- DL manuals

- Accuprint

- Printer

- AP42CL 8000

- Service Manual

Accuprint AP42CL 8000 Service Manual

Summary of AP42CL 8000

Page 1

P p ap42cl 8000 closed loop high resolution printer service manual 94ms42 rev. B1 s/w 2.06 o.

Page 2

94ms42 rev.B1 s/w ver 2.06 this manual is designed for technical personnel and should only be used by authorized dealer service personnel. This manual is written to provide an understanding of the equipment, as well as a plan for troubleshooting..

Page 3: Contents

94ms42 rev.B1 s/w ver 2.06 0-1 0. Contents 1. Specifications crated dimensions ...................................................................... 1-1 shipping weight .......................................................................... 1-1 actual dimensions ....................................

Page 4

0-2 94ms42 rev.B1 s/w ver 2.06 type mode ................................................................................... 4-8 exposure statistics (elapsed hours) ............................................ 4-9 exposure statistics (total exposures) ......................................... 4-9 se...

Page 5

94ms42 rev.B1 s/w ver 2.06 0-3 nose assembly drawings ........................................................... 9-4 nose assembly left and right covers ....................................... 9-6 10. Exposure trays mylar® replacement ...................................................................

Page 6

0-4 94ms42 rev.B1 s/w ver 2.06 idle setting ............................................................................... 13-14 lamp head blowers ................................................................ 13-15 blown fuse on pc board ........................................................ 1...

Page 7: Specifications

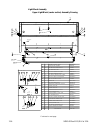

94ms42 rev.B1 s/w ver 2.06 1-1 1. Specifications 48" 51" 99" 61" 58" 96" 66" 110" 51" upper tray lower tray crated dimensions length w idth height 1 3 0 " 7 8 " 8 5 " 330cm 198cm 216cm shipping weight crated 2,400 lbs. 1089kg uncrated 2,000 lbs. 907kg actual dimensions cabinet, welded heavy gauge st...

Page 8

1-2 94ms42 rev.B1 s/w ver 2.06 effective exposure frame area width 42" 107cm depth 34" 86cm intensity ap42cl-8000 lamps can be operated at 8 kw, 5 kw, and 2 kw. Typical room requirements top view rear front 36" circuit breaker 36" 36" electrical specifications and connections 3 phase (wye) see figur...

Page 9

94ms42 rev.B1 s/w ver 2.06 1-3 earth ground l1 l2 l1 l2 l3 figure a 380 / 415v~ 50hz connection wye: 3 wires + neutral + ground terminal block n 380 / 415v~ olite power supply blowers vacuum pumps electronics drives etc. L3 n earth ground l1 l2 l1 l2 l3 figure b 208/240v~ 50hz connection delta: 3 wi...

Page 10

1-4 94ms42 rev.B1 s/w ver 2.06 connecting power to printer we recommend installing a circuit breaker box within easy reach of the operator. • install and run the main power cord through a strain relief then into the channel on the lower right rear of the printer and up to the power control box on th...

Page 11

94ms42 rev.B1 s/w ver 2.06 1-5 cooling requirements minimum pressure and flow rate of the chilled water depends on input temperature. ! Cl if water temperature and water flow do not meet the following specifications the unit will overheat, one or both light sources will shut themselves off randomly ...

Page 12

1-6 94ms42 rev.B1 s/w ver 2.06.

Page 13: Cooling System

94ms42 rev.B1 s/w ver 2.06 2-1 2. Cooling system connecting the evaporator • place the evaporator flat on the floor. • connect the hose from the evaporator to the bottom of the rear panel drain. ! Cl make sure the hose end on the evaporator is lower than the bottom of the rear panel drain or moistur...

Page 14

2-2 94ms42 rev.B1 s/w ver 2.06 connecting the chiller • mount the flow meter and temperature gauge assembly on a wall in a horizontal position. ! Cl the flow meter and temperature gauge assembly must be mounted horizontal or the flow meter will not function properly. • connect the hose from the "wat...

Page 15

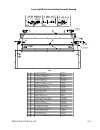

94ms42 rev.B1 s/w ver 2.06 2-3 connecting the chiller (cont.) upper heat-exchanger lower heat-exchanger 4 12 solenoid valve, two way 3 1 d e s c r i p t i o n : q'ty item 2 3 4 5 6 7 8 9 13 14 15 16 17 18 19 20 11 10 solenoid coil 1/2" npt ball valve, (bleed valve) 1"hose id.Barb-1"npt male pipe 1"h...

Page 16

2-4 94ms42 rev.B1 s/w ver 2.06 filling the closed loop system ! Cl if the closed loop system is not filled properly the unit will overheat, one or both lights sources will shut themselves off randomly under heavy usage and damage to the unit will be the result. • hook a hose to the bleed valve and p...

Page 17

94ms42 rev.B1 s/w ver 2.06 2-5 pull the solenoid coils off the solenoid valve base, the coils are retained by a spring clip and should pull off easily, do not remove the spring clip from coils. Set the thermostat on the inside of the unit to 100°f (20°c) and turn the unit on. The flow meter should r...

Page 18

2-6 94ms42 rev.B1 s/w ver 2.06 closed loop cooling assembly 30 33 33 2 pl 33 2 pl 8 41 9 a c d d 5 6 4 pl 4 2 pl 3 2 pl j 6 11 29 28 8 3 l 9 9 g 4 pl 10 7 j 1 2 h b 35 36 2 pl 23 24 7 j 45 k c 4 pl e h f 3 43 42 1 7 11 10 n 4 ref. Ref. Ref. Ref. Continued on next page.

