- DL manuals

- AIRLESSCO

- Paint Sprayer

- EZ Rent 570

- Service & Operation Manual

AIRLESSCO EZ Rent 570 Service & Operation Manual

Summary of EZ Rent 570

Page 1

001-794 sept 08 ® airlessco ez rent 570 &700 a irless p aint s prayer s ervice /o peration m anual.

Page 2: Table of Contents

2 1 table of contents section figures introduction........................................................................ 1 warnings ........................................................................... 2 flushing............................................................................. 5 ...

Page 3: Introduction

2 1 introduction no modifications or alterations of any airlessco equipment or part is allowed. All service procedures to be performed by an authorized airlessco service center only. Handle this unit as you would a loaded firearm! High pressure spray can cause extremely serious injury. Observe all w...

Page 4: Warnings

2 3 note to physician: injection in the skin is a traumatic injury. It is important to treat the injury surgically as soon as possible. Do not delay treatment to research toxicity. Tox- icity is a concern with some exotic coatings injected directly into the blood stream. Consultation with a plastic ...

Page 5: Warnings - Continued

2 3 warnings - continued hazardous fluid or toxic fumes can cause serious injury or death if splashed in eyes or on skin, inhaled or swallowed. Know the hazards of the fluid you are using. Store & dispose of hazardous fluids according to manufacturer, local, state & national guidelines. Always wear ...

Page 6: Warnings - Continued

4 5 this sprayer operates at 3000 psi (205 bar). Always be sure that all components and accessories have a maximum working pressure of at least 3000 psi to avoid rupture which can result in serious bodily injury including injection and property damage. Never leave a pressurized sprayer unattended to...

Page 7: Flushing

4 5 warning: to reduce the risk of static sparking, which can cause fire or explosion, always hold a metal part of the gun firmly against the metal pail when flushing. This also reduces splashing. Refer to fig 4. Your unit was factory tested in an oil solution which was left in the pump. Before usin...

Page 8: Setting Up

6 7 setting up fig. 5 1. Connect the hose and gun 2. Fill the packing nut/wet cup 4. Grounding a. Remove the plastic cap plug from the outlet and screw a conductive or grounded 3000 psi spray hose onto fluid outlet. B. Connect an airless spray gun to the other end of the hose, but do not install the...

Page 9: Starting Up

6 7 2. Prepare the material a. Turn the pressure control knob clockwise to increase pressure and counterclockwise to decrease pressure. B. Always use the lowest pressure necessary to completely atomize the material. Note: operating the sprayer at higher pressure than needed, wastes material, causes ...

Page 10: Pressure Relief Procedure

8 9 pressure relief procedure 5. Re-engage gun safety latch and close prime/pressure relief valve. To avoid possible serious body injury, always follow this procedure whenever the sprayer is shut off, when checking it, when installing, changing or cleaning tips, whenever you stop spraying, or when y...

Page 11: Fig. 7

8 9 spray attach spray gun to airless unit and tighten fittings securely. Set the gun safety latch. (also may be called gun safety lock, or trigger lock) * the gun safety latch should always be set when the gun is not being triggered. Read all warnings and safety precautions supplied with the spray ...

Page 12: Airless Spray Gun

10 11 airless spray gun fig. 11 3* 9 8 7 6 5 4 2* 1* 13 19 16 15 14 12 11 10* 17 18 parts list figure 11 item no. Part no. Description 1 120-530* gun seat assembly 2 120-535* gasket-seat 3 120-520* needle assembly 4 120-529 gun seat adapter 5 120-562 trigger guard 6 120-539 pivot trigger pin 7 120-5...

Page 13

10 11 airless spray gun troubleshooting defects cause correction coarse spray low pressure increase the pressure excessive fogging (overspray) high pressure material too thin reduce the pressure to satisfactory pattern distrabution use less thinner patten too wide spray angle too large use smaller s...

Page 14: Tip Selection Guide

12 13 thickness of the paint coat per stroke is determined by spray tip "fan width", rate of the spray gun movement, and distance to surface. Two tips having the same tip size, but different pattern widths will deliver the same amount of paint over a different area (wider or narrower strip). A spray...

Page 15: Electric Motor Maintenance

12 13 electric motor maintenance 1. Lubrication - this motor is supplied with pre- lubricated ball bearings, lubricated for the life of the bearing. 2. Motor brushes - need periodic inspection and replacement as wear indicates. Brush wear is greatly influenced by individual application. It is recomm...

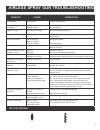

Page 16: Field Troubleshooting

14 15 1 2 3 4 5 6 7 8 9 10 problem cause solution unit doesn’t prime airleak due to: •loose suction nut • worn o-rings • hole in suction hose stuck or fouled balls • tighten suction nut • replace o-ring (106-018) on suction seat & o-ring (106-017) below suction seat • replace suction hose • service ...

Page 17: Servicing The Fluid Pump

14 15 servicing the fluid pump refer to figure 14 1. Follow the pressure relief procedure on page 8. 2. Flush the material you are spraying out of the machine. 3. Remove the connecting rod shield. 4. Move the piston rod to its lowest position by cycling pump slowly. 5. Turn off the motor. 6. Unscrew...

