- DL manuals

- AIRLESSCO

- Paint Sprayer

- Mustang 11500

- Operation - Repair - Parts

AIRLESSCO Mustang 11500 Operation - Repair - Parts - Control Box Ts1750 Hose Reel

Control Box TS1750 Hose Reel

3A4147B

47

Control Box TS1750 Hose Reel

33

34

115

177

68

63

96

65

38

82

82

32

150

147

26

23

52

142

131

59

144

143

60

75b

75

75d

75ref

137

ti29430a

148

88

Ref.

Torque

10-15 in-lb (1.1 - 1.7 N•m)

40-45 in-lb (4.5 - 5.0 N•m)

9-11 in-lb (1.0 - 1.2 N•m)

200-230 in-lb (22.6 - 25.9 N•m)

30-35 in-lb (3.3 - 3.9 N•m)

15-20 in-lb (1.7 - 2.2 N•m)

2-3 in-lb (0.23 - 0.34 N•m)

1

2

3

4

5

6

7

1

2

3

2

4

5

6

7

Summary of Mustang 11500

Page 1

3a4147b en operation/repair/parts sl1250, ts1750, mustang 11500 electric airless sprayers for professional use only. Not approved for use in explosive atmospheres or hazardous locations. For portable spray application of architectural paints and coatings. 3300 psi (22.7 mpa, 227 bar) maximum working...

Page 2: Models

2 3a4147b models * etl listed model part number voltage sl1250 -na 17m140* 120v ts1750 -na 17m145 ts1750 hose reel - na 17m147 allpro mustang 11500 hiboy - na 17m155* sl1250 - ap/sca 17m243 240v ts1750 - ap/sca 17m244 ts1750 hose reel - ap/sca 17m245.

Page 3: Table of Contents

Table of contents 3a4147b 3 table of contents warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 standard models (sl1250 & ts1750) . . . . . . . . . . . . . . . . . . ...

Page 4: Warnings

Warnings 4 3a4147b warnings the following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual...

Page 5

Warnings 3a4147b 5 skin injection hazard high-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment. • do not aim the gun at, or spray any person or animal. • keep hands and other body parts away fr...

Page 6

Warnings 6 3a4147b fire and explosion hazard flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion: • do not spray flammable or combustible materials near an o...

Page 7

Warnings 3a4147b 7 equipment misuse hazard misuse can cause death or serious injury. • always wear appropriate gloves, eye protection, and a respirator or mask when painting. • do not operate or spray near children. Keep children away from equipment at all times. • do not overreach or stand on an un...

Page 8

Warnings 8 3a4147b moving parts hazard moving parts can pinch, cut or amputate fingers and other body parts. • keep clear of moving parts. • do not operate equipment with protective guards or covers removed. • pressurized equipment can start without warning. Before checking, moving, or servicing equ...

Page 9: Component Identification

Component identification 3a4147b 9 component identification standard models (sl1250 & ts1750) off on a b d j i i h g e e c c i h h c b b f d g g f f d ti29386b a amp switch (not available on all units) b on/off switch c pressure control d prime / spray valve e trigger lock f filter g strainer h pump...

Page 10: Component Identification

Component identification 10 3a4147b component identification ts1750 hose reel a a r g p e j h d c b r off on g p h j f n c d e ti29387b a display b amp switch (not available on all units) c on/off switch d pressure control e spray / prime f trigger lock g filter h strainer j pump n unit / serial tag...

Page 11: Grounding

Grounding 3a4147b 11 grounding the sprayer cord includes a grounding wire with an appropriate grounding contact. Do not use the sprayer if the electrical cord has a damaged ground contact. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local co...

Page 12: Pails

Grounding 12 3a4147b pails solvent and oil-based fluids: follow local code. Use only conductive metal pails, placed on a grounded surface such as concrete. Do not place pail on a nonconductive surface such as paper or cardboard which interrupts grounding continuity. Grounding a metal pail: connect a...

