- DL manuals

- Anritsu

- Measuring Instruments

- MP1632C

- Operation Manual

Anritsu MP1632C Operation Manual

Summary of MP1632C

Page 1

Anritsu mp1632c manual get pricing & availability at apexwaves.Com call today: 1-800-915-6216 email: sales@apexwaves.Com https://www.Apexwaves.Com/analyzers/anritsu/data-analyzer/mp1632c.

Page 2: Anritsu Corporation

Document no.: m-w1859ae-6.0 anritsu corporation mp1632c digital data analyzer operation manual for safety and warning information, please read this manual before attempting to use the equipment. Keep this manual with the equipment. Sixth edition.

Page 3: Danger

Ii safety symbols to prevent the risk of personal injury or loss related to equipment malfunction, anritsu corporation uses the following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the symbols before using the equipment. Some or all of t...

Page 4: Warning

For safety iii warning 1. Always refer to the operation manual when working near locations at which the alert mark shown on the left is attached. If the advice in the operation manual is not followed there is a risk of personal injury or reduced equipment performance. The alert mark shown on the lef...

Page 5: Warning

For safety iv warning 4. This equipment cannot be repaired by the operator. Do not attempt to remove the equipment covers or unit covers or to disassemble internal components. Only qualified service personnel with a knowledge of electrical fire and shock hazards should service this equipment. There ...

Page 6: Caution

For safety v caution 1. Always remove the mains power cable from the power outlet before replacing blown fuses. There is a risk of electric shock if fuses are replaced with the power cable connected. Always use new fuses of the type and rating specified on the rear panel of the instrument. There is ...

Page 7: Caution

For safety vi caution this equipment uses a poly-carbomonofluoride lithium battery to backup the memory. This battery must be replaced by service personnel when it has reached the end of its useful life; contact the anritsu sales section or your nearest representative. Note: the battery used in this...

Page 8: Equipment Certificate

Vii equipment certificate anritsu corporation certifies that this equipment was tested before shipment using calibrated measuring instruments with direct traceability to public testing organizations recognized by national research laboratories, including the national institute of advanced industrial...

Page 9

Viii notes on export management this product and its manuals may require an export license/approval by the government of the product's country of origin for re-export from your country. Before re-exporting the product or manuals, please contact us to confirm whether they are export-controlled items ...

Page 10

Ix crossed-out wheeled bin symbol equipment marked with the crossed-out wheeled bin symbol complies with council directive 2002/96/ec (the “weee directive”) in european union. For products placed on the eu market after august 13, 2005, please contact your local anritsu representative at the end of t...

Page 11: Software License Agreement

X software license agreement please read this software license agreement before using the accompanying software program (hereafter this software). You are authorized to use this software only if you agree to all the terms of this license. By opening the sealed package containing this software, you a...

Page 12

Xi end-user license agreement for microsoft software important-read carefully: this end-user license agreement ("eula") is a legal agreement between you (either an individual or a single entity) and the manufacture(“manufacturer”) of the special purpose computing device(“system”) you acquired which ...

Page 13

Xii 4. Copyright. All title and copyrights in and to the software (including but not limited to any images, photographs, animations, video, audio, music, text, and "applets" incorporated into the software), the accompanying printed materials, and any copies of the software are owned by microsoft or ...

Page 14: Ce Conformity Marking

Xiii ce conformity marking anritsu affixes the ce conformity marking on the following product(s) in accordance with the council directive 93/68/eec to indicate that they conform to the emc and lvd directive of the european union (eu). Ce marking 1. Product model model: mp1632c digital data analyzer,...

Page 15: C-Tick Conformity Marking

Xiv c-tick conformity marking anritsu affixes the c-tick marking on the following product(s) in accordance with the regulation to indicate that they conform to the emc framework of australia/new zealand. C-tick marking 1. Product model model: mp1632c digital data analyzer, and expansion unit 2. Appl...

Page 16: Power Line Fuse Protection

Xv power line fuse protection for safety, anritsu products have either one or two fuses in the ac power lines as requested by the customer when ordering. Single fuse: a fuse is inserted in one of the ac power lines. Double fuse: a fuse is inserted in each of the ac power lines. Example 1: an example...

Page 17

Xvi.

