- DL manuals

- Ace Heating Solutions

- Water Heater

- Mini-Pack

- Operating And Maintenance Instruction Manual

Ace Heating Solutions Mini-Pack Operating And Maintenance Instruction Manual

Summary of Mini-Pack

Page 1

Operating and maintenance manual designed and manufactured in accordance with asme code section viii, division i photo shown may vary from actual model. Electric “mini-pack” system semi-instantaneous water heater steam-to-water system u.

Page 3: Table of Contents

Ace boiler inc. Page 2 table of contents page 3 operating and installation instruction 4 the mini-pack name plate and model number 5 the parts of the boiler how it works 6 receiving your mini-pack general installation instruction 10 installation diagram single-wall double-wall 12 before start-up sta...

Page 4: Operating and Installation

Ace boiler inc. Page 3 operating and installation instructions (pneumatic) congratulations on your purchase of a new ace boiler “mini-pack”. In this book, we have included installation and maintenance instructions that, if followed, will provide you with many years of service from your new unit. Als...

Page 5: The Mini-Pack Nameplate

Ace boiler inc. Page 4 the mini-pack nameplate and model number the mini-pack nameplate the following illustration is an accurate depiction of the nameplate found on the mini-pack. A. Nb or serial number b. Shell pressure c. Shell temperature d. Tube pressure e. Tube temperature f. Min. Atmospheric ...

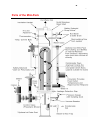

Page 6: Parts of The Mini-Pack

Ace boiler inc. Page 5 parts of the mini-pack.

Page 7

Ace boiler inc. Page 6 how it works! The mini-pack is designed to heat domestic hot water using existing plant steam or hot boiler water, and regulates the domestic hot water outlet temperature to a close tolerance of +4 qf from the set point. The advantage of this system is it replaces the need for...

Page 8: Receiving Your Mini-Pack

Ace boiler inc. Page 7 receiving your mini-pack check equipment received. Inspect the unit for any shipping damage. Make sure you have received all loose parts, as listed on the “bill of lading”. Larger strainers, usually 2 ½ and above, are shipped loose. Note any damages or shortages on the bill of...

Page 9

Ace boiler inc. Page 8 torque's: the following are recommended bolt torque requirements mp size bolt size* gasket thickness** compressed thickness min torque max torque*** (y) (x) (t) (t) 4" 1/2" 1/4" 0.018" 45 ft.Lb 60 ft.Lb 5" 1/2" 1/4" 0.018" 45 ft.Lb 60 ft.Lb 6" 1/2" 3/8" 0.025" 45 ft.Lb 60 ft.L...

Page 10

Ace boiler inc. Page 9 water connections: see typical piping diagram ( page 10 and 11 ). Condensate: the condensate leaving the mini-pack must be drained by gravity without lifts, to a vented receiver or gravity condensate line. The receiver must be located below the level of the condensate outlet. ...

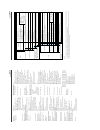

Page 11: Installation Diagram

Ace boiler inc. Page 10 installation diagram (single-wall).

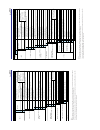

Page 12: Installation Diagram

Ace boiler inc. Page 11 installation diagram (double-wall).

Page 13: Before Start-Up

Ace boiler inc. Page 12 before start-up 1. Verify the mini-pack is installed in accordance with the appropriate installation diagram located on page 10 and 11. 2. The condensate outlet union has been factory installed with an orifice plate. Do not remove this orifice, as it acts as a simple steam tr...

Page 14

Ace boiler inc. Page 13 5. Plant steam is used as the heating medium and is controlled by a pneumatic control valve, which in turn receives its signal from the temperature controller (accritem). Connect the air supply to the filter/regulator (minimum 35 psi supply to the air pressure regulator). The...

Page 15

Ace boiler inc. Page 14 16. Check the flange bolt section for leaks. Tighten only enough to stop leakage. Never tighten more than necessary. Excessive tightening will shorten the life of the gasket and stretch the studs. See page 8 for proper torque values. Shut down instructions 1. De-energize all ...

Page 16: Trouble Shooting

Ace boiler inc. Page 15 trouble shooting 1. Water temperature too high: 1. Check the setting of the accritem and its sensitivity screw (and positioner if provided), and verify a steady 30 psi air supply pressure to the accritem. The outlet pressure gauge on the accritem should read 30 psi when fully...