Page 13: Pressure Relief Procedure

Pressure relief procedure 3a4147b 13 pressure relief procedure follow the pressure relief procedure whenever you see this symbol. 1. Turn power off. Wait 7 seconds for power to dissipate. 2. Engage trigger lock. 3. Remove guard and switchtip. 4. Turn pressure to lowest setting. Trigger gun to reliev...

Page 14: Setup

Setup 14 3a4147b setup 1. All sprayers except hose reel: connect airless hose to sprayer. Tighten securely. If using the optional hopper, remove the nipple fitting from the filter. Install 45° elbow (included with hopper accessory kit) into filter and install nipple fitting into elbow. Then connect ...

Page 15

Setup 3a4147b 15 6. Fill throat packing nut with throat seal oil to prevent premature packing wear. Do this each time you spray. 7. Turn power off. 8. Plug power supply cord into a properly grounded electrical outlet. 9. Turn prime valve down to drain position. 10. Place pump in grounded metal pail ...

Page 16: Startup

Startup 16 3a4147b startup 1. Perform pressure relief procedure, page 13. 2. Turn pressure control to lowest pressure. 3. Turn power on. 4. Increase pressure 1/2 turn to start motor and allow fluid to circulate through drain tube for 15 seconds; turn pressure down. 5. Turn prime valve forward to spr...

Page 17

Startup 3a4147b 17 7. Inspect for leaks. If leaks occur, perform pressure relief procedure, page 13. Tighten fittings. Performs startup, steps 1-5. If no leaks, proceed to step 8. 8. Place pump in paint pail. 9. Trigger gun again into flushing pail until paint appears. Move gun to paint pail and tri...

Page 18: Switch Tip Installation

Switch tip installation 18 3a4147b switch tip installation 1. Perform pressure relief procedure, page 13. 2. Use spray tip (a) to insert oneseal ™ (b) into guard (c). 3. Insert switch tip. 4. Screw assembly onto gun. Tighten. Spray 1. Spray test pattern. Increase pressure to eliminate heavy edges. U...

Page 19: Hose Reel

Hose reel 3a4147b 19 hose reel 1. Make sure hose is routed through hose guide. 2. Lift and turn pivot lock 90° to unlock hose reel. Pull on hose to remove it from hose reel. 3. Pull reel handle up and turn clockwise to reel in hose. Note: the hose reel can be locked into two positions: usage (a) and...

Page 20: Digital Tracking System

Digital tracking system 20 3a4147b digital tracking system operation main menu short press to move to next display. Press and hold (5 seconds) to change units or reset data. 1. Turn pressure to lowest setting. Trigger gun to relieve pressure. Turn prime valve down to drain position. 2. Turn power on...

Page 21: Secondary Menu - Stored Data

Digital tracking system 3a4147b 21 secondary menu - stored data 1. Perform pressure relief, steps 1 - 4 if they have not already been done. 2. Turn power switch on while holding button down. 3. Serial number scrolls past and then serial number (e.G. 00001) displays. 4. Short press button and motor h...

Page 22: Cleanup

Cleanup 22 3a4147b cleanup 1. Perform pressure relief procedure, page 13, steps 1 - 4. Remove tip guard from gun. Note: use water for water-base material, mineral spirits for oil-base material, or other solvents recommended by manufacturer. 2. Turn power on. Turn prime valve forward to spray positio...

Page 23

Cleanup 3a4147b 23 9. Remove filters from gun and sprayer, if installed. Clean and inspect. Install filters. 10. If flushing with water, flush again with mineral spirits, or pump life, to leave a protective coating to prevent freezing or corrosion. 11. Wipe sprayer, hose and gun with a rag soaked in...

Page 24: Troubleshooting

Troubleshooting 24 3a4147b troubleshooting perform pressure relief procedure, page 13. Problem cause solution for units with display: code xx is displayed. Fault condition exists determine fault correction from table, page 27. Pump output is low spray tip worn follow pressure relief procedure on pag...

