- DL manuals

- Animo

- Coffee Maker

- OptiFresh Bean NG

- Service Book

Animo OptiFresh Bean NG Service Book

Summary of OptiFresh Bean NG

Page 1

Optifresh bean ng model 2012 service book machine with taste optifresh ng.

Page 2

2 2016/01 rev. 0.3 optifresh (bean) ng table of contents foreword ........................................................................................................................... 5 1. Introduction optifresh ng ..................................................................................

Page 3

3 2016/01 rev. 0.3 optifresh (bean) ng en 4. Menu structure ............................................................................................................ 45 4.1 the operator and service menu 4.2 the operator menu ...........................................................................

Page 4

4 2016/01 rev. 0.3 optifresh (bean) ng 9 electronics overview ................................................................................................ 84 9.1 main control 9.1.1 main circuit board inputs .................................................................................. 85 9.1...

Page 5

5 2016/01 rev. 0.3 optifresh (bean) ng en © 2016 animo® all rights reserved. No part of this document may be reproduced and/or made public in print, microfilm, electronic media or any other form without the manufacturer’s prior consent. This also applies to the corresponding diagrams and/or charts. ...

Page 6

6 2016/01 rev. 0.3 optifresh (bean) ng 1. Introduction optifresh ng explanation optifresh ng type designation: designation meaning description cup volume dispensing hight cup thermos jug 1e digit number canisters 1 - 4 bean with grinder whole beans - cups / mugs 50-240ml 60-155mm 167mm ng next gener...

Page 7

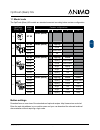

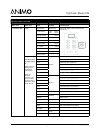

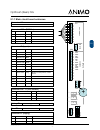

7 2016/01 rev. 0.3 optifresh (bean) ng en 1.1 model code the optifresh (bean) ng models are standard executed according below canister configuration. Optifresh (bean) ng model code canister configurations 1 2 3 4 5 1 1 2f 1b coffee (beans) 2 3 1 2f 2b coffee (beans) topping 2f 5b cocoa 2f 6b instant...

Page 8

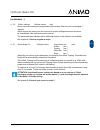

8 2016/01 rev. 0.3 optifresh (bean) ng 2. First menu settings after installation the following data must be set in the operator and service menus immediately after the machine’s first use. The language factory setting is english. Switch on the machine ● follow the instructions on the display out of ...

Page 9

9 2016/01 rev. 0.3 optifresh (bean) ng en (continued…) ● 2.2 button settings (set) every machine contains pre-programmed basic recipes. Each key can be changed, if required. Which recipes are factory-set can be found in recipes settings document which can be downloaded. See http://www.Animo.Eu/nl/sd...

Page 10

10 2016/01 rev. 0.3 optifresh (bean) ng (continued…) ● 2.3 recipe setting unit 1 start brewer pause 1 start 2 pause 2 (set) (extraction) start 3 pause 3 (set) (drying) start 4 pause 4 (set) (emptying) see the below table, which brewer setting in relation to the cup volume is recommended. Pause 1 pau...

Page 11

11 2016/01 rev. 0.3 optifresh (bean) ng en (continued…) reset display messages ● run the cleaning program (without cleaner) to reset the cleaning message place cup cleaning place cup 12:00 06-09-15 ● open the brewer chamber to reset the replace brewer filter message wait at least 30 seconds before c...

Page 12

12 2016/01 rev. 0.3 optifresh (bean) ng 2.1 how to program a recipe? Every machine contains pre-programmed basic recipes. Each key can be changed, if required. In below example button 1 will be change from coffee into cappuccino. 2.2 button settings │ └── 2.1.01 button 1 │ │ └─── recipe │ │ └───────...

Page 13

13 2016/01 rev. 0.3 optifresh (bean) ng en 2.2 how do you correct a recipe? Easy way to check the dispensed drink- volume and taste without leaving the menu! 2.1 quick recipe pro │ └── 2.1.01 coffee (recipe) │ │ │ └─── coffee │ │ cup volume │ │ │ │ │ └─ cup volume 120ml │ │ │ └─── coffee │ coffee(be...

Page 14

14 2016/01 rev. 0.3 optifresh (bean) ng 2.3 how do you measure the weight of an ingredient only? Only the grinder (of bean) / ingredient motor will be driven (no water is dispensed). It is strongly recommended to check the coffee measurement using a set of mini scales. These are simple to order via ...

