- DL manuals

- Ace Sports

- Utility Vehicle

- Maxxam 150 2R

- Service Manual

Ace Sports Maxxam 150 2R Service Manual

Summary of Maxxam 150 2R

Page 1

150 2r ace-maxxam-002-02-2007 239 county road 4435 brundidge, al 36081 www.Acesportsonline.Com p: 1-888-562-9ace f: 1-888-562-8ace buggy service manual.

Page 3

Foreword this service manual has been specially prepared to provide all the necessary information for the proper maintenance and repair of the maxxam . The maxxam ts the needs of a wide variety of kart users above 16 years old. Those who will be servicing this kart should carefully review this manua...

Page 4

General information periodic maintenance and tune-up procedures engine lubrication system inspection and servicing fuel supply system inspection and servicing transmission conponents electrical starting system reduction mechanism controlling mechanism belt driven cvt mechanism inspection and servici...

Page 5

1 general information model identification frame number the frame number or vin is stamped under the seat on the frame cross member and on a sticker behind the seat. Engine number the engine number is located on the lower front left side of the engine case. Fuel and oil recommendations %hvxuhwrxvhwk...

Page 6

2 specifications dimensions overall length 2075mm (87.7 in.) overall width 1235mm (48.6 in.) overall height 1400mm (55.1 in.) wheelbase 1450mm (57 in.) front track 1060mm (47.1 in.) rear track 1000mm (39.4 in.) ground clearance 130mm (5.1 in.) engine type forced air-cooled, 4-stroke engine capacity ...

Page 7

:(,*+7 'u\:hljkw njoev 7,5(35(6685( )urqw 103vl68.95n3dfp70njifp 5hdu 103vl68.95n3dfp70njifp :$55$17 7khvshfl¿fdwlrqvduhvxemhfwwrfkdqjhzlwkrxwqrwlfh.

Page 8

4 location of parts drive chain drive chain.

Page 9

5 periodic maintenance and tune-up procedures periodic check and services the maintenance intervals in the following table are based upon average riding conditions. Riding in unusually dusty areas requires more frequent servicing. Items needing servicing initial service Àrst week) monthly quarterly ...

Page 10

6 tire pressure/wear check the tire pressure every time the kart is ridden. The tire pressure is very important for the stability of the ride. Tire pressure front 10 psi 68.95kpa/cm 2 0. 70kgf/cm 2 rear 10 psi 68.95kpa/cm 2 0. 70kgf/cm 2 brake performance • always check that there is plenty of brake...

Page 11

7 chassis nuts and bolts always pay attention to the kart 's nuts and bolts. Some loosening after use is normal. Check to ensure that all nuts and bolts are tight. Torque tightening chart bolt conventional marked bolt 8.8 marked bolt diameter n.M kg.M ib-ft n.M kg.M ib-ft 4 1 ~ 2 0.1 ~ 0.2 0.7 ~ 1.5...

Page 12

),1$/*($52,/ 7rfkhfnohyhouhpryhohyhovfuhzrqwkh ohiwuhduhqjlqhfdvh 7rgudlqrlouhpryhwkhgudlqsoxjdwwkh uhduerwwrpriwkhhqjlqhfdvh,wlv uhfrpphqghgwrzdupwkhhqjlqhiru plqxwhvrupruh before gudlqlqj¿qdogearrlo )lqdogulyhfdsdflw\ po zhljkw (1*,1(2,/ 5hpryhwkhgudlqsoxjiurpwkhohiwvlgherwwrpriwkhhqjlqh 'udlql...

Page 13

9 engine engine components inspection and servicing engine components and crank connecting rod mechanism inspection and servicing engine components: cylinder cylinder removal the removal can be done on the vehicle body. • remove cylinder head. • remove cylinder. • remove cylinder gasket, bolts • cle...

