3 owners manual model v410 (includes vibrapulse cleaning system*) • introduction • specifications • unpacking • installation • mounting • electrical • operation • maintenance • troubleshooting • replacement parts • motor trouble guide ***important*** this manual contains precautionary statements rel...

4 always use airflow systems, inc. Replacement parts and filters to maintain warranty. To order spare parts contact: the local exhaust & ventilation company inc. 22–1050 brock rd, pickering, ontario l1w 3x4 tel: 905.831.7001 fax: 905.831.7443 toll free: 1.888.862.5356 e-mail: sales@lev-co.Com web si...

5 table of contents 1. Safety.............................................................................................................................. 4 2. Airflow systems sets the standard ............................................................................... 5 3. Specifications ........

6 read this manual carefully before attempting to install or operate the model v410 unit. Retain these instructions for future reference. Safety rules follow all electrical and safety codes as well as the national electrical code (nec), national fire protection association (nfpa), and the occupation...

7 5. Always disconnect unit from power source before inspecting or servicing. Airflow systems sets the standard the airflow systems model v410 collects dust, welding smoke, and other dry pollutants in industrial plants, shops, schools and factories. The general theory of operation is that air bearin...

8 figure 1..

9 specifications(*): model v410 std dim: 36" w x 26" d x 53" h [0.91m w x 0.66m d x 1.35m h] weight: 680 lb. (std) [309 kg] construction: 12 gauge welded zinc coated steel cabinet, finished with a two part chemical and oil resistant paint. Includes separate filter and blower access doors, dust pan, ...

10 inspection and unpacking inspect your afs unit for shipping damage immediately upon receipt. Damaged carton(s), broken crate(s), etc. Are indications that the unit may have been damaged in shipment. It is also possible shipping damage may be concealed and not noticed until the unit is installed a...

A2 unit (see the maintenance section for more details). If any problems are found, consult the troubleshooting section in this manual. Electrical all 3 phase ac model v410 units have wiring terminated inside the junction box located on the side of the unit. Motor starters and disconnects are not sup...

A3 three phase motor. Consult the motor name plate and verify the line input voltage before attempting to make this change. Caution in large plants, when rolling unit from one building to another, you may be on a different substation transformer. Units using a three phase blower motor may run backwa...

A4 maintenance warning always disconnect the unit from the power source before working on or near the motor or wiring assemblies. Lock out disconnects to prevent unexpected application of power. The model v410 comes standard with (2) clean 2 filter cartridges of 150 square feet of media each. An opt...

A5 1 - hose (2vp2-1012), quantity as required by applicable unit (1 hose per cartridge). Figure 7. 7. Remove the old vibra pulse hose. This is done by loosening the hose clamp securing the spring at the top of the vp hose where the vp hose attaches to the 3/8” hose barb. Slide the spring and hose cl...

A6 9. Install the new vibra pulse hose onto the air cleaner’s hose barb until fully seated against brass hex on barb, see figure 9. Lubricate with water or windex to ease installation. Do not use oil or grease as lubricant! Figure 8. Figure 9..

A7 10. Slide the spring/clamp up over the hose and 3/8” hose barb until it fully seats against the barb’s hex, see figure 10. 11. Tighten the hose clamp using screw driver or 1/4” nut runner. Do not overtighten! 12. Replace filter(s) into unit. Note: make sure not to pinch hose - position vibra puls...

A8 filter replacement/ removal for cleaning 1. Turn unit off and disconnect from power source. 2. Remove filter access panel. 3. Release filter retaining latch located between cartridges, (see figure 11.) this will lower the filter holding frame. Unhook latch to let holding frame rest at lowest posi...

A9 it is important to use only clean and dry compressed air to clean the filters, otherwise contamination to cartridge filter element will result. Do not hook up to a compressed air line that has an automatic oiling device on it. Oil or water will make cleaning difficult and shorten the filter life....

A10 3. Refill with the new adsorber material. After refilling, shake module to pack granules tightly before replacing cover plate to make sure module is full. Remove the end cover plate and top-off any void in the module. 4. Vacuum any excess carbon dust that occurs from settling during handling. Af...

A11 replacement parts the following section lists typical replacement parts for the model v410 . If a part is not listed in table 2, contact your local airflow systems representative or the afs factory. Refer to figures 14 and 15 for parts illustrations. Table 2. Item part number qty description 1 7...

A12 figure 14. Model v410 filter lifting assembly. Figure 15..