Page 17

Ace boiler inc. Page 16 the case the sensitivity screw needs adjustment or the air passage is clogged. Under normal operating conditions the outlet gauge reading will fall within this range. 2. Confirm steam supply pressure to the control valve meets that specified in the list of materials. Check fo...

Page 18: Maintenance Instruction

Ace boiler inc. Page 17 maintenance instruction keep tubes clean: in order to maintain high efficiency, the mini-pack tubes should be cleaned periodically. The frequency of cleaning the tubes depends on the characteristics of the water and the type of installation. Contact your local water treatment...

Page 19

Ace boiler inc. Page 18 mini-pack component weights single-wall units double-wall units gasket installation caution: it is recommended that you wear proper eye protection. 1. Thoroughly clean the gasket surface of foreign matter and scratches. Dirt and scale provide leakage paths. 2. Lubricate the b...

Page 20

Ace boiler inc. Page 19 4. Complete the seal by crossing the ends near a bolt hole. Cross one end over the other about 1" and cut (as shown in view "b"). View "b" 5. Assemble the flanged joints and torque the bolts as follows. A) run up all the nuts, finger tight. B) develop the required bolt stress...

Page 21

Ace boiler inc. Page 20 3. Install heat exchanger bundle: bundle should be lifted or jacked with care as to not damage the tubes or tube sheet gasket surface. Lift the bundle to the proper height prior to tightening nuts down. Do not use the nuts to lift the bundle into the shell. Bundle should be l...

Page 22

Ace boiler inc. Page 21 preventive maintenance every 3 months: 1. Visually check for leaks at any joints, including the valve body, piping, and controls. 2. Visually check for corrosion on the control valve, pilot, bulb, and strainer. 3. Check for full valve shut-off. Refer to trouble shooting secti...

Page 23

A jax b oiler i nc. - a ce b oiler i nc. Factory limited warranty policy the ajax boiler factory limited warranty provides assurance that all products are free from manufacuteres defects at the time of shipment and meet specifi cations and performance described in the product literature. It is impor...

Page 24: Arranty

A jax b oiler i nc. - a ce b oiler i nc. W arranty limited thermal shock in addition to our standard one (1) year warranty against defective parts and workmanship, ajax boiler inc. Provides the following guarantee with all commercial hot water, forced circulation, space heating boilers: ajax boiler ...

Page 25: Arranty

A jax b oiler i nc. - a ce b oiler i nc. Limited w arranty ajax boiler inc. Provides a limited warranty on its products against defective material and/or workmanship only. This limited warranty is not applicable to operational failures, electrical failures, gasket leaks, wear or malfunctions caused ...

Page 26: Arning

A jax b oiler i nc. - a ce b oiler i nc. W arning product safety notice ajax boiler and water heater products operate at high temperature and pressures • before using this product, read and understand instructions. Save these instructions for future use. • before servicing, to prevent serious burns ...

Page 27

Operating manual for mini-pack with electric valve control panel operating procedures introduction the information in this chapter provides a guide to the operation of the ace mini-pack semi- instantaneous water heater with electric valve. The control panel is mounted on the front of the unit. It is...

Page 28

Operation all the data from the pid modulation controller is displayed on two lines of seven segments led display. The display has three main zones: 1. Pv display: current outlet temperature (pv) or parameter type is shown depending on the function of the screen. 2. Sv display: current setpoint temp...

Page 29

Upper display lower display description pv – outlet temperature sv – setpoint displays current and setpoint temperature. This is the initial screen of operation mode. Pv – outlet temperature output – modulation output lower display shows modulation output in percentage. In this screen modulation out...

Page 30

Upper display lower display description para set setup mode initial screen klc off key lock setting p 20.0 output proportional band setting i 20.0 output integral time d 5 output derivative time mr 0.0 output manual reset sf 0.40 output target value function * o_l * 0.0 or 20.0 output lower limit un...

Page 31

When at is executed, control operates in on-off mode output response is used to calculate new pid parameter. When auto tuning is completed, new pid value is stored, auto tuning ends and at lamp goes off. Stop auto tuning to stop auto tuning in the middle of execution, select off by using the button ...

Page 32

Lock setting description 1 locks up all setup mode parameters. 2 locks up all setup mode parameters and all operation mode parameters except the initial screen of operation mode. Only setpoint parameter can be adjusted. 3 locks up all the parameters. Off no lock, any data can be changed. Table 3 – k...

