcaps. On lt8 lampheads you can now access the trigger board and shutter position switch that are located at the opposite end from the shutter motor under the air plenum plate. Side view shutter ...

Page 90

13-10 94ms41 rev c1 s/w ver. 2.06 shutter brake the motor that drives the shutter has a brake that is magnetically operated. When the motor core magnetizes, it pulls a lever to release the brake. If the shutter coasts or rotates continuously, look at the shutter led on the pc board. On early boards,...

Page 91

94ms41 rev c1 s/w ver. 2.06 13-11 • rotate the sprocket to tighten the other two screws and attach the wires. • the shutter can be tested with the unit open by disconnecting one of the lamp leads and holding the interlock switch. ! C do not light the lamp without the safety glass or when you are clo...

Page 92

13-12 94ms41 rev c1 s/w ver. 2.06 lt8 shutter assembly drawing e 4 11 f 11 25 18 27 26 17 25 b 3 2 c 1 10 a b c 24 4 1 1 25 18 13 16 15 9 1 18 18 25 25 14 28 22 10 21 18 25 25 10 21 28 22 18 9 1 14 newer units have fixed spacer here d 2 19 8 25 2 19 18 1 12 14 2 apply loctite 242 to threads where in...

Page 93

94ms41 rev c1 s/w ver. 2.06 13-13 idle setting • the idle level occurs between exposures and low power exposures. The idle setting determines the power and temperature of the lamp, while at idle. It also allows for much lower idle power than was ever attainable before. • this lower power level provi...

Page 94

13-14 94ms41 rev c1 s/w ver. 2.06 lamp head blowers • the lamp head blowers are controlled by the printed circuit board to provide the correct cooling to the lamp. During warm-up, the blowers are off or run very slowly. At idle and during low exposure, the blowers vary in speed. Both at high exposur...

Page 95

94ms41 rev c1 s/w ver. 2.06 13-15 lamp head signals signals at the terminal strip (cable to the lamp head) a great deal of information about the operation of the lamp may be found at the terminal strip, in the power supply that connects to the lamp head. The terminals are counted number 1 at the end...

Page 96

13-16 94ms41 rev c1 s/w ver. 2.06 and depends on the lamp age and ambient temperature. When an exposure at high power is initiated, the lamp voltage rises to the maximum. The voltage remains there after the lamp returns to low power, until the lamp temperature again stabilizes. • #6 the shutter volt...

Page 97

94ms41 rev c1 s/w ver. 2.06 13-17 light function states model warm-up idle low exp. Med exp. High exp. Cool down trigger unit fans on / on on / on on / on on / on on / on on / on on / on power relay on / on on / on on / on on / on on / on off / off off / off shutter closed / off closed / off open / ...

Page 98

13-18 94ms41 rev c1 s/w ver. 2.06 printed circuit board layout this is a description of the signals and voltages present on the pins of the printed circuit board. 64mv407v24 control board layout. Note: graphic of the new style p.C.Board is shown. Relay style p.C.Board has the same connector hookups ...

Page 99

94ms41 rev c1 s/w ver. 2.06 13-19 signal description power connector p1) v~ hot: supply to board approximately 125v~. P2) v~ common: common to board is the common also for relays, shutter fans, and the internal lamp head interlock. (this may not be at ground potential and should be measured with cau...

Page 100

13-20 94ms41 rev c1 s/w ver. 2.06 s7) high switch: switch to select high power level. Low (0v) for high. S8) low/med switch: switch to select power level when high switch is off. Low (0v) for medium power, high (12vdc) for low power. S9) manual switch: manual expose switch. Low (0v) to cause exposur...

Page 101

94ms41 rev c1 s/w ver. 2.06 13-21 circuit diagram (64mv407v24) 1 high expose 4 power on 2 dc common 3 low expose 1 2 3 4 6 7 8 9 10 5 11 12 +12 v not used 110 vac ac common not used aux terminal connector p2 input filters input filters e1 e2 lamp signal lamp cooling logic 1 2 3 4 6 7 8 9 10 5 11 12 ...