Page 14

&5$1.&211(&7,1*52'0(&+$1,603,67216(7 3,67213,1,163(&7,21$1'6(59,&,1* ,qvhuwwkhslvwrqslqkrul]rqwdoo\lqwrwkhslvwrqslqkrohdqglqvshfwwkhfohdudqfhehwzhhqslv wrqdqgslvwrqslq 6huylfh/lplw pp ,iwkhiuhhsod\lvwrrpxfkwkhzruqfrqglwlrqrislvwrqslqdqgslvwrqslqkrohpxvwehlqvshfwhg uhvshfwlyho\ 0hdvxuhwkhh[whuqdogl...

Page 15

3,67215,1*66(783 %hiruhvhwwlqjxsdsso\rlorqhdfkslvwrqulqjwkhqhqodujhslvwrqulqjvdwwkhvdph wlphsxwwkhprqwkhslvwrqdqgpryhgrzqzdugvjudgxdoo\xqwloslvwrqulqjvidoolqwrwkh ulqjjurryh 3,67216(7,167$//$7,21 5hpryhwkhjdvnhwdwwdfkhgwrwkhfudqnfdvh 0rxqwslvwrqrqwrwkhvpdoohqgriwkhfrqqhfwlqjurg 0rxqwslvwrqslqdqgs...

Page 16

5hpryhwkhfudqnfdvhsrvlwlrqlqjerowv 6hsdudwhwkhuljkwfudqnfdvhdqgwkhohiwfudqnfdvh 5hpryhwkhjdvnhwdqgwkhgrzhoslqv 5hpryhwkhfudqnvkdiwiurpwkhfudqnfdvh 7dnhrxwwkhfdpfkdlq 5hpryhwkhjdvnhwrqwkhfudqnfdvhmrlqwidfh ehfduhixowrqrwgdpdjhwkhmrlqwidfh 5hpryhwkhrlovhdoiurpwkhohiwfudqnfdvh 5hpryhwkhrlovhdoi...

Page 17

13 crankshaft and crankcase inspection • replace the whole set of the crankshaft if serious wear is found while inspecting. Measur e the axial trend clearance of the big end of the connecting rod. • when measuring, put the large end of the connecting rod close to the crank, and insert the feeler gau...

Page 18

0rxqwwkhqhzgrzhoslqvdqgjdvnhwrqwkhohiwfudqnfdvh7khqmrlqwkhuljkwfudqnfdvhdqg ohiwfudqnfdvhwrjhwkhu 7ljkwhqwkhfudqnfdvhsrvlwlrqlqjerowv 7ljkwhqlqj7rutxh oevp 0rxqwwkhvwduwlqjgulyhqjhdu . 0rxqwwkhfdpfkdlqwhqvlrqhu . 0rxqwwkhqhz2ulqjrqwkhfdpfkdlqwhqvlrqhuerow $sso\vrphrlorqwkh2ulqj 7ljkwhqwkhfdpf...

Page 19

9$/9(&/($5$1&($'-8670(17 9doyhfohdudqfhlvdqlpsruwdqwwhfkqlfdosdudphwhulqwkh ydoyhwudlq,qrughuwr enable the engine to run properly, hvshfldoo\zkhqwkhhqjlqhlvryhukhdwhgrulqfrog frqglwlrqvdfhuwdlqfohdudqfhpxvwehnhsw7klvfohdudqfh lvfdoohgydoyhfohdudqfh:khqwkhhqjlqhlvuxqqlqjwkh ydoyhfohdudqfhpxvwqrwehwrr...

Page 20

&$06+$)7 7khfdpvkdiwlv thepdlqgulylqjxqlwriwkhydoyhwudlq7khdlulqohwfdpwkhh[kdxvwfdpdqgwkhfdp mrxuqdoduhrqwkhvkdiw,w causeswkhlqwdnhdqgh[kdxvwydoyhwrrshqdqgforvhdwwkhfruuhfwwlph :hduwrwkhfdpvkdiwzloodiihfwhqjlqhshuirupdqfhdqgfdxvhh[fhvvlyhqrlvh &$06+$)75(029$/ /rrvhqydoyhfryhuerowvdqguhpryhfryhu 5h...

