For portable application of architectural paints and coatings. For professional use only. Not approved for use in european explosive atmosphere locations. 3000 psi (20.7 mpa, 207 bar) maximum working pressure see page 3 for model information. Related manuals important safety instructions read all wa...

Contents 2 332882a contents models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 component identification . . . . . . . . . . . . . . . . . . . . 8 operation . . . . . . . . . . . . . . . . . . . ....

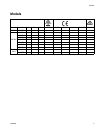

Models 332882a 3 models model model no. Series hi-boy stand 120v 240v euro 220v cn 220v la 220v ap 230v anz mp300 868058 a x x mp400 868050 a x x 868051 a x x 868054 a x x 868055 a x x 868056 a x x 868057 a x x 868060 a x x mustang 4800 868052 a x x 868053 a x x.

Warnings 4 332882a warnings the following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manu...

Warnings 332882a 5 warning warning warning warning fire and explosion hazard flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion: • do not spray flammable or combustible materials near an open flame or sources of ignition such as c...

Warnings 6 332882a skin injection hazard high-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment. • do not aim the gun at, or spray any person or animal. • keep hands and other body parts away fr...

Warnings 332882a 7 moving parts hazard moving parts can pinch, cut or amputate fingers and other body parts. • keep clear of moving parts. • do not operate equipment with protective guards or covers removed. • pressurized equipment can start without warning. Before checking, moving, or servicing equ...

Component identification 8 332882a component identification ti22321a a b c d e a power switch turns sprayer on and off b pressure control knob adjusts pressure. Turn clockwise to increase pressure and counterclockwise to decrease pressure. C prime valve primes pump. D prime valve open position valve...

Operation 332882a 9 operation grounding air and fluid hoses: use only electrically conductive hoses with a maximum of 500 ft. (150 m) combined hose length to ensure grounding continuity. Check elec- trical resistance of hoses. If total resistance to ground exceeds 29 megohms, replace hose immediatel...

Operation 10 332882a pails solvent and oil/based fluids: follow local code. Use only conductive metal pails, placed on a grounded sur- face such as concrete. Do not place pail on a nonconductive surface such as paper or cardboard which interrupts grounding continuity. Grounding a metal pail: connect...

Operation 332882a 11 setup connect the hose and gun 1. Remove the plastic cap plug from the outlet and screw a conductive or grounded 3000 psi spray hose onto fluid outlet. 2. Connect an airless spray gun to the other end of the hose. Do not install spray tip. Fill the packing nut/wet cup 1. Remove ...

Operation 12 332882a 4. Turn pressure control knob to low. 5. Open the prime valve to the open (priming) position. This will allow an easy start. 6. Turn the power on/off switch to on. 7. Point the gun into the metal pail and hold a metal part of the gun firmly against the pail. Maintain firm metal ...

Operation 332882a 13 clearing clogs 1. Release trigger. Engage trigger lock. Rotate spray tip. Disengage trigger lock. Trigger gun at waste area to clear clog. 2. Engage trigger lock. Return spray tip to original position. Disengage trigger lock and continue spraying. Adjusting the pressure when adj...

Maintenance 14 332882a maintenance daily maintenance 1. Keep the displacement pump packing nut/wet cup lubricated with throat seal oil (tso) or packing seal fluid at all times. The oil or fluid help protect the rod and packings. 2. Inspect the packing nut daily. If seepage of paint into the packing ...

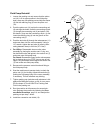

Maintenance 332882a 15 fluid pump reinstall 1. Loosen the packing nut and ensure that the piston rod (10) is in its upper position in the fluid pump body, snap cap onto packing nut and slip the sleeve (3) and the retaining ring (4) over the piston rod (10). 2. Push the piston rod (10) up into the co...

Maintenance 16 332882a servicing the inlet valve - hi-boy 1. Relieve pressure, page 10. Disconnect power from unit. 2. Un-thread and remove suction nut from the fluid pump body (8). 3. Remove suction seat assembly (12). 4. Clean all parts and inspect them for wear or dam- age, replacing parts as nee...

Maintenance 332882a 17 8. Take three spring washers (16) and slide over the top of the piston (14) in the following order: • first spring - curve facing up • second spring - curve facing down • third spring - curve facing up 9. Take the upper male gland (17) and place it rounded side up. 10. Take th...

Maintenance 18 332882a gear and pump assembly servicing gear box assembly 1. Remove fluid pump. See fluid pump disconnect, page 14. 2. Remove frame from the gearbox by loosening the four mounting screws. 3. Separate cover assembly (13) from box by remov- ing bolts (1) from front of cover and back of...

Maintenance 332882a 19 replacement of electrical components note: anytime the pressure control assembly, sensor, or both are replaced, perform the calibrations. Pressure control assembly (electrical control board) 1. Unplug machine’s power cord. 2. Remove two screws from terminal box. 3. Disconnect ...