Page 18: Introduction

I introduction organization of operation manuals the mp1632c digital data analyzer is the main unit of the measuring equipment into which the plug-in units can be installed. Operation manuals have been prepared for the main unit and the other units, respectively, and consist of the following four op...

Page 19: Contents

Ii contents chapter 1 overview......................................................................................................1 1.1 product overview ........................................................................................................................... 2 1.2 structure of op...

Page 20

Iii 5.5 entering data.......................................................................................................................................47 5.6 using software keyboard ....................................................................................................................

Page 21

Iv 8.4 calibration ............................................................................................................................................99 8.5 scrapping ...............................................................................................................................

Page 22: Chapter 1 Overview

1 chapter 1 overview.

Page 23

2 1.1 product overview the mp1632c digital data analyzer (hereafter simply called 'the instrument') is the mainframe into which various plug-in units can be installed to configure various systems. Combining the instrument and other units enabled various digital communication equipment, the modules s...

Page 24

3 1.2 structure of operation manual the operation manual consists of the following nine chapters. Chapter number description chapter 1 overview product overview, structure of operation manual, equipment configuration, and specifications chapter 2 setup environmental conditions of installation locati...

Page 25

4 1.3 equipment configuration 1.3.1 standard configuration the standard configuration of the instrument is shown in the following table. Table 1-1 standard configuration item model name and symbol product name quantity remarks equipment configuration mp1632c digital data analyzer 1 accessories suppl...

Page 26

5 1.3.2 list of units the plug-in units that can be inserted in the instrument are shown in the following table. Table table table table 1111----2222 list of units list of units list of units list of units item product name remarks mu163220c 3.2g pulse pattern generator the pulse pattern generator o...

Page 27

6 1.3.3 list of options the options that can be used in the instrument are shown in the following table. Table table table table 1111----3333 list of options list of options list of options list of options item product name remarks mp1632c*01 gpib gpib interface board mp1632c*02 ethernet ethernet in...

Page 28

7 1.4 specifications the specifications of the instrument are shown in table 1-5. The items marked by asterisk (*) require installation of options. Their contents are shown outside the table. Table table table table 1111----5555 specifications (1/2) specifications (1/2) specifications (1/2) specific...

Page 29

8 table 1-5 table 1-5 table 1-5 table 1-5 specifications (2/2) specifications (2/2) specifications (2/2) specifications (2/2) item specifications dimensions and weight dimensions weight 426(W), 221.5(h), 451(d) mm 20 kg or less (when no units are inserted, without opt03) 25 kg or less (when no units...

Page 30: Chapter 2 Setup

9 chapter 2 setup.

Page 31

10 2.1 ambient conditions the instrument operates under the ambient temperature of 5℃ to 45℃, and ambient humidity of 85% or less. For storage, store the instrument under the ambient temperature of -20℃ to 60℃, and ambient humidity of 85% or less. Avoid using the instrument in the following location...

Page 32

11 2.2 safety precautions for safety assurance's sake, observe the safety precautions given below. For tips on starting and stopping the instrument, see chapter 4, "starting and stopping the mp1632c." 1. Before connecting the ac power cord, be sure to confirm that the power switch of the instru- men...

Page 33

12 8. Do not turn off the main power of the instrument while the hard disk access lamp on the front panel is illuminating. If not, the hard disk can be damaged. 9. Do not use anything other than the supplied unique pen and fingers to operate the touch panel. 10. Never open the instrument. There can ...

Page 34

13 2.3 connecting the power cord check that the power switch on the front panel is turned off (switched to the (o) side). Insert the power plug into an outlet, and connect the other end to the power inlet on the rear panel. To ensure that the instrument is grounded, always use the supplied 3-pin pow...

Page 35

14 (blank).

Page 36

15 chapter 3 panel description and connections.

Page 37

16 3.1 panel description the view of the instrument's front and rear panels are shown below, along with a summary descrip- tion of their component functions. Front panel panel lock hdd a . 1 4 7 m/k enter shift p/g n/m c _ 3 6 9 d tab bs f e b 0 2 5 8 mp1632a remote digital data analyzer (1) (2) (3)...

Page 38

17 rear panel (1) (2) (3) (4) (5) (6) (7) (8) (9) (11) (13) f 8a rs-232c (com1) keyboard m ouse crt optio n-01 ~lin e 4 7.5-63 hz 1kva max pri nt er (12) option-03 3.2g internal synthesizer clock(0.05-3.2ghz) output 1.0vp-p 50Ω ! Input 0.5 - 2 . 0vp-p 50Ω ! Output 1 . 0v p-p 50Ω ! Lock(10mhz) (10) f...