Page 15

15 2016/01 rev. 0.3 optifresh (bean) ng en 2.4.2 grinder (optifresh bean) • there are two factors that affect the output of the coffee grinder. The set grinder duration ( 2.1 quick recipe pro / coffee) and the grinding fineness of the coffee grinder. • when the coffee grinder is set coarser, the vol...

Page 16

16 2016/01 rev. 0.3 optifresh (bean) ng 2.4.3 coffee waste hand dry (ideal) when the coffee waste is wiped from the filter it must be hand dry. The wiper wipes the coffee residue easy from the filter into the waste bin. Too wet when the coffee residue is too wet the brewer must use high force to wip...

Page 17

17 2016/01 rev. 0.3 optifresh (bean) ng en 2.4.4 troubleshooting problem probable cause action coffee does not taste strong enough. The used coffee is too course. Optifresh: prevent overdosing, use a ‘fresh brew’ coffee quality. This quality has coffee particles which are much smaller to shorten the...

Page 18

18 2016/01 rev. 0.3 optifresh (bean) ng problem probable cause action the coffee residue remains too wet. Coffee residue drops from both sides when the brewer chamber lifts. The permanent filter is dirty or worn. Clean or replace the permanent filter. The coffee residue is not being vacuumed long en...

Page 19

19 2016/01 rev. 0.3 optifresh (bean) ng en 2.5 detailed recipe settings to change detailed recipe settings (service menu 2.3) you first need to be aware of the various parts such as valves, brewer motor, ingredients motor and mixers that work together. See section 2.6 time bar recipe settings. The f...

Page 20

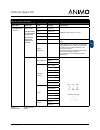

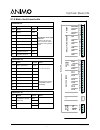

20 2016/01 rev. 0.3 optifresh (bean) ng 2.7 principles of operation unit 1 unit 2 unit 3 dv 1 dv 2 dv 3 brewer mixer 2 mixer 3 optifresh 4 optifresh 3 unit 1 unit 2 dv 1 dv 2 brewer mixer 2 optifresh 2 optifresh 1 dv 4 hot water kw 3 cold water dv 4 hot water kw 3 cold water coffee topping coffee co...

Page 21

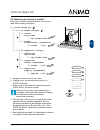

21 2016/01 rev. 0.3 optifresh (bean) ng en 3. Principles of operation item description item description 1. Coffee waste bin 9. Gear motor instant canister 2. Freshbrew group 10. Inlet valve 3. Gear motor brewer 11. Evaporation extractor ring 4. Coffee bean canister (of bean) 12. Mixer housing fresh ...

Page 22

22 2016/01 rev. 0.3 optifresh (bean) ng 3.1 water management code description code description wf water filter dv2 mixer 2 dispensing valve kw1 inlet valve dv3 mixer 3 dispensing valve nrv non-return valve dv4 hot water dispensing valve h1 boiler kw3 cold water inlet valve (h&c optional) t1 ntc sens...

Page 23

23 2016/01 rev. 0.3 optifresh (bean) ng en 3.2 components component image inlet valve kw1 [02801] opens and closes the water supply, 24 vdc coil closure. Water flow abt. 2,5 litre/min. Boiler open 3l boiler manufactured entirely from material aisi 316l , insulated. Temperature sensor [1000740] screw...

Page 24

24 2016/01 rev. 0.3 optifresh (bean) ng component image model optifresh ng is executed with a fresh brew canister (pre-grinded coffee) fresh brew canister [03400] the coffee canisters is powered by a 130rpm motor. The coffee is forced out of the canister by a coil and drops through the dispens- ing ...

Page 25

25 2016/01 rev. 0.3 optifresh (bean) ng en component image cup detection sensor [1003231] reflection infrared sensor. This sensor can optionally build in the machine door. This sensor checks whether there is a cup / mug positioned under the (correct) spout. See chapter 3 .3 cup detection for operati...

Page 26

26 2016/01 rev. 0.3 optifresh (bean) ng 3.3 cup detection (optional) the sensors detect the presence of a cup below the coffee outlet of the beverage dispenser. Coffee is only prepared when a cup has been placed. Also the outlet for hot water is equipped with a cup sensor. The sensitive sensors will...

