- DL manuals

- Aircel

- Dryer

- 1000

- Installation And Operation Manual

Aircel 1000 Installation And Operation Manual

Throughout this manual,

signal words are present to

advise of safety precautions

and/or standard practices.

Obey these signal words as defined

below:

DANGER!

- indicates an

imminently hazardous situation

which, if not avoided, will result

in death or serious injury.

WARNING!

- indicates a

potentially hazardous situation

which, if not avoided, could

result in death or serious injury.

CAUTION

! - indicates a

potentially hazardous situation

which, if not avoided, may

result in

minor or moderate

injury.

Notice:

- used to address

practices not related to personal

injury.

This manual is property of the owner, and should be left with the unit when

start-up is complete. Aircel LLC. reserves the right to change design and

specifications without prior notice.

Installation,

Operation, and

Service Information

Aircel

VF Series Non-Cycling Refrigerated Air Dryer

Models VF-10, 15, 25, 40, 50, 60, 75, 100, 125, 150, 200, 250,

300, 400, 500 600, 800, 1000, and 1200

Installation

and Operation Manual

Summary of 1000

Page 1

Throughout this manual, signal words are present to advise of safety precautions and/or standard practices. Obey these signal words as defined below: danger! - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning! - indicates a potentiall...

Page 2: Warning!

2 warning! General safety procedures • improper installation, operation, or maintenance may contribute to conditions in the work area or facility that could result in personal injury and product or property damage. Check that all equipment is properly selected and sized for the intended use. • consu...

Page 3

Non-cycling refrigerated air dryer 3 contents safety statements .................................................. 2 data sheet ............................................................. 3 refrigerated air dryer serial plate label .............. 4 refrigerant safety precautions .....................

Page 4

4 data sheet model number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ serial number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ date of manufacture _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ ship date _ _ _ _ _ _ ...

Page 5: Caution!

Non-cycling refrigerated air dryer 5 refrigerant safety precautions refrigerant first aid recommendations inhalation if high concentrations are inhaled, immediately remove individual from affected area to an area with a fresh air supply. Keep individual calm. If not breathing, give artificial respir...

Page 6

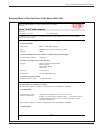

Design parameters type of dryer: refrigerated power supply: 115, 230, 460 volt / single or three phase / 60hz refrigerant type: r-134a & r-404a chemical composition: hfc parameter description optimum maximum minimum air pressure (psig) 100-125 200 80 air inlet temperature (°f) 80-100 100 40 ambient ...

Page 7

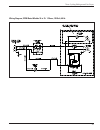

Refrigeration circuit refrigerant is compressed by the compressor to a gas with high temperature and high pressure, which then travels to the condenser (air or water cooled) to condense the gas into a liquid. Liquid travels to the evaporator (refrigerant-to-air part of the heat exchanger) and back t...

Page 8

8 air inlet air outlet separation cell air to refrigerant heat exchanger refrigerant inlet air refrigerant refrigerant outlet exiting air incoming air stainless steel mist eliminator pre-cooler / heater typical schematic flow diagram (75 - 1200 scfm rated models) aircel vf series - models 10 - 1200

Page 9: Caution!

Non-cycling refrigerated air dryer 9 purpose and intended use non-cycling refrigerated air dryers are designed to remove moisture from compressed air by use of mechanical refrigeration. They can provide pressure dew points as low as (38° f- 42° f). Referigerated dryers are used to protect industrial...

Page 10: Warning!

Lifting information 1. Use all lifting points provided. Special care must be used when lifting the dryer to prevent tip- over. 2. Use clevis connectors, not hooks, on lifting slings. 3. Only lift unit under support frame/base by using the fork lift openings provided. Do not lift by piping. 4. Check ...

Page 11

Installation 1. Locate unit on a level foundation. Dryer should be mounted on a suitably structured flat and level floor or base that is free from vibration. 2. Install unit to provide adequate clearance for maintenance services. Dryer and accompanying filters should be installed with at least 2 to ...

