- DL manuals

- Airflow

- Ventilation

- Duplexvent Flexi DV 2600

- Installation, Use And Maintenance Manual

Airflow Duplexvent Flexi DV 2600 Installation, Use And Maintenance Manual

Summary of Duplexvent Flexi DV 2600

Page 1

Installation, use and maintenance manual for d uplexvent flexi dv1100,1600, 2600, 3600

Page 2

2 dear customer, thank you for choosing our product and we hope that you will be fully satisfied. This manual contains all necessary instructions, information, hints and recommendations for safe and correct equipment installation and commissioning. Please read the manual carefully and follow the ins...

Page 3

3 1 . C o n t e n t 1. Content ........................................................................................................................................................................................ 3 2. Safety instructions ..............................................................

Page 4

4 2 . S a f e t y i n s t r u c t i o n s 2.1 general safety ● only adults sufficiently familiar with the operation and maintenance manual may operate the equipment. ● the user must not tamper with or modify any part of the equipment, particularly the power supply lines! ● only professional service ...

Page 5

5 solely permitted methods of handling 4 . D e s c r i p t i o n 4.1 general ● duplex vent flexi series ventilation units with heat recovery are compact appliances containing in a single cabinet two independently powered fans with flexibly mounted engines, a highly efficient heat recovery exchanger ...

Page 6

6 duplex vent series appliances have a single-stage filtration system. Appliances in a hygienic version in compliance with hygienic standard vdi 6022 must have an class f7 filter fitted on the inlet (applies to outdoor air e1/oda class oda 1 and oda 2). When outdoor air is class 3, a class f5 filt...

Page 7

7 plan view - windowsill position window position: - the appliance is placed on height-adjustable feet (h min = 147 mm) included in delivery (4 pieces in size 1100, 5 pcs in size 1600, 6 pcs in sizes 2600 and 3600). - due to the condensate drain the appliance must be sloped toward section i2 (eha). ...

Page 8

8 - for the ceiling position use the condensate outlet in section i2 (eha) ● connect a pipe or hose (not included; a standard washing machine hose is recommended) to the condensate outlet and shape it into a siphon trap with dimensions as shown in the picture. Appropriately secure the siphon trap sh...

Page 9

9 ● especially make sure that the arrow showing the direction of air flow through the filter cassette can be seen from the side of the operator (the arrow is by the unit´s door) and that it is always pointing toward the heat recovery exchanger! ● the unit is supplied with filter cassette labels unat...

Page 10

10 note: values in the tables apply to external static pressure 200 pa. Different pressure requirements may result in a different situation. If needed, the detailed initial and final pressure loss data of the filters are available on request from the supplier of the unit. ● make sure that the positi...

Page 11

11 the following rules must be adhered to during the installation of the water chiller: ● the water chiller in all versions must be filled with an antifreeze solution with sufficient thermal resistance, or it must be drained for the period during which outdoor temperature might fall below 0°c. ● max...

Page 12

12 7 . H y g i e n i c i n s t r u c t i o n s f o r t h e a p p l i a n c e a s p e r v d i 6 0 2 2 7.1 general instructions basic hygiene-related requirements are contained in charter 5.2. the appliance has been manufactured in a hygienic design that complies with all requirements of the vdi 6...

Page 13

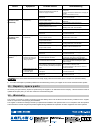

13 8 . I n s p e c t i n g t h e a p p l i a n c e 8.1 overview of inspections and measures to ensure compliance with hygiene requirements the appliance must be regularly inspected for the following areas from the list below required interval in calendar months activity measures to be taken 1. 3. 6....

Page 14

14 8.3 check noise silencer for impurities, damage and corrosion repair x 8.4 check hygienic conditions of air duct at sample point determine cause, clean relevant air duct sections x 9 air vents 9.1 check mounted perforated metal sheet, wire mesh or screens (random checks) clean or replace x 9.3 ch...

Page 15

15 ● spare filter cassettes are to be ordered from the manufacturer. Please include in your order the order code of the cassette (the code is shown on the identification plate of the appliance). ● after opening the unit door, slide out the contaminated cassettes from the guide rails and insert new o...

Page 16

16 failure symptoms possible causes troubleshooting - mechanical obstruction in fresh air intake or supply air outlets - look for mechanical obstructions of fresh air inlet ports - look for mechanical obstructions of supply air outlets - remove obstructions, if any - not found - disconnect from powe...

Page 17

17 1 3 . V i s u a l a p p e n d i x - m a n u a l s 13.1 connecting the condensate drain line.

Page 18

18 13.2 rotating the fan.

Page 19

19 13.3 fitting the filters.