- DL manuals

- Airflow

- Ventilation

- DUPLEXVENT DV72 L

- Installation Instructions And User Manual

Airflow DUPLEXVENT DV72 L Installation Instructions And User Manual

1

Commissioning Data: to be completed by the installer

Date of installation:

Configuration

Left Hand

Right Hand

Product Serial No:

90000556/90000557 – Issue 9 10/15

Important: This multi speed unit required Air Flow Rates to be adjusted when system is commissioned.

This manual must be kept by the householder

MODEL: DV72 R & L

Mechanical Ventilation with Heat Recovery

Installation Instructions and User Manual

Summary of DUPLEXVENT DV72 L

Page 1

1 commissioning data: to be completed by the installer date of installation: configuration left hand right hand product serial no: 90000556/90000557 – issue 9 10/15 important: this multi speed unit required air flow rates to be adjusted when system is commissioned. This manual must be kept by the ho...

Page 2: Index

2 index page general information 3 about the unit 4 wiring diagram 5 technical specifications 6 installation instructions 7 - 15 commissioning 16 check list 17 maintenance 18 – 19 sap appendix q testing results 20 – 22 declaration of conformity 23 warranty 24.

Page 3: General Information

3 general information to maintain a healthy indoor environment, closely controlled ventilation is essential. There are many pollutants that will affect the indoor air quality: human body waste products in the shape of co 2 , dead skin, perspiration and moisture. Add to this the waste products of coo...

Page 4

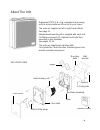

4 about the unit mounting plate wall bracket exploded view spigot heat recovery cell spacers fixing rods motor assembly front cover drain front shell remote control filter & filter plugs duplexvent dv72 r & l are complete heat recovery units to ensure optimum efficiency for your home. The units are ...

Page 5

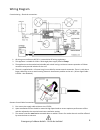

5 wiring diagram commissioning – electrical connections. 1. All wiring must conform to bs 7671 : latest edition iee wiring regulations. 2. This appliance is suitable for 230v ~ 50hz single phase supply fused at 3 amp . 3. The appliance must be earthed and a double pole switch having a minimum contac...

Page 6

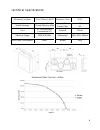

6 technical specifications spigot Ø 125mm commutated dc) duplexvent static pressure - airflow maximum flow rate 75 l/s (270m 3 /h) max* protection class ipx2 g3 fans ec (electronically max power consumption 140w weight 14kg 560 x 635 x 260mm dimensions 230v/1ph/50hz electrical supply g3 supply filte...

Page 7

7 installation instructions important be sure to have read and understood safety and recommendations • all wiring must comply with building regulations and the current i.E.E. Wiring regulations (bs7671) or the equivalent standards for your country. The final installation should be examined and teste...

Page 8

8 installation instructions control options frost protection when the cell temperature in the unit falls below 3ºc the unit automatically warms the cell with extracted air to prevent the formation of frost. Boost - switched live the unit comes with switched live as standard. It is an automatic funct...

Page 9

9 installation instructions first fix - installing ductwork and electrical supply important note: this unit is for wall or floor mount only. Ceiling mounting unit are configured differently and should be ordered separately. 1. Locate external terminations (supply and extract) in accordance with the ...

Page 10

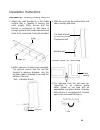

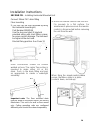

10 installation instructions second fix – installing vertically hung unit 1. Attach the wall bracket to a flat stable surface that is capable of bearing the unit’s weight, 12kg. Ensure that the bracket is positioned so that there is enough space for the condensate drain and ducts to be connected. Fi...

Page 11

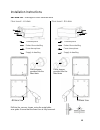

11 installation instructions second fix – installing vertically hung unit airflow and drain fitting - lh airflow and drain fitting - rh drains are factory fitted. The units has either a lh or rh drain. T o a tm o s p h e re f ro m a tm o sp h e re e xt ra ct f ro m d w e lli n g s u p p ly to d w e ...

Page 12

12 wall mounting bracket dimensions please note that there is only one loose bracket with the two tab bracket factory fitted. Picture of “tie down cable”..

Page 13

13 horizontal mounting bracket dimensions.

Page 14

14 up). Installation instructions second fix – installing horizontal mounted unit connect 22mm pvc drain fitting floor mounting 5. 6. Mount the remote control near the unit. Fix securely to a flat surface. For maintenance please ensure the remote control is disconnected before removing the unit from...

Page 15

15 installation instructions second fix - drainage for floor mounted units floor mount - lh drain floor mount - rh drain to atmosphere extract from dwelling from atmosphere supply to dwelling to atmosphere extract from dwelling from atmosphere supply to dwelling place stopper provided into the fitte...

Page 16

16 commissioning setup guide for the duplexvent the commissioning the remote switch. Panel is found on the commissioning mode is chosen by pressing the set button for 4 seconds, all sensor inputs will be disabled in this mode so that they do not interfere with flow rates. All leds will light with th...

Page 17

17 checklist • installation instructions have been understood • ducting Ø125mm or larger has been used from the unit • the unit is securely fixed into position with enough space left for servicing • condense drain is tight, drains to a suitable location and has been water tested.

Page 18

18 maintenance pack of 2 x filters. Part number 9041511 filter cover front cover general advice: regular filter inspection is recommended. Minimum recommendation is to check filters every 6 months. Some installations will need more frequent filter inspection to ensure maximum efficiency of unit. Fil...

Page 19

19 maintenance disassembly of unit for engineering access and maintenance: 1. Remove the velcro pads. Front cover...Held on with 3. Carefully remove the top foam moulding by pulling it straight forward. Foam mouldings must remain parallel. Take care gaskets. Not to damage the sealing 2. Remove retai...

Page 20

20 sap appendix q testing results central mechanical supply and exhaust ventilation system packages with heat recovery used in a single dwelling brand name airflow model duplexvent dv72r and dv72l model qualifier (if applicable) current manufacturer and contact details name airflow developments ltd ...

Page 21

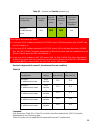

21 results for sap calculations (at minimum flow rate condition) this product has only been tested with rigid ductwork and the data are not applicable for sap calculations if installed with flexible ductwork. Table q2 – systems with rigid ductwork only exhaust terminal configuration fan speed settin...

Page 22

22 table q3 – systems with flexible ductwork only exhaust terminal configuration fan speed setting specific fan power (w/l/s) heat exchange efficiency (%) energy saving trust best practice performance compliant kitchen + 1 additional wet room n/a n/a n/a n/a these figures are entered into either: (a...

Page 23: Declaration Of Conformity

23 declaration of conformity we declare that the equipment detailed below conforms to the requirements of the ec council directives relating to electromagnetic compatibility and safety of electrical equipment. Equipment type: the heat recovery appliance model: dv72 supplied by airflow developments l...

Page 24: Warranty

Warranty this product has a warranty period of two years. The warranty can be upgraded to three years from the date of purchase against faulty material or workmanship by registering on our web site www.Airflow.Com the warranty only covers the product and not the installation cost. In case such a fau...