- DL manuals

- Ace Heating Solutions

- Water Heater

- Packaged Storage Water Heater Steam-to-Water System

- Operating And Maintenance Manual

Ace Heating Solutions Packaged Storage Water Heater Steam-to-Water System Operating And Maintenance Manual

Summary of Packaged Storage Water Heater Steam-to-Water System

Page 1

Operating and maintenance manual designed and manufactured in accordance with asme code section viii photo shown may vary from actual model. Packaged storage water heater steam-to-water system u.

Page 3: Table of Contents

Ace boiler inc. Page 2 table of contents page 3 operating and installation instruction 4 the packaged storage water heater name plate and model number 5 the parts of the packaged storage water heater how it works 7 receiving your packaged storage water heater general installation instruction 10 befo...

Page 4: Operating and Installation

Ace boiler inc. Page 3 operating and installation instructions (pneumatic / pilot-operated) congratulations on your purchase of a new ace boiler, packaged storage water heater. In this book, we have included installation and maintenance instructions that, if followed, will provide you with many year...

Page 5: And Model Number

Ace boiler inc. Page 4 the packaged storage water heater nameplate and model number the packaged storage water heater nameplate the following illustration is an accurate depiction of the nameplate found on the packaged storage water heater. A. Nb or serial number b. Shell pressure c. Shell temperatu...

Page 6: Water Heater

Ace boiler inc. Page 5 b drain recirculation line boiler water inlet manhole 12" x 16" (42" dia. & larger) optional 1-1/2" insulation & metal jacket relief valve pneumatic control b.W. Temperature gauges (2) - in & out ace temp control system with sensors circulator pump cold water inlet press. & te...

Page 7

Ace boiler inc. Page 6 how it works! The packaged storage water heater is designed to heat domestic hot water using existing plant steam or hot water. The control valve regulates the heating medium through the tube bundle. As there is a demand for domestic hot water, the temperature control bulb wil...

Page 8

Ace boiler inc. Page 7 receiving your packaged storage water heater check equipment received. Inspect the unit for any shipping damage. Make sure you have received all loose parts, such as listed on the “bill of lading”. Larger strainers and valves, usually 2-1/2” and above, are shipped loose. Note ...

Page 9

Ace boiler inc. Page 8 torque’s: the following are recommended bolt torque requirements bolt size min torque max torque 1/2" 45 ft-lbf. 60 ft-lbf. 5/8" 90 ft-lbf. 120 ft-lbf. 3/4" 150 ft-lbf. 200 ft-lbf. 7/8" 240 ft-lbf. 320 ft-lbf. 1" 368 ft-lbf. 490 ft-lbf. 1 1/8" 533 ft-lbf. 710 ft-lbf. 1 1/4" 75...

Page 10

Ace boiler inc. Page 9 water connections: pipe cold domestic water in, hot out, and drain according to the cover drawing. Steam piping: check the steam supply pressure. The steam supply pressure should not exceed the maximum pressure specified on the control valve, relief valve, or vessel nameplate....

Page 11: Before Start-Up

Ace boiler inc. Page 10 before start-up installation and hook-up 1 place tank in location desired, and level tank carefully to insure levelness of heating coil loops which are installed in the tank. Provide sufficient clearance in front to permit removal of the tube bundle. 2 remove temporary pipe p...

Page 12

Ace boiler inc. Page 11 start-up instruction 1 it is assumed that installation is complete and that all connections have been made, including: electrical, steam, domestic water, instrument air, vents, drains and safety valve discharge lines. 2 if an optional control box is included, make sure the po...

Page 13

Ace boiler inc. Page 12 operation of storage water heater 1 the entire system should be clean before starting operation to prevent plugging of tubes. Under some conditions, the use of strainers in the pipe may be required. 2 when placing unit in operation, open a vent and start to circulate the cold...