Page 19

94ms42 rev.B1 s/w ver 2.06 2-7 closed loop cooling assembly (cont.) 25 j h 11 17 10 18 20 1 g k 3 1 18 20 4 3 20 19 ref. 27 12 23 17 24 19 3 26 12 3 30 31 32 ref. E l 14 1 15 16 9 f 1 14 16 7 44 m n 7 18 43 42 20 25 31 31 31 31 31 8 c 3 15 5 16 14 a 6 11 38 37 39 40 b 1 6 14 13 d 2 17 18 11 20 6 5 1...

Page 20

2-8 94ms42 rev.B1 s/w ver 2.06.

Page 21

94ms42 rev. B1 s/w ver. 2.06 3-1 3. Integrator functions and features microprocessor-controlled light integrator with led display, 40 memories, battery backup, single button control, lamp statistics and self- diagnostics. The operator control panel is composed of two sections, the display board and ...

Page 22

3-2 94ms42 rev. B1 s/w ver. 2.06 u menu this key is used as the autostep indicator and for the continuous vacuum feature. Note: u menu special function the u key has the optional function to be used to set auto-step and continuous vacuum per memory in normal operating mode. The frame control switch ...

Page 23

94ms42 rev. B1 s/w ver. 2.06 3-3 feature quick reference the following feature descriptions appear in the exposure window while setting each feature. In order to select or setup the following features you must first be in the setup mode. [lock] lock level feature [code] lock code feature [2ual] 2 (t...

Page 24

3-4 94ms42 rev. B1 s/w ver. 2.06 operator control panel p the ap 30 heavy duty exposure system has a power key on the integrator. • press the p key to turn on the unit. • press the p key again after use, and the system will run through a 2 minute cool down cycle and then turn off all blowers. S stop...

Page 25

94ms42 rev. B1 s/w ver. 2.06 3-5 calibration procedures note: the ap42 high resolution printer has been calibrated at the factory. Note: the following calibration procedures can be applied to all three light intensities, if starting calibration from scratch. To adjust existing calibration set the in...

Page 26

3-6 94ms42 rev. B1 s/w ver. 2.06 • press the g button twice. This will send the frame into the unit and start the exposure. • after the exposure, retrieve your frame by holding down the s button and press g button. When the frames start to move, release both buttons. • record the resulting mj readin...

Page 27

94ms42 rev. B1 s/w ver. 2.06 3-7 matching exposure surfaces • do a test exposure in the frame being calibrated to the reference frame. • determine the correction necessary to make each surface the same at the reference surface. If this is done with a step scale the correction is as follows. .15 dens...

Page 28

3-8 94ms42 rev. B1 s/w ver. 2.06 splitting steps a densitometer can be used to assist in determining a fractional difference in step scales. When measuring density, make several measurements to avoid being influenced by pinholes. Example original reference second scale a b • pick a step from the ref...

Page 29: Integrator Program Set Up

94ms42 rev. B1 s/w ver. 2.06 4-1 4. Integrator program set up to enter the select mode note: this step must be followed in several of the program set ups. • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1,2,3...

Page 30

4-2 94ms42 rev. B1 s/w ver. 2.06 dim. Enter the lock level desired. • press the v key to set entry. • if the lock level is set for 2, 3 or 4, the exposure window will read [code]. Enter your 3 digit code. • press the v key. • press the 0 key. • press the v key. Note: if you want a higher lock level ...

Page 31

94ms42 rev. B1 s/w ver. 2.06 4-3 setting or changing your lock code feature note: if you are setting the code you must know the existing code. Note: lock level must be set to 0 to program this step and reset when finished see lock level feature. • press the p key on the integrator to power up the li...

Page 32

4-4 94ms42 rev. B1 s/w ver. 2.06 • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1,2,3t 4 in sequence. The vacuum window will read [sel_]. This places you in the select mode. • press the 9 key five (5) times....

Page 33

94ms42 rev. B1 s/w ver. 2.06 4-5 [spgt] press and release the e key until [spgt] appears in the exposure window. This places you in the split exposure option. • press the v key to cycle the split exposure mode on or off. • press the 0 key twice to exit this mode. Single surface mode the printer may ...

Page 34

4-6 94ms42 rev. B1 s/w ver. 2.06 [sel_] press 1,2,3t 4 in sequence. The vacuum window will read [sel_]. This places you in the select mode. • press the y key once. The memory window will read [su]. [bcnt] press and release the e key until [bcnt] appears in the exposure window. This places you in the...

Page 35

94ms42 rev. B1 s/w ver. 2.06 4-7 [auac] press and release the e key until [auac] appears in the exposure window. This places you in the automatic vacuum option. • press the v key to cycle the automatic vacuum mode on or off. • press the 0 key twice to exit this mode. Auto step mode note: this featur...

Page 36

4-8 94ms42 rev. B1 s/w ver. 2.06 tray mode ! C the default tray speed is set at the factory to 5 seconds. Olec does not recommend changing this setting without consulting the olec factory. Damage to the transport can occur. • press the p key on the integrator to power up the light, the front remote ...

Page 37

94ms42 rev. B1 s/w ver. 2.06 4-9 exposure statistics (elapsed hours) note: the exposure statistics should be reset to zero when the lamps are changed. Note: this provides the operating hours on the lamps in total and at each intensity since the last reset. This function should be used whenever the e...

Page 38

4-10 94ms42 rev. B1 s/w ver. 2.06 [ehi_] press the 2 key. The letters [ehi_] will appear in the vacuum window. The exposure window will display the number of exposures made at high power. [elo_] press the 2 key a second time. The letters [elo_] will appear in the vacuum window. The exposure window w...

