- DL manuals

- Ace Heating Solutions

- Boiler

- Atlas A050

- Operating And Maintenance Manual

Ace Heating Solutions Atlas A050 Operating And Maintenance Manual - 1 Introduction

8

Rev 2.1

1 Introduction

This manual covers installation, maintenance, and operation instructions as well as instruction manuals for each of the

control options. Please review this manual carefully before installation or operation. A copy of this manual should be kept

with the boiler at all times for reference. If this manual is misplaced or lost, check the Ace Heating Solutions, LLC.

website,

www.aceheatingllc.com

, to print from an electronic copy or contact your local Ace Heating Solutions, LLC

representative.

Atlas Series High Efficiency Condensing Boilers have a rugged all-steel frame and low jacket temperatures allowing zero-

clearance installation. It features 6½" forklift holes for easy handing, a front removable exchanger assembly for

serviceability, an efficient blower allowing at least 30 ft each of intake and exhaust vertical venting, and a microprocessor

based flame safeguard with non-volatile ignition lockout.

The heat exchanger tubes are formed into a cylindrical shape to provide maximum waterside and fireside performance.

The entire heat exchanger assembly is easily removable and replaceable using hand tools only, without performing

welding or cutting operations and without the use of gaskets. Your condensing boiler is E.T.L. listed and carries the E.T.L.

listing mark. It is constructed and stamped in accordance with Section IV of the ASME Code, and is stamped on the

nameplate with applicable markings.

Warning:

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury, loss of warranty, exposure to hazardous materials or loss of life. Review the information in this manual carefully.

For your safety:

Do not store or use gasoline or other flammable vapors and liquids or other combustible materials in the

vicinity of this or any other appliances. To do so may result in an explosion or fire.

What to do if you smell gas:

x Do not try to light any appliance

x Open any windows and secure area

x Do not touch any electrical switch; do not use any phone in your building.

x Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

x If you cannot reach your gas supplier, call the fire department.

Installation and Service must be performed by a qualified installer, service agency or the gas supplier

Warning: Make sure the gas on which the boiler will operate is the same as that specified on the boiler rating plate

(natural gas/propane).

Warning: Caution when servicing gas train components. Propane (LPG) is heavier than air and may trap in pipes, vents,

combustion chamber, or other areas. Always handle with care.

Warning: Should overheating occur or if the gas supply valve fails to shut, do not turn off or disconnect the electrical

supply to the boiler. Instead, shut off the gas supply at a location external to the boiler.

Warning: Do not use this boiler if any part has been under water. Immediately call a qualified service technician to inspect

the boiler and to replace any part of the control system or any gas control which has been under water.

Warning: To minimize the possibility of improper operation, serious injury, fire, or damage to the boiler:

1. Always keep area around the unit(s) free of chlorine, combustible materials, gasoline, and other flammable liquids and

vapors.

2. Water to be heated in the boiler should be free or have low levels of chlorine or other chemicals or water conditions that

would be harmful to the copper heat exchanger. Boiler room ambient temperature shall not exceed 100 degrees F.

3. Boiler should never be covered or have any blockage to the flow of fresh air to the boiler.

Warning: Risk of electrical shock. More than one disconnect switch may be required to de–energize the equipment

before servicing.

Summary of Atlas A050

Page 1

Operating and maintenance manual designed and manufactured in accordance with asme code section iv heating boilers photo shown may vary from actual model. Copper-fin coil high efficiency condensing boiler / water heater models a050-a300 e.T.L. Listed e.T.L. Canadian listed c hlw u.L. 795 csa 3.1 h.

Page 2: Table of Contents

2 rev 2.1 table of contents description page # 1 introduction .......................................................................................................................................................... 8 1-1 pre-installation ...............................................................

Page 3

3 rev 2.1 3-6 diagnostic mode ........................................................................................................................................ 41 3-7 error mode ......................................................................................................................

Page 4

4 rev 2.1 5-1.5 to change ch loop time of day setpoint ....................................................................................... 69 5-1.6 to change ch loop off hysteresis ................................................................................................... 69 5-1.7 to cha...

Page 5

5 rev 2.1 5-6.1 to enable or disable dhw high limit ............................................................................................. 76 5-6.2 to change dhw high limit setpoint ................................................................................................ 77 5-6.3 to ch...