Page 14: Trouble-Shooting Guide

Ace boiler inc. Page 13 trouble-shooting guide a water temperature too high 1 check the setting of the pilot controller and adjust the hand wheel as necessary. 2 confirm steam supply pressure to the valve does not exceed that specified in the list of materials. 3 bad sensing element. 4 check bleed p...

Page 15: Maintenance Instruction

Ace boiler inc. Page 14 maintenance instruction the following service is recommended for proper and safe use of this equipment monthly or more often. 1 open relief valve(s) momentarily by lifting try lever to be sure valve(s) will open and are operational. 2 check tank pressure gauge. Pressure of sy...

Page 16

Ace boiler inc. Page 15 9 a new manhole gasket will probably be required when replacing the manhole cover. To facilitate replacement of the manhole gasket, and cover, it will be helpful to tape the gasket to the cover with 4 pieces of adhesive tape, to avoid slippage of gasket from cover. Gasket and...

Page 17

A jax b oiler i nc. - a ce b oiler i nc. Factory limited warranty policy the ajax boiler factory limited warranty provides assurance that all products are free from manufacuteres defects at the time of shipment and meet specifi cations and performance described in the product literature. It is impor...

Page 18: Arranty

A jax b oiler i nc. - a ce b oiler i nc. Limited w arranty ajax boiler inc. Provides a limited warranty on its products against defective material and/or workmanship only. This limited warranty is not applicable to operational failures, electrical failures, gasket leaks, wear or malfunctions caused ...

Page 19: Arning

A jax b oiler i nc. - a ce b oiler i nc. W arning product safety notice ajax boiler and water heater products operate at high temperature and pressures • before using this product, read and understand instructions. Save these instructions for future use. • before servicing, to prevent serious burns ...

Page 20

Gasket replacement gasket and gasket surfaces should be thoroughly cleaned and should be free of scratches and other defects. Gasket should be properly positioned before attempting to retighten bolts. It is recommended that when a heavy heat exchanger is dismantled for any purpose, it needs to be re...

Page 21: Pneuma

Pr oduct s pecific a tion mar ch 2005 pneuma tic actu a ted industrial v a lves series: 2800 sizes 1/2 to 2 inches precision globe control v alves tw o- w ay a n d t h re e- w ay , r ec ipr o ca ting , br o n ze o r st ai n le ss ste el b o dy v alve s fo r pr o cess a n d u tili ty applic at ion s ...

Page 22: 2800

2 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 description w arren controls series 2800 precision globe control v alves feature rugged bronze or stainless steel bodies with a variety of trim materials and port ...

Page 23

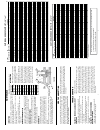

4 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 flo w coefficients (cv) v ersus tr av el ty pica l flow cu rve u pper low e r com b ine d 2830 0 10 20 30 40 50 60 70 80 90 100 110 100 90 80 70 60 50 40 30 20 10 ...

Page 24: 2820

6 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 shut-off Δ p r atings maximum shut-off Δ p in psi fail closed fail open reverse acting direct acting v alve actuator notes: 1) 2820 seat closure ansi class iv (sta...

Page 25

Actuators, positioners, & accessories size action low full high xtra-high dl49 direct 3-9 4-13 8-12 n/a dl49 reverse 4-10 5-14 10-14 n/a dl84 direct 3-9 3-15 9-15 n/a dl84 reverse 3-9 3-15 9-15 n/a dl84xr direct n/a n/a n/a see note dl84xr reverse n/a n/a n/a see note note: the spring range of xr (e...

Page 26

Positioners (continued) blx electro-pneumatic explosion proof models: bfx_: full range signal (4-20 ma) blx_: lo w range signal (4-12 ma) bhx_: high range signal (12-20 ma) options 2spdt limit switches , 4-20 ma f eedbac k ing ress & corrosion protection: nema 4x, ip66 appro v als & ratings: fm intr...

Page 27

Factory default settings input signal failure modes actuator electro- increasing loss of signal 1 loss of supply v alve t ype action pneumatic pneumatic signal v alve fails… v alve fails… 2820 direct 3-15 psi 4-20 ma closes v alve open open reverse 3-15 psi 4-20 ma opens v alve closed closed 2830 & ...

