- DL manuals

- Acer

- Grinder

- Supra 2040PD

- Operation Manual

Acer Supra 2040PD Operation Manual - Spindle (818)

818 PD

__________________________________________________________________________

SPINDLE (818)

A: WHEEL ASSEMBLY (1013)

NO.

PART NO.

DESCRIPTION Q,TY SIZE

1.

1080001005

BALANCING ARBOR

1

2.

WHEEL

extractor

1

3.

2630008005 NUT

1

4. 3950007005

WHEEL SETTING NUT

1

5. 3930006005

WASHER

1

6.

GRINDING WHEEL

1

ψ203x31.75x12

7. 3920018005

WHEEL HUB

1

8.

3960006005

BALANCE BLOCK

3

9.

STEEL BALL

3

ψ4

10.

SET SCREW

3

M5x5L

BALANCING STAND (C0301)

NO.

PART NO.

DESCRIPTION Q,TY SIZE

1.

SET SCREW

1

M8x16L

2.

1000001005 BALANCING STAND

1

3.

HEX SOCKET SCREW

2

M8x25L

B: WHEEL GUARD (1012)

NO.

PART NO.

DESCRIPTION Q,TY SIZE

1. 2630014005

LOCK SCREW

1

2. 3900028005

WHEEL GUARD DOOR

1

3.

RETAINING RING

1

E8

4. 1910001005

WHSEEL GUARD

1

5.

CROSS HEAD SCREW 2 M5x8L

6. 3500036005 COVER

1

C: SPINDLE ASSEMBLY (2011A)

NO.

PART NO.

DESCRIPTION Q,TY

SIZE

1.

SET SCREW 1 M5x5L

2. 2630005005

SETTING NUT 1

3. 1460001005

COLLAR

1

4. 2630002005

PRESSING PLATE

1

5.

BALL BEARING 1 NN3006

6. 1440006005

SPACING RING

1

7. 1050007005

SPINDLE

1

8.

SETTING

KEY

1

6x6x15L

9.

BALL BEARING

2

#7204C

10. 1440003005

BEARING WASHER

1

11. 1440004005

NEARING WASHER

1

12.

SETTING NUT

2

AN04

13.

HECX SOCKET SCREW

6

M6x30L

- PL-01.1 -

Summary of Supra 2040PD

Page 1

Acer high precision automatic surface grinder operation manual model:supra 818pd~ supra 2040pd taiwan: ya-gin machine tool manufacturing, inc. No. 101, lane 506, seng-karng district, taichung city, taiwan tel: 886-4-2520-4120 fax: 886-4-2520-4123 ca: springwood industrial, inc. 1062 n. Kraemer place...

Page 2

818~2040 pd contents chap. 1 safety rules 1.1 general notices for operation -------------------------------------------------------- 1-1 1.2 notices for use of grinding wheel--------------------------------------------------- 1-1 chap. 2 description of machine features 2.1 m a c h i n e f e at u r e...

Page 3

818~2040 pd chap. 6 machine maintenance 6.1 n o t i c e s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7 - 1 6.2 h y d r a u l i c s y s t e m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ...

Page 4

818~2040 pd ___________________________________________________________________________ 1-1 chap. 1 safety rules safety first! we are pleased to give instructions of safety rules for the machine operation. Always pay attention to your safety when operating the machine. Properly save this operation m...

Page 5

818~2040 pd ___________________________________________________________________________ 2-1 chap. 2 description of machine features 2.1 machine features: 1. High precision cartridge type spindle: the spindle runs in 4 precision angular contact ball bearings in combination with roller bearings. Befor...

Page 6

818~2040 pd ___________________________________________________________________________ 2-2 2.2 machine specifications 2.2.1 818 pd specifications: model descriptions 818pd table area w x l(mm) 203x460 max. Grinding length (mm) 480 max. Grinding width (mm) 228 max. Distance from spindle center line ...

Page 7

818~2040 pd ___________________________________________________________________________ 2-3 2.2.2 1020 pd & 1224 pd specifications: model descriptions 1020pd 1224pd table area w x l(mm) 254x508 300x600 max. Grinding length (mm) 520 600 max. Grinding width (mm) 280 300 max. Distance from spindle cent...

Page 8

818~2040 pd ___________________________________________________________________________ 2-4 2.2.3 14/16 pd specifications: 1428pd 1436pd 1632pd 1640pd 305x712 305x915 406x813 406x1020 712 915 813 1020 330 410 standard column: 630 300x700 300x900 400x800 400x1000 760 960 890 1060 830 1000 930 1100 60...

Page 9

818~2040 pd ___________________________________________________________________________ 2-5 2.2.4 2040 pd specifications: model descriptions 2040pd table area w x l (mm) 406x1020 max. Grinding length (mm) 1020 max. Grinding width (mm) 500 max. Distance from spindle center line to table surface (mm) ...

Page 10

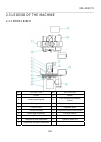

818~2040 pd ___________________________________________________________________________ 2-6 2.3 legend of the machine 2.3.1 model 818pd no. Description no. Description 1 column 10 saddle 2 grinding wheel guard 11 cross movement handwheel (z-axis) 3 grinding wheel 12 cross travel regulation knob 4 co...

Page 11

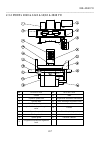

818~2040 pd ___________________________________________________________________________ 2-7 2.3.2 model 1020 & 1224 & 14/16 & 2040 pd no. Description no. Description 1 saddle 10 table 2 hydraulic power unit 11 longitudinal movement handwheel 3 spindle head 12 cross movement regulation knob 4 grindin...

Page 12: Model

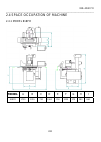

818~2040 pd ___________________________________________________________________________ 2-8 2.4 space occupation of machine 2.4.1 model 818pd model a b c d e f g h i 818pd 1730 1355 720 1960 700 1020 270 280 860

Page 13: Model

818~2040 pd ___________________________________________________________________________ 2-9 2.4.2 model 1020 & 1224 & 14/16 & 2040 pd it is requested to leave sufficient spaces, which should be bigger than the values shown on the table below. Model a b c d e f g h i 1020pd 1700 1500 1065 2340 760 95...

Page 14

818~2040 pd ___________________________________________________________________________ 2-10 2.5 grinding capacity: 2.5.1 818 pd pd model 818 (1) max. Width of grinding 228mm (2) max. Height of grinding 358mm (3) max. Table travel 515mm (4) max. Table load 202kg (5) magnetic chuck sizes (mm) 200x450...

Page 15

818~2040 pd ___________________________________________________________________________ 2-11 2.5.1 1020 pd & 1224 pd pd model 1020 1224 (a) grinding wheel size 205mm(8”) 305mm(12”) (1) max. Width of grinding 281mm 308mm (2) max. Height of grinding 397mm 427.5mm (3) max. Manual travel of table 620mm ...

Page 16

818~2040 pd ___________________________________________________________________________ 2-12 2.5.2 14/16 pd & 2040 pd pd model 1428 1436 1632 1640 2040 (1) max. Width of grinding 330mm 330mm 410mm 410mm 530mm (2) max. Height of grinding 450mm 450mm 450mm 450mm 552.5mm (3) max. Table travel 830mm 100...

Page 17

818~2040 pd ___________________________________________________________________________ 2-13 2.6 accessories: standard accessories: 1. Tool box with tools -------------------------------------- 1set 2. Wheel extracting nut -------------------------------------- 1set 3. Balancing bar ----------------...

Page 18

818~2040 pd ___________________________________________________________________________ 3-1 chap. 3 moving the machine 3.1 fixing the machine: before shipping or moving the machine, all moving parts of the machine are completely fixed. 1. The “l” shaped pieces are applied for fixing between the tabl...