Page 39

18 the view of the 3.2g internal synthesizer (opt03) rear panel is shown below, along with a summary description of its component functions. Option-03 3.2g internal synthesizer clock(0.05-3.2ghz) output 1.0v p-p 50Ω ! Input 0. 5-2. 0vp- p 50 Ω ! Output 1. 0vp- p 50 Ω ! Lock(10mhz) (1) (2) (3) fig. F...

Page 40

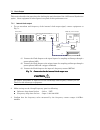

19 3.2 connections 3.2.1 sample connections of peripherals a mouse, a keyboard, a printer, an external display, and a personal computer (used as a controller) can be connected to the instrument's rear panel. Sample connections are shown below. C1,c2,c3,c4,c7. Opton-01 90ナ246v prnter ナ`line 47.5-63hz...

Page 41

20 3.2.2 connecting peripherals procedures for connecting peripherals to the instrument are described below, along with tips. Mouse connect the ps/2 mouse (supplied with the instrument as a standard accessory) to the rear-panel mouse connector while the instrument is off, and then turn it on. The mo...

Page 42

21 external display an external display connected to the instrument provides high-resolution display images. To connect an external display to the instrument, follow these steps. 1. Connect an external display to the rear-panel vga connector while the instrument is off. 2. Turn on the instrument. Th...

Page 43

22 3.2.3 connection between 3.2g internal synthesizer and unit this section describes how to connect 3.2g internal synthesizer to another unit inserted in the mp1632c. Z connection between 3.2g internal synthesizer and ppg slot3 : mu163220c 3.2g pulse pattern generator cable : sma cable f 8a rs-232c...

Page 44

23 z connection from peripherals cable : bnc cable f 8a rs-232c (com1) keyboard mouse crt option-01 ~line 47.5-63hz 1kva max printer option-03 3.2g internal syntesizer mu163220a 3.2g pulse pattern generator clock(0.05-3.2ghz) output 1.0vp-p 50Ω lock(10mhz) input 0.5-2.0vp-p 50Ω ! Output 1.0vp-p 50Ω ...

Page 45

24 (blank).

Page 46

25 chapter4 starting and stopping the mp1632c.

Page 47

26 4.1 starting and stopping the mp1632c microsoft® ms-dos® operating system and microsoft® windows® operating system (hereafter simply called windows®) are used as display control software in the instrument, so that you can run the application for the instrument the same way as you do applications ...

Page 48

27 4.2 definitions of keywords because the instrument supports windows®, windows® terms are sometimes used in its context in this user's guide. Windows® terms and operations frequently mentioned in this guide are defined below. General terms general terms appearing in the user's guide are defined be...

Page 49

28 note the instrument has a touch screen, which can be operated by touching it. Touch screen operations are essentially similar to mouse operations, except that the function of the right mouse button is not supported. Think of the function of pressing the left mouse button as touching the screen su...

Page 50

29 z control menu box click to open the control menu, from which the window can be maximized, minimized, and so on. Additionally, to close the window double-click it. Fig. Fig. Fig. Fig. 4444----3333 control menu control menu control menu control menu z minimize button click to minimize the window, ...

Page 51

30 menu actions may have choices of items. When an item is selected, it is marked by a check mark (fig. 4-5). Click another item the clicked item is marked by a check mark check mark fig. Fig. Fig. Fig. 4444----5555 menu with a check mark menu with a check mark menu with a check mark menu with a che...

Page 52

31 z to maximize a window click the maximize button in the window, and the window will be enlarged to the full size of the screen. The window will also be maximized by double-clicking the title bar. When the window is maximized, the maximize button changes to a restore button to restore the window t...

Page 53

32 controls the controls used with the instrument are defined below. Group box option button check boxes command button list box text box spin box dropdown list box fig. Fig. Fig. Fig. 4444----8888 control control control control z command button a rectangular button labeled with a function name. Cl...

Page 54

33 z group box a frame or box that encloses a set of related controls..

Page 55

34 (blank).

Page 56

35 chapter 5 display description.

