- DL manuals

- AirSep

- Medical Equipment

- NewLife Intensity 10

- Service Manual

AirSep NewLife Intensity 10 Service Manual

Summary of NewLife Intensity 10

Page 1

Newlife ® intensity 10 oxygen concentrator service manual.

Page 2

Mn134-1 rev c ii expedited product warranty check service is available at 800-482-2473.

Page 3: Table Of Contents

Mn134-1 rev c iii table of contents section 1.0 introduction 1.1 equipment provider responsibility 1 1.2 important notice and symbol explanations 2 1.3 functional specifications 4 section 2.0 operation check and oxygen concentration test 2.1 description of operation 5 2.2 operation check 5 2.3 alarm...

Page 4: Section 5.0

Mn134-1 rev c iv section 5.0 main components 5.1 components 10 5.2 cabinet removal 10 5.2.1 removing side panel(s) 10 5.2.2 removing back panel 10 5.2.3 removing lower front panel 10 5.2.4 removing control panel 10 5.2.5 superstructure 10 5.2.6 caster replacement 10 5.3 compressor 11 5.3.1 compresso...

Page 5: Section 6.0

Mn134-1 rev c v section 6.0 troubleshooting 6.1 operating pressure test 20 6.1.1 high operating pressure 20 6.1.2 low operating pressure 20 6.2 general troubleshooting 21 6.3 troubleshooting chart 22 6.4 tool kit and pressure test gauge 25.

Page 6: 1.0 Introduction

Mn134-1 rev c 1 1.0 introduction 1.1 equipment provider responsibility all equipment providers of the newlife ® intensity 10 oxygen concentrator must assume responsibilities for handling, operational check-out, patient instruction, and oxygen concentration checks. These responsibilities are outlined...

Page 7

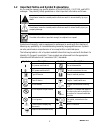

Mn134-1 rev c 2 1.2 important notice and symbol explanations as you read the manual, pay special attention to the warning, caution, and note messages. They identify safety guidelines or other important information as follows: describes a hazard or unsafe practice that can result in severe bodily inj...

Page 8

Mn134-1 rev c 3 method for disposing of waste: all waste from the newlife intensity 10 (patient circuit, etc.) must be disposed of using appropriate methods. Method for disposing of the device: in order to preserve the environment, the concentrator must only be disposed of using the appropriate meth...

Page 9

Mn134-1 rev c 4 1.3 functional specifications oxygen concentration: 2-9 lpm: 92% +3.5/-3% 10 lpm: 90% +5.5/-3% (based on 70°f [21°c] at sea level) accuracy: flowmeter ± 10% or ± 200ml of indicated flow, whichever is greater. Response time: allow 5 minutes to attain maximum oxygen concentration. Posi...

Page 10: 2.2 Operation Check

Mn134-1 rev c 5 2.0 operational check and oxygen concentration test 2.1 description of operation air is drawn into the newlife intensity 10 oxygen concentrator through an external air intake gross particulate filter. Before this air enters the compressor, it passes through the unit’s suction resonat...

Page 11: 2.4

Mn134-1 rev c 6 oxygen monitor detects lower than therapeutic levels of oxygen concentration. The alarm remains on until you correct the alarm condition or you set the i /0 power switch to the “0” position. Refer to section 6.0 for a list of probable alarm causes. 2.3.1 start up/battery test each ti...

Page 12: 3.0 Patient Instructions

Mn134-1 rev c 7 3.0 patient instructions 3.1 instructions it is important that patients thoroughly understand how to operate the airsep newlife intensity 10 unit. This enables proper treatment, as prescribed by a licensed health care provider/physician. If patients experience any discomfort or the u...

Page 13: 4.1 Instructions

Mn134-1 rev c 8 4.0 provider instructions 4.1 instructions to ensure that the unit’s output of oxygen is within specification, you must perform a test of the oxygen concentration. Test the unit upon delivery to a patient and at periodic intervals. Equipment providers need to establish and implement ...

Page 14: Infection Control

Mn134-1 rev c 9 4.1.5 recording maintenance as the equipment provider, you can record all routine maintenance and repairs performed on the newlife intensity 10 unit, including hours and dates of service. A history record label is located on the side panel inside the unit. Keep this record current to...

Page 15: 5.0 Main Components

Mn134-1 rev c 10 5.0 main components 5.1 components the design of the airsep newlife intensity 10 oxygen concentrator allows for easy access and removal of most components. This allows you to perform repair and replacement of parts with minimal time and effort. To prevent accidental electrical shock...

Page 16: 5.3 Compressor

Mn134-1 rev c 11 5.3 compressor the compressor is the “pump” within the oxygen concentrator that pushes the room air into the bottom of the sieve beds. This allows oxygen to flow out of the top of the sieve beds in the newlife intensity 10 unit. Two different aspects of the compressor cause concern:...