Page 19

818~2040 pd ___________________________________________________________________________ 3-2 model 1020~2040pd 3.2 lifting machine by hoist: 3.2.1 machine packed by crate: 1. The packed machine weight (gross weight) is marked on the crate. Below table also shows the weight of machine for reference: m...

Page 20

818~2040 pd ___________________________________________________________________________ 3-3 4. Shown as figure below, you need to wrap the steel wires under the bottom of crate, and fit another ends the steel wires in the hook of hoist. 5. When lifting the packed machine, pay attention to machine le...

Page 21

818~2040 pd ___________________________________________________________________________ 3-4 4. Shown as figure below, insert the two ends of steel wires through the lifting bolts. Then place the middle of steel wires at the hook of the hoist (two steel wires are required). 5. When lifting the machin...

Page 22

818~2040 pd ___________________________________________________________________________ 3-5 4. When moving the machine, it should be properly positioned on a forklift as shown on figures below. Also, pay attention to the machine stability and its gravity-balance. 3.3.2 lifting unpacked machine: 1. T...

Page 23

818~2040 pd ___________________________________________________________________________ 4-1 chap.4 installing machine 4.1 placing the machine 4.1.1 machine space required: machine space required for each model is shown on below table: model 818 series 1020 series 1224 series 1428 series length (mm) ...

Page 24

818~2040 pd ___________________________________________________________________________ 4-2 4.2 adjusting machine leveling 1. Thoroughly clean the table, then place two precision level gauges (a,b) on the table, shown on below figure (a). 2. Adjust the leveling screws (4, 5) under the machine base u...

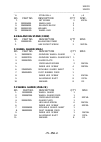

Page 25: Brand Grade Brand

818~2040 pd ___________________________________________________________________________ 4-3 4.3 installing hydraulic system for longitudinal feed 1. Place the hydraulic oil tank at the right side of the machine, shown as figure below. 2. Connect oil hoses (a, b) to the hydraulic oil tank. 3. Connect...

Page 26

818~2040 pd ___________________________________________________________________________ 4-4 4.4 installing coolant system: 4.4.1-1 placing and installing coolant system on 818pd series: (see fig below) 1: install the coolant tank at the left lower side of the machine. Fit the coolant hose (a) to the...

Page 27

818~2040 pd ___________________________________________________________________________ 4-5 4.4.1-2 placing and installing coolant system on 1020~2040 pd series: install the coolant tank at the left side of the machine before connecting coolant hoses (a, b). The guide bushing of coolant tank must al...

Page 28

818~2040 pd ___________________________________________________________________________ 4-6 4.5 electric wiring: a. It’s a power wire for coolant with dust collector unit, which should be connected to a socket marked with , located at the back side of the electrical cabinet. B. The power wire of hyd...

Page 29

818~2040 pd ___________________________________________________________________________ 5-1 chap. 5 grinding operation 5.1 mounting, dismantling and balancing grinding wheel 5.1.1 mounting and removing the grinding wheel: 1. When mounting or removing the grinding wheel, an extracting nut shall be ap...

Page 30

818~2040 pd ___________________________________________________________________________ 5-2 5.1.2 balancing the grinding wheel grinding wheel balancing method 1. Place the balancing stand on a stable plane. Use the precision level gauges to calibrate the leveling of the slideways on the balancing st...

Page 31

818~2040 pd ___________________________________________________________________________ 5-3 5.1.3 dressing the grinding wheel 1. In case too much dusts exist on the grinding wheel surface or its surface is not smooth, then you should apply a diamond dresser to dress the grinding wheel. 2. The diamon...

Page 32

818~2040 pd ___________________________________________________________________________ 5-4 5.1.4 corresponing table for various brands of grinding wheels brand workpiece material carbo kinik tairouly dry grinding c46h8v1a same as left same as left cast iron wet grinding c46hi8v1a same as left same ...

Page 33

818~2040 pd ___________________________________________________________________________ 5-5 5.2 mountng workpiece to achieve high accuracy of grinding, one of the important requirements is to mount the workpiece correctly and stably. The correct workpiece holding methods depend on the workpiece size...

Page 34

818~2040 pd ___________________________________________________________________________ 5-6 5.2.3 thin with small workpiece a. Mounting thin with small workpiece: this type of workpiece should be mounted on the magnetic conductive plate that may prevent workpiece distortion due to powerful magnetic ...

Page 35

818~2040 pd ___________________________________________________________________________ 5-7 5.3 surface grinding 5.3.1 surface grinding procedures the most common operation for a surface grinder is the flat surface grinding. The operation is to grind a surface to the desired finish, then grind it to...

Page 36

818~2040 pd ___________________________________________________________________________ 5-8 q. Perform several times of coarse grinding as desired. Grind out complete cutting marking until size approaches to your desired value. R. Fine sharpening on the grinding wheel. S. Apply a dressing strip to s...

Page 37

818~2040 pd ___________________________________________________________________________ 5-9 5.4 workpiece side surface grinding 5.4.1purpose of workpiece sides grinding the top / bottom sides, right / left and front / back sides of flat and rectangular workpieces must be ground to accurate squarenes...

Page 38

818~2040 pd ___________________________________________________________________________ 5-10 圖(c) a workpiece is clamped on the angle plate grind the first side surface 5.4.5 grinding side or end surface of workpiece adjacent surfaces grinding procedures: once the workpiece is clamped on the angle p...

Page 39

818~2040 pd ___________________________________________________________________________ 5-11 5.4.6 grinding 3 rd and 4 th side surfaces use the first and the second ground surfaces as reference, then performing grinding on the third and the fourth side surfaces. Place the ground surface on the magne...

Page 40

818~2040 pd ___________________________________________________________________________ 5-12 5.5 vertical surface grinding 5.5.1 importance of vertical surface grinding in some cases, there is a need to grind a vertical surface without need to change the workpiece position. 5.5.2 mounting workpiece ...

Page 41

818~2040 pd ___________________________________________________________________________ 5-13 5.5.5 vertical surface grinding procedures a. Install a grinding wheel especially suitable for vertical surface grinding. You also need to balance, shape and sharpen the grinding wheel. B. Mount a diamond dr...

Page 42

818~2040 pd ___________________________________________________________________________ 5-14 triangle. The corresponding height of opposite side (the composite height of block) between 0º and 90º can be calculated by triangular principle. Below contents give calculation of composite block height: si...

Page 43

818~2040 pd ___________________________________________________________________________ 5-15 5.6.4 angular surface grinding angular surface grinding: as above mentioned, the angular surface grinding can be performed by using the straight face of grinding wheel to grind a workpiece, which is position...

Page 44

818~2040 pd ___________________________________________________________________________ 5-16 5.7 trouble shooting for surface grinding 5.7.1 two factors that cause grinding problem there are many factors that may affect the final grinding result. A machine operator must understand wheat items should...

Page 45

818~2040 pd ___________________________________________________________________________ 5-17 5.7.3 surface grinding problem analysis surface grinding defects and causes are shown on below table: surface grinding defects and causes defect conditions causes burning or grid pattern workpiece poor finis...

Page 46

818~2040 pd ___________________________________________________________________________ 5-18 5.8 recommended grinding wheel specifications for surface grinding the grinding wheel specifications supplied by kinik are shown on below table: recommended grinding wheel specifications for surface grinding...

Page 47

818~2040 pd ___________________________________________________________________________ 5-19 5.9 performance comparison among various grinding wheels below table shows various grinding wheels performance. Performance comparison among various grinding wheels symbol description: ◎ excellent, ○ good, △...