Page 57

36 5.1 kinds of displays the instrument has a number of setup displays and windows, which can be grouped into four broad categories according to their operation and functions. In this user's guide, these displays and win- dows are called by the names mentioned below. Parent window subwindow panel c ...

Page 58

37 fig. Fig. Fig. Fig. 5555----2222 dialog box dialog box dialog box dialog box z dialog box a window that is opened by clicking a command button or selecting a menu on a panel. Once you open a dialog box with the instrument, you cannot operate other window unless you close it. Dialog boxes are norm...

Page 59

38 5.2 window organization 5.2.1 window hierarchy the hierarchy of the parent window, subwindows, and panels supported by the instrument with a 3.2g internal synthesizer (opt03), a pulse pattern generator (ppg), and an error detector (ed) unit installed in it. For descriptions of the shaded displays...

Page 60

39 5.2.2 organization of panel display images the instrument can house a number of units. Setup and measurement data information is available in a unit-specific manner. Panels display setup and measurement data information in the following organizations: z displaying information on multiple units in...

Page 61

40 z displaying information on a single unit and the instrument the 'setup:frequency' panel, the 'result:eye margin' panel, and so on each display information on one unit at a time. Unlike the organization described above, no unit-specific group boxes ex- ist in this case. Group box for the units in...

Page 62

41 5.2.3 toolbar organization the instrument provides a number of icons on the toolbar. The icons are in the form of buttons asso- ciated with frequently used functions. When buttons are pressed, their corresponding functions are executed. The table below defines the functions corresponding to the i...

Page 63

42 5.3 opening and closing windows 5.3.1 opening and closing subwindows and switching their displays procedures for opening and closing subwindows and switching their displays are described. Opening and closing a subwindow to open a subwindow click a subwindow open/close button in the parent window....

Page 64

43 switching subwindow displays you can maximize an open subwindow or switch its display. Z to maximize a subwindow click the maximize button. The subwindow will then be maximized in the parent window. Z to return a maximized subwindow to its original size when a subwindow is maximized, the maximize...

Page 65

44 z to display open subwindows side by side select [window]-[tile] from the parent window menu bar. Multiple open subwindows will be displayed, side by side, in the parent window. Fig. Fig. Fig. Fig. 5555----7777 windowmenu windowmenu windowmenu windowmenu z to display open subwindows overlapped se...

Page 66

45 5.3.2 switching panels subwindows contain multiple panels each. You cannot view multiple panels of a single subwindow at once. C c tab click option tab click system tab c c c fig. Fig. Fig. Fig. 5555----8888 switching panels switching panels switching panels switching panels z to display a hidden...

Page 67

46 5.4 basic setup procedures with the instrument, settings are normally changed by opening dialog boxes. (some settings are changed on panels.) this section describes how to change instrument settings via dialog boxes. C setup…button click setup…button click ok button or click cancel button fig. Fi...

Page 68

47 5.5 entering data with the instrument, the following methods are used to manipulate displays: z mouse manipulations you can run the application for the instrument the same way as you do windows® applica- tions on a personal computer. Z touch screen manipulations the instrument's touch screen offe...

Page 69

48 procedures for entering data are described below, along with operational differences, with pri- mary regard to the usage of the front-panel keys and the rotary encoder. Moving from one control to the next in a window where multiple controls exist in a single window, you can move the focus from on...

Page 70

49 entering data with spin boxes you can use spin boxes and the rotary encoder to enter numeric values. 1. Move the focus to the spin box to manipulate. When the spin box becomes the focus, a digit of the numeric value is highlighted. 2. Select the digit to change by moving the highlighted cursor, i...

Page 71

50 using controls to manipulate controls with panel keys, follow these steps. Z command button manipulations 1. Move the focus to the command button. 2. Press the [enter] key. The function associated with the button is executed. Z drop-down list boxes 1. Move the focus to the drop-down list box to b...

Page 72

51 5.6 using software keyboard 5.6.1 character input the front panel of the instrument provides only the strict minimum of keys for numerical input. Therefore, a software keyboard is provided as an auxiliary function for character input. The software keyboard allows character input even when no keyb...

Page 73

52 5.6.2 setting the software keyboard the size and display format of the software keyboard provided with the instrument can be changed to suit each usage condition. Z changing the size click the button at the top left of the software keyboard to open the control box. Click the size in the menu, and...