Page 12

Preliminary start-up checklist notice: for scfm rated models 10 - 250, wait at least 6 hours after transporting or moving of dryer system before starting the dryers. Turn the main power switch to the dryer on, but do not turn the dryer on/off switch to the on position until 6 hours have passed. For ...

Page 13

5. With the customer-supplied compressed air to the system, open the inlet valve slowly to gradually pressurize the system. Do not open valve too quickly. Opening valve and suddenly pressurizing the system can cause damage to the dryer heat exchanger and other components. 6. Check the air system pip...

Page 14

Automatic drain valve adjustments the automatic drain valve supplied is standard on the separator and should open regularly and discharge any accumulated water into the drain line. The period between openings varies with the dryer and operating conditions (electronic type). To minimize air losses, t...

Page 15

Cooling water requirements (water cooled condensing units) cooling water is required for water-cooled refrigerant condensers (scfm rated model 100 and up). The user is responsible for piping the water to and from the condenser. The required water flow rate depends on the water temperature. A water-r...

Page 16: Warning!

Shut-down procedures shut-down emergency the non-cycling refrigerated air dryer system can be shut down under any conditions and at any time by turning the unit off at the dryer or at the main disconnect switch. Once power is removed from the dryer system, the dryer must be isolated from the compres...

Page 17: Warning!

Service information to reach a field service technician or for technical support, please call the number on the manual back cover. Maintenance refrigerated air dryers require very little maintenance for satisfactory operation. Optimum performance can be expected if the following routine maintenance ...

Page 18

Filter element replacement 1. Depressurize the air system to release the compressed air from the air dryer. Notice: shutting down the air compressor will not depressurize the air dryer unit. Close air line valves before and after dryer and then depressurize unit. Depressurize dryer by pushing the te...

Page 19: Warning!

Troubleshooting warning! • before any service or maintenance work is performed on the refrigerated air dryer system, disconnect power supply and lock out power supply and depressurize system. • follow proper lock out/tag out procedures before performing service or maintenance work. • prior to perfor...

Page 20: Warning!

Warning! Before any service or maintenance work is performed on the refrigerated air dryer system, disconnect power supply and lock out power supply and depressurize system before performing maintenance or service work. 20 1. High refrigerant readings generally indicate: • dirty condenser - clean im...

Page 21

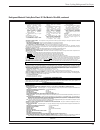

Troubleshooting table non-cycling refrigerated air dryer problem probable cause remedy water downstream of dryer system or no discharge from separator/ filter. Failed or short circuited timer on drain. Replace timer drain. Failed drain solenoid. Replace timer drain. Bulk liquid entering the dryer fr...

Page 22

Troubleshooting table, continued 22 problem probable cause remedy water downstream and dryer system not working properly or not working (cont). Refrigeration compressor cycles on/off and cannot maintain suction pressure, dryer undersized. Check airflow (cfm) and dryer capacity. Reduce airflow throug...

Page 23

23 non-cycling refrigerated air dryer problem probable cause remedy low air pressure downstream due to continuous air flow through the moisture drain line. Failed or short circuited timer on drain. Replace timer drain. Failed drain solenoid. Replace timer drain. Solenoid valve stuck open. If power i...

Page 24

Troubleshooting table, continued 24 problem probable cause remedy high refrigeration circuit head pressure (compressor is overloaded and gauge is reading out of recommended pressure range). Refrigeration condenser coil fouled or dirty or air flow blocked. Clean / blow off condensing coil of dirt or ...

Page 25

25 non-cycling refrigerated air dryer problem probable cause remedy high refrigerant suction pressure, suction gauge reading out of range and water downstream of refrigeration dryer. Refrigeration circuit hot gas bypass valve out of adjustment or defective. Contact technical support for assistance. ...

Page 26

Appendix material safety data sheet prepared to u.S. Osha, cma, ansi and canadian whmis standards 1. Product identification chemical name; class: non-flammable gas mixture containing one of the following components in a nitrogen or air balance gas: dichlorodifluoromethane, 0.0005-2.0%; trichlorofluo...