Page 102

13-22 94ms41 rev c1 s/w ver. 2.06 lamphead for all lights 12 10 8 6 4 2 shutter position switch 11 9 7 5 3 1 shutter motor lamp trigger board blowers thermostat thermostat safety glass switch.

Page 103

94ms41 rev c1 s/w ver. 2.06 13-23 al 56 power supply 60hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2 yel...

Page 104

13-24 94ms41 rev c1 s/w ver. 2.06 al 56-480 power supply 60hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2...

Page 105

94ms41 rev c1 s/w ver. 2.06 13-25 al 66 power supply 50hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2 yel...

Page 106

13-26 94ms41 rev c1 s/w ver. 2.06 interconnect cable 1 2 4 3 6 5 8 7 10 9 12 11 white green violet blue orange black yellow red brown heat shrink 1 2 4 3 6 5 8 7 10 9 12 11 white green violet blue orange black yellow red brown heat shrink.

Page 107

94ms41 rev. C1 s/w ver 2.06 14-1 14. Printing light check list check list for printing light troubleshooting and service ! C in order for this check list to be effective it must be followed step by step. 1) disconnect the integrator/timer from the power supply. This will make sure that a faulty inte...

Page 108

14-2 94ms41 rev. C1 s/w ver 2.06 • you must be able to reach up, place your fingers against the safety glass and there must be play front to back and side to side. Otherwise the glass does not have room for expansion and will more than likely shatter under use. ! C never operate the light source wit...

Page 109

94ms41 rev. C1 s/w ver 2.06 14-3 8) check capacitors and relay circuit by: the capacitors and relays are checked by watching the voltage changes that take place at the different intensity levels. If a capacitor is not in the circuit the voltage readings on input and output will be the same. If the c...

Page 110

14-4 94ms41 rev. C1 s/w ver 2.06 60hz 6kw with l1280 lamp orange yellow brown blue #1 blue #2 a. Idle/low 700+ 360-380 700+ 700+ 700+ b. Medium 730+ 380-410 380-410 730+ 700+ c. High 750+ 415-445 415-445 415-445 415-445 50hz 6kw with l1280 lamp orange yellow brown blue #1 blue #2 a. Idle/low 700+ 36...

Page 111

94ms41 rev. C1 s/w ver 2.06 14-5 ‡ the voltage readings described in the following are typical of 5kw light sources see voltage chart to find high and low values for others. 10) if a reading remains high (500v~ or more see note ‡) and it should be low (less than 300v~ see note ‡), the capacitor is n...

Page 112

14-6 94ms41 rev. C1 s/w ver 2.06 19) if the shutter fails to rotate at any time, then check the following: 20) when the shutter is supposed to be moving. Check for 120v~ between terminals 4 & 6. If there is voltage, go to the lamphead and check for voltage at the shutter motor then skip to step 22. ...

Page 113: 15. Fault Trees

94ms41 rev. C1 s/w ver 2.06 15-1 15. Fault trees no strike fault tree does shutter rotate when light turned on? Yes no check safety glass and lever no good are any led's lit on the pc board? Yes yes yes yes yes yes no no no no no no good reinstall safety glass test 1 is power relay pulling in? Go to...

Page 114

15-2 94ms41 rev. C1 s/w ver 2.06 shutter rotation fault tree front view of control board 12 1 12 1 p1 p2 e2 e1 j1 u4 u5 q3 q5 q4 q6 q2 d14 d16 d15 d17 d18 d13 f1 k2 k4 k3 k5 k1 power relay medium relay high relay shutter motor power supply fan lamp head fans d14 d16 d15 d17 d13 d18 led's pc board to...