Page 39

94ms42 rev. B1 s/w ver. 2.06 4-11 setting the light intensity low • press the i key to set intensity. Press i for the first time. The first led on the left indicates the intensity is set to low 2kw. Medium • press: i for the second time. The first two leds light to indicate the intensity is set to m...

Page 40

4-12 94ms42 rev. B1 s/w ver. 2.06 error handling system if an error occurs, the machine displays an error code to aid in troubleshooting. The error codes defined are: [err_] the message [err_] will appear in the vacuum window, and a number in the exposure window. Look up the number below for a descr...

Page 41: Diagnostics

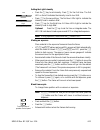

94ms42 rev. B1 s/w ver. 2.06 5-1 5. Diagnostics output diagnostics one of the many advancements olec has introduced to the field is the ability of its equipment to run a self-diagnostic check. All computer- activated functions and all internal and external switches can be checked out on the integrat...

Page 42

5-2 94ms42 rev. B1 s/w ver. 2.06 functions table e function value 1 heat exchanger solenoids [0001] 2 blower on/off [0002] 3 upper vacuum pump o n/off [0004] 4 lower vacuum pump on/off [0008] 5 work light and nose section fans o n/off [0016] 6 motor direction control [0032] 7 frame motor o n/off [00...

Page 43

94ms42 rev. B1 s/w ver. 2.06 5-3 input diagnostics • switch check the switch check can be done while in the select mode. • press the p key on the integrator to power up the light, the front remote switches, and the exposure unit's computer system. [sel_] press 1,2,3, then 4 in sequence. The vacuum w...

Page 44

5-4 94ms42 rev. B1 s/w ver. 2.06 • lower tray in, frame switch closed, door and emergency switches closed. [0044] the exposure window should read [0044]. [0172] when the g button is pushed the value should change to [0172]. [0060] when the s button is pushed the value should change to [0060]. Typica...

Page 45: Lamp Changing Instructions

94ms42 rev. B1 s/w ver 2.06 6-1 6. Lamp changing instructions ! Wthe lamps and safety glass may be very hot and cause burns. Prior to changing the lamp, ensure the lamp head is turned off and allowed to complete its cooldown cycle. Olec recomends that every year you unplug your light, remove the saf...

Page 46

6-2 94ms42 rev. B1 s/w ver 2.06 reflectors and glass can substantially reduce light output. • wear the white lightweight fabric gloves that are provided and unpack the new lamp. Clean the lamp with the alcohol wipe included. • place each end of the new olite lamp (one end at a time) on the holders. ...

Page 47: Preventive Maintenance

94ms42 rev. B1 s/w ver 2.06 7-1 7. Preventive maintenance preventive maintenance daily (approximately 15 minutes required) • clean exposure frame glass and mylar. The exposure frame glass and mylar should be kept meticulously clean. Dirt and resist flakes on these surfaces will cause exposure defect...

Page 48

7-2 94ms42 rev. B1 s/w ver 2.06 ! C do not use silicone spray lubricants in the printer. • lubricate frame drive chain and check tension. • apply a light coat of machine oil to the exposure frame drive chain by rubbing an oil wetted rag along the chain. Do not wet the chain enough to cause the oil t...

Page 49: Vacuum System

94ms42 rev. B1 s/w ver 2.06 8-1 8. Vacuum system vacuum pumps description: the printer uses two 1 / 4 -hp oilless rotary vane vacuum pumps, one for each exposure frame. Pressing the g button on the front nose assembly activates the pump for frame that is out of the cabinet. The vacuum gauge on the f...

Page 50

8-2 94ms42 rev. B1 s/w ver 2.06 flushing option #1 this option requires two pipe nipples at least 4" (102 mm) long with 3/ 8 " npt threads on one end. • remove the filter elements from the front of the muffler box and screw the nipples into the same holes. • with the pump running, allow about 2 tbsp...

Page 51

94ms42 rev. B1 s/w ver 2.06 8-3 voltage at the pump. If voltage is present at the pump connector, but the pump fails to operate, replace the pump. If the control box led is not on, check the wiring and connections from the switch to the control box. Pump replacement vacuum pump replacement is straig...

Page 52

8-4 94ms42 rev. B1 s/w ver 2.06 tubing/fitting replacement if a vacuum line or connection is cracked, loose, leaking or broken, replace it as soon as possible. A faulty vacuum line or connection will greatly increase the vacuum drawdown time required, if not eliminate full vacuum altogether. All vac...

Page 53

94ms42 rev. B1 s/w ver 2.06 8-5 vacuum seal replacement a cut, torn or otherwise damaged vacuum frame seal will greatly inhibit, if not prevent, full vacuum. A bad seal can be lifted and peeled off the frame glass. If necessary, use a razor blade or other suitable item to remove any leftover seal ad...

Page 54

8-6 94ms42 rev. B1 s/w ver 2.06 vacuum seal replacement (cont.) • unless otherwise specified dimensions are in inches. Dwg. Per ansiy14.5 tolerances are: angles ±5 deg. .X±1 .Xx±.03 .Xxx±.010 .Xxxx±.0030. • clean glass perimeter. Press transfer tape onto glass. (as shown) trim tape along edge of gla...

Page 55

94ms42 rev. B1 s/w ver 2.06 8-7 phototool wiring diagram (optional) if the unit is equipped with the glass photo tool option you will have a third vacuum pump installed in the bottom of the unit. See vacuum pumps and tubing/fitting replacement for vacuum problems. Several different glass tools are a...

