Dp-airless page 1 of 22 operating instruction product model: dp6825,6830,6835 diaphragm pump sprayer dp6825 dp6830,6835 please read and keep this manual, read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all saf...

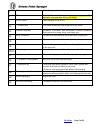

Dp-airless page 2 of 22 table of contents warnings...................................................................................................................3-5 component identification ..........................................................................................6-7 technical da...

Dp-airless page 3 of 22 warnings the following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this m...

Dp-airless page 4 of 22 skin injection hazard high-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment. ● do not aim the gun at, or spray any person or animal. ● keep hands and other body parts aw...

Dp-airless page 5 of 22 moving parts hazard moving parts can pinch, cut or amputate fingers and other body parts. ●keep clear of moving parts. ●do not operate equipment with protective guards or covers removed. ●pressurized equipment can start without warning. Before checking, moving, or servicing e...

Dp-airless page 6 of 22 component identification 15(1) 13 10 3 11 1 handle carry machine. 2 pressure gage easy for you to read the pressure you ’re spraying. 3 prime/spray valve ●in prime position (pointing down) directs fluid to prime tube. ●in spray position (pointing forward) directs pressurized ...

Dp-airless page 7 of 22 7 motor make the power for machine. 8 oil cover prevent the oil leaked out. (please change the 46# hydraulic oil inside after 300 hours using) 9 on-off switch turns sprayer on and off. 10 ** outlet valve the valve control the fluid going out of the pump 11 pressure regulator ...

Dp-airless page 8 of 22 technical data model number. Dp6825 dp6830 dp6835 type electric & diaphragm electric & diaphragm electric & diaphragm pressure controlling mechanical mechanical mechanical power 1100w 1500w 1500w max.Pressure (bar) 250bar/3630psi 250bar/3630psi 250bar/3630psi max.Delivery (l/...

Dp-airless page 9 of 22 operation trigger lock always engage the trigger lock when you stop spraying to prevent the gun from being triggered accidentally by hand or if dropped or bumped. Pressure relief procedure follow this pressure relief procedure whenever you stop spraying and before cleaning, c...

Dp-airless page 10 of 22 setup 1. Prepare the paint according to the manufacturer ’s recommendations this is probably one of the most important steps toward trouble-free spraying! Remove any skin that may have formed on the top of the paint. If necessary, thin the paint. Finally, strain the paint th...

Dp-airless page 11 of 22 startup 1. First be sure the on/off switch is off. 2. Adjust pressure regulator valve 9# counter clockwise to lowest pressure. 3. Place the suction hose 3# into the coating barrel. 4. Pull up the prime spray valve 2# into a: prime position. (see picture below) 5. Place the s...

Dp-airless page 12 of 22 spraying spraying technique 1. The key to a good paint job is an even coating over the entire surface. With spray painting, this is done by using even strokes, with your arm moving at a constant speed and keeping the spray gun a constant distance from the surface. 2. As much...

Dp-airless page 13 of 22 7. When taking a short break from painting (up to 1 hr.), lock the spray gun trigger off, reduce pressure to its minimum (zero) setting and set the unit to a: prime position . Turn sprayer off and unplug. Refer to pressure relief procedure. 8. For interior corners, such as o...

Dp-airless page 14 of 22 tip selection selecting tip hole size tips come in a variety of hole sizes for spraying a range of fluids. Your sprayer includes an 0.017 in (0.43 mm) tip or maybe 0.019 ” (0.48mm) for use in most spraying applications. Use the following table to determine the range of recom...

Dp-airless page 15 of 22 understanding tip number the last three digits of tip number contain information about hole size and fan width on surface when gun is held 12 in. (30.5 cm) from surface being sprayed . Last two digits = tip hole size in thousands of an inch reversible tip selection chart fan...

Dp-airless page 16 of 22 cleanup as with all spray equipment, your sprayer must be cleaned properly or it will not operate properly. Clogged valves and filters are the most common causes of problems. If followed, these guidelines will insure trouble free performance from your sprayer. 1. Lock the gu...

Dp-airless page 17 of 22 14. Attach paint hose to gun, tighten with two wrenches 15.Turn the unit on and unlock gun trigger. Turn to spray b and point gun to side of cleaning bucket. 16.Trigger gun and gradually turn pressure knob clock- wise to 1/2 pressure. Continue for approximately 30 seconds 17...

Dp-airless page 18 of 22 remove inlet valve 3. Test movement of the valve by pushing on it from the open end of the valve housing with the eraser end of a pencil or a screwdriver. It should move about 1/16 inch. If it doesn't move, it is probably full of dry paint or other debris and should be clean...

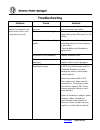

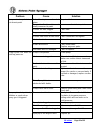

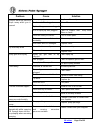

Dp-airless page 19 of 22 . Troubleshooting problem cause solution pressure is set at zero pressure. Turn pressure control knob clockwise to increase pressure setting. Motor or control is damaged. Please contact with your supplier or ningbo dino-power machinery co.,ltd directly. Electric outlet is no...

Dp-airless page 20 of 22 problem cause solution unit will not prime or has lost prime re prime unit no paint. Suction tube not totally immersed in paint immerse suction tube in paint suction set filter clogged. Clean filter. Hopper screen clogged clean screen. Suction tube loose at inlet valveclean ...

Dp-airless page 21 of 22 problem cause solution worn spray tip replace with new tip. Suction set filter clogged clean filter. Optional hopper screen cloggedclean screen gun or spray tip filter plugged. Clean or replace filter. Keep extra filters on hand paint too heavy or coarse. Thin or strain pain...

Dp-airless page 22 of 22.