Page 6

6 rev 2.1 5-14.1 to enable lead lag master .............................................................................................................. 82 5-14.2 to change lead lag ch setpoint..................................................................................................... 82 5...

Page 7

7 rev 2.1 5-24.4 to change burner name ................................................................................................................... 87 5-24.5 to change installation data ..............................................................................................................

Page 8: 1 Introduction

8 rev 2.1 1 introduction this manual covers installation, maintenance, and operation instructions as well as instruction manuals for each of the control options. Please review this manual carefully before installation or operation. A copy of this manual should be kept with the boiler at all times fo...

Page 9

9 rev 2.1 warning: when servicing ceramic fiber based refractory or insulation blanket, gloves and respirators should be worn to reduce exposure to airborne refractory ceramic fibers. Caution: this boiler requires forced water circulation when burner is operating. See minimum and maximum flow rates....

Page 10: Atlas A 150 C - W

10 rev 2.1 1-2 boiler nameplate and model number the boiler name plate the following illustration is an accurate depiction of the nameplate found on the rear side of the boiler. You will also find an asme nameplate on the inlet pipe with some of the same information. A. Boiler description b. Model n...

Page 11

11 rev 2.1 (no suffix refers to indoor jacketing) 1-3 rating and certifications all units must be installed in accordance with all state and local codes, and national codes, including but not limited to: x ansi z21.10.2, gas water boilers x ansi z223.1/ nfpa 54, national fuel code x ansi/ nfpa 70, n...

Page 12

12 rev 2.1 and severe burns or death from scalds. When supplying general purpose domestic hot water, the recommended setting for the operating control is 125 degrees f. Safety and energy conservation are factors to consider when setting the temperature aquastat on the unit. The most energy–efficient...

Page 13: 2 Installation

13 rev 2.1 2 installation 2-1 installation codes installations must follow these codes: x local, state, provincial, and national codes, laws, regulations and ordinances x national fuel gas code, ansi z223.1/ nfpa 54 – latest edition (nfgc) x national electrical code, ansi/ nfpa 70 – latest edition (...

Page 14

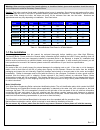

14 rev 2.1 must allow sufficient space behind the boiler to service vent connections, water pipe connections, piping and other auxiliary equipment, as well as the appliance. Model top clearance front clearance side clearance bottom clearance a050 18" 36" 6" 0" a075 18" 36" 6" 0" a100 18" 36" 6" 0" a...

Page 15

15 rev 2.1 provisions for combustion and ventilation air must be in accordance with air for combustion and ventilation, of the latest edition of the national fuel gas code, ansi z223.1, in canada the latest edition of cga standard b149 installation code for gas burning appliances and equipment, or a...

Page 16

16 rev 2.1 2. The exhaust vent must be installed with a slight upward slope of not more than ¼ inch per foot of horizontal run to vent terminal. 3. The exhaust vent must be insulated through the length of the horizontal run. 4. Intake and exhaust vents with vertical termination should have a rain ca...

Page 17

17 rev 2.1 3. The opening must have a minimum free area of 1 sq. In. Per 3,000 btuh of the total input rating of all equipment in the room, or no less than the sum of the areas of all vent connectors in the confined space. (for additional information, referred to the latest nfgc) warning: do not use...

Page 18

18 rev 2.1 note: your atlas series condensing boiler requires category iv venting. (see nfgc, nfpa 54, section 7 “venting equipment” for more detailed information). The atlas is designed to operate with a chamber pressure of 0 to +0.5" w.C. The atlas condensing boiler is capable of 100 feet of verti...

Page 19

19 rev 2.1 us installations refer to the latest edition of the national fuel gas code. 1. Vent must terminate at least 4ft below, 4 ft horizontally from or 1 ft above any door, window or gravity air inlet to the building. 2. The vent must not be less than 7ft above grade when located adjacent to pub...

Page 20

20 rev 2.1 vertical venting (category iv) the maximum and minimum venting length for this category iv appliance shall be determined per the nfgc (us) or cga, b149 (canada). The diameter of the vent flue pipe should be sized according to nfgc (us) and appendix b of the cga, b149 (canada). The minimum...