Page 27

Refrigerant material safety data sheet: r-134a models 10 to 800, continued non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 2 of 5 3. Hazard identification emergency overview : this gas mixture is a colorless, odorless gas. Releases of this gas mixture for which nitrogen is...

Page 28

Non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 3 of 5 8. Exposure controls - personal protection ventilation and engineering controls : no special ventilation systems or engineering controls are needed under normal circumstances of use. As with all chemicals, use this gas...

Page 29

Non-flammable gas mixture msds - 50040 effective date: april 19, 2005 page 4 of 5 11. Toxicological information 1,1,2-trichloro-1,1,2- trifluoroethane (continued): lc 50 (inhalation-mouse) 260 gm/m 3 /2 hours: behavioral: somnolence (general depressed activity), ataxia; lungs, thorax, or respiration...

Page 30

15. Regulatory information additional u.S. Regulations: u.S. Sara reporting requirements : this gas mixture is subject to the reporting requirements of sections 302, 304, and 313 of title iii of the superfund amendments and reauthorization act, as follows: compound sara 302 (40 cfr 355, appendix a) ...

Page 31

Refrigerant material safety data sheet: r-404a models 1000 to 1200 non-cycling refrigerated air dryer 31 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 1/14 this sds adheres to the sta...

Page 32

32 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 2/14 vapours are hea...

Page 33

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 33 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 3/14 necessary. Call ...

Page 34

34 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 4/14 fire. Further i...

Page 35

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 35 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 5/14 7.3. Specific en...

Page 36

36 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 6/14 predicted no ef...

Page 37

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 37 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 7/14 the choice of an...

Page 38

38 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 8/14 section 10: sta...

Page 39

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 39 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 9/14 lc50 / 4 h rat :...

Page 40

40 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 10/14 • 1,1,1,2-tetr...

Page 41

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 41 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 11/14 animal testing ...

Page 42

42 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 12/14 • pentafluoroe...

Page 43

Refrigerant material safety data sheet: r-404a models 1000 to 1200, continued non-cycling refrigerated air dryer 43 safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 13/14 no data availab...

Page 44

44 aircel vf series - models 10 - 1200 refrigerant material safety data sheet: r-404a models 1000 to 1200, continued safety data sheet according to regulation (ec) no 1907/2006 and 453/2010 dupont ™ suva ® 404a refrigerant version 4 . 0 revision date 21.11.2012 ref. 130000000494 14/14 14.4. Packing ...

Page 45

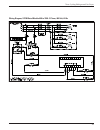

Wiring diagram, scfm rated models 10 to 75: 1 phase, 120 volt, 60 hz non-cycling refrigerated air dryer 45.

Page 46

Wiring diagram, scfm rated models 100, 125, and 150: 1 phase, 120 volt, 60 hz 46 aircel vf series - models 10 - 1200

Page 47

Wiring diagram, scfm rated model 200: 1 phase, 208/230 volt, 60 hz non-cycling refrigerated air dryer 47.

Page 48

Wiring diagram, scfm rated model 250 and 300: 3 phase, 460 volt, 60 hz 48 aircel vf series - models 10 - 1200

Page 49

Wiring diagram, scfm rated models 400 to 1200: 3 phase, 460 volt, 60 hz non-cycling refrigerated air dryer 49.

Page 50

50 date service performed notes aircel vf series - models 10 - 1200 service notes.

Page 51

Date service performed notes non-cycling refrigerated air dryer 51 service notes, continued.

Page 52

© 2013 aircel llc. Printed in usa october 2013 aircel llc. 323 crisp circle maryville, tn 37801 sales@airceldryers.Com orderentry@airceldryers.Com www.Airceldryers.Com parts and service for genuine aircel replacement parts, call: 800-767-4599 www.Airceldryers.Com for faster service, have unit’s mode...