- DL manuals

- Ace Heating

- Boiler

- "B_G" Series

- Operating And Maintenance Manual

Ace Heating "B_G" Series Operating And Maintenance Manual

Summary of "B_G" Series

Page 1

Operating and maintenance manual designed and manufactured in accordance with asme code section iv, heating boilers e.T.L. Listed asme code construction and stamped. Photo shown may vary from actual model. Model “b_g” series gas-fired copper fin water boilers hlw h.

Page 2

Installation and maintenance instructions for series “e” and “g” copper fin coil heaters for your safety if you smell gas 1. Open windows 2. Don’t touch electrical switches 3. Extinguish any open flame 4. Immediately call your gas supplier for your safety do not store gasoline or other flammable vap...

Page 3

Caution should over heating occur, or the gas supply fail to shut off, tur n off the manual gas valve to the appliance immediately. A. I nstallation (1) t his section addresses the installation of a ce b oiler i nc . W ater h eaters within mechanical systems , and is intended to provide some explana...

Page 4

S ection 250 continued f. R elief v alves (1) the storage tank should be protected with a pressure (or combination temperature and pressure) relief valve set so as not to exceed the maximum tank operating pressure. The relief valve should be located within 6" of the top of the tank. Refer to local c...

Page 5

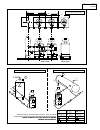

6 6 6 6 drafthood drafthood drafthood a a1 a2 c r gt prv p&t op op p&t prv cp cold in hot out gt prv p&t op c r prv cold in hot out cp p&t h o o k - u p w i t h h o r i z o n t a l ta n k h o o k - u p w i t h ve r t i c a l ta n k c i r c u l a t i o n f l o w f r o m a c e s e c t i o n 2 3 5 c gt...

Page 6

Scale: date: drawn by revised rev. Size control nu mbe r drawing number approved by: a pb 2/01/00 ace heater gas train standard for csd-1 g-22225 n/a header comb. Gas valve shut-off valve pilot line pilot line typ comb. Gas valve typ header shut-off valve b2 thru b8 indoor/outdoor csd-1 gas train fo...

Page 8

A.S.M.E. U.L. Listed 1 draft hood - not shown 2 outer lid 3 inner lid 4 coil-finned copper - includes parts no. 5, 6, 7, 8 5 manifold pipe connection (2 req’d.) 6 inner jacket - coil support & enclosure 7 stainless steel baffle for coil 8 hold down bracket - (coil & baffle) with j bolt 9 stainless s...

Page 9

A jax b oiler i nc. - a ce b oiler i nc. Factory limited warranty policy the ajax boiler factory limited warranty provides assurance that all products are free from manufacuteres defects at the time of shipment and meet specifi cations and performance described in the product literature. It is impor...

Page 10: Arranty

A jax b oiler i nc. - a ce b oiler i nc. W arranty limited thermal shock in addition to our standard one (1) year warranty against defective parts and workmanship, ajax boiler inc. Provides the following guarantee with all commercial hot water, forced circulation, space heating boilers: ajax boiler ...

Page 11: Arranty

A jax b oiler i nc. - a ce b oiler i nc. Limited w arranty ajax boiler inc. Provides a limited warranty on its products against defective material and/or workmanship only . This limited warranty is not applicable to operational failures, electrical failures, gasket leaks, wear or malfunctions caused...

Page 12: Arning

A jax b oiler i nc. - a ce b oiler i nc. W arning product safety notice ajax boiler and water heater products operate at high temperature and pressures • before using this product, read and understand instructions. Save these instructions for future use. • before servicing, to prevent serious burns ...

Page 16: Warning

Furnace, for which the controls were originally in- tended, typically operates less than 20,000 cycles per year. • exposure to water, dirt, chemicals, and heat can damage the module or the gas control and shut down the control system. A nema 4 enclosure can reduce exposure to environmental contamina...

Page 17

Connect ignition cable use honeywell ignition cable or construct an ignition cable that conforms to suitable national standards such as underwriters laboratories inc. See tables 2 and 3. Note: when using an s8610 or s8670 to replace an s86, use the enclosed adapter to convert the s86 ignition cable ...