Page 21

21 rev 2.1 figure 2.4. Suggested single fuel atlas gas piping figure 2.5. Suggested dual fuel atlas gas piping.

Page 22

22 rev 2.1 testing gas line caution: the boiler must be disconnected from the gas supply during any pressure testing of the gas supply at test pressures in excess of ½ psi (14" w.C.). Warning: the boiler must be isolated from the gas supply piping system by closing the upstream manual shut – off val...

Page 23

23 rev 2.1 caution: never operate the pump dry, the system must be filled before starting the pump. Ensure all isolation valves are open before start up. An optional pump can be ordered through ace sized for the boiler. If a pump is ordered, a wilo top z 2x30 single phase, bronze, lead free pump wil...

Page 24

24 rev 2.1 check the power source warning: using a multi–meter, check the following voltages at the circuit breaker panel prior to connecting any equipment. Make sure proper polarity is followed and house ground is proved. (see below) ac = 108 vac minimum, 132 vac max; ab = 108 vac minimum, 132 vac ...

Page 25

25 rev 2.1 2-10 dhw/ch installation and programming your atlas boiler is preprogrammed from the factory for domestic hot water or central heating application. Three different panel options are available: basic panel, enhanced panel, system operator interface panel (reference pictures below). Install...

Page 26

26 rev 2.1 2-10.3 4–20 ma remote setpoint remote setpoint control will be enabled from the factory with default setting of 40 ͼf for 4 ma and 200ͼf for 20 ma. When the remote signal is connected to the boiler, setpoint is provided using the linear interpolation of the 4 ma and 20 ma input signal fro...

Page 27

27 rev 2.1 the slave’s commanded firing rate. If at least one stage has been dropped, no stage is requested to exceed the common base load rate. 2-12.3 add stage method factory default setting for adding a stage is error threshold method. A stage is added when the error becomes excessive based on th...

Page 28

28 rev 2.1.

Page 29

29 rev 2.1 2-13.2 modbus address programming each boiler on the daisy chain network must have a unique address. Go to section 3 for instructions to change modbus address using basic panel or section 4 with enhanced display or system integrator display. 2-13.3 lead lag bus wiring lead lag system func...

Page 30

30 rev 2.1 2-14 suggested piping 2-14.1 suggested domestic hot water piping diagrams figure 2.9. Atlas in primary loop piping diagram.

Page 31

31 rev 2.1 figure 2.10. One atlas one tank suggest piping diagram.

Page 32

32 rev 2.1 figure 2.11. One atlas two tank piping diagram.

Page 33

33 rev 2.1 figure 2.12. Two atlas one tank piping diagram.

Page 34

34 rev 2.1 figure 2.13. Two atlas two tank piping diagram.

Page 35

35 rev 2.1 2-14.2 suggested central heating piping diagrams figure 2.14. Atlas primary secondary loop piping diagram.

Page 36

36 rev 2.1 figure 2.15. Two atlas in primary secondary loop piping diagram.

Page 37

37 rev 2.1 3 basic panel operating procedures 3-1 introduction the information in this chapter provides a guide to the operation of the boiler using the basic panel mounted on the front of the unit. It is imperative that the initial startup of this unit be performed by factory trained personnel. Ope...

Page 38

38 rev 2.1 3-4 user mode in user mode, the basic panel displays operating data of the unit such as outlet temperature, ch setpoint, or boiler firing rate. The user can change screens by pressing the next button. Depending on unit’s mode of operation, the basic panel distinguishes between two home sc...

Page 39

39 rev 2.1 symbol value description outlet outlet temperature or outlet setpoint display current outlet temperature and display and modify current outlet (ch) setpoint temperature inlet inlet temperature display current inlet temperature t delta temperature display delta t temperature [outlet] - [in...

Page 40

40 rev 2.1 setup mode consists of the following items in table 3.2. Pressing the next button progresses through the setup mode screens. Symbol value description °f/°c temperature unit set display to either degrees fahrenheit or degrees celsius. Lbthodlod outdoor reset parameter display and modify ou...

Page 41

41 rev 2.1 lead lag configuration lead lag configuration parameter can be changed in the setup mode. Enter setup mode and continue scrolling until remote firing control screen is reached. The following parameters are mapped to modbus addresses screen. Ll - lead lag operation x ldr: master and slave ...