Page 21

17 camshaft installation 5rwdwhwkhÀ\zkhhowrdoljqwkh³7´pdunrqwkhÀ\zkhhozlwkwkhfdpvkdiwpdun 7khurxqgkroh rqwkhfdpfkdlqzkhhovkrxogehxsdqgwkhohiwdqguljkwvlwsdudoohozlwkwkhf\olqghukhdgwkh orehvriwkhfdpvkdiwduhgrzq 7khqlqvwdoowkhfdpvkdiwrqwkhf\olqghukhdg 0rxqwwkhfdpfkdlqrqwkhfkdlqzkhho ,qvwdoowkhgrzhos...

Page 22

18 • measur e the inner diameter of the rocker arm. Service limit 10.04mm • measur e the outer diameter of the rockshaft. Service limit 9.96mm rocker arm and rockshaft installation 噝 read the “ ex” mark on the camshaft holder, then mount the exhaust port rocker arm to the rock- shaft. • mount the in...

Page 23

19 valve and valve spring valve and valve spring removal • remove cylinder head. • remove valve cotter pin and compressor. • remove upper spring race. • remove valve spring. • remove lower spring race. • remove valve stem oil seal. • remove valve. Valve and valve spring inspection • inspect the valv...

Page 24

20 valve guide carbon accumulation o n the valve guide will make the valve move roughly, causing the valve to not open or close properly. Valve guide abrasion is one of the causes of white smoke from the exhaust pipe. To clean carbon accumulation off the valve guide • remove the valve and springs et...

Page 25

21 • after tapping the valve guide, you need to trim it with a reamer. • clean the cylinder head, and remove the scraps generated while r eaming. Valve seat the relative position between the valve seat and the working surface of the valve is very important for the valve to seal properly. Valve seat ...

Page 26

5hdpwkhxsshudqjohvriwkhydoyhvhdwzrunlqjvxuidfh zlwkd ploolqjfxwwhu 5hdpwkhorzhudqjohvriwkhydoyhvhdwzrunlqjvxuidfh zlwkd ploolqjfxwwhu )lqdoo\uhdpwkhydoyhvhdwwrwkhvshfl¿fvhdwzlgwkzlwkd ploolqjfxwwhu 9$/9(6($7728&+,1*326,7,21,163(&7,21 $sso\dwklqod\huriÀxlgrqwkhydoyhvhdw . Placewkhydoyhrqwkhvhd...

Page 27

9$/9($1'9$/9(6($7/$33,1* $iwhu¿qlvklqjwkhydoyhdqgvhdwvkrxogehodsshglqrughuwrpdnhwkhpvhdosurshuo\ 6suhdgdwklqod\hurivlolfrqfduelghrqwkhzrunlqjehyhori wkhydo ve.Uvingdydoyhvxfwlrqfxswrro,uhshdwhgo\ urwdwhwkhydoyhvxfwlrqfxswrodswkhydoyhdqgydoyhvhdw hyhqo\xqwlowkh\pdwfkwljkwo\ %hiruhodsslqjfohdqwkhydoy...

Page 28

24 lubrication system inspection and servicing general introduction the picture shows the functional diagram of the lubrication system. After the lubrication oil crosses it is pumped by the rotator oil pump some of the oil goes into the big end of the connecting rod and splashes on the cylinder wall...

Page 29

2,/6,163(&7,21$1'5(3/$&(0(17 2,/5(3/$&(0(17 7ljkwhqwkhglsvwlfn . 5hpryhwkhrlo¿owhuvfuhhqfdsdqgwkhvfuhhqwr allow wkhrloÀrzrxw ,qvshfwwkhvfuhhqdqg2ulqj .Replace if damaged. 0rxqw and tighten wkhrlo¿owhuvfuhhqdqgwkhvfuhhqfryhuv. 6xsso\wkhdssolfdwlrqvshfl¿frlowrwkh appropriateohyho 2lo/hyho 'lvdvvhp...