Page 28: 1800

14 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 actuator series action spring range handwheel positioners, i/p’ s & limit switches air filter regulators special options asco solenoids 0 none r reverse stem fail...

Page 29: Pneuma

Pr oduct s pecific a tion mar ch 2005 pneuma tic actu a ted industrial v a lves series: 2900 sizes 2-1/2 to 10 inches high capacity , general purpose , globe control v alves tw o- w ay a n d t h re e- w ay , r ec ipr o ca ting , ir on b o dy v al ves f o r pr o cess a n d u tili ty applic at ion s 2...

Page 30: 2900

2 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 description w arren controls series 2900 high capacity general purpose globe control v alves feature rugged iron bodies with a variety of trim materials. The equal...

Page 31

4 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 flo w coefficients (cv) v ersus tr av el v alve trim %t ravel size (in) style 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 2-1/2 eq% 65.0 55.6 43.8 29.8 15.4 8.07 5.67...

Page 32: 2920

6 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 shut-off Δ p and cv r atings maximum shut-off Δ p in psi fail closed fail open reverse acting direct acting v alve plug size cv travel pneumatic spring air signal ...

Page 33: 2923

8 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 shut-off Δp and cv r atings maximum shut-off Δ p in psi fail closed fail open reverse acting direct acting v alve plug size cv travel pneumatic spring air signal t...

Page 34: 2932

2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 10 shut-off Δp and cv r atings notes: 1) published shut-off values are for diverting applications. The values are worst case and based on the pressure difference bet...

Page 35

2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 dimensions & w eights 12 radius is from center line of actuator to outside edge of positioner . Positioner removal clearance allo w 3-1/4 inch be y ond 760 f or co v...

Page 36

Positioners (continued) blx electro-pneumatic explosion proof models: bfx_: full range signal (4-20 ma) blx_: lo w range signal (4-12 ma) bhx_: high range signal (12-20 ma) options 2spdt limit switches , 4-20 ma f eedbac k ing ress & corrosion protection: nema 4x, ip66 appro v als & ratings: fm intr...

Page 37

16 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 factory default settings input signal failure modes actuator electro- increasing loss of signal 1 loss of supply v alve t ype action pneumatic pneumatic signal v ...

Page 38: 1800

18 2600 emrick blvd., b et hle he m, p a 18020-8010 www .W ar re nc on tr ols .C om te l: 800-922-0085 or 610-317-0800 f ax: 610-317-2989 actuator series action spring range handwheel positioners, i/p’ s & limit switches air filter regulators special options asco solenoids 0 none r reverse stem fail...

Page 39

Type e main v a l v e dimensions inches (mm) and weights pounds (kg) f ace to f ace dimensions c a b std. Mount integral mount d* approx. Wt . Size ansi ansi ansi ansi ansi ansi ci & brz. Steel steel ansi ansi ansi ansi npt 125,150 250 300 600 600 all 600 npt 125,150 250,300 600 3 / 8 4 3 / 8 ——— — ...

Page 40

( ( ( d d" d'd(d *.$)&3 0/5.%3 6 !), !*3% )6%0 71(/-2'(7 )& 0&.$& 90& "*. ",6& *3 /' ./2-",,9 $,/3&% 3*.(,& 3&"4 %&3*(. '&"452*.( 0"$+,&33 $/.3425$4*/. 9$"2 %*"0)2"(- ".%02/4&$4&%-"*.302*.( !)&. $/.42/,,&% #9 /.& /2 -/2& /' 4)& 6"2*/53 490&3 /' 0&.$& *,/43 4)*3 6",6& 7*,, "$$/-0,*3) -/34 '5.$4*/.3 2...