Page 42

42 rev 2.1 symbol value description a flame signal display current flame signal strength value in vdc. Alert alert display last alert code number (see appendix a for description). Lockout lockout display last lockout code number (see appendix b for description). Outlet outlet temp high limit display...

Page 43

43 rev 2.1 lockout a lockout code is displayed in the numerical part of the display when a lockout state is received. When the reset button is pressed, the honeywell sola controller is forced to leave the lockout state. Communication timeout alert code 981 is displayed as basic panel internal alert ...

Page 44

44 rev 2.1 xpump contact stays closed for 1 minute (configurable through enhanced or system operator interface panel) for boiler circulation pump to remove residual heat from heat exchanger. 3-9 start/stop levels start/stop levels are controlled by setpoint, on and off hysteresis. Central heating an...

Page 45

45 rev 2.1 4 enhanced/system operator interface panel operating procedures 4-1 introduction the information in this chapter provides a guide to the operation of the boiler using the enhanced panel or system operator interface panel. It is imperative that the initial startup of this unit be performed...

Page 46

46 rev 2.1 4-4 system operator interface panel home page for system operator interface multiple unit applications, each boilers is represented on the home page by an icon and name. Pressing the icon allows the user to zoom in on that boiler and see specific details about it. These details are provid...

Page 47

47 rev 2.1 figure 4.4 – keyboard 4-7 status page a status page as in figure 4.5 is displayed when a single boiler is selected on the home page or root page for equipment with enhanced panel. The status page displays the current condition of the unit and displays some of the more important configurat...

Page 48

48 rev 2.1 configuration parameters for the honeywell sola controller (flame safe guard and operating control) on any boiler connected in the global modbus™ network can be accessed from the system operator interface. Press the icon of the honeywell sola controller on the home page to access the stat...

Page 49

49 rev 2.1 figure 4.8 – login request the honeywell sola controller on each boiler also maintains a password time out that limits the scope of the password entry. Once a password is successfully entered the unit starts an internal timer that expires after 10 minutes of inactivity. After the timer ex...

Page 50

50 rev 2.1 figure 4.10 – changing configuration parameter page for safety configuration parameters an additional verification step is required to commit the changes. Safety parameters are grouped into blocks that include only safety parameters, not a mixture of safety data and non-safety data. All p...

Page 51

51 rev 2.1 the settings of all parameters in each safety block must be confirmed to commit them in the honeywell sola controller. When the user is done changing safety parameters, pressing the confirm button begins the confirmation stage. The settings for all safety parameters in each changed block ...

Page 52

52 rev 2.1 a less serious alarm condition may also occur that is treated as warning instead of a fault. Active fault codes for each annunciation and a warning code can be reported by each honeywell sola controller. Any new fault code detected in a honeywell sola controller is indicated as a lockout ...

Page 53

53 rev 2.1 figure 4.17 – honeywell sola controller alert log 4-13 operation page the operation page displays the boiler running operation, including setpoint and firing rate. From this page the user can change setpoints, view annunciation information, and switch between central heating or domestic h...

Page 54

54 rev 2.1 4-15 trend analysis page trend analysis of boiler status data can be viewed on the operator interface. A graph displays a historical view of honeywell sola controller status data over varying time periods. A 2-dimensional graph with status data values shown on the y axis over time specifi...

Page 55

55 rev 2.1 table 4.4 – honeywell sola controller identification information 4-18 central heating parameters table 4.5 displays central heat configuration parameters. Refer to 5-1 central heat related configuration for central heat parameter programming. Parameter comment password ch enable disable o...

Page 56

56 rev 2.1 maximum off point 32 °f to 240 °f (0 °c to 115 °c) none table 4.6 – outdoor reset configuration parameters 4-20 dhw configuration parameters table 4.7 displays domestic hot water (dhw) configuration parameters. Refer to 5-3 domestic hot water related configuration for domestic hot water (...

Page 57

57 rev 2.1 table 4.7 – domestic hot water (dhw) configuration parameters 4-21 modulation configuration parameters table 4.8 displays modulation configuration parameters. Refer to 5-4 modulation related configuration for modulation parameter programming. Parameter comment password ch maximum modulati...