Page 56

8-8 94ms42 rev. B1 s/w ver 2.06.

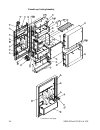

Page 57: Nose Assembly

94ms42 rev.B1 s/w ver 2.06 9-1 9. Nose assembly removing the left and right rail covers • turn unit off, allow the unit to complete its cool down cycle and disconnect power. • to remove rail covers: • to remove the right rail cover: while standing in front of the unit locate and disconnect all multi...

Page 58

9-2 94ms42 rev.B1 s/w ver 2.06 • use a small screw driver inserted between the switch and the sheet metal to break the glue holding the two black retainer clips on each side of the switch from the rail cover. • press together the switch retainer clips on the base of the switch and push the switch ou...

Page 59

94ms42 rev.B1 s/w ver 2.06 9-3 work lights note: the work lights are controlled by a rocker switch on the underside of the right front corner of the nose cover. Note: if the work lights are not turning on, check the rocker switch and power to the switch. Note: the work lights receive their power fro...

Page 60

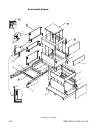

9-4 94ms42 rev.B1 s/w ver 2.06 nose assembly drawings bottom view 56 4 pl 46 43 50 11 9 9 11 10 50 43 46 4 pl 2 pl 10 -------------------- -------------------- harness, sw, operator ov45 -------------------- -------------------- -------------------- -------------------- autoformer,120/208/240v50/60h...

Page 61

94ms42 rev.B1 s/w ver 2.06 9-5 nose assembly drawings (cont.) 18 2 pl 45 44 3 pl 3 pl 4 pl 2 pl 35 5 pl 47 41 44 41 33 47 33 41 44 38 55 54 42 45 16 14 16 51 39 37 4 pl 4 pl 40 48 49 3 pl 2 pl 17 15 35 5 pl 4 pl 46 43 36 46 36 43 4 pl ref. 34 6 pl 35 34 14 pl top view 1 2 7 6 3 4 5 8 continued on ne...

Page 62

9-6 94ms42 rev.B1 s/w ver 2.06 nose assembly left and right covers 4x 2 pl 10 pl 10 pl 10x 2 pl detail b detail a a a view a a frame stop go (bot. Pos.) (top pos.) 2 2 pl 2 pl 2 pl 3 4 2 pl 2 pl a b red blk blk red ref. 12 17 1 18 3 4 2 11 19 20 21 10 12, 22 11, 21 19 nsi 6-32 kep nut zinc 41 06nkp ...

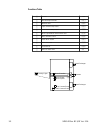

Page 63: 10. Exposure Trays

94ms42 rev.B1 s/w ver 2.06 10-1 10. Exposure trays mylar® replacement • close the mylar® frame and open the twelve cam latches. • remove the inner mylar® frame and position a pre-cut mylar® sheet into the frame. Make sure that the mylar® is overlapping on all sides. Closed position open position cam...

Page 64

10-2 94ms42 rev.B1 s/w ver 2.06 • place the new frame flat on the tray. Line up and insert the allen head screws through the hinge into the frame. Make sure the frame is 1 / 32 " to 1 / 16 " above the top of the hinge to avoid the possibility of damaging the glass, then tighten them down. • reinstal...

Page 65

94ms42 rev.B1 s/w ver 2.06 10-3 tray assembly drawing detail b detail d detail c w/connector detail a 3 4 pl 3 4 3 3 4 3 3 3 5 3 5 6 6 2 x 37" 2 x 43.25" 5 4 ref. 8 pl 2 pl 28 30 27 48 3 2 1 38 37 39 3 pl 12 9 pl 3 3 a a view 34 21 18 35 34 23 36 43 42 34 22 32 33 31 31 33 32 2 pl 2 pl 2 pl 2 pl 2 p...

Page 66

10-4 94ms42 rev.B1 s/w ver 2.06 tray assembly drawing (cont.) a b c d 11d2112a62 ramp switches, ap30/ov33 1 1 1/4-20 x 3/8 botton head 41-f0shb.37 41b12pps.37 nsi 10-32 x 3/8 ppms blk 6 9 19 29 19 8 41-f0wls nsi lockwasher split 1/4" 2 28 nsi #6 flat washer, black zinc 41b06wfr 41-06wls nsi #6 split...

Page 67

94ms42 rev.B1 s/w ver 2.06 10-5 outer frame assembly see view a a view latch / handle assembly side view 19 2 pl 23 2 pl 1 3 20 15 ref. 2 ref. 17 6 2 pl 21 6 pl 7 2 pl 12 8 2 pl 14 2 pl (knurrled surface.) 2 outer frame assembly top view 3 (glass tray assembly) 24 2 pl 9 23 3a 30 2 pl 31 2 pl 32 38 ...

Page 68

10-6 94ms42 rev.B1 s/w ver 2.06 inner frame assembly view b see view b .03 .00 4 pl 12 pl 10 25 12 pl 16 12 pl 15 15 ref. 2 pl 2 pl 11 27 26 28 22 34 13 5 2 pl bottom view 3 inner frame assembly 20 8 pl (farside) 4 4 2 pl 15 15 cut to length and apply as shown reference view b 6 pl 2 29 12 pl 18 33 ...

Page 69

94ms42 rev.B1 s/w ver 2.06 10-7 gas spring removal and replacement each frame assembly has two gas springs to support the top cover sheet frame when it is opened. • open the frame with the spring to be replaced. ! Cl the glass frame assembly is heavy, make sure you support it well before removing th...