Page 27

27 2016/01 rev. 0.3 optifresh (bean) ng en 3.4 fresh brew group the fresh brew group consists of a fresh brew unit [ 4 ] and an drive unit [ 5 ]. The drive unit carries a dc gear motor with drives the fresh brew unit (pre)grinded coffee [ 3 ] and hot water [ 4.1 ] are dispensed onto the permanent fi...

Page 28

28 2016/01 rev. 0.3 optifresh (bean) ng 3.4.1 operation after making a fresh brew drink selection the following process starts: position action start when the cycle is started, the piston starts moving upwards, while the brew chamber moves down (closing) to create a seal between the bottom of the ch...

Page 29

29 2016/01 rev. 0.3 optifresh (bean) ng en 3.4.2 wiper tension adjustment if a leak occurs between the brewer chamber [ 2 ] and the permanent filter [ 4 ] the tensile force of the brewer needs to be increased. The tensile force of the brewer should be set so that no water is able to leak between the...

Page 30

30 2016/01 rev. 0.3 optifresh (bean) ng 3.4.3 wiper adjustment tips wiper tension correct (ideal) if the brewer is adjusted correctly, the wiper moves carefully over the upper side of the cylinder and pushes the coffee residue off of the permanent filter. The wiper bends slightly. When the wiper mov...

Page 31

31 2016/01 rev. 0.3 optifresh (bean) ng en 3.4.4 removing the brewer group the brewer can be entirely removed for thorough cleaning and service. Removing the brewer: 1. Open the door of the machine and press the open/ close brewer button [1]. The brewer will turn into the ‘open’ position. 2. Remove ...

Page 32

32 2016/01 rev. 0.3 optifresh (bean) ng 3.5 drive unit the fresh brew unit [1] is driven by drive unit [2] with a 24vdc motor 5 rpm [2.1]. On the output shaft is a plastic connector [2.3] which drives the fresh brew unit [1]. A micro switch [2.5] controls the position of the fresh brew unit. The mic...

Page 33

33 2016/01 rev. 0.3 optifresh (bean) ng en 3.5.1 operation after making a fresh brew drink selection the following process starts: position brewer unit switch contact start the software always checks if the fresh brew unit is in its initial (start) position when the machine is switched on. If the pl...

Page 34

34 2016/01 rev. 0.3 optifresh (bean) ng 3.6 grinder (optifresh bean) the grinder is driven by a powerful dc motor [2.6]. The upper grinding disk [2.2] is fixed. The lower grinding disk [2.3] is driven by a drive belt [2.4]. The grind fineness can be set with an adjustment screw [2.5]. When the screw...

Page 35

35 2016/01 rev. 0.3 optifresh (bean) ng en 3.6.1 basic adjustment the coffee grinder is factory set for an average grind fineness. Warning • keep your fingers away from the grinding mechanism when the machine is in operation. Warning • if there is a sound of two stones rubbing against each other, ma...

Page 36

36 2016/01 rev. 0.3 optifresh (bean) ng 3.6.2 service life the service life of the ceramic grinding disks is approximately 3x longer than steel grinding disks. The service life depends on the type of coffee beans* and is approx. 3,000 kg of coffee beans. With an average measure of 7.5 g/sec. That ma...

Page 37

37 2016/01 rev. 0.3 optifresh (bean) ng en 3.6.5 drive belt replacement coffee grinder housing disassembly 1. Remove the bean- and instant canister [1] and remove the cover plate [2] behind it. 2. Disconnect the electrical connections to the small coffee grinder circuit board (via the rear wall). 3....

Page 38

38 2016/01 rev. 0.3 optifresh (bean) ng 3.6.5 cleaning depending on the fineness of the grind and the intensity of use, coffee residue collects in the grinder housing and on the grinding disks (fine particles, coffee oil, cof- fee residue), which can affect the grinding capacity, the measuring accur...

Page 39

39 2016/01 rev. 0.3 optifresh (bean) ng en 3.7 instant group the instant product (ingredient) is pushed out of the canister [ 1 ] by a worm screw and falls via the dispensing nozzle into the mixer unit [ 3.4 ]. At the same time, hot water is dispensed into the mixer unit. The instant product and the...

Page 40

40 2016/01 rev. 0.3 optifresh (bean) ng 3.7.1 ventilation mixer group the fan on the rear side of the machine ventilates the mixer group. The fan is easy to remove by turning the screw underneath. The fan speed can be adjusted in the service menu: 2.4 settings │ └── 2.4.05 ventilator │ └─── fan time...