Page 33

Series sr90 shimaden digit al controller °c %rh shimaden, t emperature and humidity control specialists multi-input and multi-range performance large 20mm bright display (sr93) readable from a distance and in a low light area 2-output heating and cooling control available rs232c or rs485 interface a...

Page 34

Series sr90 event action: on-off action hysteresis: 1~999 units standby action: selectable from the following 4 types ev1 and ev2: 1 without standby action. 2 standby when power is applied. 3 standby when power is applied and when sv value in execution is changed. 4 control mode without standby acti...

Page 35

Series sr90 item code specifications series sr92- input multi input control output (1) control output (2) (option) power supply remarks analog output (option) communication or sv bias (option) event output/ heater break alarm (option) 4 8 6 y- i- p- v- y- n- i- p- v- 90- 08- 0 1 2 3 0 9 mpu-based au...

Page 36

External dimensions panel cutout series sr90 sr91 sr92 out1 out2 ev1 ev2 at man sb/com 48 48 ent sr91 pv sv ˚c 45 +0.6 0 (48 × n − 3) +1 0 45 +0.6 0 45 +0.6 0 60 or more in the case of installation without leaving space between instruments n=the number of instruments unit: mm 11 100 111 44.6 11 12 1...

Page 37

Love controls division dwyer instruments inc. P .O. Box 338 - michigan city , indiana 46361, u.S.A. Series 4c, 8c and 16c micr opr ocessor based t e mperatur e pr ocess contr ol specifications - installation and operating instructions phone: 219/879-8000 www .Love-contr ols.Com fax: 219/872-9057 e-m...

Page 38: 16C

Page 3 model number identifica tion getting st ar ted 1. Install the contr ol as described on page 4. 2. W ir e your contr ol following the instructions on page 6. Please r ead the pr ecautions section located at the end of this manual befor e wiring the contr ol. 3. For best r e sults when pr ogram...

Page 39

Page 5 mounting method step 1: fr om the fr ont of the panel, slide the contr oller housing thr ough the cut out. The housing gasket should be against the housing flange befor e installing. Step 2: insert the mounting brackets into the mounting gr ooves on the top and bottom of the contr oller (4c, ...

Page 40

Page 7 front key functions key functions ar e as follows: index: pr essing the index key advances the display to the next menu item. Up arrow : incr ements a value or changes a menu item. If pr essed during the operation mode, the set point value will be incr eased. Down arrow : decr ements a value ...

Page 41

Page 9 programming and opera tion for pid theory of operation the pid method of contr ol is based on the individual tuning of pr oportional band values, integral time values, and derivative time values to help a unit automatically compensate for changes in a contr ol system. The pr oportional band i...

Page 42

Page 1 1 regula tion menu pr ess the enter key while at the home display in or der to access the regulation menu. Pr essing the index key will cycle thr ough the below menu items. The parameter will be displayed in the top display , while its value will be displayed in the bottom display . The up an...

Page 43

Initial setting menu pr ess and hold the enter key for at least 3 seconds while at the home display in or der to access the initial setting menu. Pr essing the index key will cycle thr ough the below menu items. The parameter will be displayed in the top display , while its value will be displayed i...

Page 44: Do No

Page 15 n oi t ar e p o t u pt u o mr al a e p y t mr al a e ul a v t e s f f o si t u pt u o d el b a si d n oit c n uf mr al a 0 1 deviation upper - and lower -limit: this alarm output operates when pv value is higher than the setting value sv+(al-h) or lower than the setting value sv -(al-l). 2 d...

Page 45

Communication pr otocol command code to r ead n wor ds: 03h. The maximum value of n is 3. For example, in or der to r ead two wor ds fr om contr oller 01 (addr ess 01h) at starting data addr ess 4700h, the command in ascii mode is: ascii mode: command message: response message: lrc check: lrc check ...

Page 46

Page 19 reset factory default settings note: resetting factory default settings erases all of the values enter ed by the user . Recor d any necessary settings befor e pr oceeding. W a rning: erasing the user enter ed values may r e sult in a safety hazar d and system malfunction. The following instr...

Page 47

Page 21 thermocouple t ype and t e mperatur e range input t e mperatur e sensor t ype led display t emperatur e range thermocouple txk type -328 ~ 1440°f (-200 ~ 800°c) thermocouple u type -328 ~ 932°f (-200 ~ 500°c) thermocouple l type -328 ~ 1562°f (-200 ~ 850°c) thermocouple b type 212 ~ 3272°f (...