Page 70

10-8 94ms42 rev.B1 s/w ver 2.06 • unplug the drive motor electrical connector from the control box and position both frames near the mid-travel position. • remove three linear bearing retainer block screws using a 5 / 32 " allen wrench. • lift up the frame assembly about 2" (51 mm) and slide the bea...

Page 71: 11. Center/drive Assembly

94ms42 rev.B1 s/w ver 2.06 11-1 11. Center/drive assembly center/drive assembly diagram 4 pl 4 pl drive motor assy. Detail a 14 pl 21 pl timing switch assy. Detail c. 93.5" 2 pl 3 pl 6 pl 3 pl 10 pl chain tensioner assy., detail b. 4 pl 2 pl 34 34 32 35 1 74 37 36 3 2 36 37 15 39 40 9 8 68 33 70 69 ...

Page 72

11-2 94ms42 rev.B1 s/w ver 2.06 center/drive assembly diagram (cont.) 41bf2bhx.75 5/16 - 18 x 3/4 hex bolt blk. 2 1 threaded rod 12d1751a00 1 3/8-`6 nylon lock nut, ov45 41 f3nln 12d1750a62 slide 1 6 2 switch mount, ov45 11d2111b62 62d3798a00 motor, drive ass'y 1 5 191" 2 1 81tap17 12d2150a99 11d375...

Page 73

94ms42 rev.B1 s/w ver 2.06 11-3 tray transport system the printer has two aluminum exposure tray assemblies. Vacuum for frame evacuation is drawn through two ports in the glass, one at each of the rear corners. The top mylar® frame is hinged in the back, with a gas strut on each side that holds the ...

Page 74

11-4 94ms42 rev.B1 s/w ver 2.06 will be too slow and a transport error may occur. Use the following procedure to set the clutch at the minimum setting for operation. • remove the left side center panel on the printer and locate the clutch at the left rear corner. • loosen the two set screws which lo...

Page 75

94ms42 rev.B1 s/w ver 2.06 11-5 • press the 6 key again: upper tray should move in, the vacuum window should read [0096]. • set volt meter for vdc and measure across pins 5 & 6 on motor speed connector. Adjust the 'slow' pot on the control box to read 25 to 32 vdc. Notice that the frame moves slower...

Page 76

11-6 94ms42 rev.B1 s/w ver 2.06 light block assembly upper light block (center section) assembly drawing e lh tors. Spring assy., rh side. Detail e ref. Ref. 5 pl 62d2321a00 wheel ass'y. Detail f f 62d2321a00 2 pl. 14 pl 4 pl 5 pl 4 pl ref. 2 pl rh both sides 2" 2 pl 2 pl 2 pl 2 pl 51 52 63 62 4 pl ...

Page 77

94ms42 rev.B1 s/w ver 2.06 11-7 lower light block (insert section) assembly drawing 7 5 pl 62d2321a00 wheel ass'y. (both sides) see detail c 8 pl spring ass'y. (both sides) see detail a c 4 pl ref. 62d2321a00 5 pl. 8 2 pl. 4 pl b a ref. 2 pl 8 2 pl. 16 pl. Ref. 45 48 46 49 47 45 45 53 51 50 52 30 59...

Page 78

11-8 94ms42 rev.B1 s/w ver 2.06 replacing light block springs • for the lower light block, move upper exposure frame into the cabinet. For the upper light block, move lower exposure frame into the cabinet. • disconnect main power. • remove the left and right side panels. • remove the left mounting b...

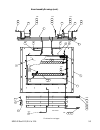

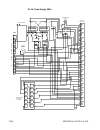

Page 79: 12. Diagrams

94ms42 rev.B1 s/w ver 2.06 12-1 12. Diagrams control box front view typical vacuum pumps accessory a/c communication set select switch to line up with led indicator light line voltage selection switch r1 motor l - swt stop in slow out fast motor slow speed 208 240 e c l u 1 4 2 5 3 12 vdc + - 1 blk ...

Page 80

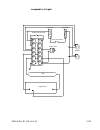

12-2 94ms42 rev.B1 s/w ver 2.06 control box wiring diagram 208vac 60hz/380vac 50hz assembly 62d3555a00 4 3 2 1 6 3 2 4 1 red black black motor/limit switches scr t7 t6 t2 t1 violet yellow cooling fan p10 t4 j13 acc. T5 64ct464 j14 j12 j9 p9 j15 j11 vacuum pumps a/c 12vdc integ. Pwr j10 t3 evaporator...

Page 81

94ms42 rev.B1 s/w ver 2.06 12-3 480vac 60hz j23 (240v) p23 1 2 j20 t9 t8 incoming power gstd power distribution blocks l1 gnd l2 l3 h1 h4 x4 x1 x3 x2 480v 240v h2 h3 5kva xfmr red black blue brown x2 x4 x1 120v 120v white white f9 1/2asb control/pump brown blue blue white 12vdc relay 4 1 -out +out n...

Page 82

12-4 94ms42 rev.B1 s/w ver 2.06 base assembly diagram 4 pl 12 pl 24 pl 2 .25 - .31 typ. 24 pl 7 7 7 a 12 7 8 c d 3 b b 13 25 6 g 10 2 e a 27 a a a c 30 f 9 1 5 4 31 c 3 pl h a 12 pl h 7 continued on next page.

Page 83

94ms42 rev.B1 s/w ver 2.06 12-5 base assembly diagram (cont.) a c f b 3 e d h 7 4 door 11d2158a00 11d2230a62 hook, door upper 12 8 9 cover, top 11d3691a00 43mag04 magnet, catch - 200 24 10 11 24 strike plate, magnet - 200 43mag05 44gkt12 gasket, foam 1/4 w x 1/4 thk. 12 13 78 ft. Screw #6-32x.38 ph....