Page 41

41 2016/01 rev. 0.3 optifresh (bean) ng en 3.8 boiler system turn on the device using the on/off switch. The display will light up. The magnetic valve [1.7] will open and the hot water reservoir [1] will be filled to the maximum level electrode [1.2]. The heating ele- ment will be switched on when t...

Page 42

42 2016/01 rev. 0.3 optifresh (bean) ng level regulation when a drink is being dispensed the water level drops and the maximum level electrode [1.2] is released; the inlet valve [1.7] (2.5 litres/min.) opens and immediately refills the reservoir until the maximum level [1.2] is reached again. If the...

Page 43

43 2016/01 rev. 0.3 optifresh (bean) ng en 3.8.1 dispensing valves after a drink has been selected one of the dispensing valves [dv] opens and lead the hot water to the brewer or mixer system. The flow rate of each valve is adjusted by means of the adjusting screw [2.5.3] on the valve. The outflow q...

Page 44

44 2016/01 rev. 0.3 optifresh (bean) ng 3.8.2 removing / replacing the hot water dispensing valves are accessible by dismantling the cover behind the ingredients canisters. 1. Switch off the machine. 2. Drain the water heater with the drain hose. Attention: hot water. 3. Take the coffee- and instant...

Page 45

45 2016/01 rev. 0.3 optifresh (bean) ng en 4. Menu structure 4.1 the operator / service menu most of the settings, including the product settings are secured by a pin code. This pin code is intended to prevent the user accessing the service menu. It is recommended not to leave this document with the...

Page 46: ▲

46 2016/01 rev. 0.3 optifresh (bean) ng • menu items are connected to each other in a ‘loop’. • exit the operator menu; press the x key 1x. • exit the service menu; press the x key 2x. • after exiting the service menu, a long peep signal follows as a sign that changed settings are being stored in th...

Page 47

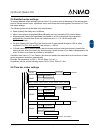

47 2016/01 rev. 0.3 optifresh (bean) ng en 4.2 the operator menu operator menu main item sub-item range set description 1.0 free vend yes-no yes set the machine for free or paid vending. 1.1 clock time hh:mm set the clock to the correct local time. Date dd-mm-yyyy set the clock to the correct local ...

Page 48

48 2016/01 rev. 0.3 optifresh (bean) ng example: three switching times set machine automatically switches from stand-by to on at 9 am. At 11am back to stand-by, etc., etc. During stand-by the key panel is switched off and the boiler temperature drops to the set stand-by temperature (menu 2.4 setting...

Page 49

49 2016/01 rev. 0.3 optifresh (bean) ng en operator menu continued... Main item sub-item range set description 1.3 recipe counters recipe 1 recipe 12 total cups total count per recipe (from free till jugs). Number of drinks free number of drinks paid low price number of drinks paid high price number...

Page 50

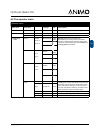

50 2016/01 rev. 0.3 optifresh (bean) ng 4.3 the service menu service menu main item sub-item range set description 2.1 quick recipe pro recipe name 1 recipe name 12 cup volume 50-200 ml 120ml use this for setting the volume and strength of coffee, milk, sugar and cocoa easily per recipe (drink key)....

Page 51

51 2016/01 rev. 0.3 optifresh (bean) ng en optilight optilight red green blue optilight red green blue colour recipes red 100% 0% 0% light blue 0% 100% 100% green 0% 100% 0% white 100% 100% 100% blue 0% 0% 100% pink 100% 0% 10% yellow 100% 50% 0% orange 100% 15% 0% table 1 purple 100% 0% 100% key sw...

Page 52

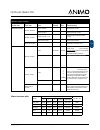

52 2016/01 rev. 0.3 optifresh (bean) ng service menu continued …. Main item sub item sub item range description 2.3 recipe setting 1 12 unit 1 dv 1 wt 0,0-30,0 s delay time water 1 dv 1 0-100 ml dispensing amount water 1 (brewer) rinse 1 wt 0,0-20,0 s delay time rinsing water 1 rinse 1 0-15 ml dispe...