Page 18

Fig. 4—s8610a,b in a heating system with an atmospheric burner. Fig. 3—s8610f,h with a vent damper plug in a heating system with an atmospheric burner and a d80d vent damper. 6 q345, q346, q348, q362, q381 pilot burner/ igniter-sensor l1 (hot) l2 thermo- stat 1 limit controller 2 4 mv mv/pv pv gnd (...

Page 19

8 fig. 7—s8610f,h; s8670d in a heating system with a two-stage gas control and power-assisted combustion. 5 mv mv/pv pv gnd (burner) 24v gnd 24v th-w (opt) vent damper plug (opt) spark 5 s8610f,h; s8670d pilot burner ground pilot gas supply q345, q346, q348, q362, q381pilot burner/ igniter- sensor 3...

Page 20

10 fig. 9—s8610f,h; s8670d in a heating-cooling system with power-assisted combustion. Mv mv/pv pv gnd (burner) 24v gnd 24v th-w (opt) vent damper plug (opt) spark 5 s8610f,h; s8670d power supply. Provide disconnect means and overload protection as required. Alternate limit controller location. Maxi...

Page 21

12 fig. 11—s8610f,h; s8670d in a commercial water heater control system. Controller 4 mv mv/pv pv gnd (burner) 24v gnd 24v th-w (opt) vent damper plug (opt) spark 4 s8610f,h; s8670d 1 power supply. Provide disconnect means and overload protection as required. Maximum cable length 3 ft [0.9 m]. Contr...

Page 22: Warning

14 operation module operation can be conveniently divided into two phases for s8610 and three for s8670. The phases are: • prepurge (s8670 only) • t rial for ignition (all models) • main burner operation (all models) figs. 12 and 13 summarize the normal operating se- quences of the modules. Prepurge...

Page 23: Warning

Warning when performing the following steps, do not touch stripped end of jumper or spark terminal. The ignition circuit generates over 10,000 volts and electrical shock can result. ■ energize the module and immediately touch one end of the jumper firmly to the gnd terminal on the module. Move the f...

Page 24

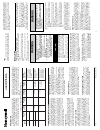

Fig. 16—s8670 troubleshooting guide. 18 • • check continuity of ignition cable and ground wire. Note: if ground is poor or erratic, shutdowns may occur occasionally even though operation is normal at the time of checkout. If checks are okay, replace module. M1173b start check line voltage power, low...

Page 25

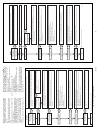

Fig. 18—representative schematic for s8610a,b. See fig. 3 for hookup. 20 l1 (hot) l2 1 24v transformer limit controller on-off switch 24v 2 thermostat or controller 24v (gnd) 1k1 1k2 3k2 2k2 3k1 gnd (bur- ner) mv/ pv mv pv igniter burner ground 1 2 power supply. Provide disconnect means and overload...

Page 26

Exhibit b procedure for installing automatic intermittent pilot systems prior to beginning this procedure, a preliminary ex- amination of the appliance and the automatic intermit- tent pilot system should be made to determine that the automatic intermittent pilot system can be properly applied to th...

Page 27: And Q381A

Pilot burner/igniter-sensor must be rigidly positioned relative to main burner m3271 g. S. • rev. 7-93 • ©honeywell inc. 1993 • form number 60-0653—8 q345a, q348a, q348b, q362a,q373a and q381a pilot burner/igniter -sensors application these pilot burner/igniter-sensors provide pilot flame ignition a...

Page 28: Arning

3 60-0653—8 fig. 5—igniter-sensor tip must be in pilot flame. Fig. 6—proper shielding of pilot flame. M1273 typical shield ■■ set the thermostat to call for heat. ■■ watch the pilot burner during the ignition sequence. See if: • ignition spark continues after the pilot is lit. • the pilot lights and...

Page 29

Listings/approvals: • ul guide (nkpz) for industrial control equipment per ul standard 508 industrial control equipment • ul guide (mfhx) for heating/cooling ap- pliance switch per ul standard 353 limit controls • csa class (321106) for industrial control equipment per csa standard c22.2 no. 14-m in...