Page 48

818~2040 pd ___________________________________________________________________________ 5-20 5.11 porous ceramic bonding grinding wheel specifications below table shows various porous ceramic bonding grinding wheel specifications recommended by japan noritake. Porous ceramic bonding grinding wheel s...

Page 49

818~2040 pd ___________________________________________________________________________ 6-1 chap. 6 machine maintenance 6.1 notices: 1. Everyday when cleaning the machine, do not apply compressed air for cleaning. 2. Do not allow dusts to enter into the linear ways. When performing dry grinding, the...

Page 50

818~2040 pd ___________________________________________________________________________ 6-2 6.2.1 adjusting hydraulic system 1. Vairious adjustment screws: a:pressure regulation handle b1,b2:right / left moving direction change impact force adjustment screw (buffering) c1,c2:right / left moving spee...

Page 51

818~2040 pd ___________________________________________________________________________ 6-3 6.3 lubrication system 6.3.1 legend of lubrication system 6.3.1-1 legend of 818pd series lubrication system a: vertical feed slideways and elevating screw lubrication on column b: cross feed screw lubrication...

Page 52

818~2040 pd ___________________________________________________________________________ 6-4 6.3.1-1 legend of 1020~2040pd series lubrication system a:lubrication oil hose for vertical feed slideways b:lubrication oil hose for elevating screw and transmission gears c:lubrication oil hose for table sl...

Page 53

818~2040 pd ___________________________________________________________________________ 6-5 6.3.2 adjusting lubrication oil flow 1. Open the lower guard located at the back side of the machine. Try to find the position h shown the figure on the previous page (lubrication oil regulation valve). 2. Ch...

Page 54

818~2040 pd ___________________________________________________________________________ 6-6 6.4.3 others 1. Periodically check if any electric wire is loosened or broken or not. 2. Check if wiring for each motor is loosened or not. Check if all electrical devices are normal or not. 6.5 periodic main...

Page 55: Acer

Acer high precision surface grinder control system operation manual model:supra 818pd~ supra 2040 pd.

Page 56

818~2040pd 2 contents chap. 1 control panel operation ---------------------------------------------------------------1 1-1 layout of control panel ---------------------------------------------------------------------1 1-2 main display and button numbers on control panel-----------------------------2...

Page 57

818~2040pd 3 chap. 1 control panel operation 1-1. Layout of control panel.

Page 58

818~2040pd 4 1-2. Main display and button numbers on control panel.

Page 59

818~2040pd 5 1-3. Grinding setting display and button numbers:.

Page 60

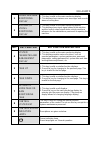

818~2040pd 6 1-4. Description of push buttons: no. Description / figure description / operation 1 emergency stop switch used for turning power off in case an emergency condition occurs (press it for turning power off. Turn it clockwise or pull up for reset) 2 operation mode selection knob select you...

Page 61

818~2040pd 7 2a after automatic grinding, the spindle may raise to a fixed position according to the value set by the display (41). 5. Once downfeed amount reaches the value shown on the display (43), the machine will perform intermittent spark out grinding according to the value shown on the displa...

Page 62

818~2040pd 8 2c manually controlled surface grinding 1: when the 4a lamp lights on, following motions can be performed: 1. Hydraulic drive longitudinal feed by using key (24). 2. Spindle drive by using key (22). 3. Cross movement controlled by keys (8, 9, 10 and 11). 4. Cross movement by handwheel c...

Page 63

818~2040pd 9 2f right side automatic feed slot grinding 1: when the 4a lamp lights on, following motions can be performed: 1. Hydraulic drive longitudinal feed by using key (24). 2. Spindle drive by using key (22). 3. Cross movement by handwheel. 4. The key (7) is used for controlling slow raising. ...

Page 64

818~2040pd 10 2g shown on the display (37). After automatic grinding is finished, stop the hydraulic system, spindle running and cooling system, etc. The spindle may raise or not according to setting the selection key (38). After automatic grinding, the spindle may raise to a fixed position accordin...

Page 65

818~2040pd 11 8 low speed downfeed key 1: the spindle head (y-axis) moves down at low speed. 2: when the blue lamp lights on, it means the key (8) is allowed to execute its function. 3: when the blue lamp flashes, it indicates downfeed at low speed is performing. 9 big downfeed key (value shown on d...

Page 66

818~2040pd 12 15 spare spare 16 spare spare 17 spare spare 18 spare spare 19 spare spare 20 automatic cross jog feed regulator / rapid cross feed speed regulator / automatic continuous cross feed speed regulator 1: for adjusting big jog feed amount in automatic cross feed. 2: for adjusting rapid cro...

Page 67

818~2040pd 13 not closed to a proper position. (2) the switch no. 30 is not energized. 26 cooler start key 1: used for starting cooler. 2: when the indication lamp lights on, it means the cooler is running. 27 cooler stop key 1: used for stopping cooler. 2: when the indication lamp lights on, it mea...

Page 68

818~2040pd 14 31 monitor it provides various functions, such as y-axis downfeed grinding data, coordinate, machine input / output signal monitoring, system parameter setting and error message monitoring, etc. 32 wheel spindle speed setting used for setting the wheel spindle speed and monitoring curr...

Page 69

818~2040pd 15 36 intermittent spark out grinding times setting value when y-axis (vertical axis) performs automatic grinding, if the total downfeed is over or equal to the setting value shown on the display (43), then automatic downfeed will stop. Once the setting times shown on the display (36) rea...

Page 70

818~2040pd 16 44 grinding start point setting value in automatic grinding when y-axis (vertical axis) performs automatic grinding, the system will calculate the total grinding amount based on this setting value in combination with the target setting value shown on the display (40). (normally set at ...

Page 71: 2-1

818~2040pd 17 chap. 2 introduction to monitor 2-1 function description on monitor outlook (front side) ⑩ ① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨ no. Key function key function description 1 y-axis grinding data setting dipslay 1. This key is valid on the main monitoring display. 2. This display provides various settings, ...

Page 72

818~2040pd 18 2 alarm message monitoring display 1. This key is valid on the main monitoring display. 2. This display shows various error messages and records alarm occurring time. 3 machine i/o status monitoring display 1. This key is valid on the main monitoring display. 2. This display shows inpu...

Page 73: 2-2

818~2040pd 19 motion indication lamp blue lamp flashes: during communication / during accessing data. Alarm indication lamp red lamp flashes: alarm is occurring 10 tft lcd screen for displaying various functions displays. (operation / display area) 2-2 function description on monitor outlook (back s...

Page 74

818~2040pd 20 1 power input terminal 6 internet pork (lan) 2 com3(rs-232/rs-422/rs-485) (support communication status indication lamp) 7 usb host 3 com2(rs-232/rs-422/rs-485) (support communication status indication lamp) 8 sound output port 4 com1(rs232) 9 battery / memory card cover 5 usb client -...

Page 75

818~2040pd 21 3-5 screen contrast & brightness window.

Page 76: 4-1

818~2040pd 22 chap. 4 function description on screen 4-1 home page- main monitoring display 單元一 單元二 單元三 unit 3 unit 1 unit 2 unit 4 unit 5.

Page 77: No.

818~2040pd 23 home page-unit description on main monitoring display main monitoring display / unit 1 no. Display unit description 1 error message running display. 2 1. Y-axis coordinate value display. 2. Or is y-axis motion indication lamp. 3. Press the key for setting y-axis coordinate at zero. Or ...

Page 78: No.

818~2040pd 24 6 or z-axis cross feed control lock 7 or two sides downfeed or back side downfeed setting main monitoring display / unit 3 no. Display unit description 01 y-axis grinding travel data setting 02 error message record & display 03 machine i/o status monitoring 04 system parameter manageme...

Page 79: No.

