- DL manuals

- AIRLESSCO

- Paint Sprayer

- TS1500 (24F573) B Series

- Operation - Repair - Parts

AIRLESSCO TS1500 (24F573) B Series Operation - Repair - Parts

3A1183C

EN

Operation/Repair/Parts

Airless Paint Sprayer

For application of architectural paints and coatings. For professional use only.

Airlessco - TS1500 (24F573) Series B

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure

Related Manuals

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Gun Manual 3A0413

ti17342a

Summary of TS1500 (24F573) B Series

Page 1

3a1183c en operation/repair/parts airless paint sprayer for application of architectural paints and coatings. For professional use only. Airlessco - ts1500 (24f573) series b 3300 psi (22.8 mpa, 228 bar) maximum working pressure related manuals important safety instructions read all warnings and inst...

Page 2: Warnings

Warnings 2 3a1183c warnings the following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manu...

Page 3: Warning

Warnings 3a1183c 3 warning warning warning warning fire and explosion hazard flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion: • do not spray flammable or combustible materials near an open flame or sources of ignition such as c...

Page 4: Warning

Warnings 4 3a1183c skin injection hazard high-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment. • do not aim the gun at, or spray any person or animal. • keep hands and other body parts away fr...

Page 5: Warning

Warnings 3a1183c 5 moving parts hazard moving parts can pinch, cut or amputate fingers and other body parts. • keep clear of moving parts. • do not operate equipment with protective guards or covers removed. • pressurized equipment can start without warning. Before checking, moving, or servicing equ...

Page 6: Component Identification

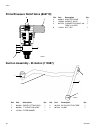

Component identification 6 3a1183c component identification ti17939a a b prime pressure ti17343a c d e f a power switch turns sprayer on and off b pressure control knob adjusts pressure. Turn clockwise to increase pressure and counterclockwise to decrease pressure. C prime/pressure relief valve prim...

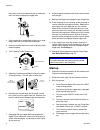

Page 7: Operation

Operation 3a1183c 7 operation setup connect the hose and gun 1. Remove the plastic cap plug from the outlet and screw a conductive or grounded 3000 psi spray hose onto fluid outlet. 2. Connect an airless spray gun to the other end of the hose. Do not install spray tip. Note: do not use thread sealer...

Page 8: Startup

Operation 8 3a1183c instruction manual provided with gun for safety fea- tures and how to engage the trigger lock. 2. Pour enough clean, compatible solvent into a large, empty metal pail to fill the pump and hoses. 3. Place the suction tube into the pail or place the pail under the pump. 4. Turn pre...

Page 9: Adjusting The Pressure

Operation 3a1183c 9 adjusting the pressure when adjusting the pressure, turn the pressure control knob clockwise to increase pressure and counterclock- wise to decrease pressure. Always use the lowest pres- sure necessary to completely atomize the material. If more coverage is needed, use a larger t...

Page 10: Maintenance

Maintenance 10 3a1183c maintenance regular maintenance 1. Always stop the pump at the bottom of its stroke when you take a break or at the end of the day. This helps keep material from drying on the rod, damag- ing the packings. 2. Keep displacement pump packing nut/wet cup 1/3 full of airlessco thr...

Page 11: Replacement of Belt/belt

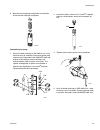

Maintenance 3a1183c 11 replacement of belt/belt adjustment note: the cog belt system does not require align- ment. When upper sheave is placed on motor shaft it is pushed on until a positive stop is reached. The set screws are then loctited. The lower pulley is placed on gearbox and held in place wi...

Page 12

Maintenance 12 3a1183c fluid pump reinstall 1. Loosen the packing nut and extend piston rod to fully up position. Slip sleeve over the piston rod. 2. Insert one of the retaining rings through the packing nut and rest the sleeve on top of it. 3. Connect the connecting rod with the fluid pump by insta...