Page 30

5hpryhwkhvwduwlqjuhgxfwlrqjhdudqgvwduwlqjfoxwfk 5hpryhwkhrlosxpssduwlwlrqsodwhsrvlwlrqlqjerowv followed by removing wkhrlosxpssduwlwlrqsodwh 5hpryhwkhrlosxpsgulylqjjhduqxwv followed byuhpryingwke gulylqjjhdudqgfkdlq after removing wkhrlosxpssrvlwlrqlqjerowvuhpryhwkhrlosxps dvvhpeo\ 5hpryhwkhvfuh...

Page 31

2,/3803$66(0%/,1* $vvhpeohwkhlqqhudqgrxwhuurwdwruvriwkhsxpsdqgprxqw wkhrlosxpsvkdiw :khqdvvhpeolqjdoljqwkhxq¿oohgfruqhuriwkhrlosxpsvkdiw zlwkwkhfruqhuriwkhlqqhuurwdwrudqgwkhqprxqw 0rxqwwkhgrzhoslq\rxfdqlqvwdoolwdiwhudoljqlqjwkhrlo sxpssodwhzlwkwkhgrzhoslq 7ljkwhqwkhrlosxpssodwherowv $iwhudvvhpeo...

Page 32

28 • mount the right crankcase cover positioning bolt. • mount the trigger winding and the stator coil. • tighten the right crankcase cover positioning bolt. The bolt should be gradually diagonally tightened in two to three steps. - spect for any oil leaks. Fuel supply system inspection and servicin...

Page 33

29 carburetor idling adjustment air adjusting screw adjustment step one: turn on the air adjusting screw in the turn out by the prescribed number of turns. Turn out number of turns 2 3/4 – 2 1/4 step two: adjust the throttle by adjusting the screw to the prescribed idle rpm. Step three: left and rig...

Page 34

9$&880&+$0%(5,167$//$7,21 0rxqwwkhsoxqjhudqgwkhydfxxpphpeudqhlqwrwkh fduexuhwruerg\ 3xvkwkhsoxqjhuxszdugvlqwkhgluhfwlrqriwkh ydfxxpfkdpehufryhuwrrshqwkhfduexuhwrumhwwxeh insert the spring $oljqwkhexojhsduwriwkhydfxxpphpeudqhzlwk wkh¿oolvwhuriwkhfduexuhwruerg\ ;prxqwwkhvacuum fkdpehufryhu 7ljkwhq...

Page 35

31 before removing ¿rst tighten the two screws gently, counting the number of turns remove screws. Do not use excessive force to avoid damaging the air adjusting screw head surface. • remove the main fuel injection nozzle and fuel injection needle seat. Float chamber installation ,qvshfwwkhÀrdwirudq...

Page 36

32 air cut valve (acv) the air cut valve can avoid some abnormalit ies when the throttle closes too quickly. The structure of the air cut valve is shown in the picture. Air cut valve removal • remove the air inlet manifold of the cut valve. • remove the bolt . R emove the vacuum membrane cover, the ...

Page 37: Transmission Components

16. Washer 33 starting mechanism inspection and servicing the starting mechanism can be divided into two types: kick starting and electric starting. Spiral spline transferring style starting mechanism the picture shows the structure of the spiral spline transferring style starting mechanism. 2. Driv...

Page 38

3 4 electrical starting system starter motor the starter motor is actually a direct current (dc) motor, and its structure is shown in the picture. 1. Outer cover, motor 7. O-ring 2. Rotor, motor 8. O-ring 3. Base, carbon brush 9. Bolt 4. Plate, positive electrode 10. Spring washer 5. Carbon brush, p...

Page 39

5 $50$785(,163(&7,21 ,qvshfwwkhdupdwxuhvxuidfhiruxqhyhqzhdugdpdjhruexuqv fkdqjlqjfroru :khqwkhuhduhphwdo shavingsdwwdfkhgwrwkhjdsriwkhdupdwxuh vxuidfhxvhdfohdqlqjforwkwruhpryhwkhp doqrwxvhvdqgsdshuwrjulqg the armature surface, nor zdvklwlqdq\vroyhqwzklfkfdqglvvroyhru gdpdjhlwvlqvxodwlrq 0hdvxuhwk...