A13 model v410 general assembly. Troubleshooting the troubleshooting guide included in this manual is for qualified personnel only. A motor trouble guide is included in appendix a. If the unit does not function properly after following the guidelines in this manual, consult an airflow systems repres...

A14 notes record start up data here model: v410 serial no.: date purchased: date installed: motor voltage (measured): motor current (measured): motor fla (from nameplate): motor voltage (from nameplate): always use airflow systems replacement parts and filters to maintain warranty to order spare par...

A15 appendix 1. Branch wiring ............................................................................... A1 2. Motor trouble guide ................................................................. A2 3. Typical installation wiring diagram ................................ A3 4. 4kt11096 - owners...

A16 motor wiring guide (branch circuit) wiring to connect motor for proper voltage and rotation, refer to connection diagram on nameplate or inside terminal/conduit box. If power factor correction capacitors are used for individual motor power factor correction, do not exceed maximum recommended val...

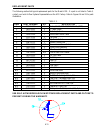

A17 hp 115v 230v 115v 230v 115v 230v 115v 230v 115v 230v 1/8 14(16) * 14(18) * 14 14(18)* 10 14(16) * 10 14(16) * 8 14 1/6 14 14(18) * 12 14(18)* 10 14(16) * 8 14 6 12 1/4 14 14(18) * 12 14(18)* 8 14 6 12 6 12 1/3 14 14(18) * 10 14(16)* 8 14 6 12 4 10 1/2 14 14(18) * 10 14(16)* 8 14 6 12 4 10 3/4 12...

A18 poor connections. 3. Load too high. 3. Check load motor is carrying at start -replace with larger motor. Motor 1. Excess loading; high 1. Reduce load. Increase takes too inertia load. Motor size. Long to 2. Inadequate wiring. 2. Increase wire size. Check for accelerate poor connections. 3. Appli...

A19 typical installation wiring diagram.

A20 owners manual addendum optional autoclean controller system models: pc / pc-2 / dc-1 / dc-2 / dt-3000 dt-800 / v-2 / v410 • introduction • specifications • unpacking • installation • electrical • operation • maintenance • replacement parts *****important***** this manual contains precautionary s...

A21 part# 4kt1-1096 (rev 11/98/a/#26-1894).

3 always use airflow systems, inc. Replacement parts and filters to maintain warranty. To order spare parts contact: the local exhaust & ventilation company inc. 22–1050 brock rd, pickering, ontario l1w 3x4 tel: 905.831.7001 fax: 905.831.7443 toll free: 1.888.862.5356 e-mail: sales@lev-co.Com web si...

3 table of contents 1. Safety......................................................................................................................... 4 2. Airflow systems sets the standard .......................................................................... 4 3. Specifications ..................

3.

4 read this manual carefully before using autoclean equipped unit. Retain these instructions for future reference. Safety rules before installing or operating this system, read this supplemental owners manual. All safety and cautionary notes from the primary owners manual are in effect after install...

5 preparation and installation through out this manual certain notes, cautions and warnings are used. They are defined as: note: used to indicate an instruction that will make a particular task simpler or easier. Caution: used when a process or item may cause damage to the equipment or system. Warni...

5.

6 single phase connection the factory installed autoclean control requires a minimum of field wiring in order to operate. All 115 vac units with factory installed unit on/off power switch are wired and require no further electrical wiring other than connection input to the power. Figure 1 illustrate...

7 three phase connection three phase connections require the use of a manual or magnetic motor starter to allow the autoclean system to operate off-line. The main power leads, l1, l2, l3 are not usually differentiated by color. The transformer power can be drawn from any two of these input power wir...

7 figure 5. (dual cartridge with relay) figure 6. (dual cartridge without relay).

8 figure 7. (dt-3000 with relay) figure 8. (dt-3000 without relay).

8.

9 autoclean unit operation when wired as shown above, the autoclean control will sense operation of the air cleaner fan motor. When the motor is turned on, the autoclean patiently waits for when the motor is turned off. When off occurs, the autoclean will wait for a time to clean. This time is adjus...

9.

10 maintenance the autoclean system requires no routine maintenance. Refer to the unit owners manual for unit required maintenance of the vibra-pulse system. Replacement parts listed below are common replacement parts for the autoclean controller system. Check nameplate for actual voltage used. Cons...

10

A5 owners manual addendum latest version of the clean air plenum which includes the static pressure relief valve the local exhaust & ventilation company inc. 22-1050 brock rd, pickering, ontario l1w 3x4 tel: 905.831.7001 fax: 905.831-7443 toll free: 1.888.862.5356 e-mail: sales@lev-co.Com web site: ...