- DL manuals

- AIRLESSCO

- Paint Sprayer

- 24F567 LP500 Stand

- Operation - Repair - Parts

AIRLESSCO 24F567 LP500 Stand Operation - Repair - Parts - Packing Replacement

Parts

24

3A1185B

Packing Replacement

ti16057a

Ref.

Part

Description

Qty.

Ref.

Part

Description

Qty.

1*

331014 Male Gland

1

16*

331025 Belleville Springs

2*

331016 Packing Polyethylene

1

17*

331022 Male Gland

1

3*

331308 Female Adaptor

1

18*

331023 Packing Polyethylene

1

4

331011 Fluid Pump Body

1

19*

331021 Female Gland

1

5

331029 Suction Ball Guide

1

20

331019 Packing Holder

1

6*

331030 Suction Ball

1

21

331037 Packing Nut

1

7*

108526 O-Ring

1

22*

331307 Packing Leather

1

11

331026 Outlet Seat

1

23*

331306 Packing Leather

1

12*

111457 O-Ring

1

24*

107313 White O-Ring

1

13*

331330 Outlet Ball

1

25*

867363 Black O-Ring

1

14

331330 Piston

1

26

867783 Cap

1

15*

331018 Spacer

1

*

331210 Packing Kit

Summary of 24F567 LP500 Stand

Page 1

3a1185b eng operation/repair/parts airless paint sprayer for application of architectural paints and coatings. Airlessco lp500, lp600, allpro mustang 5100 - 8100 3000 psi (20.7 mpa, 207 bar) maximum working pressure related manuals important safety instructions read all warnings and instructions in ...

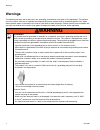

Page 2: Warnings

Warnings 2 3a1185b warnings the following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manu...

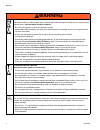

Page 3: Warning

Warnings 3a1185b 3 warning warning warning warning fire and explosion hazard flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion: • do not spray flammable or combustible materials near an open flame or sources of ignition such as c...

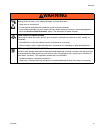

Page 4: Warning

Warnings 4 3a1185b skin injection hazard high-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment. • do not aim the gun at, or spray any person or animal. • keep hands and other body parts away fr...

Page 5: Warning

Warnings 3a1185b 5 moving parts hazard moving parts can pinch, cut or amputate fingers and other body parts. • keep clear of moving parts. • do not operate equipment with protective guards or covers removed. • pressurized equipment can start without warning. Before checking, moving, or servicing equ...

Page 6: Component Identification

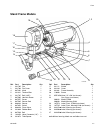

Component identification 6 3a1185b component identification ti14791a ti14790a a b c d e f ti16050a a power switch turns sprayer on and off b fuse c pressure control knob adjusts pressure. Turn clockwise to increase pressure and counterclockwise to decrease pressure. D prime/pressure (pr) relief valv...

Page 7: Operation

Operation 3a1185b 7 operation pressure relief procedure 1. Engage the gun trigger lock. Refer to the separate instruction manual provided with gun for safety fea- tures and how to engage the trigger lock. 2. Turn the unit off. 3. Disengage the gun trigger lock and trigger the gun to relieve residual...

Page 8: Flushing

Operation 8 3a1185b fill the packing nut/wet cup 1. Remove guard and cap. 2. Fill the packing nut/wet cup with 5 drops of air- lessco throat seal oil (tso). Flush the sprayer 1. Flush the sprayer. See flushing procedure on page 8. Prime and flush storage fluid before beginning a new spraying project...

Page 9: Startup

Operation 3a1185b 9 6. Turn the engine on/off switch to on. 7. Point the gun into the metal pail and hold a metal part of the gun firmly against the pail. Maintain firm metal to metal contact between gun and container. 8. Disengage the gun trigger lock and squeeze the trigger. At the same time, slow...

Page 10: Shutdown

Operation 10 3a1185b shutdown 1. Relieve pressure, page 7. 2. Clean the tip and gun as recommended in the sepa- rate gun manual supplied with the gun. 3. If spraying water-based material or a material that could harden in the sprayer overnight, flush the sprayer after use. See flushing, page 8. Stor...

Page 11: Maintenance

Maintenance 3a1185b 11 maintenance daily maintenance 1. Keep the displacement pump packing nut/wet cup lubricated with airlessco tso (throat seal oil) at all times. The tso helps protect the rod and packings. 2. Inspect the packing nut daily. If seepage of paint into the packing nut and/or movement ...