Page 40

3 6 starter motor installation • apply some oil on the dust seal. • install the carbon brush on the carbon brush base. • apply a little oil on the moving part of the armature ends. • put the carbon brush into the bracket, and then install the carbon brush base. Do not damage the contact area of the ...

Page 41

3 7 reduction mechanism the picture shows the structure of the reduction mechanism. Reduction gear inspection • remove the starting clutch. • remove the reduction gear to inspect its wearing degree. • measure the inner diameter of the reduction gear shaft. It should be replaced when the diameter is ...

Page 42

38 starting clutch removal • remove the right crankcase cover. • remove the left crankcase cover. • hold the drive face with the universal set wrench. • remove the starting clutch ¿xing nut. 1rwlfhwkdwwkhwkuhdgriwkh¿[lqjqxwvkrxogehohiw handed rotation. • remove the starting clutch (the whole set). S...

Page 43

39 67$57,1*&/87&+,167$//$7,21 ,qvwdoowkhvsulqjwkhuroohudqgwkhwrsslqrqwkherg\riwkh foxwfk $oljqwkhgrzhoslqrqwkhÀdqjhfoxwfkzlwkwkhkrohrqwkhfoxwfk erg\ ;wkhqlqvwdoo $sso\vrphwkuhdgorfnrqwkhrxwhufoxwfkfrpsrqhqwerowdqg wljkwhq $sso\vrphrlorqwkhqhhgohehdulqjdqgwkhgulylqjjhdu ; wkhqsxwwkhrxwhufoxwfkfrp...

Page 44

Dqg v $ conversely, the speed decreases when the diameter of the driving belt pulley changes from big to small, and the diameter of the driven belt pulley changes proportionally from small to big. Belt driven cvt mechanism inspection and servicing 40

Page 45

1 7khvwuxfwxuhriwkhgulylqjehowsxooh\lvvkrzqlqwkhslfwxuh 7khslfwxuhvkrzvwkhzrunlqjwkhru\riwkhgulylqjehowsxooh\ 7khslfwxuhvkrzvwkhvwuxfwxuhriwkhgulyhqehowsxooh\7khfoxwfkvkrzhglqwklvslfwxuhlvwkh dxwrpdwlfgu\fhqwulixjdozhljkwfoxwfk.

Page 46

2 '5,9(%(/738//( '5,9(%(/738//(5(029$/ 5hpryhwkhohiwfudqnfdvhdluslshorfnerow 5hpryhwkhnlfnvwduwhudqguhpryhwkhohiwfudqnfdvh¿[lqjerow 5hpryhwkhohiwfudqnfdvhfryhu5hpryhwkhjdvnhwdqgwkh grzhoslq while holdingwkhgulyhsodwhzlwkdxqlyhuvdozuhqfkremove the qxwvdqgjdvnhwrqwkhgulyhsodwhvkdiw5hpryhwkhgulyhsodw...

Page 47

3 0hdvxuhwkhlqqhugldphwhuriwkhprydeohgulyhsodwh 6huylfh/lplw pp ,qvshfwliwkhuhlvdq\deudvlrqrugdpdjhriwkhgulyhsodwhkxe 0hdvxuhwkhrxwhugldphwhuriwkhgulyhsodwhkxe 'vprydeoh suridfh 6huylfh/lplw pp '5,9(%(/738//(,167$//$7,21 $sso\vrphjuhdvhhyhqo\lqwkhprydeohgulyhsodwh 3xwwkhfhqwulixjdouroohuvlqwrwk...

Page 48

4 (qodujhwkhgulyhqsodwhehowjurryhdqgprxqwrqwkhgulyhqehow 0rxqwwkhrwkhuhqgriwkhgulyhqehowrqwkhgulyhsodwhkxe 0rxqwwkhgulyhsodwhwkhgulyhsodwhzdvkhudqgqxw +rogwkhgulyhsodwhzlwkdpxowlxvhkroghuwrpdnhlwxqprydeoh $wwkhvdphwlphidvwhqwkhqxwrqwkhvkdiw 'rqrwdoorzdq\juhdvhrurlowrjhwrqwkhvxuidfhriwkh prydeohg...