Page 18: Servicing The Outlet Valve

16 17 servicing the outlet valve 1. Disconnect the fluid pump following instructions on page 15. 2. Place piston holder in a vise. Slide piston into the holder & lock in place with a 3/8” dowel. 3. Use a 1/4” allen wrench to unscrew the outlet seat retainer from the piston. 4. Remove the outlet seat...

Page 19: Fig. 17

16 17 13. Take the packing holder & replace the white o-ring & the black o-ring with new ones from the packing kit. 14. Slide the packing holder over the top of the upper packings so they fit inside. 15. Lubricate inside of the fluid pump body & the outside of the packings with a light weight oil. 1...

Page 20: Fig. 18

18 19 15* 25* 14 13* 12* 11 20* 19* 18* 17* 16* 24* 23* 22* 21 7* 6* 5 4 3* 2* 1* 1* parts list figure 17 & 18 item no. Part no. Description 1* 331-014 male gland 2* 331-016 packing polyethylene 3* 331-308 female adaptor 4 331-011 fluid pump body 5 331-029 suction ball guide 6* 331-030 suction ball ...

Page 21: Gear And Pump Assembly

18 19 gear and pump assembly 1. Remove fluid pump as per "fluid pump disconnect" procedures on page 15. 2. Remove frame from the gearbox by loosening the four mounting screws. 3. Refer to figure 19. Separate cover assembly from box by removing bolts from front of cover & back of box & shoulder bolts...

Page 22: Lo-Boy Models

20 21 lo-boy models fig. 21 parts list figure 21 item no. Part no. Description 1 331-785 fan 2 331-786 fan cover 3 117-090 fan cover screws (3) 4 117-129 screw (2) 5 119-033 nut (2) 6 331-477 cup support 7 331-476 cup assembly 8 143-029 collar (2) 9 113-019 10” wheel (2) parts list figure 21 cont it...

Page 23: Hi-Boy Models

20 21 parts list figure 22 item no. Part no. Description 1 331-795 motor cover 2 331-788 bolt (.9hp) 3 331-337 rubber edge 4 117-044 knob 5 331-323 terminal box 6 111-037 heatsink screws parts list figure 22 cont item no. Part no. Description 7 143-029 collar (2) 8 113-019 10” wheel (2) 9 113-030 sp...

Page 24: Suction Assemblies

22 23 suction assemblies parts list figure 23 item no. Part no. Description 1 331-290 suction hose assy 2 331-217 inlet strainer 3 331-035 suction elbow 4 331-034 suction nut 5 106-020 ptfe o-ring 6 331-231 bypass hose assy 7 331-425 bypass hose 8 331-090r fitting 9 111-016 nylon tie 10 331-135 spri...

Page 25

22 23 pressure contol assy calibration note: anytime a sensor or pressure control assembly (board) or both are replaced, the following calibrations must be performed. Note: pressure control assemblies (boards) are now being equipped with a green grounding wire attached. Contect the grounding wire to...

Page 26: Fig. 25

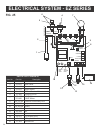

24 25 black/brown parts list figure 25 item no. Part no. Description 1 331-168 electrical cord 110v 2 331-161 strain relief 3 331-138 screw 4 331-311 toggle switch 5 301-084 thermal breaker 20a 6 117-035 protective cover 7 331-490 331-491 0.6hp motor 0.9hp motor 8 331-331-99 pressure control assy 11...

Page 27: Fig. 26

24 25 ez series pressure control box (331-324) parts list figure 26 item no. Part no. Description 1 101-482 control label (psi/bar) 2 301-002 nut 3 115-068 o-ring 4 117-044 knob 5 100-109 nipple 6 331-297 potentiometer 7 111-037 screw parts list figure 26 cont item no. Part no. Description 8 120-021...

Page 28: Figure 27

26 27 replacement of electrical components warning: always unplug the electrical cord before servicing machine! Note: anytime the pressure control assembly, sensor, or both are replaced, perform the calibrations. Pressure control assembly (electrical control board) sensor potentiometer on-off toggle...

Page 29

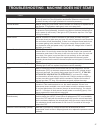

26 27 cause steps control settings step 1: after making sure that the machine is plugged into the wall, verify that the on-off switch is in the on position and that the pressure control knob is turned all the way to the right (clockwise for maximum pressure). Thermal breaker step 2: using your multi...

Page 30

28 29 ez series electric paint sprayer quick reference guide pressure control knob used to adjust pressure only. Does not relieve pressure from gun and system! Turn clockwise to increase pressure, counterclockwise to decrease pressure. Step 1a. Read safety rules! Read & understand all warnings & saf...

Page 31: Notes

28 29 notes.

Page 32: Quick Flush

A ir l e s s c o a ccessories strong yet flexible, for airless sprayers up to 3300 psi part no: hose description 100-012 3/16” whip hose, 4 ft. 100-040 1/4” whip hose, 3 ft. 100-204 1/4” whip hose, 5 ft. 100-199 3/8” whip hose, 6 ft. 100-011 1/4” hose, 50 ft. 100-023 3/8” hose, 50 ft. 100-037 1/2” h...