Page 12: Servicing The Outlet Valve

Maintenance 12 3a1185b 9. Using a 1/2” wrench, unscrew the two bolts (8) from the cover assembly (14). The fluid pump (9) will be hanging loosely at this point. 10. Remove the connecting rod pin (1) out of the con- necting rod (13), allowing the removal of the fluid pump (9) from the machine. Fluid ...

Page 13: Servicing The Inlet Valve

Maintenance 3a1185b 13 before reinstalling the outlet seat (6) support, apply two drops of loctite no. 242 (blue) on the threads and torque to 20 ft-lbs. Note: airlessco lp pump tool kit is required for this task. Kit includes: tightening bar (865008), packing removal tool (331465), piston holder (3...

Page 14

Maintenance 14 3a1185b reassembly of the fluid pump 1. Place lower male gland(1) down on the flat side. 2. Take three of the lower polyethylene packings (2) and two of the leather packings (23) and place onto the male gland (1), with the inverted side down, in the following order: • polyethylene • l...

Page 15: Gear And Pump Assembly

Maintenance 3a1185b 15 gear and pump assembly servicing gear box assembly 1. Remove fluid pump. See fluid pump disconnect, page 11. 2. Remove frame from the gearbox by loosening the four mounting screws. 3. Separate cover assembly (13) from box by removing bolts (1) from front of cover and back of b...

Page 16: Replacement of Electrical

Maintenance 16 3a1185b pressure calibration 1. Complete the zero calibration, as per “zero cal- ibration” prior to commencing this calibration. 2. Attach a 50’, 1/4” airless hose, airless gun with 0.017 tip and a 5000 psi glycerin filled pressure gauge to pump. 3. Place the suction tube into a bucke...

Page 17

Maintenance 3a1185b 17 sensor 1. Remove the four screws, heatsink, and lower the pressure control assembly. 2. Disconnect swivel from sensor by holding sensor with 7/8” wrench and loosening swivel with 11/16” wrench. 3. Disconnect sensor lead from the board. Carefully pull sensor lead out of the ter...

Page 18: Troubleshooting

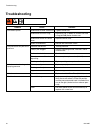

Troubleshooting 18 3a1185b troubleshooting problem cause solution unit doesn’t prime airleak due to loose suction nut tighten suction nut. Airleak due to worn o-rings replace o-ring (110636) on suction seat and o-ring (867390) below suction seat. Airleak due to hole in suction hose replace suction h...

Page 19

Troubleshooting 3a1185b 19 power source using a phillips head screwdriver, remove the four screws holding the pressure control assembly. Locate the red light on the board indicating there is power (it will be red). If the light is on, see pressure control assembly (board). If the light is off, locat...

Page 20

Troubleshooting 20 3a1185b sensor plug another sensor board into the board and perform the zero calibration procedure. If the machine starts to run, the sensor is bad. If there is no replacement sensor available, use a multi-meter to test the resistance across the red and black wires of the sensor (...

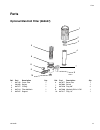

Page 21: Parts

Parts 3a1185b 21 parts optional manifold filter (865627) ref. Part description qty. Ref. Part description qty. 1 867145 cover, filter 1 6 867077 base, filter 1 2 301356 spring 1 7 867004 swivel 1 3 867377 o-ring 1 8 867420 plug 3/8” 2 4 867214 filter 60 mesh 1 9 867309 nipple 3/8”m x 1/4”m 1 5 86764...

Page 22: Fluid Pump

Parts 22 3a1185b fluid pump 1 2 3 4 5, 6 7 8 9 10 11 12 13 14 ref. Part description qty. 1 866082 connecting rod pin 1 2 331117 sleeve 1 3 331062 retaining ring 1 4 867783 plug 1 5 162453 hose connector 1 6 867005 swivel 1 7 331034 suction nut 1 8 867539 bolts 2 9 331236 331209 fluid pump (hi-boy) f...

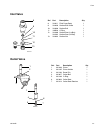

Page 23: Inlet Valve

Parts 3a1185b 23 inlet valve outlet valve ti16115a 8 9 10 11 12 13 ref. Part description qty. 8 331011 fluid pump body 1 9 331029 suction ball guide 1 10 331030 suction ball 1 11 108526 o-ring 1 12 331409 331292 suction seat (lo-boy) suction seat (hi-boy) 1 1 13 331034 suction nut 1 ref. Part descri...