Page 53

53 2016/01 rev. 0.3 optifresh (bean) ng en service menu continued… main item sub item sub item range description 2.3 recipe setting (continued…) 1 12 unit 3 dv 3 wt 0,0-30,0 s delay time water 3 dv 3 0-100 ml dispensing amount water 3 rinse 3 wt 0,0-20,0 s delay time rinsing water 3 rinse 3 0-15 ml ...

Page 54

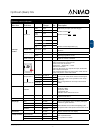

54 2016/01 rev. 0.3 optifresh (bean) ng service menu continued… main item sub item item range set- ting description 2.4 settings language english language choice display. Ex factory setting english. Nederlands (dutch) deutsch (german) français (french) svenska (swedish) norsk (norwegian) suomi (finn...

Page 55

55 2016/01 rev. 0.3 optifresh (bean) ng en service menu continued ... Main item sub-item item range set description 2.4 settings (continued...) coin system none no payment system connected g13 coin channel 1 coin channel 6 0-100.00 + token € 0.05 € 0.10 € 0.20 € 0.50 € 1.00 € 2.00 coin value per cha...

Page 56

56 2016/01 rev. 0.3 optifresh (bean) ng service menu continued ... Main item sub-item item range set description 2.4 settings (continued...) i/0 reset counters yes-no no add menu item reset counters to the operator menu. I/0 quick recipe yes-no no menu item snelrecept aan het opera- tormenu toevoege...

Page 57

57 2016/01 rev. 0.3 optifresh (bean) ng en service menu vervolg ... Hoofd item sub item item bereik set beschrijving 2.5 reset counters service counters rinse counter? Reset rinse counter. Clean counter? Reset cleaning counter. Recipe counters recipe counter 1 - 12 reset recipe counters for each rec...

Page 58

58 2016/01 rev. 0.3 optifresh (bean) ng service menu continued ... Main item sub-item sub range description 2.7 hardware test inputs temperature boiler temp shows the status of the sensors/switches concerned. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 17 18 1 2 3 4 5 16 level sensors high yes/no low yes/no...

Page 59

59 2016/01 rev. 0.3 optifresh (bean) ng en service menu continued…. Main item sub item sub range description 2.7 hardware test (continued...) calib. Valves test by holding in recipe button 11 (for 1 sec.). The relevant valve wil be opend for 10 seconds. Dv1 15 ml / sec calibrate to 150 ml (10 sec x ...

Page 60

60 2016/01 rev. 0.3 optifresh (bean) ng service menu continued ... Main item sub-item item description 2.8 read log last 20 error messages including time and date will be saved 2.9 erase log are you sure? Log will be erased 2.10 load defaults # see section 1.1 model codes model # of1 of4 type code 2...

Page 61

61 2016/01 rev. 0.3 optifresh (bean) ng en service menu continued ... Main item sub-item item description 2.11 sd menu (continued....) save data memory card memory card personal settings with this menu item personal settings can be saved on an sd memory card and/or copied to another machine. All cha...

Page 62

62 2016/01 rev. 0.3 optifresh (bean) ng service menu continued ... Main item sub-item item range set description 2.13 additional settings waste management cup amount 0-1000 130 after reaching the set total of brewer movements, dispensing is disabled and the display reads: out of order – waste bin fu...

Page 63

63 2016/01 rev. 0.3 optifresh (bean) ng en 5. Software 5.1 memory card specs type: sd (secure digital card) size: 16 mb or bigger 5.2 machine setting management the following changed settings can be saved on an sd memory card and/or copied to another machine: - personal settings - recipes the follow...

Page 64

64 2016/01 rev. 0.3 optifresh (bean) ng when loading new software the following changed settings (data) are lost: - changed recipes - changed personal settings - a non-standard language file will be overwritten by the standard language file nl/gb/du/fr counts, log and operating hours will be preserv...

Page 65

65 2016/01 rev. 0.3 optifresh (bean) ng en 6. Maintenance 6.1 daily rinsing program after 1 day the display shows rinse. This message will disappear again after the rinsing program is executed. 1. Activate the rinsing program [1a] and follow the instructions in the display. 2. The rinsing program ca...

Page 66

66 2016/01 rev. 0.3 optifresh (bean) ng 6.2 weekly cleaning program after 7 days appears the display shows cleaning. This message will disappear again after the cleaning program is executed. 1. Activate the cleaning program [1] and follow the instructions in the display. 2. The cleaning program for ...