Page 74

53 z saving setup data click the button at the top left of the software keyboard to open the control box. When click save in the menu, current setup data is saved. Fig. Fig. Fig. Fig. 5555----15 15 15 15 saving setup data saving setup data saving setup data saving setup data.

Page 75

54 (blank).

Page 76

55 chapter 6 operating instructions.

Page 77

56 6.1 touch screen calibration the instrument allows you to carry out display operations via the touch screen. The touch screen requires preliminary adjustment to ensure that the location of the display surface touched will be correctly transmitted to the software. To adjust the touch screen, follo...

Page 78

57 6.2 saving and opening setup data 6.2.1 saving setup data with the instrument, you can save setup data to floppy disks or hard disk. There are two ways to save setup data as follows: z quick save this function saves multiple records of data, such as instrument setup data and unit-specific set- up...

Page 79

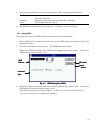

58 quick save procedure 1. Select [file]-[quick save] from the parent window menu bar. The quick save dialog box will open. 3 4 5 2 c c fig. Fig. Fig. Fig. 6666----1111 quick save dialog box quick save dialog box quick save dialog box quick save dialog box 2. Using the directories and drives control...

Page 80

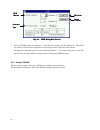

59 save procedure 1. Select [file]-[save] from the parent window menu bar. The save dialog box will open. 4 2 5 3 c c fig. Fig. Fig. Fig. 6666----2222 save dialog box save dialog box save dialog box save dialog box 2. Select the type of file to save from the type of save file drop-down list box. Mai...

Page 81

60 6.2.2 opening setup data with the instrument, you can open setup data or measurement data from floppy disks or hard disk. There are two ways to open setup data as follows: z quick open this function opens multiple records of data, such as instrument setup data and unit-specific setup data, all at...

Page 82

61 4. You may check the comment check box to read the comment on the environmental file selected, or check the information check box to view the filenames of the various files managed by the en- vironmental file created. 5. The setup procedure is now complete. Click ok to open the data. Open procedu...

Page 83

62 6.2.3 manipulating files data written to floppy disks or hard disk can be manipulated from the file manager. The file manager provides functions for deleting, moving, copying, and otherwise manipulating files. For more detailed procedural information, see the help files for file manager. Note 1. ...

Page 84

63 6.3 choosing remote control 6.3.1 choosing remote control interfaces the instrument supports rs-232c, and gpib (option), ethernet(option) as remote control inter- faces. Setup procedures for using these interfaces are described bellow. 1. Open the 'system:system' panel. 2 fig. Fig. Fig. Fig. 6666...

Page 85

64 6.3.2 setting rs-232c procedures for selecting the rs-232c remote control interface are described below. 1. Select rs-232c (com1) from the remote drop-down list, and the rs-232c (com1) group box will open on the 'system:system' panel. 2. Click the setup button in the group box. The rs-232c (com1)...

Page 86

65 7. Sets the method of flow control by selecting it from the flow control drop-down list box. Xon/xoff implements flow control using the xon/xoff characters, in addition to the rs-232c control line. Hardware implements flow control using the rs-232c control line. None do not implement flow control...

Page 87

66 fig. Fig. Fig. Fig. 6666----8888 gpib dialog box gpib dialog box gpib dialog box gpib dialog box ( ( ( (native native native native)))) 4. Now, the gpib settings are completed. To enable the settings, click the ok button. To disable the settings and return the parameters to the original values, c...

Page 88

67 6.4 setting system operations the instrument can be toggled between the system mode in which power failure measurement is en- abled or not. 1. Open the 'system:system' panel. 2 fig. Fig. Fig. Fig. 6666----9999 system:system panel system:system panel system:system panel system:system panel 2. Clic...

Page 89

68 note in these modes the following functions are operable or inoperable: function function function function normal mode normal mode normal mode normal mode measurement measurement measurement measurement power fail mode power fail mode power fail mode power fail mode power failure measurement × ○...

Page 90

69 6.5 setting date and time this section describes how to set the date and time for the instrument. 1. Open the 'system:system' panel. 2 fig. Fig. Fig. Fig. 6666----11 11 11 11 system:system panel system:system panel system:system panel system:system panel 2. Press the setup button in the date & ti...