Page 25

Troubleshooting 3a4147b 25 pump output is low pump rod damage repair pump. See pump manual. Low stall pressure turn pressure knob fully clockwise. Make sure pressure control knob is properly installed to allow full clockwise position. If problem persists, replace pressure transducer. Piston packings...

Page 26

Troubleshooting 26 3a4147b pump is difficult to prime air in pump or hose check and tighten all fluid connections. Cycle pump as slowly as possible during priming. Intake valve is leaking clean intake valve. Be sure ball seat is not nicked or worn and that ball seats well. Reassemble valve. Pump pac...

Page 27: Electrical

Troubleshooting 3a4147b 27 electrical symptom: sprayer does not run, stops running, or will not shut off. Perform pressure relief procedure; page 13. 1. Plug sprayer into correct voltage, grounded outlet. 2. Set power switch off for 30 seconds and then on again (this ensure sprayer is in normal run ...

Page 28

Troubleshooting 28 3a4147b sprayer does not run at all check transducer or transducer connections 1. Make sure there is no pressure in the system (see pressure relief procedure, page 13). Check fluid path for clogs, such as clogged filter. 2. Use airless paint spray hose with no metal braid 1/4 in. ...

Page 29

Troubleshooting 3a4147b 29 sprayer does not run at all check transducer or transducer connections (control board is not detecting a pressure signal). 1. Set sprayer to off and disconnect power to sprayer. 2. Check transducer and connections to control board. 3. Disconnect transducer from control boa...

Page 30

Troubleshooting 30 3a4147b sprayer does not run at all control is commanding motor to run but motor shaft does not rotate. Possibly locked rotor condition, an open connection exists between motor and control, there is a problem with motor or control board, or motor amp draw is excessive. 1. Remove p...

Page 31

Troubleshooting 3a4147b 31 sprayer does not run at all control is commanding motor to run but motor shaft does not rotate. Possibly locked rotor condition, an open connection exists between motor and control, there is a problem with motor or control board, or motor amp draw is excessive. 6. Perform ...

Page 32

Troubleshooting 32 3a4147b sprayer does not run at all allow sprayer to cool. If sprayer runs when cool, correct cause of overheating. Keep sprayer in cooler location with good ventilation. Make sure motor air intake is not blocked. If sprayer still does not run, follow step 1. Note: motor must be c...

Page 33

Troubleshooting 3a4147b 33 sprayer does not run at all check voltage supply to the sprayer (incoming voltage too low for sprayer operation) 1. Set sprayer to off and disconnect power to sprayer. 2. Remove other equipment that uses the same circuit. 3. Locate a good voltage supply to avoid damage to ...

Page 34

Troubleshooting 34 3a4147b sprayer does not run at all check the connections. Control is not receiving a motor position sensor signal 1. Turn power off. 2. Disconnect motor position sensor and inspect for damage at connectors. 3. Reconnect sensor. 4. Turn power on. If code continues, replace motor. ...

Page 35: Sprayer Will Not Run

Troubleshooting 3a4147b 35 sprayer will not run (see following page for steps) remove control box cover. Turn sprayer on. Observe control board status light on control board (see page 27). No light once normal operation light on continously control board commanding motor to run flashing see code sec...

Page 36

Troubleshooting 36 3a4147b - v - - 200-240v - v - - 200-240v step 1: plug power cord in and turn switch on. Connect probes to on/off switch. Turn meter to ac volts. Step 2: plug power cord in and turn switch on. Connect probes to on/off switch. Turn meter to ac volts. Troubleshooting step 3: check m...

Page 37: Sprayer Will Not Run

Sprayer will not run 3a4147b 37 sprayer will not run 1. Perform pressure relief procedure, page 13. Leave prime valve open and power switch off. 2. Remove control box cover so the control board status light can be viewed if available. Troubleshooting procedure: plumb pressure gauge into paint hose, ...