Page 67

67 2016/01 rev. 0.3 optifresh (bean) ng en 6.3 change brewer filter monthly (or 4000 cups of coffee) the display shows change filter brewer. This message will disappear again until the entire program is executed. 1. Activate the brewer open / close “button [1] and follow the instructions in the disp...

Page 68

68 2016/01 rev. 0.3 optifresh (bean) ng 6.4 periodic maintenance 6.4.1 service boiler during installation of the machine the boilers service moment has been set. See service menu item 2.6 service boiler / 2.6.1 service moment during use, the drinks are counted. When the boiler service moment is reac...

Page 69

69 2016/01 rev. 0.3 optifresh (bean) ng en 6.4.3 service contracts preface preventative maintenance will lengthen the life cycle of the device and reduce the chance of malfunction. Before carrying out maintenance, read the safety instructions in the user manual, service manual, and recommended clean...

Page 70

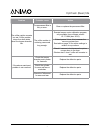

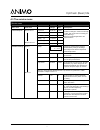

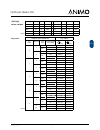

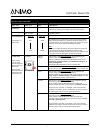

70 2016/01 rev. 0.3 optifresh (bean) ng service activity time product art.No. Optifresh (bean) 1 2 3 4 brewer 20,000 20 min. Perform maintenance at each of 20,000 brew cycles the brewer cleaning program with sachet coffee cleaner. 49009 03488 1x 1x 1x 1x brewer 40,000 20 min. Replace at least after ...

Page 71

71 2016/01 rev. 0.3 optifresh (bean) ng en service activity time product art.No. Optifresh (bean) 1 2 3 4 mixer(s) 10 min. Check the motor shaft for dirt and wear. Apply silicone grease to the water connection. Replace mixer blade. 03254 - 1x 1x 2x replace the seals in the green mixer mounting ring....

Page 72

72 2016/01 rev. 0.3 optifresh (bean) ng warning • the machine has to be opened to descale the water reservoir. This will expose parts under voltage that can easily be touched. This can lead to life threatening situations! Warning • do not leave the device during maintenance work. • when descaling al...

Page 73

73 2016/01 rev. 0.3 optifresh (bean) ng en 2 3. Remove the rear plate [ 2 ] and unscrew the reservoir lid [ 3 ]. Warning • hot ! 4. Read the warnings and instructions for use on the animo descaler sachets before dissolving two 50g sachets (8-10 dessert spoons) into 2 litres warm water. 5. Slowly pou...

Page 74

74 2016/01 rev. 0.3 optifresh (bean) ng 9. Disassemble the valves. There are three possibilities: a cleaning / descaling remove the seals and place them in a descaler solution. After the parts are cleaned build the valves back together. See section 3.5.1 dispensing valves a b c b fit a replacement s...

Page 75

75 2016/01 rev. 0.3 optifresh (bean) ng en rince! 12. Drain the boiler completely empty using the drain hose [ 8 ] and inspect if the boiler is clean. Repeat the above scaling procedure if there is still scale in the boiler. 13. Turn on the machine, the boiler refills with fresh water and heats up. ...

Page 76

76 2016/01 rev. 0.3 optifresh (bean) ng 6.6 maintenance freshbrew group 6.6.1 replacing the brewer cylinder and teflon seal the zuma brewer creates a vacuum that pulls hot water through the coffee grounds and the filter screen, and into the brewer cylinder. The brewer pauses prior to dispensing the ...

Page 77

77 2016/01 rev. 0.3 optifresh (bean) ng en 7. Remove the four old o-rings. These o-rings cannot be re-used and must be discarded. 8. Add a drop of lubri-film around the perimeter of each of the holes to temporarily hold these o-rings in place. 9. Insert a toothpick through the centre of the o-ring a...

Page 78

78 2016/01 rev. 0.3 optifresh (bean) ng maintanance freshbrew group (continuation) 6.6.2 replacing the t-bar & housing, crank arm, triple cam, and the brewer arms the following procedure will guide you through the steps required to remove the t-bar (and its housing), the crank arm, the triple cam, a...

Page 79

79 2016/01 rev. 0.3 optifresh (bean) ng en 7. Pull the two arms and the large spring connected to the arms out through the bottom of the mainframe. At this point in the procedure, the two arms can be completely removed. 8. Install the spring onto both of the brewer arms. Note that the each end of th...