818~2040pd 25 main monitoring display / unit 5 no. Display unit description 01 for inch unit, this regulator is used for setting fine grinding feed value on y-axis. 4-2 description for y-axis grinding travel data display (enter from ) no. Display unit description 1 press the red column for setting t...

Page 80: 4-3

818~2040pd 26 5 press the green column for setting the grinding start point. 6 or when performing coarse grinding, the coarse grinding figure (green area) flashes. 7 or when performing fine grinding, the fine grinding figure (green area) flashes. 4-3 description of error message display (enter from ...

Page 81: 4-4

818~2040pd 27 4-4 description of machine i/o monitoring display (enter from ) no. Description function description ① ② ③ 1 lamp numbers these are i/o monitoring lamp numbers. When external function, device and coil are conducted, the red lamp lights on. If not conducted, the red lamp extinguishes. 2...

Page 82: 4-5-1 Operator

818~2040pd 28 4-5 system parameter (enter from ) 4-5-1 operator.

Page 83

818~2040pd 29 system maintenance personnel.

Page 84: 4-5-2 Setting Password Table

818~2040pd 30 4-5-2 setting password table.

Page 85: 4-5-3 System Date & Time

818~2040pd 31 4-5-3 system date & time.

Page 86

818~2040pd 32 4-5-4 adjusting contrast & brightness.

Page 87: 5-1 Copy Display To Usb

818~2040pd 33 chap. 5 appendix 5-1 copy display to usb 5-1-1 usb the usb is used for saving the control data, and copying control data. The support file format is fat32. Suggested capacity is under 1gb. When applying usb for saving data, if you need to remove usb, be sure to shut off write-in motion...

Page 88: 5-2 Screen Displays

818~2040pd 34 5-2 screen displays 5-2-1 home page: 5-2-2 grinding main monitoring display: 5-2-3 y-axis grinding data setting display:.

Page 89: 5-2-4 Alarm Message Display

818~2040pd 35 5-2-4 alarm message display 5-2-5 machine i/o monitoring display (input, 7 pages) 5-2-6 machine i/o monitoring display (output, 5 pages).

Page 90

818~2040pd 36 5-2-7 system user management display: 5-2-8 system data setting – keep set (user) display: 5-2-9 system data setting – machine time parameter display.

Page 91

818~2040pd 37 5-2-10 system data setting – keep set (system) display:.

Page 92: 5-3 Plc I/o List

818~2040pd 38 5-3 plc i/o list input note: the input points with grey based columns are used for scanning signals. Signal point name signal point function signal point name signal point function x00 y-axis encoder a phase signal x20-3 z-axis slowly forward button x01 y-axis encoder b phase signal x2...

Page 93: Output

818~2040pd 39 output signal point name signal point function signal point name signal point function y00 y-axis pulse command pulse signal y30 f2 model function (z-axis _ speed reduce lamp) y01 y-axis pulse command direction signal y31 z-axis _ auto return direction change setting lamp y02 z-axis cw...

Page 94: 5-4-1 Alarm Message

818~2040pd 40 5-4-1 alarm message alarm no. Alarm message correction 001 y-axis stepping motor is overheat check if there is any obstacle existing on y-axis travel, which may cause y-axis motor overload and overheat. After check, reset it. 002 z-axis servo motor driver is abnormal. Check it. Check t...

Page 95

818~2040pd 41 5-4-2 operation error message for plc control. Alarm no. Alarm message correction 101 hydraulic regulation valve is not closed properly. Hydraulic motor can’t start. When the message displays, check if the hydraulic regulation valve is closed properly or not. After check, reset it. 102...

Page 96

818~2040pd 42 119 auto start fails → grinding wheel is not started grinding wheel spindle should start running at first, then auto start can be performed. 5-5 returning parameters to default setting display: 1. Set mode selection at y=0. 2. Turn the magnetic chuck selection switch to middle position...

Page 97: Parts List

818 pd ___________________________________________________________________________ .Ec machinery directive 89/392/eec parts list preserve this manual for future reference and use machine name: horizontal surface grinding machine brand: acer model: supra 8 1 8 p d manufacture: ya-gin machine tool man...

Page 98: Content

818 pd _________________________________________________________________________________________ content 1 :spindle ......................................................................................... Pl-01 2 :column .................................................................................

Page 99: Spindle

818 pd __________________________________________________________________________ spindle - pl-01 -.

Page 100: Spindle (818)

818 pd __________________________________________________________________________ spindle (818) a: wheel assembly (1013) no. Part no. Description q,ty size 1. 1080001005 balancing arbor 1 2. Wheel extractor 1 3. 2630008005 nut 1 4. 3950007005 wheel setting nut 1 5. 3930006005 washer 1 6. Grinding wh...

Page 101

818 pd __________________________________________________________________________ - pl-01.2 - no. Part no. Description q,ty size 14. 1430020005 spindle housing 1 15. 3500035005 rear cover 1 16. Hex socket screw 4 m6x25l 17. 2770011005 coupling 1 18. Set screw 2 m6x6l.

Page 102: Column

818 pd __________________________________________________________________________________________ column - pl-02 -.

Page 103: Column (818)

818 pd __________________________________________________________________________________________ - pl-02.1 - column (818) a: front cover sheet assembly (2022a) no. Part no. Description q,ty size 1. Cross head screw 6 m5x8l 2. 3500043015 front guard 1 3. 2000038005 eront guard 1 4. 2000039005 front ...

Page 104: Vertical Assembly

818 pd _________________________________________________________________________________________ vertical assembly - pl-03a -.

Page 105: Vertical Assembly

818 pd _________________________________________________________________________________________ vertical assembly a: vertaical transmitting assembly (2026c) no. Part no. Description q,ty size 1. Hex socket screw 1 m5x14l 2. 2410001005 washer 1 3. 1200020005 pinion gear 1 4. Spring pin 1 ψ4x25l 5. B...

Page 106: C: Encoder(C1801)

818 pd _________________________________________________________________________________________ - pl-03a.2 - no. Part no. Description q,ty size 43. 1210005005 timing belt pulley 1 44. Set screw 2 m5x8l 45. Timing belt 1 t5x156tx12mm 46. 2000373005 safety cover 1 47. Cross head screw 1 48. 170001400...

Page 107: Crosswise Drive (818)

818 pd ________________________________________________________________________________________ _ crosswise drive (818) - pl-04 - - pl-04a -.

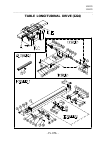

Page 108: Crosswise Drive (818)

818 pd ________________________________________________________________________________________ _ crosswise drive (818) a: crossfeed leadscrew set(2031b&2031bn) no. Part no. Description q,ty size 1. 1460002005 sleeve 1 2. Hex head screw 3 m5x20l 3. 0010002015 bearing seat 1 4. Bearing 2 6202zz 5. 14...

Page 109: F: Crossfeed Lock(2034)

818 pd ________________________________________________________________________________________ _ no. Part no. Description q,ty size 4. Bearings 2 6007z 5. 1430014005 bearing sleeve 1 6. 0010008005 bearing seat 1 7 hex socket screw 4 m8x25l 8. 1800013005 motor supporter 1 9. Hex head screw 6 m8x40l ...

Page 110: Saddle Crosswise Drive (818)

818 pd ________________________________________________________________________________________ _ saddle crosswise drive (818) - pl-05a -.

Page 111: Saddle Crosswise Drive

818 pd ________________________________________________________________________________________ _ - pl-05a.1 - saddle crosswise drive a: crosswise sensor-detected rail (2035a) no. Part no. Description q’ty spec. 1. 2260010005 sensor-detected rail 1 2. 3870003005 side cover of sensor-detcted rail 2 3...