Page 58

58 rev 2.1 parameter comment password ch pump control auto or on ch pump operation the ch pump can be turned on manually, or it can be set to operate automatically. If it is turned on, it remains on until changed back to auto. In auto mode it operates according to the demand sources listed for ch pu...

Page 59

59 rev 2.1 then a response defined by dhw high limit response will occur. Outlet high limit response lockout read only outlet high limit setpoint 32 °f to 240 °f (0 °c to 115 °c) installer table 4.11 – high limit configuration parameters 4-25 stack limit configuration parameters table 4.12 displays ...

Page 60

60 rev 2.1 alert and holds while waiting for a delay to expire, and after the delay it tries again. Recycle & delay with limit: same as above but with retry limit. If limit count is reached lockout will occur. Table 4.13 – other limit configuration parameters 4-27 frost protection configuration para...

Page 61

61 rev 2.1 table 4.16 – warm weather shutdown configuration parameters. 4-30 t-rise limit configuration parameters table 4.17 displays t-rise limit configuration parameters. Refer to 5-12 t-rise limit configuration for t-rise limit parameter programming. Parameter comment password outlet t-rise enab...

Page 62

62 rev 2.1 table 4.18 – lead lag slave configuration parameters 4-32 lead lag master configuration parameters table 4.19 displays lead lag master configuration parameters. Refer to 5-14 lead lag master configuration for lead lag master parameter programming. Parameter comment password master enabled...

Page 63

63 rev 2.1 20 ma water temperature -40 to 266f (-40 to 130c) this parameter provides the temperature for the interpolation of 4-20ma curve. This value determines the maximum possible value for the setpoint. Installer outdoor reset enable or disable this parameter enables or disables the lead lag mas...

Page 64

64 rev 2.1 value to be used instead. Some rate allocation algorithms may specify the use of this parameter, and that the slave base load setting are ignored. Table 4.26 – lead lag advanced setting: rate allocation parameters parameter comment password method error threshold: a stage is added when th...

Page 65

65 rev 2.1 figure 4.40 – honeywell sola controller detail status page status information on the detail status page is organized into groups and displayed on the page one group at a time. The user moves from one group to another using the left and right arrow buttons. Status data on the detail status...

Page 66

66 rev 2.1 each status variable displayed in the trend analysis is represented by a different colored line, as follows: x first status variable: green x second status variable: yellow x third status variable: red x fourth status variable: blue no more than two different measurement units (such as de...

Page 67

67 rev 2.1 firing rate rpm fan speed rpm flame signal v header temperature if enabled outlet temperature degrees inlet temperature if enabled dhw temperature if enabled stack temperature if enabled outdoor temperature if enabled table 4.33 – analog i/o data analog i/o data is displayed as bar charts...

Page 68

68 rev 2.1 edit the date and time and press the ok button to set the new settings. Press the cancel button to exit without changing the time or date..

Page 69

69 rev 2.1 5 installer integration guide 5-1 central heat related configuration 5-1.1 to enable or disable ch loop configure ch – central heat configuration central heat ch enable textbox (ch mode default: enable, remote mod default: enabled, dhw mode default: enabled, com mode default: enabled) x s...

Page 70

70 rev 2.1 configure ch – central heat configuration setpoint on hysteresis textbox (default: 7 ͼf) x type in desired temperature between 2ͼf and 30ͼf (1ͼc and 16ͼc) the on hysteresis is subtracted from the setpoint to determine the temperature at which demand turns on. 5-1.8 to change ch loop hyste...

Page 71

71 rev 2.1 configure ch – central heat configuration modulation i-gain textbox (default: 50) configure ch – central heat configuration modulation d-gain textbox (default: 0) x type in desired number between 0 to 400 p gain applied to the proportional term of the pid equation for the ch loop. I gain ...

Page 72

72 rev 2.1 if outdoor reset feature is enabled and the sensor is functioning properly, then the current outdoor temperature is used to determine the setpoint by interpolation. This lookup function uses two x and y points to determine a line on the graph as shown in below. The y coordinate of the top...