Page 84

12-6 94ms42 rev.B1 s/w ver 2.06.

Page 85

94ms42 rev.B1 s/w ver 2.06 12-7 unit cabling diagram (new style) p50 p51 p58 p63 p61 p62 p59 p64 p65 sw5 sw6 p67 12 11 22 21 sw7 16d3802a00 (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) 16d3801a00 16d3803a00 (red, 18 ga) (black, 18 ga...

Page 86

12-8 94ms42 rev.B1 s/w ver 2.06 unit cabling diagram (old style) b3 b4 b1 b2 b5 b6 xmr l1 l2 l3 l4 p50 p51 p52 p53 p54 p55 p56 p57 p58 p63 p60 p61 p62 p59 p64 p65 p66 j1 j2 j3 sw11 sw12 sw7 sw8 sw1 sw2 p67 12 11 22 21 sw10 sw9 16d3802a00 (red, 18 ga) (black, 18 ga) (black, 18 ga) (red, 18 ga) (red, ...

Page 87: 13. Light Source

94ms42 rev. B1 s/w ver 2.06 13-1 13. Light source component layout lamphead for al 84 and al 94 50/60hz 31mot06 shutter motor 39blo14 blower 64mv414 trigger board 55sw02 shutter position switch l1280, l1281 or l1282 replacement lamp 55sw03 safety interlock switch blower 63d0142 lamp support assembly...

Page 88

13-2 94ms42 rev. B1 s/w ver 2.06 power supply for al 84-480 60hz l1 t1 t2 l2 power power 120 vac 33rly04 33rly02 32bal01 52fuh04 39blo03 64mv407-83 53jkp01 62d3533a00 56fus15 18 terminal strip 1 output input coil voltage 3amp 250v 3ag slow blow fuse sealed relays power relay capacitor assembly safet...

Page 89

94ms42 rev. B1 s/w ver 2.06 13-3 ballast/tap switch wiring al 94 ballast wiring com 120 cap 120 cap com ballast #1 ballast #2 l1 l2 t1 t2 red blk terminal strip cap 120 com ballast #4 com 120 cap ballast #3 no. 29 (violet). No. 20 (orange to cap. Pack). Ac in 6 ga. (blk) (blk) (red) 16 18 17 15 14 1...

Page 90

13-4 94ms42 rev. B1 s/w ver 2.06 al 84-480 ballast wiring com 277 cap 277 cap com ballast #1 ballast #2 l1 l2 t1 t2 red blk terminal strip cap 277 com ballast #4 com 277 cap ballast #3 no. 29 (violet). No. 20 (orange to cap. Pack). Ac in 6 ga. (blk) (red) 16 18 17 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1...

Page 91

94ms42 rev. B1 s/w ver 2.06 13-5 • the internal interlock is a loop that travels through the light head, passing through the glass switch and two thermostats. This interlock is in series with the control circuit of the large relays in the power supply. When the interlock is opened, the relays will o...

Page 92

13-6 94ms42 rev. B1 s/w ver 2.06 trigger board a trigger board is provided in the light head to start the lamp. This board operates on demand by sensing the lamp voltage. This board can be heard when it is functioning, although the sound is faint. By turning the unit on and off, the sound can be com...

Page 93

94ms42 rev. B1 s/w ver 2.06 13-7 capacitor we use will burn open if it begins to short. A swollen capacitor should be replaced, and the unit should be tested to see that the capacitor did not damage the high or medium relay. To test the unit’s ability to switch power levels, make a manual exposure, ...

Page 94

13-8 94ms42 rev. B1 s/w ver 2.06 al 94 capacitor assembly 2 1 do not switch while unit is on caution 1 2 3 wires from harness wires to capacitor top front view of pc board 1 2 3 1 2 3 4 wire colors 1) yellow 2) brown 3) blue 4) blue with white stripe 5) orange capacitor assembly part # 62d2723a00 sw...

Page 95

94ms42 rev. B1 s/w ver 2.06 13-9 opening the lamp head • unplug the unit. • remove the glass and the four screws attaching the large outer reflector section. ! C do not touch the reflector surface with your hands. Bottom view remove the 2 center screws from the bottom side and the 2 screws from the ...

Page 96

13-10 94ms42 rev. B1 s/w ver 2.06 shutter switch the switch provides shutter position information to the pc board. This switch is in the lamp end where the cable enters, inside the manifold cover. The cam is in the chamber with the shutter. A failure of the switch can cause the shutter to rotate con...

Page 97

94ms42 rev. B1 s/w ver 2.06 13-11 ! C turn the shutter only counterclockwise (looking from the motor end) or you may damage the shutter switch on the other end of the light. • remove the chain from the sprocket with care to keep tension. The chain has shortened links and will separate if slackened. ...

Page 98

13-12 94ms42 rev. B1 s/w ver 2.06 shutter removal lt8 lampheads • remove the four hex nuts mounting the blowers, disconnect the blower and thermostat wires. End view • remove the four screws holding the rear reflector to the cooling tubes and remove the reflector and lamp from the lamp head. ! C do ...

Page 99

94ms42 rev. B1 s/w ver 2.06 13-13 lt8 shutter assembly drawing e 4 11 f 11 25 18 27 26 17 25 b 3 2 c 1 10 a b c 24 4 1 1 25 18 13 16 15 9 1 18 18 25 25 14 28 22 10 21 18 25 25 10 21 28 22 18 9 1 14 newer units have fixed spacer here d 2 19 8 25 2 19 18 1 12 14 2 apply loctite 242 to threads where in...