Page 112: & Saddle Dust (818Pd)

818 pd ________________________________________________________________________________________ _ longitudinal transmitting set & saddle dust (818pd) - pl-06 -.

Page 113: & Saddle Dust (818Pd)

818 pd ________________________________________________________________________________________ _ longitudinal transmitting set & saddle dust (818pd) a: saddle dust (2049a) no. Part no. Description q’ty size 1. 0406015005 saddle 1 2. 3500019005 slide dust cover 1 3. Washer 2 ψ6 4. Hex head screw 1 m...

Page 114

818 pd ________________________________________________________________________________________ _ - pl-06.2 - 4. Hex head screw 6 m6x10l.

Page 115: Table Longitudinal Drive

818 pd ________________________________________________________________________________________ _ table longitudinal drive - pl-07 -.

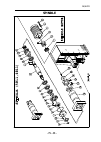

Page 116: A: Table (204A)

818 pd ________________________________________________________________________________________ _ - pl-07.1 - table longitudinal drive (818) a: table (204a) no. Part no. Description q,ty size 1. Hex head screw 3 m8x20l 2. Spring washer 3 ψ8 3. 1930009005 right-end cover 1 4. 0506017005 table 1 5. 35...

Page 117: Base (818Pd)

818 pd _________________________________________________________________________________________ base (818pd) - pl-08a -.

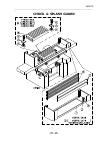

Page 118: Base (818Pd)

818 pd _________________________________________________________________________________________ base (818pd) a: oil witer set (1054) no. Part no. Description q’ty size 1. Copper wiper 4 2. Cross head screw 4 m4x6l b: base accessory set (2053a) no. Part no. Description q’ty size 1. 2000101005 plate ...

Page 119: F: Leveling Screw Set(2052)

818 pd _________________________________________________________________________________________ - pl-08a.2 - e: longitudinal hydraulic speed control set (1043) no. Part no. Description q’ty size 1. 3000046005 electrical box 1 2. 3030062005 splash cover 1 3. 3010026005 cover 1 4. 3520070005 water pr...

Page 120

818 pd _________________________________________________________________________________________ guard and magnetic chuck (818pd) - pl-09 -.

Page 121: A: Splash Guard Set (C0502)

818 pd _________________________________________________________________________________________ - pl-09.1 - guard and magnetic chuck (818pd) a: splash guard set (c0502) no. Part no. Description q’ty size 1. Wing nut 2 dcn 5m 2. Washer 2 3. 3520004005 rear aplash plate 1 4. 3520005005 guard 1 5. Was...

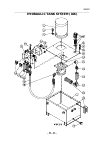

Page 122: Dydraulic Cylinder System

818 pd _________________________________________________________________________________________ dydraulic cylinder system - pl-10 -.

Page 123: Hydraulic Cylinder System

818 pd _________________________________________________________________________________________ hydraulic cylinder system a:hydraulic (1042a) no. Part no. Description q’ty size 1. Hex nut 4 m12 2. Washer 4 ψ12 3. Hex head screw 4 m6x60l 4. High pressure pipe 90°connection 2 1/2ptx3/8ph 5. 241002600...

Page 124

818 pd _________________________________________________________________________________________ - pl-10.2 - 14. 2820001015 throttle directional valce 1 15. High pressure pipe 90°connection 4 3/8ptx3/8ph 16. 1810044005 switch fixed seat 1 17. Nut 2 m5 18. Hex head screw 2 m5x30l 19. 2490009005 posit...

Page 125

818 pd _________________________________________________________________________________________ hydraulic tank system ( 106 ) - pl-11 -.

Page 126

818 pd _________________________________________________________________________________________ - pl-11.1 - hydraulic tank system ( 106 ) no. Part no. Description q’ty size 1. 3230001015 oil tank 2. Motor 1 1”hp 3. Hex scoket screw 4 m10x25l 4. Spring washer 4 5. Oil-feeding filter 1 ab1163 6. Hex ...

Page 127

818 pd _________________________________________________________________________________________ table reversing mechanism (2561) - pl-12 -.

Page 128

818 pd _________________________________________________________________________________________ - pl-12.1 - table reversing mechanism (2561) no. Part no. Description q’ty spec. 1. 2640011005 leak-proof nut 3 2. O-ring 6 p10 3. 2630013005 fixing nut 3 4. 2830003005 small throtting shaft 3 5. 2010004...

Page 129: Parts List

1020 pd 1224 pd ________________________________________________________________________________ .Ec machinery directive 89/392/eec parts list preserve this manual for future reference and use machine name: horizontal surface grinding machine brand: acer model: supra 1 0 2 0 p d & 1 2 2 4 p d manufa...

Page 130: Content

1020 pd 1224 pd _________________________________________________________________________________________ content 1 :spindle..................................................................................... Pl-01 2 :column .............................................................................

Page 131: Spindle

1020 pd 1224 pd ________________________________________________________________________________________ _ spindle - pl-01 -.

Page 132: Spindle (2511) For 1020

1020 pd 1224 pd ________________________________________________________________________________________ _ spindle (2511) for 1020 no. Part no. Description q’ty spec. 1. 3500024005 front dust guard 1 2. 2630031005 spindle front nut 1 3. 0640003005 front bearing pressing plate 1 4. 1440020005 inner s...

Page 133: Spindle (2511L) For 1224

1020 pd 1224 pd _______________________________________________________________________________ - pl-01.2 - spindle (2511l) for 1224 no. Part no. Description q’ty spec. 1. 3500055005 front dust guard 1 2. 2630032005 spindle front nut 1 3. 0640007005 front bearing pressing plate 1 4. 1440021005 inner...

Page 134

1020 pd 1224 pd ____________________________________________________________________________________________ _ column - pl-02 -.

Page 135: Column (2521) For1020

1020 pd 1224 pd ____________________________________________________________________________________________ _ column (2521) for1020 no. Part no. Description q’ty spec. 1. 0106007005 spindle seat 1 2. 0206006005 column 1 3. 2260016005 column rail 2 4. 0640004005 spindle seat ‘s pressing plate 2 5. 2...

Page 136: Column (3021) For 1224

1020 pd 1224 pd ____________________________________________________________________________________________ _ - pl-02.2 - column (3021) for 1224 no. Part no. Description q’ty spec. 1. 0106027015 spindle seat 1 2. 0206007005 column 1 3. 2260017005 column rail 2 4. 0640004005 spindle seat ‘s pressing...

Page 137: Column & Spindle

1020 pd 1224 pd _________________________________________________________________________________________ _ column & spindle - pl-03 -.

Page 138: Column & Spindle

1020 pd 1224 pd _________________________________________________________________________________________ _ - pl-03.1 - column & spindle (2510) for 8” /1020 series wheel no. Part no. Description q’ty spec. 1. 2760005005 rubber coupling 1 2. 2770003005 motor coupling 1 3. Headless screw 2 m8*10l 4. S...

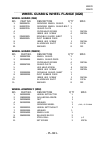

Page 139

1020 pd 1224 pd _____________________________________________________________________________________________ wheel guard & wheel flange (1020) - pl-04 -.

Page 140: Wheel Guard

1020 pd 1224 pd _____________________________________________________________________________________________ wheel guard & wheel flange (1020) wheel guard (2512) no. Part no. Description q’ty spec. 1. 3900006015 grinding wheel guard 1 2. 2620007015 grinding wheel guard bolt 1 3. 2620007015 guard pl...

Page 141: Balancing Stand (C0301)

1020 pd 1224 pd ____________________________________________________________________________________________ - pl-04.2 - balancing stand (c0301) no. Part no. Description q’ty spec. 1. Set screw 1 m8*16l 2. 1000001005 balancing stand 1 3. Hex socket screw 2 m8*25l.