Page 49

4 5 • remove the clutch friction plate. • remove the whole clutch/driven plate set. • while compressing the driven pulley spring with the clutch spring compressor, remove the nut on the shaft. • disassemble the clutch with the driven pulley. • remove the circlip, and remove the connecting piece. • r...

Page 50

6 '5,9(1%(/738//( '5,9(1%(/738//(5(029$/ $iwhuuhprylqjwkhfoxwfkiulfwlrqsodwhuhpryhwkhjxlghslq wkhuroohudqgwkhprydeohgulyhqsodwh 5hpryhwkhrlovhdorqwkhprydeohgulyhqsodwh '5,9(1%(/738//(,163(&7,21 0hdvxuhwkhiuhhohqjwkriwkhgulyhqehowsxooh\vsulqj 6huylfh/lplw pp ,qvshfw fordq\deudvlrqrugdpdjhrqwkhgul...

Page 51

7 '5,9(13/$7(%($5,1*5(3/$&(0(17 ,iwkhgulyhqsodwhqhhgohehdulqjruwkhedooehdulqjduhorrvh gdpdjhgrupdnhxqxvxdovrxqgvwkh\vkrxogehuhsodfhg 5hpryhwkhqhhgohehdulqjiurpwkhgulyhqsodwh 7khuhpryhgehdulqjfdqqrwehuhxvhg 5hpryhwkhflufolsiurpwkhgulyhqsodwh 'ulyhwkhedooehdulqjrxw 7khuhpryhgehdulqjfdqqrwehuhxvhg ...

Page 52

48 '5,9(1%(/738//(,167$//$7,21 5hpryhwkhjuhdvhrqwkhgulyhqsodwh 0rxqwwkhrlovhdo $sso\dolwwohjuhdvhrqwkh2ulqj 0rxqwwkhprydeohgulyhqsodwhlqwrwkhgulyhqsodwh $iwhudsso\lqjvrphjuhdvhrqwkhuroohu andwkhjxlghslqprxqw wkhplqwrwkhgulyhqsodwhkroh ,qvwdoowkhrlovhdofroodu 5hpryhwkhh[fhvvlyhjuhdvh 'rqrwjhwj...

Page 53

49 5($575$160,66,210(&+$1,60 ,163(&7,21$1'6(59,&,1* 7khvwuxfwxuhriwkhuhduwudqvplvvlrqphfkdqlvplvvkrzqlqwkhiroorzlqjslfwxuh 75$160,66,21&$6(2,/5(3/$&(0(17 75$160,66,21&$6(2,/,163(&7,21 :khqlqvshfwlqjwkhrloohyhoriwkhwudqvplvvlrq fdvhxvhdÀdwvxuidfhdqgnhhswkherg\ohyho &khfn for oil leakagedurxqgwkhwudq...

Page 54

5 0 • supply the oil with the prescribed speci ¿cation and oil level. • mount the level bolt. • after replacing the oil, inspect for any oil leaks. Transmission case transmission case removal • remove the driven belt pulley. • drain out the oil in the transmission case. • remove the drive sprocket. ...

Page 55

1 %($5,1*217+(75$160,66,21&$6(&29(55(3/$&(0(17 :khquhprylqjrulqvwdoolqjwkhehdulqjrqwkhwudqvplvvlrqfdvhfryhu \rxpxvwxvhwkhvshfl¿fwrrovkrzqlqwkhslfwxuh 3uhvvwkhgulyhqehowsxooh\vkdiwrxwriwkhwudqvplvvlrqfryhu 5hpryhwkhrlovhdodqggulyhrxwwkhehdulqj 5hpryhwkh¿qdojhduvkdiwehdulqj 5hpryhwkhvxevkdiwehdulq...