Page 17: 5.4 Solenoid Valves

Mn134-1 rev c 12 5.3.2 capacitor replacement the capacitor starts the compressor. If the compressor cannot start, the capacitor may be defective and require replacement. To replace the capacitor, follow the steps below: 1. Set the unit’s i/ 0 switch to the “0” position and disconnect the power cord....

Page 18: 5.5 Sieve Beds

Mn134-1 rev c 13 b. Feed/waste coil = 850ohms +/- 10% 2. 220-240vac units a. Eq coil = 4,300ohms +/- 10% b. Feed/waste coil = 3,100ohms +/- 10% you can also determine which coil is not operating by checking each valve to see if it becomes energized (magnetized) during unit operation. To check for co...

Page 19: 5.6 Cabinet Fan

Mn134-1 rev c 14 if replacement is necessary, you must replace both sieve beds at the same time. Sieve bed removal to remove sieve beds, follow the steps below: 1. Set the unit’s i/ 0 switch to the “0” position and disconnect the power cord. 2. Remove the side and back panels. 3. Cut the tie-wrap an...

Page 20

Mn134-1 rev c 15 a green light that fails to illuminate indicates a disconnected or faulty solenoid coil or an electrical malfunction in that valve circuit. The two vertical red lights indicate high and low pressure. Consult the troubleshooting chart in section 6.0 to determine when to replace the p...

Page 21

Mn134-1 rev c 16 4. Remove the 2 nd stage intake resonator, which is held in place by velcro. 5. Remove the securing nut that holds the product tank to the superstructure. (this securing nut is located in the top right area of the compressor compartment). 6. Remove the screws that hold the control p...

Page 22: 5.11

Mn134-1 rev c 17 5.9.2 product regulator cleaning or rebuilding clean or rebuild the product regulator if the regulator cannot be adjusted for lockout. 1. Set the unit’s i /0 switch to the “0” position and disconnect the power cord. 2. Remove the right side panels and back panels. 3. Use large plier...

Page 23: 5.12 Buzzer Replacement

Mn134-1 rev c 18 i /0 power switch installation follow the removal procedure for the i /0 power switch in reverse order to install a new power switch. 1. Be sure to reinstall the new switch properly with the orientation of the “0” on the switch located on the bottom when finished. 2. Same side wire ...

Page 24

Mn134-1 rev c 19 3. Open the plastic twist clamps. 4. Cut the tie-wraps (located near the power cord push-on connectors). 5. Disconnect the white power cord lead from the i /0 switch lead. 6. Disconnect the black power cord lead from the top terminal on the circuit breaker. 7. Locate strain relief i...

Page 25: 6.0 Troubleshooting

Mn134-1 rev c 20 6.0 troubleshooting 6.1 operating pressure test testing the operating pressure is a useful diagnostic tool when a concentrator produces low oxygen concentration and requires servicing. Units functioning normally do not require operating pressure tests. Use the following procedure to...

Page 26

Mn134-1 rev c 21 6.2 general troubleshooting before reviewing the troubleshooting chart, the following steps may be useful to isolate any malfunctions: 1. Turn on the concentrator. If the unit does not turn on, refer to the troubleshooting chart. 2. Verify the outlet pressure is 20 psig (138 kpa). I...

Page 27: 6.3 Troubleshooting Chart

Mn134-1 rev c 22 6.3 troubleshooting chart problem probable cause solution unit does not run. Constant audio alarm with i/0 power switch in “i” position. No power to unit from electrical outlet. Unit circuit breaker tripped/faulty. Faulty electrical connections. Faulty i /0 power switch. Faulty circ...

Page 28: Problem

Mn134-1 rev c 23 problem probable cause solution compressor runs with intermittent high pressure alarm and low oxygen concentration. Restriction in exhaust muffler. Faulty solenoid valve. Faulty circuit board. Contaminated sieve beds. Replace or clean muffler. Repair or replace solenoid valve. Repla...

Page 29: Problem

Mn134-1 rev c 24 problem probable cause solution cabinet fan does not turn. Faulty electrical connections. Faulty cabinet fan. Check electrical connections. Replace cabinet fan. Limited or low flow restriction in humidifier/tubing. Product regulator set too low. Leak. Reduced air intake (suction). F...

Page 30: 6.4

Mn134-1 rev c 25 6.4 tool kit and pressure test gauge the tools needed for you to properly service the newlife intensity 10 unit are listed below: multi-adjustable pliers, wire cutters, needle-nose pliers, slotted-head screwdriver, phillips- head screwdriver, ratchet, adjustable wrench, 1-inch deep ...

Page 31

Mn134-1 rev c caire inc. 2200 airport industrial dr., ste 500 ball ground, ga 30107 www.Chartindustries.Com/respiratoryhealthcare caire reserves the right to discontinue its products, or change the prices, materials, equipment, quality, descriptions, specifications and/or, processes to its products ...