Page 38

Sl1250, ts1750, mustang 11500 parts 38 3a4147b sl1250, ts1750, mustang 11500 parts ti29385a.

Page 39: Sl1250 and Mustang 11500

Sl1250 and mustang 11500 3a4147b 39 sl1250 and mustang 11500 62 51 83 91 76 55 108 17 58 48 24 24 41 43 56 31 31 31 11 8 31 87 94 160 ti29683a 71 126 30 127 84 37 36 72 73 90a 28 89 28 90 6 99 10 22 18 109 93 57 44 85 12 117 14 77 154 129 124 ref. Torque 40-45 in-lb (4.5 - 5.0 n•m) 9-11 in-lb (1.0 -...

Page 40

Parts list - sl1250 and mustang 11500 40 3a4147b parts list - sl1250 and mustang 11500 ref. Part description qty 6 15c753 screw, mach torx, hex 5 8 15e891 clip, retaining 2 10 156306 washer, flat 2 11* 119420 wheel, pneumatic 2 12 106115 wash, lock, spring 4 14 110141 screw, cap, socket hd 4 17 15c8...

Page 41: Ts1750

Ts1750 3a4147b 41 ts1750 62 99 17 24 90 160 72 73 31 31 58 83 12 117 14 85 48 44 43 10 22 11 8 108 31 77 56 57 51 31 87 91 41 94 24 113 ti29684a 126 127 124 84 36 28 89 93 18 28 30 90a 6 71 55 37 31 129 154 ref. Torque 40-45 in-lb (4.5 - 5.0 n•m) 9-11 in-lb (1.0 - 1.2 n•m) 200-230 in-lb (22.6 - 25.9...

Page 42: Parts List - Ts1750

Parts list - ts1750 42 3a4147b parts list - ts1750 ref. Part description qty 6 15c753 screw, mach torx, hex 5 8 15e891 clip, retaining 2 10 156306 washer, flat 2 11* 119509 wheel, pneumatic 2 12 106115 wash, lock, spring 4 14 114666 screw, cap, socket hd 4 17 276974 cap, leg 2 18 108795 screw, mach,...

Page 43: Ts1750 Hose Reel

Ts1750 hose reel 3a4147b 43 ts1750 hose reel 99 160 72 124 73 84 126 106 105 107 62 29 35 11 22 10 127 37 36 90a 90 6 83 12 14 51 31 31 55 93 94 17 41 91 44 43 56 85 87 48 77 117 108 113 24 24 28 89 30 28 57 71 31 58 31 8 ti29685a ref. Torque 40-45 in-lb (4.5 - 5.0 n•m) 9-11 in-lb (1.0 - 1.2 n•m) 20...

Page 44

Parts list - ts1750 hose reel 44 3a4147b parts list - ts1750 hose reel ref. Part description qty 6 15c753 screw, mach, hex wash hd 5 8 15e891 clip, retaining 2 10 156306 washer, flat 2 11* 119509 wheel, pneumatic 2 12 106115 washer, lock (hi-collar) 4 14 114666 screw, cap, socket head 4 17 276974 ca...

Page 45

Control box sl1250 / mustang 11500 / 3a4147b 45 control box sl1250 / mustang 11500 / ts1750 33 34 115 177 68 65 96 38 82 150 147 26 23 52 142 143 131 59 144 60 131 ti29686a 148 75 ref 75b 137 75 75d ref. Torque 10-15 in-lb (1.1 - 1.7 n•m) 40-45 in-lb (4.5 - 5.0 n•m) 9-11 in-lb (1.0 - 1.2 n•m) 200-23...

Page 46

Filter sl1250 / mustang 11500 46 3a4147b filter sl1250 / mustang 11500 67 16 86 13 74 92 9 19 69 20 15 66 42 132 81 21 80 118 50 ti29433a ref. Torque 40-45 in-lb (4.5 - 5.1 n•m) 35-45 ft-lb (47.4 - 61.0 n•m) 100-120 in-lb (11.2 - 13.5 n•m) 130-150 in-lb (14.6 - 16.9 n•m) 1 2 3 4 1 2 3 4 ref. Part de...