Page 142

1020 pd 1224 pd _______________________________________________________________________________________________ _ wheel guard & wheel flange (1224) - pl-04a -.

Page 143: Wheel Guard

1020 pd 1224 pd _______________________________________________________________________________________________ _ wheel guard & wheel flange (1224) wheel guard (2512l) no. Part no. Description q’ty spec. 1. 3900008015 grinding wheel guard 1 2. 2620007015 grinding wheel guard bolt 1 3. 2000067005 gua...

Page 144: Balancing Stand (C0302)

1020 pd 1224 pd _______________________________________________________________________________________________ _ - pl-04a.2 - balancing stand (c0302) no. Part no. Description q’ty spec. 1. 1000002005 balancing stand 1 2. Hex socket screw 3 m8*35l.

Page 145

1020 pd 1224 pd _________________________________________________________________________________________ _ - pl-05 - grinding wheel & column (1020).

Page 146: C: Water Pipe (2524)

1020 pd 1224 pd _________________________________________________________________________________________ _ grinding wheel & column (1020) a: column front dust fender (2522) no. Part no. Description q’ty spec. 1. 2000071005 column front fender 1 (2522) 2. Cross head screw 10 m6*8l 3. 3480005005 colu...

Page 147: E.2 Balancing Stand (C0301)

1020 pd 1224 pd _________________________________________________________________________________________ _ - pl-05.2- no. Part no. Description q’ty spec. 6. 3930010005 washer 1 7. 3920016005 wheel hub 1 8. 3960001005 balance block 3 9. Steel ball 3 ψ4 10. Set screw 3 m5*5l e.2 balancing stand (c030...

Page 148

1020 pd 1224 pd _________________________________________________________________________________________ _ - pl-05a - grinding wheel & column (1224).

Page 149: C: Water Pipe (2524)

1020 pd 1224 pd _________________________________________________________________________________________ _ grinding wheel & column(1224) a: column front dust fender (2522l) no. Part no. Description q’ty spec. 1. 2000072005 column front fender 1 (2522l) 2. Cross head screw 10 m6*8l 3. 3480005005 col...

Page 150: E.2 Balancing Stand (C0302)

1020 pd 1224 pd _________________________________________________________________________________________ _ - pl-05a.2- 6. Steel ball 3 ψ4 no. Part no. Description q’ty spec. 7. Set screw 3 m5*5l 8. 3920016005 wheel hub 3 9. 3960004005 balance block 3 10. 3930013005 washer 1 11. 3920006005 wheel hub...

Page 151: Saddle Crosswise Drive

1020 pd 1224 pd ________________________________________________________________________________________ saddle crosswise drive - pl-06 -.

Page 152: Saddle Crosswise Drive

1020 pd 1224 pd ________________________________________________________________________________________ saddle crosswise drive a: coolant drainer (2537) no. Part no. Description q’ty spec. 1. 2450003005 coolant drainer 1 2. Hex screw 4 m6*16l b. Crosswise sensor-detected rail (2536) no. Part no. De...

Page 153

1020 pd 1224 pd ________________________________________________________________________________________ no. Part no. Description q’ty spec. 3. Cross head screw 4 m3*25l 4. Limit switch 2 z-15gq22-b 5. Sock head cap screw 4 m4*25l c.3: crosswise safety switch (2535a2) no. Part no. Description q’ty s...

Page 154

1020 pd 1224 pd ________________________________________________________________________________________ - pl-06.1 - f: crosswise scale ring & hand wheel ( 3638,3638n ) no. Part no. Description q’ty spec. 1. 1890013005 scale indicating plate 1 2. 0890031015 feeding scale ring(mm) 1 3638 0890032015 f...

Page 155

1020 pd 1224 pd ______________________________________________________________________________________________ _ table longitudinal drive (1020) - pl-07 -.

Page 156

1020 pd 1224 pd ______________________________________________________________________________________________ _ table longitudinal drive (1020) a: longitudinal rack set (2545a) no. Part no. Description q’ty spec. 1. 1830018005 longitudinal rack seat 1 2. 1150002005 longitudinal rack 1 3. Sock head ...

Page 157

1020 pd 1224 pd ______________________________________________________________________________________________ - pl-07.2 - no. Part no. Description q’ty spec. 5. 2430002005 clamping block of sensor-detected sheet 4 6. 2490004005 longitudinal limit block 2 7. 2890004005 longitudinal sensor adjusting ...

Page 158

1020 pd 1224 pd ______________________________________________________________________________________________ _ table longitudinal drive (1224) - pl-07a -.

Page 159

1020 pd 1224 pd ______________________________________________________________________________________________ _ table longitudinal drive (1224) a: longitudinal rack set (3045a) no. Part no. Description q’ty spec. 1. 1150004005 longitudinal rack 1 2. Sock head cap screw 7 m6*20l b: longitudinal hand...

Page 160

1020 pd 1224 pd ______________________________________________________________________________________________ - pl-07a.2 - 6. 2490004005 longitudinal limit block 2 no. Part no. Description q’ty spec. 7. 2890004005 longitudinal sensor adjusting block 2 8. 2620005005 lobe knob 2 9. Cross head screw 4...

Page 161: Vertical Feed

1020 pd 1224 pd _________________________________________________________________________________________ vertical feed - pl-08 -.

Page 162: Vertical Feed

1020 pd 1224 pd _________________________________________________________________________________________ vertical feed a: vertical leadscrew assembly (2552d&2552dn) no. Part no. Description q’ty spec. 1. Headless screw 6 m10x25l 2. Headless screw 4 m6x25l 3. 2420027005 fixing plate of elevating nut...

Page 163

1020 pd 1224 pd _________________________________________________________________________________________ - pl-08.2 - 16. Bearing 1 6006zz 17. 2630001005 nut 1 18. 1430035005 bearing nuts 1 19. Nut 2 an04 20. 1700007005 motor fixing plate 1 21. Sock head cap screw 1 m6*12l 22. Bearing 23. 0010014005...

Page 164: Lifting Structure

1020 pd 1224 pd _________________________________________________________________________________________ lifting structure lifting structure - pl-09 -.

Page 165: Eye Bolt Set (2554)

1020 pd 1224 pd _________________________________________________________________________________________ - pl-09.1 - eye bolt set (2554) no. Part no. Description q’ty spec. 1. 2620009005 hanging screw 4 2. 2620010005 hanging screw 1 leveling screw set (2555) no. Part no. Description q’ty spec. 3. 2...

Page 166

1020 pd 1224 pd ________________________________________________________________________________________ _ longitudinal hydraulic system (254c/1020) - pl-10 -.

Page 167

1020 pd 1224 pd __________________________________________________________________________ - pl-10.1 - longitudinal hydraulic system ( 254c/1020 ) a: longitudinal throttling valve (2543) no. Part no. Description q’ty spec. 1. Fixed handle 1 m6 2. 2490007015 flow control knob 1 3. Pin 1 d8*50l 4. 172...

Page 168

1020 pd 1224 pd ________________________________________________________________________________________ _ - pl-10.2 - no. Part no. Description q’ty spec. 10. 0640011005 fixed oil pipe socket 1 11. Socket screw 2 m8*35l 12. Socket screw 2 m8*65l 13. High pressure pipe 90°connection 1 3/8pt*3/8ph*40l...

Page 169

1020 pd 1224 pd ________________________________________________________________________________________ _ longitudinal hydraulic system (304c/1224) - pl-11 -.

