- DL manuals

- AIRLESSCO

- Paint Sprayer

- Prolight Contractor Series

- Operation manual

AIRLESSCO Prolight Contractor Series Operation manual

Summary of Prolight Contractor Series

Page 1

001-664 oct 08 ® airlessco prolight contractor series flat handle spray gun a irless spray gun s ervice /o peration m anual.

Page 2: Table of Contents

2 1 table of contents introduction section figure introduction safety warnings ................................................................ 1 pressure relief procedure ................................................ 2 airless spray gun operation ............................................ 3 ai...

Page 3: Warnings

2 1 fluids under high pressure from spray or leaks can penetrate the skin and cause extremely serious injury, including the need for amputation. Never point spray gun at anyone or at any body part. Never put hand or fingers over the spray tip. Do not use rag or other materials over your fingers. Pai...

Page 4: Pressure Relief Procedure

2 3 pressure relief procedure 5. Re-engage gun safety latch and close prime/pressure relief valve. To avoid possible serious body injury, always follow this procedure whenever the sprayer is shut off, when checking it, when installing, changing or cleaning tips, whenever you stop spraying, or when y...

Page 5: Fig. 1

2 3 spray attach spray gun to airless unit and tighten fittings securely. Set the gun safety latch. (also may be called gun safety lock, or trigger lock) * the gun safety latch should always be set when the gun is not being triggered. Read all warnings and safety precautions supplied with the spray ...

Page 6: Spray Technique

4 5 spray technique good spray gun technique is at the core of any spray paint operation. Operator skill and efficiency is as important as good equipment and good paint. Good spray technique is a skill that can be quickly learned by following these simple instructions. Hold the spray gun 12 - 15 inc...

Page 7: Spray Technique

4 5 spray technique trigger point trigger point the actual pa int stroke total gun movement- arm movement - full sweep for even paint coat,overlap half the width of each paint stroke it is important to “trigger” the gun after gun movement (arm movement) has started and release trigger (shut gun off)...

Page 8: Tip Selection Guide

6 7 tip selection guide 1st 3-digits identifies it as a rev-tip tm for airless paint spraying (p.N. 560-xxx), a rev-tip tm for airless line striping (p.N. 562-xxxst), or a rev-tip tm for fine finishing (p.N. 571-xxx) 4th digit is the fan width - the number is half the fan width, e.G., 5 means a 10” ...

Page 9: Tip Selection Guide

6 7 *pump will support tip worn to next larger size. Rev-tip tm for painting fan width (12” from surface) spray tip - orifice size (inches) in. Mm .007 .009 .011 .013 .015 .017 .019 .021 .023 .025 .027 .029 .031 .035 .039 .041 4-6 102-152 209 211 213 215 217 219 221 223 225 227 229 6-8 152-203 307 3...

Page 10: Airless Spray Gun

8 9 airless spray gun fig. 5 3* 9 8 7 5 4 2* 1* 13 16 15 14 12 11 10* 17 parts list figure 5 item no. Part no. Description 1 120-530 gun seat assembly 2 120-535 gasket-seat 3 120-520 needle assembly 4 120-529 gun seat adapter 5 120-562 trigger guard 6 120-539 trigger pin 7 120-109 gun head 8 120-540...

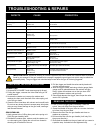

Page 11: Troubleshooting & Repairs

8 9 defects cause correction coarse spray low pressure increase the pressure excessive fogging (overspray) high pressure material too thin reduce the pressure to satisfactory pattern distribution use less thinner patten too wide spray angle too large use smaller spray angle tip pattern too narrow sp...

Page 12: Quick Flush

A ir l e s s c o a ccessories strong yet flexible, for airless sprayers up to 3300 psi part no: hose description 100-012 3/16” whip hose, 4 ft. 100-040 1/4” whip hose, 3 ft. 100-204 1/4” whip hose, 5 ft. 100-199 3/8” whip hose, 6 ft. 100-011 1/4” hose, 50 ft. 100-023 3/8” hose, 50 ft. 100-037 1/2” h...