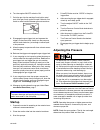

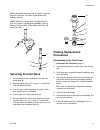

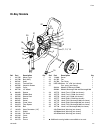

Page 24: Packing Replacement

Parts 24 3a1185b packing replacement ti16057a ref. Part description qty. Ref. Part description qty. 1* 331014 male gland 1 16* 331025 belleville springs 2* 331016 packing polyethylene 1 17* 331022 male gland 1 3* 331308 female adaptor 1 18* 331023 packing polyethylene 1 4 331011 fluid pump body 1 19...

Page 25

Parts 3a1185b 25 ref. Part description qty. 1* 331014 male gland 1 2* 331016 packing polyethylene 1 3* 331308 female adaptor 1 4 331011 fluid pump body 1 5 331029 suction ball guide 1 6* 331030 suction ball 1 7* 108526 o-ring 1 8 331409 331292 suction seat (carry and lo-boy) suction seat (hi-boy) 1 ...

Page 26: Gear and Pump Assembly

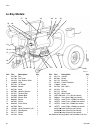

Parts 26 3a1185b gear and pump assembly ti16058a 1 2 12 10 7 6 5 4 8 13 14 15 16 17 1 2 motor 11 9 ref. Part description qty. Ref. Part description qty. 1 107445 bolt 2 11 331074 tube spacer 2 2 866338 shoulder bolt 2 12 331111 shield 1 4 331117 sleeve 1 13 331234 cover 1 5 331062 retaining spring 1...

Page 27: Stand Frame Models

Parts 3a1185b 27 stand frame models ti16114a 1, 2 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ref. Part description qty. Ref. Part description qty. 1 331785 fan 1 17 331111 shield 1 2 331786 fan cover 1 18 331234 cover 1 4 867291 knob 1 19 331401 frame assembly 1 5 331321 terminal box 1 20 119048 s...

Page 28: Lo-Boy Models

Parts 28 3a1185b lo-boy models 5 7 8 9 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 14 13 12 11 ti16117a ref. Part description qty. Ref. Part description qty. 1 331785 fan 1 24 331174 handle 1 2 331786 fan cover 1 25 867488 screw 2 5 331476 cup, suction drain 1 26 331176 bushing 2 7 143029 ...

Page 29: Hi-Boy Models

Parts 3a1185b 29 hi-boy models ti16060a 1 2 3 4 5 7 8 9 10 23 22 24, 14 15 16 18 19 20 21 11, 12, 13 6 ref. Part description qty. Ref. Part description qty. 1 331795 motor cover 1 23 119048 screw 4 2 331788 bolt (.9hp) 1 24 331785 fan 1 4 867281 knob 1 25 331786 fan cover 1 5 331321 terminal box 1 2...

Page 30: Suction Assemblies

Parts 30 3a1185b suction assemblies ti16062a carry chassis (865717) ref. Part description qty. 1 331290 suction hose assembly 1 2 187651 inlet strainer 1 3 867370 ptfe o-ring 1 4* drain hose 1 5* 241920 threaded deflector 1 6* 867759 male connector 1 7* 865721 bypass assembly (includes 4, 5, 6, 8) 1...

Page 31: Electrical System

Parts 3a1185b 31 electrical system black/brown s1 s2 a2 a1 l1 l2 inhibit switch p-zr on-sl y a l p s i d r o s n e s pot green black black r e d r e d b l k lcd zero e r u s s e r p e r u s s e r p lcd set phase limit phase limit 1 2 3 4 5 7 zero yellow light 9 10 11 12 13 14 b k & & w t r e w o p r...

Page 32: Electrical Components

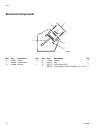

Parts 32 3a1185b electrical components 5 6 1 2 3 4 ti16066a ref. Part description qty. Ref. Part description qty. 1* 867547 screw 4 4* 117281 spacer 4 2 342449 label, control 1 5* 867327 nut 4 3* 331360 window 1 6* 331377 lcd display (psi) 1 * 865651 lcd display kit (psi) (includes 1, 3, 4, 5, 6) 1.

Page 33: Technical Data

Technical data 3a1185b 33 technical data power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120v ac, 60 hz, 11a, 1 phase generator required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 w minimum maximum working pressure . ...

Page 34: Airlessco Standard Warranty

To place an order or for service, contact your airlessco distributor, or call 1–800–223-8213 to identify the nearest distributor. All written and visual data contained in this document reflects the latest product information available at the time of publication. Airlessco reserves the right to make ...