Page 41

%7-.;d 78;6*5d ,87-2=287d ,8695.=.D -2 *=d ;.0>5*; 27=.;?*5278=d ;.,866.7-.-d d ?*5?.D 4.9=d ;.5*=2?.5bd /;..D 8/d -2;= @255d/>7,=287d/8;db.*;6d*==.7=287 /=.;d =1.D /2; /.@d -*b8/d 89.;*=287d *7-d =@2,.D *d b.*;d =1. /8558@270d5-d+.D,1.,4.- 78d 7 *55d 3827=/8;d 5.*4*0.D ..9d +85==201=d .?.;d *558@ d...

Page 42

T o disassemble and r eplace sensitive tube assembly: the accrite m contr oller r equir es a clean, r eliable supply of co m pr essed air or cold water at r o o m te m peratur e and 15 to 20 pounds of pr essur e. Other fluids m ay be used, such as gas, oil, etc., pr oviding pr ovision is m ade for s...

Page 43

Tc744-1 page 4 350 300 250 150 100 50 180 10 40 70 100 130 160 c f powers process controls skokie, il. Mississauga, ontario product no. Da te code action r 21 21 21 31 32 front view of cover air operated water operated section “a–a” *used in water-operated controllers only 1/4 ″ npt to drain (water ...

Page 44

Tc744-1 page 6 figur e 8. Additional infor mation on controller action and applications. Opera tion (continued) application heating cooling mixing direct acting normally open valve normally closed valve hot piped to normally open port of valve valve opens on air failure valve closes on air failure v...

Page 45

Tc744-1 page 8 w arranty informa tion powers warrants that the equip m ent m anufactur ed by it is fr ee fr o m defects in m aterial and work m anship and, without char ge, equip m ent found to be defective in m aterial and work m anship will be r epair ed, or at seller’ s option, r eplaced f .O.B. ...

Page 46: Series 174A-740

Dimensions - weights ma terials series 174a • bronze body construction • nonmetallic disc-to-metal seating series 740 • iron body construction • nonmetallic disc-to-metal seating pressure - tempera ture series 174a pressure range: 30 psi to 150 psi (2 to 10 bars) with corresponding high btu/hr ratin...

Page 47

1 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps product review: wil o-star /s tar s range: wi lo-s tar > m ai ntenance free single- hea d ci rcul ators > p ip e c o nn ecti on : • flange • flange r o tated 90° • uni ons • in ter nal sweat > c ast iron body for a...

Page 48

3 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps product review: wil o-star /s tar s function, equipment & technical data wilo-star (cast iron body) materials pump hou sing - cast iro n • ••• •• •• p u m p h o u si n g - b ro n z e –– ––– –– – impe ller pl a st i...

Page 49

5 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps product review: wil o-star /s tar s function, equipment & technical data wilo-star s (cast iron body) materials pump hou sing - cast iro n ••• • p u m p h o u si n g - b ro n z e –– –– impe ller pl astics (p p – 40...

Page 50

7 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps product review: wil o-star /s tar s function, equipment & technical data wilo-star (bronze body) materials p u m p h o u si n g - c a st ir o n – – – ––– –– – pump hou sing - bronz e • • •• ••• •• impe ller pl a st...

Page 51

9 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps product review: wil o-star /s tar s function, equipment & technical data wilo-star s (bronze body) materials pump hou sing - cast iro n – – pump hou sing - bronz e •• impe ller pl a st ic s (pp – 4 0 % g f ) shaft ...

Page 52

11 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps wilo-star/star s pump curves wilo-star wilo-sta r 1 6 f, fx, bfx wilo-star 17 fx wilo-sta r 2 1 f, fx, bfx wilo-star 30 f, bu h [ft] 0 0 p 1 [w] p 1 [hp] h [m] 10 0 30 70 5 10 15 20 5 10 15 [us gpm] 0 5 10 15 0 [u...