Page 80

80 2016/01 rev. 0.3 optifresh (bean) ng 12. Once you are certain that the crank arm and triple cam are properly aligned, place a center punch in the centre of the crank arm shaft (on the side with the plastic crank arm), and give it one or two taps. If the two are properly aligned, the crank arm wil...

Page 81

81 2016/01 rev. 0.3 optifresh (bean) ng en 7. Transport / storage please do the following before transporting or putting the device in storage. 1. Carry out the brewer and mixer unit cleaning programme. 2. Clean the ingredient canister(s), mixer system, leaking tray and casing. 3. Switch off the dev...

Page 82

82 2016/01 rev. 0.3 optifresh (bean) ng 8. Component accessibility waste bin switch main switch ventilator sd-cardholder circuit board brewer coffee outlet bean canister mixer waste bin instant canisters fresh brew canister optifresh ng optifresh bean ng drip tray full sensor ingredient motors dispe...

Page 83

83 2016/01 rev. 0.3 optifresh (bean) ng en brewer motor solid state relais ginder print main pc board ginder pc board water reservoir boil dry safety level / ntc inlet valve 24v power supply.

Page 84

84 2016/01 rev. 0.3 optifresh (bean) ng 9. Electronics summary warning during repairs or maintenance work, avoid electrostatic discharge (esd) on the control unit. ● main pc board .............................................. 9.1 ● interface / display .......................................... 9.2 ...

Page 85

85 2016/01 rev. 0.3 optifresh (bean) ng en 9.1.1 main circuit board entrances connector j12 connector cable between the main circuit and door circuit connector j250 (pwm fan) pin fan colour notes 1 pwm signal black 2 - 3 pos red 4 neg blue connector j7 (inputs) pin sensor colour notes 1-2 - - 3 lb d...

Page 86

86 2016/01 rev. 0.3 optifresh (bean) ng 9.1.2 main circuit board exits connector j2 pin motor colour notes 17-18 brewer black pay attention to the right direction! Common +24 vdc (red wire) to red point on bre- wer, mixer and ingredient motor. 15-16 mixer 2 violet 13-14 mixer 3 pink 11-12 grinder si...

Page 87

87 2016/01 rev. 0.3 optifresh (bean) ng en 9.1.3 main circuit board communication the machine has standardized vending machine con- nections for connecting coin mechanism, coin changer or cashless payment systems. These connectors meet the mdb protocol for vending machines. For further information o...

Page 88

88 2016/01 rev. 0.3 optifresh (bean) ng 9.2 interface / display the interface connects all the components located in and on the door and is connected by a cable to the main control. 9.2.1 connections interface & display conn notes j100 main control j101 front membrane panel j102 service membrane pan...

Page 89

89 2016/01 rev. 0.3 optifresh (bean) ng en 9.3 power supply the 24 vdc supply consists of a 24 vdc – 65 w switched power supply and can be accessed by removing the rear wall. ● on an overload, the power supply switches itself off automatically. Reset the power supply by turning the main switch off a...

Page 90

90 2016/01 rev. 0.3 optifresh (bean) ng 9.4 grinder circuit board this grinder circuit board converts 230 vac (alternating current) into 230 vdc (direct current) with a rectifier to drive the grinder motor. (optifresh bean) the im1 signal (24 vdc) from the main control is connected to connection j5-...

Page 91

91 2016/01 rev. 0.3 optifresh (bean) ng en 10. Fault analysis warning ● when carrying out repairs and cleaning the device, the plug should always be removed from the wall socket before the device is opened. Preface before searching for the defect, check that all parts are in their correct position. ...

Page 92

92 2016/01 rev. 0.3 optifresh (bean) ng 10.3 display messages during use display possible cause action make your choice rinsing rinse program not activated in time. Run the rinse program and follow the instructions in the display. See chapter 5. Maintenance / 5.1 daily rinsing program make your choi...

Page 93

93 2016/01 rev. 0.3 optifresh (bean) ng en display possible cause action out of order waste bin missing waste bin is not detected. Check the waste bin. Out of order door open for safety reasons, the machine automatically switches off if the door is opened. The machine can be operated with the door o...

Page 94

94 2016/01 rev. 0.3 optifresh (bean) ng 10.4 troubleshooting display possible cause action out of order e1 level error minimum electrode error: mini- mum electrode detects no water but maximum electrode does. Inlet valve shuts. Check that the level sensors are func- tioning. See service menu 2.7 har...