Page 170: B: Hydraulic Piping (3042)

1020 pd 1224 pd __________________________________________________________________________ - pl-11.1 - longitudinal hydraulic system (304c/1224) a: longitudinal throttling valve (3043) no. Part no. Description q’ty spec. 1. Fixed handle 1 m6 2. 2490007015 flow control knob 1 3. Pin 1 d8*50l 4. 17200...

Page 171

1020 pd 1224 pd ________________________________________________________________________________________ _ - pl-11.2 - no. Part no. Description q’ty spec. 9. Socket screw 2 m6*35l 10. 0640011005 high pressure pipe connection 1 11. Socket screw 2 m8*35l 12. Cross head screw 2 m8*65l c: longitudinal h...

Page 172

1020 pd 1224 pd ________________________________________________________________________________________ _ table reversing mechanism (3661) - pl-12 -.

Page 173

1020 pd 1224 pd ________________________________________________________________________________________ _ - pl-12.1 - table reversing mechanism (3661) no. Part no. Description q’ty spec. 1. 2640011005 leak-proof nut 3 2. O-ring 6 p10 3. 2630013005 fixing nut 3 4. 2830003005 small throtting shaft 3 ...

Page 174

1020 pd 1224 pd ________________________________________________________________________________________ _ hydraulic tank system ( 256 ) - pl-13 -.

Page 175

1020 pd 1224 pd ________________________________________________________________________________________ _ - pl-13.1 - hydraulic tank system ( 256 ) no. Part no. Description q’ty spec. 1. 1910068005 upper protection cover of oil tank 1 2. Hydraulic motor 1 2hp6p 3. Hex socket screw 4 m10*20l 4. Stra...

Page 176: Chuck & Splash Guard

1020 pd 1224 pd ________________________________________________________________________________________ _ chuck & splash guard chuck & splash guard a: chuck (2548/1020,3048/1224) optional no. Part no. Description q’ty spec. 1. 2630046005 t-nut 2 2. Hexagon head screw 2 m12*55l 3. Chuck(250*500mm) 1...

Page 177: Electrical and Control Box

1020 pd 1224 pd - pl-15 - electrical and control box electrical and control box no. Part no. Description q’ty spec. 1. 3000012005 electrical box 1 2. 3030067005 splash cover 1 3. 1440034005 separation pole in electrical plate 1 4. 2410060005 cushion pad in cover 1 5. 3520070005 water proof cover in ...

Page 178: Lubrication System ( 258 )

1020 pd 1224 pd lubrication system ( 258 ) - pl-16 -.

Page 179: Lubrication System ( 258 )

1020 pd 1224 pd - pl-16.1 - lubrication system ( 258 ) a: no. Part no. Description q’ty spec. 1. Sock head cap screw 2 m6x10l 2. 1820023005 pump fixed stand 1 3. Sock head cap screw 2 m6x10l 4. Compression sleeve 3 pb-6 5. Compression bushing 3 pa-6 6. Aluminium tubing 1 ψ6 6.1. Aluminium tubing 1 ψ...

Page 180

1020 pd 1224 pd - pl-16.2 - no. Part no. Description q’ty spec. 9. Aluminium tubing 1 ψ4 10. Aluminium tubing 1 ψ4.

Page 181: Parts List

14/16 pd __________________________________________________________________________________________ .Ec machinery directive 89/392/eec parts list preserve this manual for future reference and use machine name: horizontal surface grinding machine brand: acer model:1428pd, 1436pd 1632pd, 1640pd manufa...

Page 182: Content

14/16 pd content 1 :spindle ................................................................................... Pl-01 2 :column .................................................................................. Pl-02 3 :spindle motor .....................................................................

Page 183: Spindle

14/16 pd spindle - pl-01 -.

Page 184: Spindle (3811/14) (4811/16)

14/16 pd - pl-01.1 - spindle (3811/14) (4811/16) no. Part no. Description q’ty spec. 1. 3500056015 front dust guard 1 2. O-ring 1 p120 3 3520068005 water pipe 1 4 o-ring 1 p45 5. 2630052005 spindle front nut 1 6. 0640021005 front bearing pressing plate 1 7. 1460009005 spacr ring 1 8. Bearing 2 7210 ...

Page 185

14/16 pd column (3821,3821h/14series,4821,4821h/16series) - pl-02 -.

Page 186: Column)

14/16 pd - pl-02.1- column (3821,3821h/14, 16series) (3821, 4821 standard column/3821h, 4821h high column) no. Part no. Description q’ty spec. 1. 0106010005 spindle seat 1 0106017005 spindle seat 1 (4821) 2. 0206010005 standard column 1 (3821) 0206011005 high column 1 (3821h) 3. 2260028005 standard ...

Page 187: Wheel Guard & Wheel Flange

14/16 td wheel guard & wheel flange - pl-04 -.

Page 188: Wheel Guard & Wheel Flange

14/16 pd wheel guard & wheel flange a: grinding wheel (3813) no. Part no. Description q’ty spec. 1. 3940003005 wheel extract screw & nut 1 2. 1080008005 balancing arbor 1 3. 2620013005 lock bolt 1 4. 2410056005 washer 1 5. 12” grinding wheel 1 355x127x50mm flange (c0602): no. Part no. Description q’...

Page 189

14/16 pd - pl-04.2 - no. Part no. Description q’ty spec. 7. 2350019005 splash guard 1 8. 3850005005 dust rubber piece 1 9. Inner hex screw 1 m6x14l 10. Aluminium rivet 8 d3x5l 11. Washer 8 m3.

Page 190

14/16 pd ____________________________________________________________________________ dust guard & water pipe system dust guard & water pipe system - pl-05 -.

Page 191: C: Water Pipe (3824)

14/16pd ____________________________________________________________________________ - pl-05.1 - a: column front dust fender (3822) no. Part no. Description q’ty spec. 1. 1910076015 standard column front fender 1 2. Cross head screw 10 m6x8l 3. 3520028005 column front dust sheet 2 4. Cross head scre...

Page 192: Saddle Crosswise Drive

14/16pd ____________________________________________________________________________________________ saddle crosswise drive - pl-05 -.

Page 193: Saddle Crosswise Drive

14/16pd ____________________________________________________________________________________________ saddle crosswise drive a: coolant drainer (3633) no. Part no. Description q’ty spec. 1. 2450003005 coolant drainer 1 2. Hex screw 4 m6x16l b. Crosswise sensor-detected rail (2536) no. Part no. Descri...

Page 194

14/16pd ____________________________________________________________________________________________ no. Part no. Description q’ty spec. 3. Cross head screw 4 m3*25l 4. Limit switch 2 z-15gq22-b 5. Sock head cap screw 4 m4*25l c.3: crosswise safety switch (2535a2) no. Part no. Description q’ty spec....

Page 195

14/16pd ____________________________________________________________________________________________ - pl-05.1 - 5. 210169015 motor pulley in cross movement motor 1 no. Part no. Description q’ty spec. 6. Set screw 2 m5*6l 7. Hex head screw 4 m8*16l 9. Washer 4 d8 10. Hex head screw 4 m8*12l f: cross...

Page 196

14/16 pd __________________________________________________________________________________________ _ table longitudinal drive (1428) - pl-06 -.

Page 197

14/16pd __________________________________________________________________________________________ _ table longitudinal drive (1428) a: longitudinal rack set (3745a) no. Part no. Description q’ty spec. 1. 1150006005 longitudinal rack 1 2. Sock head cap screw 7 m6x20l b: longitudinal hand wheel set (...

Page 198: D: Table Set (374)

14/16 pd __________________________________________________________________________________________ _ - pl-06.2 - no. Part no. Description q’ty spec. 7. 2890004005 longitudinal sensor adjusting block 2 8. 2620005005 lobe knob 2 9. Cross head screw 4 m4x20l 10. Cross head screw 2 m4x8l 11. Cross head...

