- DL manuals

- Animo

- Coffee Maker

- OptiFresh

- Service Book

Animo OptiFresh Service Book

Summary of OptiFresh

Page 1

Nl gb d f service boek service book servicehandbuch manuel de service / maintenance.

Page 2

42 05/2008 rev. 0.6 content preface .....................................................................................................................................44 1. Basic functioning ..........................................................................................................4...

Page 3

05/2008 rev. 0.6 43 6. Component accessibility ............................................................................................70 6.1 electronics summary .......................................................................................................71 6.1.1 control unit ............

Page 4

44 05/2008 rev. 0.6 © 2008 animo® all rights reserved. No part of this document may be reproduced and/or made public in print, microfilm, electronic media or any other form without the manufacturer’s prior consent. This also applies to the corresponding diagrams and/or charts. Preface purpose of this...

Page 5

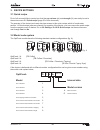

05/2008 rev. 0.6 45 1. Basic functioning 1. Waste bin 6. Fresh brew coffee canister 2. Hot water outlet 7. Coffee canister motor 3. Coffee outlet/drink outlet (instant) 8. Dispensing valves 4. Brewer 9. Water reservoir 5. Brewer motor 10. Inlet valve instant (optifresh 2 model and upwards) 11. Insta...

Page 6

46 05/2008 rev. 0.6 1.1 boiler system turn on the device using the on/off switch. The display will light up. The magnetic valve (fig. 1-10) will open and the hot water reservoir (fig. 1-9) will be filled to the maximum electrode. The heating element will be switched on. The display shows [ boiler fillin...

Page 7

05/2008 rev. 0.6 47 1.6 evaporation extractor system evaporation released during mixing is largely absorbed by the evaporation extractor ring (fig. 1-18) and sucked into the machine via the filter cassette (fig. 1-14). The evaporation and ingredient residue are absorbed by the filter. The filter (fig. 1-1...

Page 8

48 05/2008 rev. 0.6 1.7.1 adjustment if a leak occurs between the brewer unit and the permanent filter the tensile force of the brewer needs to be increased. The tensile force of the brewer should be set so that no water is able to leak between the brewer unit (fig. 3-1) and the permanent filter (fig. 3...

Page 9

05/2008 rev. 0.6 49 1.7.2 setting tips tensile force too low (fig. 4) tensile force correct (fig. 5) tensile force too high (fig. 6) if the wiper moves over the upper side of the cylinder it makes no contact with the permanent filter, so that coffee residue is left on the filter. The wiper does not bend ...

Page 10

50 05/2008 rev. 0.6 1.7.3 troubleshooting problem probable cause action the wiper pushes against the coffee residue when moving to the left. The brewer unit does not rise far enough. The brewer unit is hindered during the upward movement. Check if the brewer unit is able to move upwards freely. The ...

Page 11

05/2008 rev. 0.6 51 2. Menu structure 2.1 the operator/service menu the majority of settings, including product settings, are protected by a pin code. This pin code ensures that users do not gain access to the service menu. It is recommended not to leave this document with the user after installatio...

Page 12

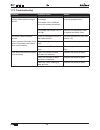

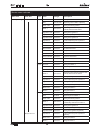

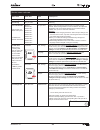

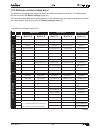

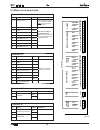

52 05/2008 rev. 0.6 2.2 the operator menu operator menu main item sub item item range set description 1.0 free dispensing yes/no yes set the device to free or paid dispensing here. 1.1 clock time hh:mm set the clock to the correct local time here. Date dd-mm-jjjj set the clock to the correct local t...

Page 13

05/2008 rev. 0.6 53 2.3 the service menu service menu main item sub item item range set description 2.1 quick recipe recipe name 1 recipe name 12 cup volume 50-200 ml 120ml use this for setting the volume and strength of coffee, milk, sugar and cocoa easily per recipe (drink key). Only the ingredien...

Page 14

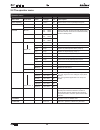

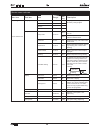

54 05/2008 rev. 0.6 service menu continued …. Main item sub item sub item range description 2.3 recipe setting recipe name 1 recipe name 12 unit 1 dv 1 wt 0,0-30,0 s waiting time water 1 dv 1 0,0-100,0 ml dispensing amount water 1 (brewer) rinse 1 wt 0,0-20,0 s waiting time rinsing water 1 rinse 1 0...