Page 73

73 rev 2.1 x select sensor only for dhw demand from selected dhw modulation sensor x select dhw (s6) switch for dhw demand from dhw switch (switch replaces the dhw sensor) when sensor input is shorted burner demand exist outlet sensor will provide the temperature control x select stat terminal for d...

Page 74

74 rev 2.1 5-3.10 to change dhw loop p-i-d parameters configure dhw – domestic hot water configuration p-gain textbox (default: 50) configure dhw – domestic hot water configuration i-gain textbox (default: 50) configure dhw – domestic hot water configuration d-gain textbox (default: 0) x type in des...

Page 75

75 rev 2.1 5-4.5 to change dhw loop forced rate time configure modulation configuration dhw forced rate time textbox (default: 0m10s) x type in desired time between 0 to 5 minutes for dhw demand, if the dhw forced rate time is non-zero, then the firing rate will be held at the rate specified here du...

Page 76

76 rev 2.1 this time indicates how long the ch pump should remain on after demand from any source ends. That is, whenever the pump has been on, but the last requests for the pump to be on ends, it always continues to run for the time given by this parameter. 5-5.3 to set dhw loop pump control on or ...

Page 77

77 rev 2.1 x select disable to disable dhw loop high limit this parameter enables or disables the dhw high limit function. It must be disabled when the dhw input is used as a switch to indicate dhw demand. 5-6.2 to change dhw high limit setpoint configure high limits dhw high limit setpoint textbox ...

Page 78

78 rev 2.1 5-8 delta-t limit related configuration 5-8.1 to enable or disable delta-t limit configure delta t inlet to outlet flow delta-t enable textbox (default: no delta-t) x select enable to enable delta-t limit x select disable to disable delta-t limit this parameter enables or disables the ent...

Page 79

79 rev 2.1 x select recycle & delay with retry limit to recycle and delay in event of delta-t inverse limit up to delta-t retry limit 5-9 frost protection related configuration 5-9.1 to enable or disable ch loop frost protection configure frost protection configuration ch frost protection enable tex...

Page 80

80 rev 2.1 (default: 5m0s) x type in desired time between 0 to 5 minutes this time indicates how long the dhw pump should remain on after frost protection demand ends. That is, whenever the pump has been on due to frost protection and then this demand ends, it always continues to run for the time gi...

Page 81

81 rev 2.1 x select enable to enable outlet t-rise x select disable to disable outlet t-rise 5-12.2 to change t-rise degree configure t-rise limit configuration t-rise degree textbox (default: 50 ͼf/sec) x type in desired outlet t-rise degree if the outlet temperature rises faster than this number o...

Page 82

82 rev 2.1 5-13.5 to change demand to firing delay configure lead lag slave configuration demand to firing delay textbox (default: 2m0s) x type in desired slave demand to firing delay length of time to wait between requesting a stage to fire and detecting that it has failed to start. 5-13.6 to chang...

Page 83

83 rev 2.1 differential above setpoint when last ll stage boiler is turned off. 5-15.3 to change lead lag on hysteresis configure lead lag master configuration advanced setting modulation on hysteresis textbox (default: 10 ͼf) x type in desired ll on hysteresis differential below setpoint when first...

Page 84

84 rev 2.1 5-16.5 to enable or disable lead lag ch loop outdoor reset configure lead lag master configuration advanced setting central heat outdoor reset textbox (default: disabled) x select enable to enable ch loop outdoor reset x select disable to disable ch loop outdoor reset if outdoor reset is ...

Page 85

85 rev 2.1 this parameter represents the lead lag firing rate when frost protection is enabled. 5-19 lead lag advanced setting: wwsd parameter 5-19.1 to enable or disable lead lag wwsd configure lead lag master configuration advanced setting wwsd enable textbox (default: disabled) x select disable t...

Page 86

86 rev 2.1 configure lead lag master configuration advanced setting rate allocation base load common textbox (default: 40%) x type in desired rate % if this parameter is zero, this parameter is disabled. For any non zero value, individual base rate of each slave to be ignored by the ll master’s rout...

Page 87

87 rev 2.1 configure lead lag master configuration advanced setting drop stage detection time textbox (default: 0m30s) x type in desired time this parameter determines how long drop stage condition needs to persist for drop stage to occur. 5-23.3 to change drop stage error threshold configure lead l...