Page 30

Fig. 4 caution: screw the device into the tee fitting as shown. Care must be taken to properly orient the device for the direction of the flow. Do not tighten by grasping the switch enclosure. Use the wrenching flats on the bushing only. Turning radius required for mounting the ifs is 3". Fig. 5 use...

Page 31

Schema tic sketch shows arrangement of thermost at s and unitrol 7000 bgo in typical fryer applica tion information subject to change without notice. 7/99 refer to appliance manufacturer ’s instructions for proper system operation. The 7000 “d” series controls cont ain dual automatic valves (solenoi...

Page 32: L4008A,

95-5971—2 2 l4008a,b,e,l; l6008a,g,h remote bulb aquastat ® controllers the aquastat® controller can be remotely mounted— either vertically on a wall or panel, or directly on the boiler, tank, or vessel. If the system is filled, drain the system to a point below the boiler tapping, or to wherever th...

Page 33

95-5971—2 4 l4008a,b,e,l; l6008a,g,h remote bulb aquastat ® controllers home and building control honeywell limited-honeywell limitée 740 ellesmere road scarborough, ontario m1p 2v9 helping you control your world 95-5971—2 j.H. Rev . 9-95 printed in u.S.A quality is key home and building control hon...

Page 34: Vr8104, Vr8204, and

Vr 8104 , vr 820 4 an d vr 8304 i n t e r m it ten t pi lo t co m b in a t io n g a s co n t r o l s 69 -122 5—4 2 a avai la b le onl y on c e v r 82 04 m odel s. T a bl e 4. Vr 820 4a, h /v r 8 304a ,h ,u ce . A the vr 82 04u use s s tan dar d u .S. C onst ru ct ion. I n le t a nd out le t por ts a...

Page 35

Vr 8104 , vr 820 4 an d vr 8304 i n t e r m it ten t pi lo t co m b in a t io n g a s co n t r o l s 69 -122 5—4 4 co rrosive chemica ls c o rr osi ve chem ic al s can at ta ck t h e co nt ro l, ev ent ual ly causi ng a f a ilur e. I f chem ic al s ar e use d fo r r o u ti ne cl e ani n g , av oi d ...

Page 36

Vr 8104 , vr 820 4 an d vr 8304 i n t e r m it ten t pi lo t co m b in a t io n g a s co n t r o l s 69 -122 5—4 6 fi g . 3. S e d im e n t t rap i n st al la ti on. Ins tall con trol 1. M ount ed 0 t o 90 d egr ees i n an y di re c ti on, in cl ud in g ver ti cal ly , fr om t he upr ight p o si ti ...

Page 37

Vr 8104 , vr 820 4 an d vr 8304 i n t e r m it ten t pi lo t co m b in a t io n g a s co n t r o l s 69 -122 5—4 8 f ig. 8. T y p ica l w ir ing con nect ions f o r 2 4 v o lt con tr o l in i n te rm it ten t i gni ti on s yst em w it h s8 6 00. St artup and checkout w arnin g fi re o r e x pl os io...

Page 38

Vr 8104 , vr 820 4 an d vr 8304 i n t e r m it ten t pi lo t co m b in a t io n g a s co n t r o l s 69 -122 5—4 1 0 4. Wi th m a in bu rn e r op er a ti ng, c heck t h e gas cont ro l fl ow r a te usi ng t he m e te r c locki ng m e thod o r che ck pr essur e usi ng a m a nom et er co nnect ed t o ...

Page 39

69 -122 5—4 g.R. Rev . 9- 00 www .Hone ywell.Com h o m e an d bu il di n g c o nt rol h o m e an d bu il di n g c o nt rol h oney w el l inc. H o n eyw el l l im it ed-h oneyw el l l im it ée 1985 d ougl as d ri v e n o rt h 35 d ynam ic d ri v e g o ld en v al ley, mi nnesot a 554 22 scar bor ough,...

Page 40: Deliming Kit

Deliming procedure — connect a ce deliming kit as shown in picture. 1. Close gas cock at heater. 2. Turn off water to and from heater and drain heater. 3. Type “c” a ce heater, remove upper aquastat and well and install faucet; type “d”, “e” and "g" a ce heater, remove pipe plug on left side of uppe...