Page 15

05/2008 rev. 0.6 55 service menu continued …. Main item sub item sub item range description 2.3 recipe setting (continued…) recipe name 1 recipe name 12 dv 4 wt 0,0-30,0 s waiting time water 4 dv 4 0,0-100,0 ml dispensing amount water 4 (hot water dispensed) dv 5 wt 0,0-30,0 s waiting time water 5 d...

Page 16

56 05/2008 rev. 0.6 service menu continued… main item sub item item range set- ting description 2.4 settings * from software 2.0 language english language choice display. Ex factory setting english. Dutch german french temperature temp. Boiler 70-97°c * 95°c * boiler temperature standard model 1a - ...

Page 17

05/2008 rev. 0.6 57 service menu continued ….. Main item sub item item range set- ting description 2.4 settings (continued…) * from software 2.0 coin system g13 coin channel 1 coin channel 6 0-100,00 + token € 0,05 € 0,10 € 0,20 € 0,50 € 1,00 € 2,00 coin value setting for each channel. €0.05-€2 resp...

Page 18

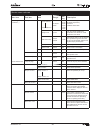

58 05/2008 rev. 0.6 service menu continued…. Main item sub item sub range description 2.7 hardware test inputs temperature boiler temp shows the status of the sensors/switches indicated level sensors high yes/no low yes/no drip tray sensor yes/no waste bin yes/no door switch yes/no brewer switch yes...

Page 19

05/2008 rev. 0.6 59 service menu continued…. Main item sub item item description 2.8 read log saves last 20 error messages, including date and time 2.9 clear log are you sure? Clears log 2.10 load defaults # see chapter 3.2 model code system * available from software version 2.0 model # of1a xx00 of...

Page 20

60 05/2008 rev. 0.6 service menu continued… main item sub item item range set description 2.13 addit. Settings from software 2.0 moved to menu 2.4.10 waste manag. Cup amount 0-1000 250 after reaching the set total of brewer movements, dispensing is disabled and the display reads: out of order – wast...

Page 21

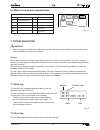

05/2008 rev. 0.6 61 3. Recipe settings 3.1 quick recipe first of all we would like to remind you that the cup volume (ml) and strength (%) can easily be set in the service menu 2.1 quick recipe (page 53 of this document). The operator of the device (end user) also has access to this quick recipe, wh...

Page 22

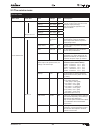

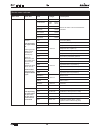

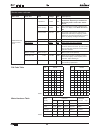

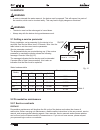

62 05/2008 rev. 0.6 3.3 button settings 3.3.1 standard canister configuration the standard of programmed recipes (table 3) can easily be transferred over the 12 recipe buttons. See service menu 2.2 button settings (page 53). The optional recipes table are already contained in the software and can eas...

Page 23

05/2008 rev. 0.6 63 3.3.2 different canister configuration* the standard of programmed recipes (table 4) can easily be transferred over the 12 recipe buttons. See service menu 2.2 button settings (page 53). The optional recipes table are already contained in the software and can easily be programmed ...

Page 24

64 05/2008 rev. 0.6 3.4 detailed recipe settings to change detailed recipe settings (service menu 2.3) you first need to be aware of the various parts such as valves, brewer motor, ingredients motor and mixers that work together. See section 3.5 timebar recipe settings. The following rules should be ...

Page 25

05/2008 rev. 0.6 65 dv 1 = 15ml/sec. (brewer) dv 4 = 20ml/sec. (hot water) dv 2 = 15ml/sec. (mixer 2) dv 3 = 15ml/sec. (mixer 3) dv 5 = 20ml/sec. (option brewer by-pass) 3.6 calibrating the hot water valves the brewer and mixers are supplied with water by the dis- pensing valves (dv). In the unlikel...

Page 26

66 05/2008 rev. 0.6 5.0 service warning • in order to descale the water reservoir, the device must be opened. This will expose live parts of the machine, which can be touched easily. This may lead to highly dangerous situations! Warning • the device must not be submerged or hosed down. • always stay...

Page 27

05/2008 rev. 0.6 67 water filter we strongly advise you to use a water softener and/or water filter if the mains water is heavily chlorinated or is too hard. This increases the quality of the drink and will ensure that you do not have to descale the device too often. Brewer unit in some cases, a subst...