Page 88

88 rev 2.1 configure system configuration temperature units textbox (default: fahrenheit) x select fahrenheit to show temperature in fahrenheit x select celsius to show temperature in celsius this parameter determines whether temperature is represented in units of fahrenheit or celsius degrees. 5-24...

Page 89: 6 Start Up Instructions

89 rev 2.1 6 start up instructions your unit has been pressure tested in accordance with asme code section iv and fire tested in accordance with ul 795. A copy of the factory test report is included inside the unit behind the display panel, and a test report label is located on the inside of the top...

Page 90

90 rev 2.1 when unit is started up, it is important to check the following parameters and adjust them to the values seen on the factory test report. Please record the values in the blank spaces below. The values must be within the range seen below. Carbon monoxide __________ ppm (must be kept below ...

Page 91

91 rev 2.1 6-4.2 pilot turndown test - (optional at installation, required annually after) to test that the main burner can be lit by the smallest pilot flame the can be seen by the flame amplifier and energize the flame led. Clean the flame detector to make sure that it detects the smallest accepta...

Page 92

92 rev 2.1 5) if the flame signal is higher than 0.5 vdc and the flame led does come on, contact your local ace heating solutions, llc. Representative for more help. Figure 6.4. Voltmeter connected to control panel 6-4.4 gas valve leak test this test is to check the closure tightness of the gas shut...

Page 93

93 rev 2.1 figure 6.5 vas valve diagram figure 6.6 test setup diagram *warning- remove power from the system before beginning the valve leak test to prevent electrical shock. 1) de-energize the control system to make sure no power goes to the valves. 2) close the upstream manual gas cock 3) make sur...

Page 94

94 rev 2.1 the gas train has been checked before shipping, but could come loose during shipping. Turn “off” all electric power and open the main gas valve. Turn the unit’s switch to the “on” position and open the main gas valve and the ball valve to the burner mixer tube (the one between the fuel-ai...

Page 95

95 rev 2.1 6-4.6 blocked drain test - (optional) the blocked drain safety feature checks to make sure the drain does not have any blockage by ensuring the water level from the condensate does not exceed a specific level. This check is not necessary, but is recommended. To check if the safety device ...

Page 96

96 rev 2.1 6. Enter diagnostic mode by pressing next button on the basic panel for 3 seconds. Once in diagnostic mode and press next button until min icon is flashing and diag icon is solid. Unit will now be running at 10% firing rate. 7. Using the combustion analyzer, adjust the throttle screw to a...

Page 97

97 rev 2.1 in some extreme conditions, such as high altitudes or low heating value gas, it may not be possible to fire at the rated maximum with the appropriate amount of excess air. In this case, reduce the high-firing rate until the desired excess air has been obtained at the maximum firing rate. ...

Page 98

98 rev 2.1 • set the burner cutoff switch on the display panel to the off position. • wait for the unit to complete its postpurge. • turn off the power supply to the unit via the user installed disconnect switch. • close the unit’s main gas valve. Warning failure to follow the shut down procedure wi...

Page 99: 7 Maintenance

99 rev 2.1 7 maintenance maintenance is an important part of keeping the atlas boiler running efficiently and for a long period of time. Ace recommends that a maintenance schedule be kept. For extended warranty, schedule must be kept and made available to ace if failure occurs. A document must be pr...

Page 100

100 rev 2.1 if combustion readings are not between recommended values, then adjustments should be made to the gas valve until all readings are within these recommended values. Carbon monoxide __________ ppm (must be kept below 100 ppm) carbon dioxide __________ % (should be kept between 7-9%) excess...

Page 101

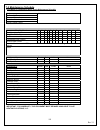

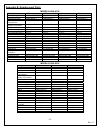

101 rev 2.1 7-2 maintenance schedule atlas model a condensing boiler yearly maintenance schedule daily notes observe op temp observe noise check for water leak check lockout codes monthly check 1 2 3 4 5 6 7 8 9 10 11 12 test operating control pilot/main flame sig air filter condensate drain system ...

Page 102: Appendices

102 rev 2.1 appendices appendix a - troubleshooting and hold/lockout code to support the recommended troubleshooting, the honeywell sola controller has a history file. Review the alert history for possible trends that may have been occurring prior to the actual lockout. Alert code and hold/lockout c...