Page 48

Page 23 exter nal dimensions dimensions ar e in millimeter (inch) 4c 8c 16c love controls division dwyer instruments inc. P .O. Box 338 - michigan city , indiana 46361, u.S.A. Phone: 219/879-8000 www .Love-contr ols.Com fax: 219/872-9057 e-mail:love@love-contr ols.Com ©copyright 2010 dwyer instrumen...

Page 73

50-60 hanover road, florham park, new jersey 07932 asco v alves pa ge 2 of 2 form no.V5433r3 c a ution : do not damage center hole (pilot orifice) in piston assembly . Damage will cause valve malfunction. 4. Insert a wire, bent paper clip or similar tool into the bleed hole on top of the piston asse...

Page 74

50 - 60 hanover road, florham park, new jersey 07932 asco v alves pa ge 2 of 2 form no.V6855r1 impor tant : these solenoid valves are intended for use on clean dry air or inert gas, filtered to 50 micrometres or better . The dew point of the media should be at least 10 c ( 18 f ) below the minimum t...

Page 75

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 2 of 4 form no.V6583r7 10 ± 2 in - lb s [ 1, 0 ± 1 ,2 nm ]. A ta ppe d ho le is pr ovi de d i n t he so len oi d f or gr ound ing, us e a # 10 - 32 ma ch ine sc re w. To rq ue g round ing sc re w to 1 5 - 20 in- lb s [ 1, 7 - ...

Page 76

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 4 of 4 form no.V6583r7 torque chart part name torque value in inch-p ounds torque value in newton-meters terminal block screws 10 ± 2 1,1 ± 0,2 socket head screw 15 - 2 0 1,7 - 2,3 center screw 5 ± 1 0,6 ± 0,1 screw terminal a...

Page 77

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 2 of 4 form no v5848r2 ca ution : to protect the solenoid valve, install a strainer or filter suitable for the service involved in the inlet side as close to the valve as possible. Clean periodically depending on service condi...

Page 78

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 4 of 4 form no v5848r2 torque chart part name torque value inch-p ounds torque value newton-meters solenoid base sub - assembly 175 ± 25 19,8 ± 2,8 bonnet screws 95 ± 10 10,7 ± 1,1 figure 3. Series 8210 - dc construction witho...

Page 79

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 2 of 4 form no.V6584r8 facilitate wiring, the solenoid may be rotated 360 . For the watertight and explosionproof solenoid, electrical fittings must be approved for use in the approved hazardous locations. Ca ution : cryogenic...

Page 80

50 hanover road, florham p ark, new jersey 07932 www .Ascovalve.Com pa ge 4 of 4 form no.V6584r8 torque chart part name torque value in inch-p ounds torque value in newton-meters terminal block screws 10 ± 2 1,1 ± 0,2 socket head screw 15 - 2 0 1,7 - 2,3 center screw 5 ± 1 0,6 ± 0,1 screw terminal a...

Page 81: Ution

95-5973—3 2 2. Remove plug (or old well) from boiler tapping. 3. Install the immersion well included with the control- ler. If boiler tapping is greater than 1/2 in., use a reduction fitting to adapt the boiler opening to the 1 in. Threads that are standard with the well or fitting. Fittings with 3/...

Page 82

95-5973—3 4 quality is key home and building control home and building control helping you control your world honeywell inc. H oneywell limited—honeywell limitée 1985 douglas drive north 740 ellesmere road golden valley, mn 55422 scarborough, ontario m1p 2v9 printed in u.S.A. Fig.6—typical wiring ho...

Page 83

Pr oduct specifications ashcroft model number: 1000, 2071a size: 4 1 ⁄ 2 ˝ case: 1000 - black painted steel 2071a- black painted aluminum with back flange ring: 1000 - black painted steel, friction fit 2071a- chrome plated steel, friction fit window: glass dial: black figures on white background, st...

Page 84

86 a halliburton company 4 1 ⁄ 2 ˝ gauges type 1000, grade b, (3-2-3%) type 2071a, grade a, (2-1-2%) ashcroft ® t ype 1000 gauges ha v e a b lac k steel case and r ing with a glass windo w . These gauges are ap- propr iate f or gener al industr ial appli- cations and can be customiz ed to complement...

Page 85

2 standard circulating pumps p roduct review: wi lo-star/ star s wilo-star/star s range: wilo -star > s ingle head pu mps: • wet rotor circulation pump, with flanged or unio n connections > a ppl ic ati on s: • cast ir on bo dy for hot-w ater heating sys- tems of all kind s, ind ustr ial cir culatio...