Page 100

13-14 94ms42 rev. B1 s/w ver 2.06 idle setting • the idle level occurs between exposures and low power exposures. The idle setting determines the power and temperature of the lamp, while at idle. It also allows for much lower idle power than was ever attainable before. • this lower power level provi...

Page 101

94ms42 rev. B1 s/w ver 2.06 13-15 lamp head blowers • the lamp head blowers are controlled by the printed circuit board to provide the correct cooling to the lamp. During warm-up, the blowers are off or run very slowly. At idle and during low exposure, the blowers vary in speed. Both at high exposur...

Page 102

13-16 94ms42 rev. B1 s/w ver 2.06 lamp head signals signals at the terminal strip (cable to the lamp head) a great deal of information about the operation of the lamp may be found at the terminal strip, in the power supply that connects to the lamp head. The terminals are counted number 1 at the end...

Page 103

94ms42 rev. B1 s/w ver 2.06 13-17 rises it increases. As the lamp reaches temperature, the fans speed increases to regulate the lamp. At idle, this voltage is typically 45 - 90v~ and depends on the lamp age and ambient temperature. When an exposure at high power is initiated, the lamp voltage rises ...

Page 104

13-18 94ms42 rev. B1 s/w ver 2.06 light function states model warm-up idle low exp. Med exp. High exp. Cool down trigger unit fans on / on on / on on / on on / on on / on on / on on / on power relay on / on on / on on / on on / on on / on off / off off / off shutter closed / off closed / off open / ...

Page 105

94ms42 rev. B1 s/w ver 2.06 13-19 printed circuit board layout this is a description of the signals and voltages present on the pins of the printed circuit board. 64mv407v24 control board layout. Note: graphic of the new style p.C.Board is shown. Relay style p.C.Board has the same connector hookups ...

Page 106

13-20 94ms42 rev. B1 s/w ver 2.06 signal description power connector p1) v~ hot: supply to board approximately 125v~. P2) v~ common: common to board is the common also for relays, shutter fans, and the internal lamp head interlock. (this may not be at ground potential and should be measured with cau...

Page 107

94ms42 rev. B1 s/w ver 2.06 13-21 switch connection (cont.) s7) high switch: switch to select high power level. Low (0v) for high. S8) low/med switch: switch to select power level when high switch is off. Low (0v) for medium power, high (12vdc) for low power. S9) manual switch: manual expose switch....

Page 108

13-22 94ms42 rev. B1 s/w ver 2.06 circuit diagram (64mv407 60hz) 1 high expose 4 power on 2 dc common 3 low expose 1 2 3 4 6 7 8 9 10 5 11 12 +12 v not used 110 vac ac common not used aux terminal connector p2 input filters input filters e1 e2 lamp signal lamp cooling logic 1 2 3 4 6 7 8 9 10 5 11 1...

Page 109

94ms42 rev. B1 s/w ver 2.06 13-23 lamphead for all lights 12 10 8 6 4 2 shutter position switch 11 9 7 5 3 1 shutter motor lamp trigger board blowers thermostat thermostat safety glass switch.

Page 110

13-24 94ms42 rev. B1 s/w ver 2.06 al 84 power supply 60hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2 yel...

Page 111

94ms42 rev. B1 s/w ver 2.06 13-25 al 84-480 power supply 60hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2...

Page 112

13-26 94ms42 rev. B1 s/w ver 2.06 al 94 power supply 50hz safety interlock din socket 1 2 3 4 5 wht 6 7 8 9 10 blu 11 12 1 blk 2 wht 3 blu 4 red 5 blu/wht 6 brn/wht 7 org/wht 8 red/wht 9 10 brn 11 org 12 gry 18 17 16 15 14 blk 13 wht 12 red 11 10 blk 9 clear 8 brn 7 org 6 red 5 blu 4 wht 3 pur 2 yel...

Page 113

94ms42 rev. B1 s/w ver 2.06 13-27 interconnect cable 1 2 4 3 6 5 8 7 10 9 12 11 white green violet blue orange black yellow red brown heat shrink 1 2 4 3 6 5 8 7 10 9 12 11 white green violet blue orange black yellow red brown heat shrink.

Page 114

13-28 94ms42 rev. B1 s/w ver 2.06.

Page 115

94ms42 rev. B1 s/w ver 2.06 14-1 14. Printing light check list check list for printing light troubleshooting and service ! C in order for this check list to be effective it must be followed step by step. 1) disconnect the integrator/timer from the power supply. This will make sure that a faulty inte...

Page 116

14-2 94ms42 rev. B1 s/w ver 2.06 • you must be able to reach up, place your fingers against the safety glass and there must be play front to back and side to side. Otherwise the glass does not have room for expansion and will more than likely shatter under use. ! C never operate the light source wit...

Page 117

94ms42 rev. B1 s/w ver 2.06 14-3 8) check capacitors and relay circuit by: the capacitors and relays are checked by watching the voltage changes that take place at the different intensity levels. If a capacitor is not in the circuit the voltage readings on input and output will be the same. If the c...

Page 118

14-4 94ms42 rev. B1 s/w ver 2.06 8kw with l1280 lamp orange yellow brown blue #1 blue #2 a. Idle 700+ 360 700+ 700+ 700+ b. Low 700+ 360 700+ 700+ 700+ c. Medium 700+ 390 390 700+ 700+ d. High 700+ 425 425 425 425 8kw with l1281 lamp orange yellow brown blue #1 blue #2 a. Idle 700+ 395 700+ 700+ 700...