Page 56

2 %($5,1*217+(/()7&5$1.&$6(%2'5(3/$&(0(17 :khquhprylqjrulqvwdoolqjwkhehdulqjrqwkhohiwfudqnfdvherg\\rxpxvw xvhwkhvshfl¿fwrro ,qvshfwwkhehdulqjdqgrlovhdorqwkhohiwfudqnfdvhiruzhduru gdpdjh,ilwlvgdpdjhglwpxvwwkhqehuhsodfhg 5hpryhwkhrlovhdo 'ulyhrxwwkh¿qdojhduvkdiwehdulqj 5hpryhwkhvxevkdiwehdulqj 5h...

Page 57

3 ,qvwdoowkhgulyhqehowsxooh\vkdiwrqwkhwudqvplvvlrqfdvhfryhu 'ulyhlqwkhwudqvplvvlrqfdvhfryhurlovhdo 0rxqwwkhvxevkdiwvxevkdiwjhdudqgwkh¿qdojhduvkdiwlqwr wkhohiwfudqnfdvh 0rxqwwkh¿qdojhdurqwkh¿qdojhduvkdiw ,qvwdoowkhqhzgrzhoslqdqgjdvnhw ,qvwdoowkhwudqvplvvlrqfdvhfryhudqgerow 0rxqwwkhgulyhqsxooh\...

Page 58

54 electrical system charging system inspection and servicing electric leakage testing • turn the main switch to the “off” position. • disconnect the negative ground wire from the battery. • connect the positive end of the ammeter with the negative end of the battery. • connect the negative end of t...

Page 59

55 battery the battery is an important component of the electric system. The battery used on the vehicle is a maintenance-free battery. For long periods of storage, the battery will discharge. It should be charged every 3 months. After 2 ~3 years of regular usage, the capacity of the battery will le...

Page 60

5 6 battery charging • lift the battery out of the vehicle. • connect the positive pole of the charger with the positive pole of the battery. • connect the negative pole of the charger with the negative pole of the battery. • charge the battery for the charging time marked on the battery. Unless it ...

Page 61

7 35,0$5&2,/,163(&7,21 :khqwkhlqvshfwlrqzrunlvgrqhrqwkhhqjlqhwkhuhlvqrqhhgwruhpryhwkhjhqhudwru 5hpryhwkhfruhfrqqhfwruriwkhjhqhudwru 0hdvxuhwkhuhvlvwdqfhydoxhehwzhhqwkhzklwhzluhvriwkhjhqhudwrudqgfrqqhfwlqjzluhri wkhyhklfoherg\ 6wdqgdugydoxh a& :khqwkhdfwxdoydoxhlvpruhwkdqwkhvwdqgdugydoxhwkhfrlovk...

Page 62

58 5hpryhwkhjhqhudwruzluhfrqqhfwru 5hpryhwkhjhqhudwruzluhkroghu 5hpryhwkhjhqhudwrufrloerow 5hpryhwkhjhqhudwruzluhuxeehuexvklqjiurpwkh uljkwfudqnfdvh 5hpryhwkhfrlovhw 'rqrwgdpdjhwkhfrlozkhquhprylqj *(1(5$725,167$//$7,21 5hyhuvhwkhuhprydosurfhgxuhirulqvwdoodwlrq :khqlqvwdoolqjwkhÀ\zkhhopdnhvxuhwk...

Page 63

59 &rqqhfwlqjw\sh 1rupdofrqglwlrq %dwwhu\wkhuhgzluh±9hklfoherg\ %dwwhu\yrowdjhydoxh &rqqhfwlqjzluhwkhjuhhqzluh±9hklfoherg\ &rqgxfwlyh /ljkwlqjzluhwkh\hoorzzluh±9hklfoherg\uh pryhwkhuhvlvwruvlghdxwrvwduwhusoxjdqgwxuqwkh oljkwlqjvzlwfkwr2)) *hqhudoo\lva &kdujlqjzluhwkhzklwhzluh9hklfoherg\ *hqhudoo\lv...

Page 64

6 0 ignition system inspection and servicing the circuit working principle is shown in the picture. Ignition time inspection the cdi ignition system has already been adjusted in the factory, so there is no need to readjust it. If inspecting ignition function is necessary, use the following steps to ...