Page 95

95 2016/01 rev. 0.3 optifresh (bean) ng en display possible cause action out of order e5 brewer error brewer was not returned to its initial position. Check the brewer switch and brewer motor function in the service menu 2.7 hardware test. Switch the device off and on again. Check break pin of brewe...

Page 96

96 2016/01 rev. 0.3 optifresh (bean) ng display possible cause action out of order e13 mixer error brewer and mixer output group overloaded (current too high). The control has disabled the output. Carry out the checks as specified for e7 and e8. Switch the machine off and on again. E14 output err. I...

Page 97

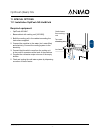

97 2016/01 rev. 0.3 optifresh (bean) ng en 11. Special options 11.1 installation optifesh ng hot&cold required equipment: • optifresh ng h&c • base cabinet with cooling unit [1001569]. 1. Build the cooling unit in the cabinet according the instructions supplied. 2. Connect the machine to the water (...

Page 98

98 2016/01 rev. 0.3 optifresh (bean) ng 11.2 installation optibean with waste to litter bin required equipment: • optifresh ng • base cabinet with access to litter bin [1001559] • top board with access to litter bin, [65031] small or [65032] large. 1. Build up the cabinet [ 1 ] according the instruc...

Page 99

99 2016/01 rev. 0.3 optifresh (bean) ng en 12. Payment systems 12.1 coin mechanism (optional) the optifresh is available with an optional coin mechanism suitable for euros (€0.05 - €2.00). Other currencies are available on request. The coin mechanism can also easily be programmed to accept tokens. I...

Page 100

100 2016/01 rev. 0.3 optifresh (bean) ng s1 s2 10x 10x 12.1.3 activating existing tokens the token shown here is programmed in the coin mechanism as standard. Configure the service menu as described in the following section from point 4. Token art. No. : 03344 12.1.4 programming a new token ● requir...

Page 101

101 2016/01 rev. 0.3 optifresh (bean) ng en 12.1.6 accepting tokens only (no euro’s) carry out sections 12.1.3 and 12.1.4 beforehand. 1. Open the service menu 2. Set to token using menu 2.2 button settings / button 1-12 / price. 3. Block the €0.05 - €2.00 coins using the coin mechanism dil switches ...

Page 102

102 2016/01 rev. 0.3 optifresh (bean) ng 1 2 3 4 5 7 8 9 10 6 12.2 coin changer (optional) the optifresh is available with an optional coin changer suitable for euros (€ 0.05 to 2.00). Other currencies are available on request. The changer has 6 change tubes (€ 0.05 / 2x 0.10 / 0.20 / 0.50 / 1.00). ...

Page 103

103 2016/01 rev. 0.3 optifresh (bean) ng en 12.2.3 programme a new token the token shown opposite is already programmed in the coin changer [token a]. For programming a new token {[b] see detailed token teach instructions in the nri technical documentation. Attention; switch the machine off/on twice...

Page 104

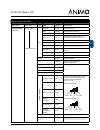

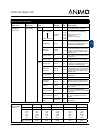

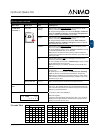

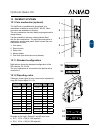

104 2016/01 rev. 0.3 optifresh (bean) ng 236 1008 coin sy st em (optional) 409 463 - 485 773 16 7 60 -1 15 575 coin sy st em (optional) coin sy st em (optional) 338 61 104 ~ volt optifresh ng 575 374 575 374 coin sy st em (optional) 802 163 569.

Page 105

105 2016/01 rev. 0.3 optifresh (bean) ng en coin sy st em (optional) 569 236 1008 coin sy st em (optional) 409 463 - 485 773 792 92 16 7 60 -1 15 575 coin sy st em (optional) coin sy st em (optional) 338 61 104 ~ volt 575 374 802 163 optifresh bean ng.

Page 106: Animo B.V.

Animo b.V. Dr. A.F. Philipsweg 47 9403 ad assen the netherlands tel. No. +31 (0) 592 376376 fax no. +31 (0) 592 341751 e-mail: info@animo.Nl www.Animo.Eu rev. 0.3 01/2016 art.Nr 1002019.

Page 107

107 2016/01 rev. 0.3 en.