Page 119

94ms42 rev. B1 s/w ver 2.06 14-5 checks affect the operation and can make them appear to be operating incorrectly. Also check blower voltage at terminals 4 & 5 for most lights this voltage should be a minimum of 65v~ to 75v~ some lights this voltage will be higher depending on lamp used and lamp con...

Page 120

14-6 94ms42 rev. B1 s/w ver 2.06 26) before you reassemble everything it is a real good idea to: check the manual operations of the light source. Just to make sure everything is back together. 27) reconnect all wires to the integrator and then: check the remote operations of the light source from th...

Page 121: 15. Fault Trees

94ms42 rev.B1 s/w ver 2.06 15-1 15. Fault trees no strike fault tree does shutter rotate when light turned on? Yes no check safety glass and lever no good are any led's lit on the pc board? Yes yes yes yes yes yes no no no no no no good reinstall safety glass test 1 is power relay pulling in? Go to ...

Page 122

15-2 94ms42 rev.B1 s/w ver 2.06 shutter rotation fault tree front view of control board pc board to terminal strip repair or replace wiring from pc board replace no yes board connector on pc 2 and 4 at power 120vac at pins lit, check for if led #d17 is tree no strike fault lit. Go to the the lamp be...

Page 123

94ms42 rev.B1 s/w ver 2.06 15-3 drive motor fault tree manually position both frames in a mid position turn unit on does upper frame move into unit? Yes wait 20 seconds. Does integrator display an error message? No yes no does lower frame move into unit no yes try a blank tray cycle. Do frames switc...

Page 124

15-4 94ms42 rev.B1 s/w ver 2.06.

Page 125: 16. Parts List

94ms42 rev.B1 s/w ver 2.06 16-1 16. Parts list part number description qty. Per unit 62ap42cl base kit accuprint closed loop 1 39vap05 vacuum pump 230 v 60 hz 2 55sw45-6 button, white ‘go’ 1 55sw45-7 button, white ‘stop’ 1 62d3542a00 assembly rail cover, ov45 1 62d3705a00 base assembly ap 42cl 1 68d...

Page 126

16-2 94ms42 rev.B1 s/w ver 2.06 part number description qty. Per unit 43spr17 spring, tors. Lh 1 43spr18 spring, tors, rh 1 44gkt01 gasket, 1/16 thick 0 44tie08 nsi cable tie, uv 5 55sw02 switch, timing 4 55sw55 pushbutton switch 2 62d2321a00 assembly, wheel, lig 2 62d3706a00 exposure tray(lower) 1 ...

Page 127

94ms42 rev.B1 s/w ver 2.06 16-3 part number description qty. Per unit 43fit46 reducer nipple-male 3 43fit49 female conn. 1"npt brass 2 43fit51 male-female elbow 2 43fit52 female tee, brass, 1"npt 3 43fit54 cross-female, 3 / 4 "npt 1 43fit57 hex nipple-male 8 43fit58 bushing,femal-male 1" x 1 / 2 " 2...

Page 128

16-4 94ms42 rev.B1 s/w ver 2.06 part number description qty. Per unit 49vav01 valve, vacuum relief 2 62d2321a00 assembly, wheel, light bl 2 62ap42cl-nsa assy nose fan/work light 1 11d1939a62 bracket, filter holder 2 11d1939b62 bracket, filter holder 2 11d3733a07 reflector, worklight 1 11d3734a08 air...

Page 129

94ms42 rev.B1 s/w ver 2.06 16-5 part number description qty. Per unit 62d3476a00 assy, condensate evap-cls 1 39evp01 condensate evaporator, 23 1 42hhs2175 grommet,rubber 3 / 4 " 1 51tml03 terminal male 14-20 awg 3 52rcp08 receptacle, 3 pin 1 68d3477a00 instr. Assy,cond evap-cls 1 62d3555a00 assy,ctr...

Page 130

16-6 94ms42 rev.B1 s/w ver 2.06 part number description qty. Per unit 33rly20 relay, 12vdc, chassis mount 1 44rub03 grommet,continuous .06 0 44tie03 nsi cable tie 7 1 / 2 "#50 max 10 51si18 nsi spade, ins 22-18 # 8 2 52fuh04 fuse holder, 3ag/3ab 6 52fuh07 fuse block- 13 / 32 " x 1 1 / 2 " 1 52fuh08 ...

Page 131

94ms42 rev.B1 s/w ver 2.06 16-7 part number description qty. Per unit 62cl84-480-l2 power supply 480v 60hz,8k 16d2617b00 power cable, al85-ap42 ps 16d1045a00 harness, beau plug 1 16d1585 interlock harness 1 16d2617a00 power cable 1 16d2629a00 harness, 8k-b p/s - main 1 32bal01 ballast, al 83 4 33rly...

Page 132

16-8 94ms42 rev.B1 s/w ver 2.06 part number description qty. Per unit 55sw03 switch, glass, 2 pos blk 1 56thm01 thermostat, model k 2 62lhk01 switch assembly 1 63d3669a00 idler, arms assy lt8 1 64mv414-t trigger board tested 8k 1.

Page 133: 17. Warranty

94ms42 rev. B1 s/w ver. 2.06 17-1 17. Warranty olec limited warranty olec equipment is warranted against defects in material for one (1) year from date of purchase. Faulty parts will be repaired, replaced, or purchase price refunded at olec's option, for the original buyer, provided the parts have b...

Page 134

O corporation 17112 armstrong avenue, irvine ca u.S.A. 92614 u.S.A. (949) 399-6500 fax (949) 399-6501.