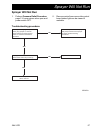

Page 47: Control Box Ts1750 Hose Reel

Control box ts1750 hose reel 3a4147b 47 control box ts1750 hose reel 33 34 115 177 68 63 96 65 38 82 82 32 150 147 26 23 52 142 131 59 144 143 60 75b 75 75d 75ref 137 ti29430a 148 88 ref. Torque 10-15 in-lb (1.1 - 1.7 n•m) 40-45 in-lb (4.5 - 5.0 n•m) 9-11 in-lb (1.0 - 1.2 n•m) 200-230 in-lb (22.6 - ...

Page 48

Parts list - control box ts1750 hose reel 48 3a4147b parts list - control box ts1750 hose reel ref. Part description qty 23 117791 screw, cap, flange head 2 26 114391 screw, grounding 1 32 115522 screw, mach, pnh 3 33 15c979 switch, rocker, 120v 1 15d527 switch, rocker, 230v 1 34 116167 knob, potent...

Page 49: Ts1750 Filter

Ts1750 filter 3a4147b 49 ts1750 filter 42 42a 42d 67 13 20 40 118 ref 94 42 (see chart) 39 114 66 9 74 81 86 50 21 92 80 ti29431a 1 2 3 4 5 ref. Part description qty 9 117285 packing, o-ring 1 13 16u013 screw, cap, socket head 3 20 111457 packing, o-ring 1 21 15c972 pin, grooved 1 39 24j081 tube, fo...

Page 50: Ts1750 Hose Reel & Gun

Ts1750 hose reel & gun 50 3a4147b ts1750 hose reel & gun 173 172 170 171 180 99 163 164 168 183 169 42 201 174 174 167 39 16 18 5 154 129 179 178 ti29432a 1 2 3 3 4 ref. Part description qty 5 16c975 plate, pivot mount 1 16 121311 fitting, connector, npt x jic 1 18 260212 screw, hex washer hd 2 39 2...

Page 51: Technical Data

Technical data 3a4147b 51 technical data sl1250 and mustang 11500 sprayers us metric sprayer maximum working pressure 3300 psi 227 bar maximum delivery 0.95 gpm 3.6 lpm maximum tip size 0.031 in. 0.031 in. Fluid outlet npsm 1/4 in. 1/4 in. Cycles 226 per gallon 60 per liter generator minimum 5000 w ...

Page 52: Ts1750 Sprayers

Technical data 52 3a4147b ts1750 sprayers us metric sprayer maximum working pressure 3300 psi 227 bar maximum delivery north america models 1.35 gpm 5.1 lpm international models 1.2 gpm 4.5 lpm maximum tip size north america models 0.039 in. 0.039 in. International models 0.035 in. 0.035 in. Fluid o...

Page 53: Wiring Diagram

Wiring diagram 3a4147b 53 wiring diagram 120v pressure transducer potentiometer power plug motor thermal switch mo t or sensor leads motor leads green/ground green/ground on/off switch white black bla ck blue led display amp switch ti29805a.

Page 54: 240V

Wiring diagram 54 3a4147b 240v pressure transducer potentiometer power plug motor thermal switch motor sensor leads motor wire jumper leads led display green gr ound on/off switch brown blue br o w n blue blue black ti29806a.

Page 55: Airlessco Standard Warranty

Airlessco standard warranty 3a4147b 55 airlessco standard warranty airlessco warrants all equipment referenced in this document which is manufactured by airlessco and bearing its name to be free from defects in material and workmanship on the date of sale to the original purchaser for use. With the ...

Page 56: Airlessco Information

To place an order or for service, contact your airlessco distributor, or call 1–800–223-8213 to identify the nearest distributor. All written and visual data contained in this document reflects the latest product information available at the time of publication. Airlessco reserves the right to make ...