Summary of LHR 215/5

Page 1

Compressor lhr 215/5 36646 instruction manual.

Page 2

Versie 02.2006 please read this instruction manual carefully before use. (gb) waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your local authority or retailer for recycling advice. Importeur airpress, p.O. Box 114, nl-8900 a...

Page 3

1 compressor 36646/versie 02.2006.

Page 4: Table of Contents

2 table of contents english 1. Prefatory notes page 25 2. Safety instructions page 26 3. Warnings page 27 4. Specifications page 29 5. Parts and features page 29 6. Installation and assembly page 30 7. Operating procedures page 32 8. Maintenance page 32 9. Storage page 34 10. Troubleshooting guide p...

Page 5: 2.0 Safety Instructions

3 2.0 safety instructions important: please read and observe the following safety instructions before using the machine. •nobody must be allowed to use the compressor unless they have read the instruction manual and have been instructed in the regulations to follow for correct and safe use. •the mac...

Page 6: Danger Plates

4 excessive heat, oil and sharp objects. • never leave the machine unattended with the power supply "on". Also disconnect the power cable when: - you leave the machine, even for a short time - not in use - carrying out maintenance work - changing attachment or moving the machine. • warning: the warn...

Page 7

5 tank may reduce the tank's strength and cause an extremely hazardous condition. Welding on the tank in any manner will void the warranty. Check the manufacturer's maximum pressure rating for air tools and accessories. Compressor outlet pressure must be regulated so as to never exceed the maximum p...

Page 8: 4. Specifications

6 4. Specifications order number 36646 pump oil-lubricated direct drive motor 1,5 hp/1,1 kw voltage single phase 230 volt air tank capacity 5 litres oil tank capacity 0,25 litres cut-in pressure 6 bar cut-out pressure 8 bar max. Charge 30% per 60 minutes sound pressure 77 db(a)/7 m air intake capaci...

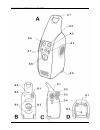

Page 9: 6. Installation & Assembly

7 wheels: roll the unit on its wheels to move it into position for use and storage handle: use the convenient handle to move the air compressor into the desired position for use and storage. Tank: stores high pressure air from the air compressor pump. 6. Installation & assembly warning the air compr...

Page 10

8 location of the air compressor the air compressor should always be located in a clean, dry, and well-ventilated environment. The unit should have at minimum, 12 inches of space on each side. The air filter intake should be free of any debris or obstructions. Check the air filter on a daily basis t...

Page 11: 7. Operation Procedures

9 7. Operation procedures daily start-up procedures 1. Set the auto-on/off lever to the off position. 2. Check the air compressor visually for any damage or obstruction. 3. Close the drain valve. 4. Check the oil level of the pump. 5. Attach the air hose to the quick coupler by pulling back on the o...

Page 12

10 check tank safety valve x overall unit visual check x check oil level x change oil x x check air filter (more frequently in dusty or humid environments) x drain moisture from tank x caution to ensure efficient operation and longer life of the air compressor unit, a routine maintenance schedule sh...

Page 13: 9. Storage

11 cleaning air filter to clean the air intake filter, be sure to do the following: 1. Turn the unit off and unplug the power cord from the receptacle. 2. Allow the compressor time to cool if it has been in operation. 3. Open the drain valve to bleed all air from the tank. After the tank is empty, c...

Page 14

12 problem possible correction air leaks at the check valve or at the pressure relief valve. A defective check valve results in a constant air leak at the pressure release valve when there is pressure in the tank and the compressor is shut off. Drain the tank, then remove and clean or replace the ch...

Page 15: Danger Plates

13 danger plates the plates fitted on the compressor unit are part of the machine; they have been applied for safety purposes and must not be removed or spoiled for any reason..

Page 16

14 vorstvrij opstellen frostfrei aufstellen frost-proof installation installer à l’abri du gel instalacion a prueba de heladas pas op voor hete delen heisse teile beware of hot parts faites attention aux pièces chaudes tenga cuidado con las piezas calientes regelmatig oliepeil controleren regelmäßig...

Page 17

15 ec-declaration of conformity we, airpress, p.O. Box 114, 8900 ac leeuwarden, the netherlands, taking full responsibility, declare that the products compressors lhr 215/5 to which this declaration refers, comply with the machinery directive 98/37/ec, the emc directive 89/336/ec, the low tension di...

Page 18

Ec-declaration of conformity we, airpress, p.O. Box 114, 8900 ac leeuwarden, the netherlands, taking full responsibility, declare that the products compressors lhr 215/5 to which this declaration refers, comply with the machinery directive 98/37/ec, the emc directive 89/336/ec, the low tension direc...

Page 19: Compressor

Compressor lhr 215/5 version 02.2006.