Page 115: 16. Parts List

94ms41 rev. C1 s/w ver 2.06 16-1 16. Parts list part number description qty. Per unit 62apcl01 assy kit base expo ap30 1 ea 11d249 h d1 lamphead heat 2 ea 11d3395a17 deflector, air 2 ea 11d3945a62 slm guide lt block upper 1 ea 11d3945b62 slm guide lt block upper 1 ea 11d3994a07 external reflector, a...

Page 116

16-2 94ms41 rev. C1 s/w ver 2.06 part number description qty. Per unit 62d3553a00 assy,ctrl bx-5k, cls,gt 1 ea 62d4308a00 assy,pcb control basic 1 ea 43spr31 gas spring 4 ea 55sw45-go button, white "go" 1 ea 55sw45-stop button, white "stop" 1 ea 56tmp01 temperature control 1 ea 62ata accuprint tray ...

Page 117

94ms41 rev. C1 s/w ver 2.06 16-3 part number description qty. Per unit 11d2426a17 divider, nose ap30 left 1 ea 11d2426b17 divider,nose ap30 right 1 ea 11d2427a08 air director no.1, nose 1 ea 11d2433a08 air director no. 2 - nose 1 ea 11d2438a08 air director no 3 - nose 1 ea 11d3255a07 reflector,work ...

Page 118

16-4 94ms41 rev. C1 s/w ver 2.06 part number description qty. Per unit 62d3202a00 assy,ctl bx 8k 220v~ 50hz 1 ea 16d2641a00 harness, cntrl bx 1 ea 16d3208a00 harness, cntrl bx -gtools 1 ea 31msc02 motor, speed control-kb 1 ea 32psf01 power supply, open frame, 1 1 ea 32trc01 autoformer 208-240v~ 1 ea...

Page 119

94ms41 rev. C1 s/w ver 2.06 16-5 part number description qty. Per unit 52ts19 power dist.Block 3 pole 4 2 ea 56fus04 fuse, 5a/250v slow bl 3ag 2 ea 56fus14 fuse 15a 250v 2 ea 56fus15 fuse, 3a 250v 3ag slow blow 1 ea 56fus16 fuse, 1/2a 250v 3ag slow bl 1 ea 56fus20 fuse, 20a 250v, slow blow 3 2 ea 56...

Page 120

16-6 94ms41 rev. C1 s/w ver 2.06 part number description qty. Per unit 12d2476a00 ball stud, shortened, gas 2 ea 43spr12 spring 7/16 x 9/16 compr. 2 ea 44hdl03 handle, 6". Alum 1 ea 62mfoa01 mylar frame outer assy 1 ea 11d4306a07 bracket right angle 4 ea 12d4473a76 frame mylar outer front 1 ea 12d44...

Page 121

94ms41 rev. C1 s/w ver 2.06 16-7 part number description qty. Per unit 62d2726a00 assembly, capacitor pack 1 ea 64mv407v24 prnt light ctrl pcb w/min 1 ea 62cl56-480 complete 6k/480 60hz power sup. 2 ea 11d0932a02 cover, al54/64 1 ea 11d0933a02 divider p/s narrow body 1 ea 11d0934a02 component wall 1...

Page 122

16-8 94ms41 rev. C1 s/w ver 2.06 62lhk01 switch assembly 1 ea 63d3669a00 idler, arms assy lt8 1 ea 64mv414v01 trigger bd tested 6k 1 ea 62lhk02-83 roller assembly al 83 1 ea 62sa83-b shutter ass'y 8k se rev. 1 ea.

Page 123: 17. Warranty

94ms41 rev. C1 s/w ver 2.06 17-1 17. Warranty olec limited warranty olec equipment is warranted against defects in material for one (1) year from date of purchase. Faulty parts will be repaired, replaced, or purchase price refunded at olec 's option, for the original buyer, provided the parts have b...

Page 124

O corporation 17112 armstrong avenue, irvine ca u.S.A. 92614 u.S.A. (949) 399-6500 fax (949) 399-6501.