Page 199

14/16 pd __________________________________________________________________________________________ _ table longitudinal drive (1436/1632/1640) - pl-07a -.

Page 200

14/16 pd __________________________________________________________________________________________ _ table longitudinal drive (1436/1632/1640) a: longitudinal rack set (3845a/1632)(3945a/1436)(4545a/1640) no. Part no. Description q’ty spec. 1. 1150008005 longitudinal rack 1 (3845a) 1150010005 longi...

Page 201: D: Table Set (394/1436)

14/16 pd __________________________________________________________________________________________ _ c: longitudinal sensor-detected set (2544a1/3844a1) no. Part no. Description q’ty spec. 1. 2260033005 longitudinal induction rail 1 2. 3870003005 side cover of induction rail 2 3. 2000033005 longitu...

Page 202: Table Set (414/1640)

14/16 pd __________________________________________________________________________________________ _ - pl-07a.1 - 6. 520064005 anti-water plate 1 no. Part no. Description q’ty spec. 7. Cross head screw 2 m4x8l table set (414/1640) no. Part no. Description q’ty spec. 1. 0506040015 table 1 2. 1930021...

Page 203: Vertical Feed

14/16 pd _________________________________________________________________________________________ _ vertical feed - pl-08 -.

Page 204: Vertical Feed

14/16 pd _________________________________________________________________________________________ _ vertical feed a: vertical leadscrew set (3651x,3651xn) no. Part no. Description q’ty spec. 1. Hex head screw 6 m10x20l 2. Hex head screw 4 m6x25l 3. 2420027005 fixing plate of elevating nut 1 4. 8300...

Page 205

14/16 pd _________________________________________________________________________________________ _ - pl-08.2 - 16. 2630050005 regulating nut 2 no. Part no. Description q’ty spec. 17. Double head flate key 2 6x6x25l 18. Bearing 1 6205 19. Hex head screw 1 m8x35l 20. 0010014005 rear bearing seat 1 2...

Page 206

14/16 pd __________________________________________________________________________________________ _ lifting structure (1428,1436,1632,1640)(pd) - pl-09 -.

Page 207: Eye Bolt Set (3654)

14/16 pd __________________________________________________________________________________________ _ - pl-09.1 - lifting structure (1428,1436,1632)(pd) eye bolt set (3654) no. Part no. Description q’ty spec. 1. 2620011005 hanging screw 4 2. 2620012005 hanging screw 1 leveling screw set (3655) no. P...

Page 208

14/16pd longitudinal hydraulic system - pl-10 -.

Page 209

14/16 pd longitudinal hydraulic system a: longitudinal throttling valve(3643) no. Part no. Description q’ty spec. 1. 3700549005 flow control name plate 1 2. Headless screw 1 m6x6l 3. 3130008015 flow control knob 1 4. Inner retaining ring 1 ψ42 5. 1720003015 flow switch 1 6. Sock head cap screw 2 m6x...

Page 210: B: Hydraulic Piping (3642)

14/16 pd b: hydraulic piping (3642) no. Part no. Description q’ty spec. 1. Hex socket nut 4 m16 2. Disc washer 4 d16xd32x1.5t 3. 2410043005 washer 2 4. 2410045005 recoil cushion 6 5. High pressure pipe(1/2”phx510l) 1 1228 high pressure pipe(1/2”phx520l) 1 1236,1632 high pressure pipe(1/2”phx550l) 1 ...

Page 211

14/16 pd longitudinal hydraulic cylinder set (3841/1632) no. Part no. Description q’ty spec. 1. Dust ring 2 dh22.4 2. 1830029005 oil seal seat 2 3. Oil seal 2 uhs 22.4 4. Oil seal 2 gsw 22.4x30x5 5. O-ring 2 p42 6. Bearing 2 du1810 7. 2910002005 left hydraulic cylinder top head 1 8. O-ring 2 p50 9. ...

Page 212

14/16 pd - pl-10.2 - longitudinal hydraulic cylinder set (4141/1640) no. Part no. Description q’ty spec. 1. Dust ring 2 dh22.4 2. 1830029005 oil seal seat 2 3. Oil seal 2 uhs 22.4 4. Oil seal 2 gsw 22.4x30x5 5. O-ring 2 p42 6. Bearing 2 du1810 7. 2910002005 left hydraulic cylinder top head 1 8. O-ri...

Page 213

14/16 pd __________________________________________________________________________ table reversing mechanism (3661) - pl-11 -.

Page 214

14/16 pd __________________________________________________________________________ - pl-11.1 - table reversing mechanism (3661) no. Part no. Description q’ty spec. 1. 2640011005 leak-proof nut 3 2. O-ring 6 p10 3. 2630013005 fixing nut 3 4. 2830003005 small throtting shaft 3 5. 2010004005 side cove...

Page 215

14/16 pd __________________________________________________________________________ hydraulic system ( 366 ) - pl-12 -.

Page 216

14/16 pd __________________________________________________________________________ - pl-12.1 - hydraulic system ( 366 ) no. Part no. Description q’ty spec. 1. 1910068005 upper protection cover of oil tank 1 2. Hydraulic motor 1 3hp6p 3. Hex head screw 4 m10x20l 4. Straight connection pipe 1 1/2 "pt...

Page 217: Chuck & Splash Guard

14/16 pd ____________________________________________________________________________________________ _ chuck & splash guard - pl-13 -.

Page 218: Chuck & Splash Guard

14/16 pd ____________________________________________________________________________________________ _ - pl-13.1 - chuck & splash guard a: chuck optional (3748/1428) (3948/1436) (4648/1632)(4148/1640) no. Part no. Description q’ty spec. 1. 2630046005 t-nut 2 1428,1436 2630046005 t-nut 4 1632,1640 2...

Page 219

14/16 pd ________________________________________________________________________________________ _ electrical and control box - pl-14 -.

Page 220: C: Electric Box Set ( 3695A)

14/16pd ________________________________________________________________________________________ _ electrical and control box a: control box set (3694b)(3694bn) no. Part no. Description q’ty spec. 1. A18ba0aw12 locked washer 1 aw12 2. A12000an12 locked nut 1 an12 3. 3050075035 control box 1 4. Contr...

Page 221

14/16 pd ________________________________________________________________________________________ _ - pl-14.2 - no. Part no. Description q’ty spec. 42. 2030004005 electric box ground strap 1 43. Sock head cap screw 1 m10x30l.

Page 222: Lubrication System (368)

14/16 pd lubrication system (368) - pl-15 -.

Page 223: Lubrication System (368)

14/16 pd - pl-15.1 - lubrication system (368) a: no. Part no. Description q’ty spec. 1. 1910069005 cover 1 2. Sock head cap screw 2 m5x8l 3. Sock head cap screw 6 m6x15l 4. Oil level switch 1 fs-8102 5. Sock head cap screw 2 m6x20l 6. 1820016005 pump fixed stand 1 7. Oil separator 1 8. Elbow connect...

Page 224

14/16 pd no. Part no. Description q’ty spec. 10. Aluminium tubing 1 ψ4 11. Aluminium tubing 1 ψ4 - pl-15 - - pl-15.2 -.

Page 225

Ac er ta iw an.

Page 226

A c er ta iw an.

Page 227

A c er ta iw an.

Page 228

A c er ta iw an.

Page 229

A c er ta iw an.

Page 230

A c er ta iw an.

Page 231

A c er ta iw an.

Page 232

A c er ta iw an.

Page 233

A c er ta iw an.

Page 234

A c er ta iw an.

Page 235

A c er ta iw an.

Page 236

A c er ta iw an.

Page 237

A c er ta iw an.

Page 238

A c er ta iw an.