Page 13: Service

Maintenance 3a1183c 13 service pressure relief procedure 1. Engage gun trigger lock. 2. Turn on/off switch to off. 3. Unplug power cord. 4. Disengage gun trigger lock. Hold metal part of gun against grounded metal pail and trigger gun into pail to relieve pressure. 5. Engage gun trigger lock. 6. Ope...

Page 14

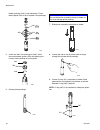

Maintenance 14 3a1183c 2. Unscrew intake valve from cylinder. 3. Disassemble intake valve. Clean and inspect. O-ring (227) may require a pick for removal. 4. Tap piston rod out of cylinder with a hammer or flip over and tap piston rod against a bench. Note: sleeve may come out of cylinder with pisto...

Page 15

Maintenance 3a1183c 15 8. Remove throat packings and glands from cylinder. Discard throat packings and glands. Assembling the pump 1. Soak all leather packings in sae 30w oil for 1 hour minimum prior to assembly. Stack male gland (204) on piston rod. Alternately stack uhmwpe (208) and leather (218) ...

Page 16

Maintenance 16 3a1183c leather packings (223) (note orientation). Place female gland (224) in top of cylinder. Seat packings. 5. Install seal (201) into packing nut (202), install throat adjustment spacer (228) onto packing nut. Loosely install packing nut into cylinder. 6. Grease piston packings. 7...

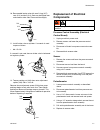

Page 17: Replacement of Electrical

Maintenance 3a1183c 17 10. Reassemble intake valve with new o-ring (227), seat (212) and ball (214), seat may be flipped over and used on other side. Clean seat thoroughly. 11. Install intake valve on cylinder. If a wrench is used torque as follows: • 80 +/-5-ft-lb if a wrench is not used, be sure i...

Page 18

Maintenance 18 3a1183c on-off toggle switch 1. Lower the pressure control assembly as described above. 2. Disconnect the two wires on the toggle switch. 3. Use a 9/16” wrench to loosen the nut on the toggle switch shaft. 4. Reassemble in reverse order. Liquid crystal display (lcd) 1. Ensure the powe...

Page 19: Troubleshooting

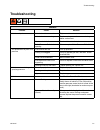

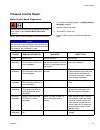

Troubleshooting 3a1183c 19 troubleshooting general problem cause solution unit doesn’t prime airleak due to loose suction nut tighten suction nut. Airleak due to worn o-rings replace o-ring on suction seat and o-ring below suction seat. Stuck or fouled balls service inlet and outlet valves. Prime/pr...

Page 20

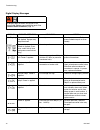

Troubleshooting 20 3a1183c motor remove the motor brush covers and turn the machine on. Set the potentiometer (pot) at maximum pressure and check for dc voltage across both brush terminals. It should read greater than 80 volts dc. If you have dc voltage, turn the machine off and unplug it from the w...

Page 21: Pressure Control Repair

Troubleshooting 3a1183c 21 pressure control repair motor control board diagnostics note: keep a new transducer on hand to use for test. 1. For sprayers with digital display, seedigital display messages, page 22 2. Remove screws and cover. 3. Turn on/off switch on. 4. Observe led operation and refere...

Page 22

Troubleshooting 22 3a1183c digital display messages no display does not mean that spayer is not pressurized. Relieve pressure before repair. See pressure relief procedure, page 13 display sprayer operation indication action no display sprayer stops. Power is not applied. Sprayer may be pressurized. ...

Page 23

Troubleshooting 3a1183c 23 airless spray gun problem cause solution coarse spray low pressure increase the pressure excessive fogging (overspray) high pressure reduce the pressure to satisfactory pattern distribution. Material too thin use less thinner pattern too wide spray angle too large use smal...

Page 24

Troubleshooting 24 3a1183c tip clogs continually debris in paint thoroughly strain the paint before use gun filter missing do not operate without inlet strainer coarse filter mesh do not operate without inlet strainer problem cause solution test the pattern good, full spotty pattern, increase pressu...