Page 91

70 4. Set the time by entering into the time spin box. The time will appear in hour-minute-second format. 0 to 23:step 1: sets from 0 to 23 hours. 0 to 59:step 1: sets from 0 to 59 minutes. 0 to 59:step 1: sets from 0 to 59 seconds. 5. The setup procedure is now complete. Press the ok button to enab...

Page 92

71 6.6 setting buzzer this section describes how to set the on or off of buzzer for the instrument. 1. Open the 'system:system' panel. 2 3 5 4 fig. Fig. Fig. Fig. 6666----13 13 13 13 system:system panel system:system panel system:system panel system:system panel 2. To switch error buzzer, press the ...

Page 93

72 6. Select the type of desired system error by pressing the corresponding check box. Checked sys- tem error becomes valid. Press the ok button to enable the settings. Description of each system error is below. (pll unlock (pll unlock (pll unlock (pll unlock)))) the pll circuit in the internal synt...

Page 94

73 6.7 checking occurred system error when a system error occurs a bell-button appears at upper right corner of the parent window. C bell-button fig. Fig. Fig. Fig. 6666----15 15 15 15 bell button bell button bell button bell button clicking this button opens a dialog box where the type of occurred ...

Page 95

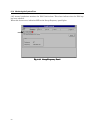

74 6.8 viewing the configuration of units inserted in the mp1632c 'system:option' panel lets you view the hardware system configuration and the software configura- tion of the instrument. It displays the following kinds of information: z hardware system configuration ・ kinds of units inserted in slo...

Page 96

75 2. The hardware system configuration and the software configuration of the instrument are dis- played. A dotted box means that the slot is empty or any other instruments current version of the soft- ware can control, is inserted the slot. Click the available unit button in the software group box,...

Page 97

76 6.9 printing out display images the instrument permits hard-copying display images to a printer. 1. Before carrying out a hard-copy operation, you need to set up the printer. Select [file]-[printer setup] from the parent window menu bar. The printer setup dialog box will open. 2 3 fig. Fig. Fig. ...

Page 98

77 6.10 resetting to factory defaults the instrument can be reset to its factory defaults by initializing its setup status and measurement data. 1. Select [file]-[initialize] from the parent window menu bar. 2. The instrument is reset to its factory defaults. Before initialization begins, a warning ...

Page 99

78 6.11 recovering software the instrument is controlled by microsoft® ms-dos® operating system, microsoft® windows® op- erating system, and other applications. The instrument may fail to work correctly if any part of the software is corrupted by hdd fails or invalid file manipulations. If this happ...

Page 100

79 recovery preparations complete the following preparations before beginning software recovery: 1. Connect an external keyboard to the instrument. The execution of the recovery software requires an external keyboard to be connected to the keyboard. Connect a keyboard to the rear-panel keyboard conn...

Page 101

80 recovery procedures the software recovery procedures are described below. Z system software recovery 1. After this system is ready for recovery, the recovery tool starts and the message below appears on the screen. When the message shown below appears, answer [y] to proceed with recovery and part...

Page 102

81 4. When the formatting is finished, files are copied to the hd. Replace fds according to the screen guidance. MP1632A --------recovery tool-------- insert disk no.2,and press [enter] 67% completed C fig. Fig. Fig. Fig. 6666----24 24 24 24 copying in progress copying in progress copying in progres...

Page 103

82 messages displayed during recovery the messages shown below may be displayed while recovery is in progress. Suggested responses are described below. 1. "one or more visual basic applications are running. One or more visual basic applications are running. One or more visual basic applications are ...

Page 104

83 2. “can not copy file a: can not copy file a: can not copy file a: can not copy file a: ctl3d.Dl_ since the destination file is already in use ctl3d.Dl_ since the destination file is already in use ctl3d.Dl_ since the destination file is already in use ctl3d.Dl_ since the destination file is alre...

Page 105

84 6. "the main frame version isn't compatible with this application the main frame version isn't compatible with this application the main frame version isn't compatible with this application the main frame version isn't compatible with this application" this message is displayed when the instrumen...

Page 106

85 6.12 using the mp1632c menu when the instrument application is terminated and then windows® exited, the mp1632c menu program starts running, allowing the following menu of functions to be executed: 1. Mp1632c startup 2. Defrag 3. Scandisk 4. Windows setup 5. Mp1632c startup with default settings ...