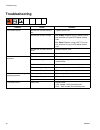

Troubleshooting 20 332882a troubleshooting problem cause solution unit doesn’t prime air leak due to loose suction nut tighten suction nut. Air leak due to worn o-rings for hi-boy: replace o-ring (108526) on suc- tion seat and o-ring (867370) below suction seat. For stand: replace o-ring (120777) on...

Troubleshooting 332882a 21 machine does not start control settings make sure machine is plugged into the wall. Verify the on-off switch is in the on position and the pressure control knob is turned all the way to the right (clockwise for maximum pres- sure). Pressure control assembly (board) if the ...

Parts 22 332882a parts manifold filter (868014) model 868057 inlet valve 1 2 3 4 5 9 6 10 7 46 44 ref. Part description qty. 1 867145 cover 1 2 301356 spring 1 3 867377 o-ring 1 4 867214 filter 60 mesh 1 5 867647 support 1 6 867077 base 1 7 867420 plug 1 9 867309 nipple 3/8” npt x 1/4” npt 1 10 5573...

Parts 332882a 23 stand frame parts diagram 42 1 63 2 42 53 ti22328a ref. Part description qty. 1 331101 frame, carry 1 2 16f551 fastener,thread,external 4 42 331048 rubber boot 2 53 hse1450 hose cpld 1/4” x 50 ft. (mp400, mustang 4800) 1 245449 hose, 1/4” x 25 ft., (mp300) 1 63 289316 gun, 500,2 fin...

Parts 24 332882a hi-boy parts diagram 1 2 3 4 5 6 7 77 78 ti17483a ref.Part description qty. 2 331273 frame 1 3 16f551 fastener,thread, external 4 4 866356 spacer 2 5 867736 wheel,10” x 3.5” 2 6 143029 collar, screw, set 2 7 331048 rubber boot 2 77 hse1450 hose cpld, 1/4” x 50’ 1 78 289316 gun, 500,...

Parts 332882a 25 control parts diagram ti17482a 26 36 25 33 30 31 32 28 34 29 38 39 28 27 35 34 37 220/230v models 120v models ti22429a ref. Part description qty. 25 867243 gasket, seal 1 26 868000 box, terminal, weldment 1 27 868013 seal, rubber 1 28 331342 screw, 10-24 x 0.50 6 29 116969 nut, lock...

Parts 26 332882a motor and drive parts diagram 3 8 6 7 9 24 15 16 17 19 18 10 12 11 23 4 4 5 5 51 52 26 25 33 33 30 30 28 20 41 22 44 43 40 13 56 57 57 58 58 45 44 46 159 160 157 158 66 69 35a 35b 35c 35d 35e ti17481a ti22329a stand model see page 29.

Parts 332882a 27 drive parts additional warning labels are available at no cost. Ref. Part description qty. 3 motor 331491 1hp, 120v (120v models) 1 331492 0.5 hp, 220v (220v-240v models) 1 3a 331785 fan (not shown) 1 3b 331786 fan cover (not shown) 1 3c 331787 bolt (not shown) 1 4 866338 screw, sho...

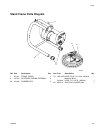

Parts 28 332882a packing replacement ref. Part description qty. 1* 331014 male gland 2 2* 331016 packing polyethylene 6 3* 331308 female adaptor 1 4 331011 fluid pump body 1 5 331029 suction ball guide 1 8 331292 suction seat (hi-boy) 1 331051 suction seat (lo-boy) 1 9 331034 suction nut 1 10+ 33131...

Parts 332882a 29 suction assemblies 1 2 3 gearbox sleeve bearing replacement note: when replacing item (1), cover outside of sleeve with 6 drops of loctite 246 prior to inserting into cover assembly. Ref. Part description qty. 1 331061 sleeve bearing 1 2 331103 washer 2 3 331197 screw 2 ti16059a sta...

Parts 30 332882a electrical system black white on/off switch power plug green pressure control red (ground) black white on/off switch power plug green pressure control red (ground) brown blue to motor 120v ti22336a ti22337a 230v 1 7 to motor board kit 868018 3 1 7 board kit 868019 ref. Part descript...

Technical data 332882a 31 technical data mp400/300, mustang 4800 us metric sprayer power requirements 120v ac, 60 hz, 10.5a, 1 phase 230v ac, 50/60 hz, 5a, 1 phase (mp400) 230v ac, 50/60 hz, 4a, 1 phase (mp300) generator required 3000w minimum maximum working pressure 3000 psi 20.7 mpa, 207 bar cycl...

Airlessco standard warranty 32 332882a airlessco standard warranty airlessco warrants all equipment referenced in this document which is manufactured by airlessco and bearing its name to be free from defects in material and workmanship on the date of sale to the original purchaser for use. With the ...