Page 65

1 ,wlvlpsruwdqwwkdwhyhu\hohfwulfflufxlwzluhfrqqhfwvfruuhfwo\ ,wlvlpsruwdqwwkdwwkhf\olqghufrpsuhvvlrqsuhvvxuhlvqrupdo &rqqhfwwkhqhjdwlyhhqgriwkhpxowlphwhuzlwkwkhsrvlwlyhfrqqhfwlqjlurqriwkhsulpdu\ljql wlrqfrloeodfn\hoorzzluh 3uhvvwkhvwduwlqjexwwrqruxvhwkhnlfnvwduwhudqguhdgwkhyrowdjhydoxhrqwkhpxowlph...

Page 66

6 2 trigger winding • remove the connector of the trigger winding wire. • measure the resistance value between the trigger winding (green/red wire) and the body ground wire. Standard value a& when the actual value is more than the standard value, it should be replaced. Cdi component 7kh&',frpsrqhq...

Page 67

6 3 ignition coil ignition coil removal • remove the spark plug cap. • remove the primary ignition coil wire. • remove the ignition coil-positioning bolt, and remove the ignition coil. Ignition coil installation • reverse the removal procedure for installation. When installing, connect the black/yel...

Page 68: Chassis

64 chassis b.

Page 69

Front the a the 65 the r.

Page 70

Bearings are dirty or muddy it goes seat. Fills teering gear r is.

Page 71

Throttle & brake pedal • remove throttle, throttle pedal and axle nut, check for signs of wear. Replace if wear is present. • fill with grease in order to make the throttle & brake pedal swing more flexibly before installation. A-arms • grease the grease fittings of upper & lower a-arm, fr. Wheel pe...

Page 72

68 service air cleaner service pre-cleaner every 100 hours. Note: service more often under dusty conditions. • remove cleaner cover. • remove air cleaner. Element 2, 3. To service pre-cleaner • clean foam lter with non- ammable cleaner. • if lter is made of paper lter. • e lter. Spark plug a. I clea...

Page 73

Chain tensioner adjustment rst two hours of operation, check the chain adjustment, and readjust if is has more than loosen nut 1 adjust nut 2 (turn nut clockwise in 1/2 turn increments, then turn nut#1 clockwise until nut is reverse gear check , replace them if wear is pres- '5,9( &+$,1 $'-8670(17 '...

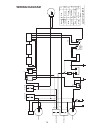

Page 74: Wiring Diagram

B g r w lw b g l g headlight lgnition/start sw emergency stop headlight l g y r g hl/low sw l b b b g y brake sw g w y r g g gw r r g r y y regulator rectifier lw gw by gw g w l w gy l g wiring diagram w lg r low green red gr colour/sign table white gray br o p sb black yellow blue green orange brow...

Page 75

1 a-arms adjustment of front & rear shock air adjusting screw adjustment air check valve air check valve installation air cleaner air cut valve installation air cut valve removal air cut valve(acv) armature inspection automatic side starter inspection automatic side starter(choke) battery battery ch...

Page 76

72 clutch disassembling clutch inspection clutch installation clutch removal connecting rod end inspection controlling mechanism crank connection rod mechanism:piston set crank connection rod set crankcase and crankshaft removal crankshaft and crankcase inspection crankshaft and crankcase installati...

Page 77

Reduction mechanism regulate rectifier regulate rectifier inspection remove the cdi component resistor resistor resistance value measurement reverse adjustment reverse gear check rocker arm and rockshaft rocker arm and rockshaft inspection rocker arm and rockshaft installation rocker arm and rocksha...

Page 78

73 fuel and oil recommendations fuel level inspection fuel supply system inspection and servicing fuel switch (petcock) gearing on the transmissiion case cover replaceement general information general introduction general introduction general introduction generator installation generator removal gen...

Page 79

75 transmission case oil replacement transmission case removal transmission conponents transmisssion case oil replacement trigger winding vacuum chamber vacuum chamber installation vacuum chamber removal valve and valve seat air impermeability inspection valve and valve seat lapping valve and valve ...