Page 25: Parts

Parts 3a1183c 25 parts optional manifold kit (301440) optional filter kit (866123) ref. Part description qty. 1 866123 filter, assy 1 3 867188 fitting, elbow street 90 3/8 npt 2 4 867309 fitting, nipple, 3/8 npt to 1/4 npt 2 5 866445 spacer, .377 id x .40 lg al 2 6 305140 bracket - filter 1 7 867534...

Page 26: Frame Parts Diagram

Parts 26 3a1183c frame parts diagram 8 31 24 32 34 20 25 114 23 22 27 38 59 14 64 19 18 17 132 4 56 16 62 28 96 82 ti 17876a ti17476a ref part description qty. 4 342425 ▲ label - high voltage 1 8 label,designation 1 14 867791 frame,cart 1 16 301134 plug,neoprene 2 17 143029 collar,screw,set (special...

Page 27: Motor and Drive

Parts 3a1183c 27 motor and drive 84 61 57 68 65 67 76 78 77 77 55 83 70 71 52 79 63 69 72 74 45 80 49 49 51 50 50 75 66 65 64 46 44 47 43 41 48 73 85 81 60 58 60 59 115 12 13 53 54 94 93 10 42 6 5 ti17477a.

Page 28: Motor and Drive Parts List

Parts 28 3a1183c motor and drive parts list ref. Part description qty 5 342473 ▲ label general warning 1 6 342506 ▲ label never/always lp&sl 1 10 16f596 label,airlessco, ts1500, front 1 12 16f597 label,airlessco, ts1500, right 1 13 16f598 label,airlessco, ts1500, left 1 41 189920 strainer,(1-11 1/2 ...

Page 29: Ts1500 Pump Parts Diagram

Parts 3a1183c 29 ts1500 pump parts diagram 14 14 4 5 20 21 21 21 21 22 22 22 23 2 25 3 24 1 15 17 16 19 18 6 13 7 18 12 9 11 11 11 10 10 10 10 ref. Part description qty. 1 196753 housing, valve, intake 1 2 cylinder, pump 1 3 193032 nut. Packing 1 4 248210 sleeve, cylinder 1 5 24e353 rod, piston 1 6 ...

Page 30

Parts 30 3a1183c prime/pressure relief valve (865719) suction assembly - 55 gallon (119087) ref. Part description qty. 2 865013 adapter,valve 1 3 15g563 handle, valve 1 4 867759 connector, male, 3/8 tube x 1/8 pipe 1 8 116424 nut, cap 1 2 3 4 8 ti16004a ref. Part description qty. Ref. Part descripti...

Page 31: Control Parts Diagram

Parts 3a1183c 31 control parts diagram 80 122 121 125 120 129 129 126 126 59 59 33 79 86 87 91 92 90 88 89 82 84 83 4 81 38 ti17478a ref. Part description qty. 4 342425 ▲ label - high voltage 1 33 24b599 transducer,pressure control 1 38 866049 cable,assy 9” lg 1 59 110637 screw,mach,panhead 13 79 55...

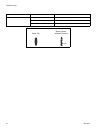

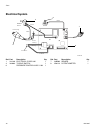

Page 32: Electrical System

Parts 32 3a1183c electrical system on/off switch power plug from motor red (+) white black green 2 x white black (-) black black ti12471a 1 4 6 7 8 ref. Part description qty. Ref. Part description qty. 1 331168 electrical cord110v 1 7 24b599 sensor 1 4 301083 toggle switch 1 8 256219 potentiometer 1...

Page 33: Technical Data

Technical data 3a1183c 33 technical data power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 ac, 50 hz, 11a, 1 phase generator required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 w minimum maximum working pressure . ....

Page 34: Airlessco Standard Warranty

To place an order or for service, contact your airlessco distributor, or call 1–800–223-8213 to identify the nearest distributor. All written and visual data contained in this document reflects the latest product information available at the time of publication. Airlessco reserves the right to make ...