Page 28

68 05/2008 rev. 0.6 warning • do not leave the device during maintenance work. • when descaling always follow the instructions for the descaler used. • it is advisable to wear safety goggles and protective gloves when descaling. • after descaling, allow the device to run a minimum of three times. • ...

Page 29

05/2008 rev. 0.6 69 6. Pour the acid solution into the reservoir (fig. 14-1). The acid solution will now react with the lime scale. 7. Leave the solution to soak for a minimum of 10 minutes, until the foaming has stopped. 8. Use a brush to spread the acid over the level electrodes during the soaking ...

Page 30

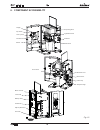

70 05/2008 rev. 0.6 6. Component accessibility water reservoir boil dry safety level / ntc control unit drip tray full sensor inlet valve door switch waste bin senso main switch brewer motor power relay 24v power supp ventilator ingredient motors dispensing valves display key switch service panel ci...

Page 31

05/2008 rev. 0.6 71 6.1 electronics summary warning during repairs or maintenance work, avoid electrostatic discharge (esd) on the control unit. ● control unit ........................................ 6.1.1 ● power supply 230vac:24v 65w ........ 6.1.2 ● circuit board ...................................

Page 32

72 05/2008 rev. 0.6 6.1.2 interface / display the interface (fig. 17) connects all components found inside and on the door with the main control unit via a flat cable. 6.1.3 power supply the 24 v dc power supply (fig. 18) consists of a 24v dc 65w switch mode power supply and can be accessed by removing...

Page 33

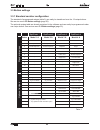

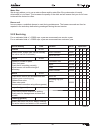

05/2008 rev. 0.6 73 6.2 main circuit board entrances connector j12 connector cable between the main circuit and door circuit connector j7 pin sensor colour comments 1-2 - 3 drip tray sensor yellow 4 drip tray sensor mass black 5 level sensor low brown 6 level sensor mass green 7 level sensor high wh...

Page 34

74 05/2008 rev. 0.6 6.3 main circuit board exits connector j2 pin motor colour comments 17-18 brewer / mixer 1 black correct direction of rota- tion = red wire (+24vdc) not on red spot of the brewer motor 15-16 mixer 2 violet take care to rotate in the right direction! Shared +24 dc (red wire) on re...

Page 35

05/2008 rev. 0.6 75 6.4 main circuit board communication communication conn comments g13 coin tester nri g13 mdb future port csi future port rs232 future port usb future port 7. Troubleshooting warning ● when carrying out repairs and cleaning the device, the plug should always be removed from the wa...

Page 36

76 05/2008 rev. 0.6 7.3 troubleshooting display messages and errors possible cause action out of order boiler filling when used for the first time: boiler is still empty and is being filled. No action required. When boiler reaches the appropriate level, the display will show 'boiler is heating up'. Dur...

Page 37

05/2008 rev. 0.6 77 display messages and errors possible cause action out of order e4 brewer error brewer was not started from its initial position. Brewer motor not turning. Check the brewer motor function in the service menu 2.7 hardware test . Switch the device off and on again. Out of order e5 b...

Page 38

78 05/2008 rev. 0.6 8. Coin mechanism (optional) the optifresh is available with an optional coin mechanism suitable for euros (€0.05 - €2.00). Other currencies are available on request. The coin mechanism can also easily be programmed to accept tokens. It is also possible to have an existing device...

Page 39

05/2008 rev. 0.6 79 8.3 activating existing tokens the token shown here (fig. 26) is programmed in the coin mechanism as standard. Configure the service menu as described in the following section from point 4. Token art. No. : 03344 8.4 programming a new token ● required: 10 tokens ● attention: rememb...

Page 40

80 05/2008 rev. 0.6 8.6 accepting tokens only carry out sections 5.3.3 and 5.3.4 beforehand. 1. Open the service menu 2. Set to token using menu 2.2 button settings / button 1-12 / price. 3. Block the €0.05 - €2 coins using the coin mechanism dil switches and the table below. 4. The recipe buttons a...

Page 41

Animo b.V. Headoffice dr. A.F. Philipsweg 47 p.O. Box 71 9400 ab assen the netherlands tel. No. +31 (0)592 376376 fax no. +31 (0)592 341751 e-mail: info@animo.Nl internet: http://www.Animo.Eu rev. 0.6 05/2008 art.Nr 09782.