Page 103

103 rev 2.1 2. Check the module power supply and make sure that frequency, voltage and va meet the specifications. 50 modulation fault internal sub-system fault. 1. Review alert messages for possible trends. 2. Correct possible problems. H 51 pump fault h 52 motor tachometer fault h 53 ac inputs pha...

Page 104

104 rev 2.1 3. If previous steps are correct and fault persists, consult factory. 94 header sensor fault 1. Check wiring and correct any possible errors. 2. Replace the header sensor. 3. If previous steps are correct and fault persists, consult factory. H 95 stack sensor fault 1. Check wiring and co...

Page 105

105 rev 2.1 2. If fault repeats, consult factory 152 combustion pressure on 1. Check wiring and correct any errors. 2. Inspect the combustion pressure switch to make sure it is working correctly. 3. Reset and sequence the relay module. 4. During standby and prepurge, measure the voltage between j6 t...

Page 106

106 rev 2.1 209 invalid pilot type setting l 210 invalid postpurge time setting l 211 invalid power up with lockout setting l 212 invalid pre-ignition time setting l 213 invalid prepurge rate setting l 214 invalid prepurge time setting l 215 invalid purge rate proving setting l 216 invalid run flame...

Page 107

107 rev 2.1 alert code description code description 0 none (no alert) 1 alert pcb was restored from factory defaults 2 safety configuration parameters were restored from factory defaults 3 configuration parameters were restored from factory defaults 4 invalid factory invisibility pcb was detected 5 ...

Page 108

108 rev 2.1 69 modulation was overridden due to sensor fault 75 absolute max fan speed was out of range 76 absolute min fan speed was out of range 77 fan gain down was invalid 78 fan gain up was invalid 79 fan minimum duty cycle was invalid 80 fan pulses per revolution was invalid 81 fan pwm frequen...

Page 109

109 rev 2.1 164 dhw sensor type was invalid 165 inlet sensor type was invalid for dhw 166 outlet sensor type was invalid for dhw 171 dhw control was suspended due to fault 172 dhw temperature was invalid 173 dhw inlet temperature was invalid 174 dhw outlet temperature was invalid 183 lead lag p-gain...

Page 110

110 rev 2.1 294 abnormal recycle: flame was lost during run 295 abnormal recycle: leakage test failed 296 abnormal recycle: interrupted air flow switch was off during drive to purge rate 297 abnormal recycle: interrupted air flow switch was off during measured purge time 298 abnormal recycle: interr...

Page 111

111 rev 2.1 360 abnormal recycle: check parameters failed 361 internal error: no factory parameters were detected in control 362 internal error: pid iteration frequency was invalid 363 internal error: demand-rate interval time was invalid 364 internal error: factory calibration parameter for modulat...

Page 112

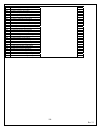

112 rev 2.1 appendix b- replacement parts models a050-a150 description a050 a075 a100 a150 heat exchanger athx050 athx075 athx100 athx150 water flow switch ppfis-1 ppfis-1 ppfis-1 ppfis-1 temp sensor well chmanaqwl-1 chmanaqwl-1 chmanaqwl-1 chmanaqwl-1 outlet /stack temp sensor caa50001464-007 caa50...

Page 113

113 rev 2.1.

Page 114: Atlas Warranty

114 rev 2.1 atlas warranty ace atlas condensing boiler limited parts warranty scope: ace heating solutions, llc warrants the original owner that all parts of this unit which are manufactured by ace will be free from failure under normal use and service for the specified warranty periods and subject ...

Page 115

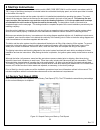

115 rev 2.1 extended warranty: an extended 7-year heat exchanger warranty to the customer follows the same conditions as stated above and will be as follows: year discount 1-5 100% 6 50% 7 25% summary of atlas acceptable conditions (per o & m manual) subjects condition min velocity minimum flow is b...

Page 116: Ace Heating Solutions, Llc

N o t i c e this owners & operation manual provides warnings of risk of harm from improper installation, operation and/or maintenance of ace products. Ace heating solutions, llc. Used ordinary care and complied with ul and asme standards in the design and manufacture of ace products. Proper installa...