Page 86

17 as at: 0 3 /2 008 - s u b ject t o cha nge wit h out prior notice standard circulating pumps dimensions, weights wi lo-star/ star s in ch wi lo -s ta r... A b c d e f g h i Ø k Ø l m w e ig ht ap pr o x . Draw- in g no. [i n ] [i n ] [i n ] [i n ][ in ] [i n ][ in ][ in ][ in ][ in ] [i n ][ in ]...

Page 87

8 standard circulating pumps p roduct review: wi lo-star/ star s equipment /function & technical data wilo-star (bronze body) wilo-star/star s materials p u m p h o u si n g - c a st ir o n – ––– ––– –– pump hous ing - b ronze • • ••• •• •• impe lle r en gine er e d c o mposi te (pp – 40 % g f ) sha...

Page 88

15 as at: 0 3 /2 008 - s u b ject t o cha nge wit h out prior notice standard circulating pumps wi lo-star/ star s wiring diagrams, motor data wiring diagram s ingle phas e motor 2-p ole, 1~11 5 v/60 h z with integrat ed capacitor ln pe m o to r d a ta w il o - s ta r wilo-st ar... Rate d pow er spe...

Page 89

K unkle saf ety and relief pr oducts t yco reser ves the right to c hang e pr oduct design and specifications kukmc-0392 without notice . Cop yright © 2002 b y t yco international ltd. 8 models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927 models 912, 913, 918, 919 asme section viii, stea...

Page 90

K unkle saf ety and relief pr oducts t yco reser ves the right to c hang e pr oduct design and specifications kukmc-0392 without notice . Cop yright © 2002 b y t yco international ltd. 10 models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927 models 912, 913, 918, 919 asme section viii, ste...

Page 91

K unkle saf ety and relief pr oducts t yco reser ves the right to c hang e pr oduct design and specifications kukmc-0392 without notice . Cop yright © 2002 b y t yco international ltd. 14 models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927 models 910, 911, 912, 913, 916, 917, 918, 919 no...

Page 92

Kunkle pressure relief valves installation and operating instructions pre-installation handling this pressure relief valve is designed to protect equipment from overpressure. The valve should be handled with care, not subjected to heavy shock loads, and p rotected to prevent contamination from getti...

Page 93

V acuum br eak ers - page 2 se ri e s vb8 v a c uum bre ake r s c at al o g numb er vb8-3 8-br -p-s-e pi p e t hre a d size 20 .3 1. 4 9 0. 7 3 ou tle t p ip e size to tal l en gt h “l ” en gage d le ngt h “e” o .D .Of t ub e “d ” h ex b o d y size diam et er of o rific e diam et er of ball 10 .0 0....

Page 94

V a c uum bre ake r s approximate series vb8 air handling capacities th e a ir h an dl in g c ap a ci ty cur ve s we re pl ot te d f ro m c al cul atio ns u si ng t he c v fa ct ors of t he va cuum bre ake r un its .T he c v fa ct or i s a f low c o ef fic ie nt d et er m in ed by a ct ual t est w h...

Page 95

Vacuum breaker installation figure 1 – standard vertical installation pipe as shown if possible for a preventative measur e. If the outlet is exposed it can become fouled with dust and dirt. Upon operation this contami nation can prevent the vacuum breaker from resealing. Figure 2 – high temperature...

Page 96: Series 40, 140, 240 & 340

Es-40, 140, 240, 340 0130 printed in u.S.A. Direct side tapping for external flue heaters use extra len g th extension thermostat to extend into water stora g e tank. For internal flue heaters use short or standard len g th thermostat. Vertical dischar g e line must be installed with its direction d...

Page 97: Series 174A-740

Dimensions - weights ma terials series 174a • bronze body construct ion • non m etall ic d isc-to- m etal seat ing series 740 • iron body construct ion • non m etall ic d isc-to- m etal seat ing pressure - tempera ture series 174a pressure range: 30 ps i to 150 ps i (2 to 10 bars) w ith correspond i...

Page 100: Ace Heating Solutions, Llc

N o t i c e this owners & operation manual provides warnings of risk of harm from improper installation, operation and/or maintenance of ace products. Ace heating solutions, llc. Used ordinary care and complied with ul and asme standards in the design and manufacture of ace products. Proper installa...