Page 53

13 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps wilo-star/star s pump curves wilo-star s wilo-star s 16 f, fx, bfx wilo-star s 21 f, fx, bfx h [ft] 0 0 p 1 [w] p 1 [hp] h [m] 0 2 4 6 8 10 12 14 16 18 2 4 6 8 10 12 14 [us gpm] 0 2 4 6 8 10 12 14 0 [us gpm] [m 3 ...

Page 54

15 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps wilo-star/star s dimension, weights wilo-sta r, dra w ing no.: 1 w ilo-star, drawing no. : 2 wilo-sta r, dra w ing no.: 3 w ilo-star, drawing no. : 4 wi lo-sta r s , dra wing no.: 5 b g i m h a e d c g b ic d h a ...

Page 55

17 as a t: 03/2 00 7 - su b jec t to ch ang e without prior n o tice circulating pumps wilo-star/star s dimension, weights me tr ic wi lo- st a r... A b c d e f g h i Ø k Ø l m w e ight appr o x . Draw- in g no. [mm ] [m m ] [m m ] [mm] [mm ] [m m ] [mm] [m m ] [mm ] [m m ] [mm] [m m ] [k g ] st ar ...

Page 56

Pr oduct specifications ashcroft model number: 1000, 2071a size: 4 1 ⁄ 2 ˝ case: 1000 - black painted steel 2071a- black painted aluminum with back flange ring: 1000 - black painted steel, friction fit 2071a- chrome plated steel, friction fit window: glass dial: black figures on white background, st...

Page 57

86 a halliburton company 4 1 ⁄ 2 ˝ gauges type 1000, grade b, (3-2-3%) type 2071a, grade a, (2-1-2%) ashcroft ® t ype 1000 gauges ha v e a b lac k steel case and r ing with a glass windo w . These gauges are ap- propr iate f or gener al industr ial appli- cations and can be customiz ed to complement...

Page 58: 4)/.3

4he combined in 4emperature 0ressure relief valve provi des the least ex pensive and proven means for protection against both excessive temperatu re and pressure emergency conditions &ully automatic temperature and pressure relief protection for domesti c hot water supply tanks and heaters based on ...

Page 59

V acuum br eak ers - page 2 se ri e s vb8 v a c uum bre ake r s c at al o g numb er vb8-3 8-br -p-s-e pi p e t hre a d size 20 .3 1. 4 9 0. 7 3 ou tle t p ip e size to tal l en gt h “l ” en gage d le ngt h “e” o .D .Of t ub e “d ” h ex b o d y size diam et er of o rific e diam et er of ball 10 .0 0....

Page 60

V a c uum bre ake r s approximate series vb8 air handling capacities th e a ir h an dl in g c ap a ci ty cur ve s we re pl ot te d f ro m c al cul atio ns u si ng t he c v fa ct ors of t he va cuum bre ake r un its .T he c v fa ct or i s a f low c o ef fic ie nt d et er m in ed by a ct ual t est w h...

Page 61

Vacuum breaker installation figure 1 – standard vertical installation pipe as shown if possible for a preventative measur e. If the outlet is exposed it can become fouled with dust and dirt. Upon operation this contami nation can prevent the vacuum breaker from resealing. Figure 2 – high temperature...

Page 62: Ution

95-5973—3 2 2. Remove plug (or old well) from boiler tapping. 3. Install the immersion well included with the control- ler. If boiler tapping is greater than 1/2 in., use a reduction fitting to adapt the boiler opening to the 1 in. Threads that are standard with the well or fitting. Fittings with 3/...

Page 63

95-5973—3 4 quality is key home and building control home and building control helping you control your world honeywell inc. H oneywell limited—honeywell limitée 1985 douglas drive north 740 ellesmere road golden valley, mn 55422 scarborough, ontario m1p 2v9 printed in u.S.A. Fig.6—typical wiring ho...

Page 64: Ace Heating Solutions, Llc

N o t i c e this owners & operation manual provides warnings of risk of harm from improper installation, operation and/or maintenance of ace products. Ace heating solutions, llc. Used ordinary care and complied with ul and asme standards in the design and manufacture of ace products. Proper installa...