Page 107

86 scandisk select 3 in response to select number on the menu, the ms-dos® command scandisk will start running. The scandisk command analyzes the status of the disk and correct errors. Proceed to run scan- disk as directed by the screen guidance. Note if you continue using a hard disk without correc...

Page 108

87 mp1632c startup with default settings select 5 in response to select number on the menu and mp1632c application will start with all set- ting initialized after windows® start..

Page 109

88 6.13 setting a frequency 3.2g internal synthesizer can generate clock pulses within the frequency range of 50 mhz to 3.2 ghz. Let us take a look at how to make the following settings: z clock source z reference signal z frequency 1. Open the 'setup:frequency' panel. 2 fig. Fig. Fig. Fig. 6666----...

Page 110

89 3. Set whether an internal or external reference signal is to be used by selecting a reference signal type from the reference drop-down list box. Int use an internal reference signal. Ext 10mhz use an external reference signal. (10mhz) 4. Select a clock frequency from the frequency spin box. 50 0...

Page 111

90 6.14 monitoring the system error 3.2g internal synthesizer monitors the pll unlock alarm. This alarm indicates that the pll loop has been unlocked. When this alarm occurs, indication led on the 'setup:frequency' panel lights. Fig. Fig. Fig. Fig. 6666----32 32 32 32 setup:frequenc setup:frequenc s...

Page 112

91 6.15 for the users of the existing berts 6.15.1 customize subwindow the customize subwindow is a setup screen that adopts the 1-key/1-parameter operation method of the existing berts, allowing you to monitor the measurement result by inputting measurement parameters directly. The screen consists ...

Page 113

92 6.15.2 assigning setting items to setup frames this section describes the procedures for assigning setting items to setup frames. A maximum of six items can be assigned. 1. Press the display setup button in the customize subwindow. C display setup fig. Fig. Fig. Fig. 6666----34 34 34 34 display s...

Page 114

93 chapter 7 performance test.

Page 115

94 7.1 clock output this section describes the procedures for checking the main function of the 3.2g internal synthesizer option. Some equipment in below figures is required for this performance test. 7.1.1 internal clock output 1. To test waveform and frequency of the internal clock output signal, ...

Page 116

95 4. Confirm that the amplitude of the waveform measured by the sampling oscilloscope is in the range according to fig.7-2. 1vp-p±0.3v fig. Fig. Fig. Fig. 7777----2222 specification of the clock output signal waveform specification of the clock output signal waveform specification of the clock outp...

Page 117

96 (blank).

Page 118: Chapter 8 Maintenance・

97 chapter 8 maintenance・ ・ ・ ・ scrapping.

Page 119

98 8.1 daily care z to remove surface smears from the instrument, wipe with a cloth moistened with a weak neutral detergent solution. Z if dirt or dust collects on the instrument, suck with a vacuum cleaner. Z clean head of floppy disk drive with 3.5 inch head cleaning disk set regularly. Z if parts...

Page 120

99 8.3 shipping when shipping the instrument, package it in the packing materials in which it had been delivered if they are still retained; if not, follow the packaging steps below. In handing the instrument, wear clean gloves and handle it gently with care not scratch or dent it. 1. Clean the exte...

Page 121

100 (blank).

Page 122: Appendixes

101 appendixes.

Page 123

102 appendix a display-specific setup items panel panel panel panel group box group box group box group box setup item setup item setup item setup item default default default default system:system remote rs-232c(com1) system mode normal mode rs-232c(com1) speed 9600 parity none data bit length 8bit...

Page 124

103 appendix b troubleshooting following error message is appeared at the power on. “error found in back-up data. All settings and measured data cleared to default.” if the above error message is appeared after power on again, the internal-memory back up battery life is ended. Please, call your near...

Page 125

104 message asking for windows® disk insertion appears when you are setting printers with the windows® control panel, message like "insert microsoft windows 3.1 disk #5 ...." may appear. In such a case, insert the correspond recovery fd. The correspondence between number in the message and number la...

Page 126

105 appendix c entry table of performance test result instrument name : option-03 3.2g internal synthesizer serial no. : ambient temperature : ℃ ambient humidity : % z internal clock output frequency [hz] frequency [hz] frequency [hz] frequency [hz] standard [hz] standard [hz] standard [hz] standard...

Page 127

106. (blank).