- DL manuals

- Anritsu

- Measuring Instruments

- Sire Master S331D

- User Manual

Anritsu Sire Master S331D User Manual

Summary of Sire Master S331D

Page 1

User guide site master ä s331d cable and antenna analyzer anritsu company pn: 10580-00079 490 jarvis drive revision: k morgan hill, ca 95037-2809 published: april 2009 usa copyright ã 2003-2009 anritsu co..

Page 2

Warranty the anritsu product(s) listed on the title page is (are) warranted against defects in materials and workmanship for one year from the date of shipment. Anritsu's obligation covers repairing or replacing products which prove to be defec- tive during the warranty period. Buyers shall prepay t...

Page 3

S331d, ms2711d.

Page 4

ѻકЁ᳝↦᳝ᆇ⠽䋼ܗ㋴ⱘৡ⿄ঞ䞣 ᳝↦᳝ᆇ⠽䋼ܗ㋴ 䚼ӊৡ⿄ 䪙 3e ∲ +j 䬝 &g ݁Ӌ䫀 >&uĎ@ ⒈㘨㣃 3%% ⒈Ѡ㣃䝮 3%'( ॄࠋ㒓䏃ᵓ 3&$ h ƻ h h ƻ ƻ ᴎǃᬃᶊ &kdvvlv h ƻ h h ƻ ƻ /&' h h h h ƻ ƻ ݊Ҫ˄⬉㓚ǃ亢ǃ 䖲఼ㄝ˅ $sshqghgjrrgv h ƻ h h ƻ ƻ ƻ˖㸼⼎䆹᳝↦᳝ᆇ⠽䋼䆹䚼ӊ᠔᳝ഛ䋼ᴤ᭭Ёⱘ䞣ഛ 6-7 ᷛޚ㾘 ᅮⱘ䰤䞣㽕∖ҹϟDŽ h˖㸼⼎䆹᳝↦᳝ᆇ⠽䋼㟇ᇥ䆹䚼ӊⱘᶤϔഛ䋼ᴤ᭭Ёⱘ䞣䍙ߎ 6-7 ᷛޚ㾘ᅮⱘ䰤䞣㽕∖DŽ ⦃ֱՓ⫼ᳳ䰤 䖭Ͼᷛ䆄ᰃḍ ݀ᏗⱘNj⬉ᄤֵᙃ...

Page 5: Table Of Contents

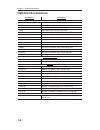

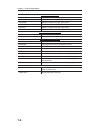

Table of contents chapter 1 general information introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-...

Page 6

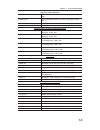

Chapter 3 getting started introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 power on procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 cable and antenna analyzer mode . . . . . . . . . . . . . . . . . . . . . . 3-2 all modes. . . . . . . . . ....

Page 7: III

Chapter 7 handheld software tools introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 system requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 installation ....

Page 9: Chapter 1

Chapter 1 general information introduction this chapter provides a description, performance specifications, optional accessories, preventive maintenance, and calibration requirements for the site master™ model s331d. Throughout this manual, the term site master will refer to the s331d. Model frequen...

Page 10: Standard Accessories

Standard accessories the handheld software tools and master software tools pc-based software programs provide a database record for storing measurement data. Software tools can also convert the site master display to a microsoft windows ä workstation graphic. Measurements stored in the site master i...

Page 11: External Detectors

External detectors the following anritsu detectors can be used with the site master s331d when equipped with option 5, power monitor. Model frequency range impedance return loss input conn. Frequency response 5400-71n50 0.001 to 3 ghz 50 w 26 db n(m) ±0.2 db, ±0.3 db, 5400-71n75 0.001 to 3 ghz 75 w ...

Page 12: Optional Accessories

Optional accessories part number description calibration components icn50b instacal™ calibration module, 2 mhz to 6.0 ghz, n(m), 50 w osln50-1 precision open/short/load, dc to 6 ghz, 42 db, 50 w, n(m) oslnf50-1 precision open/short/load, dc to 6 ghz, 42 db, 50 w, n(f) 22n50 open/short, dc to 18 ghz,...

Page 13: 1-5

Test port cables, armored 15nn50-1.5c test port cable armored, 1.5 meters, n(m)-n(m), 6 ghz, 50 w 15nn50-3.0c test port cable armored, 3.0 meters, n(m)-n(m), 6 ghz, 50 w 15nnf50-1.5c test port cable armored, 1.5 meters, n(m)-n(f), 6 ghz, 50 w 15nnf50-3.0c test port cable armored, 3.0 meters, n(m)-n(...

Page 14: 1-6

Power monitor detectors 5400-71n50 detector, .001 to 3 ghz, n(m), 50w 5400-71n75 detector, .001 to 3 ghz, n(m), 75w 560-7n50b detector, 10 mhz to 20 ghz, n(m), 50 w 560-7s50b detector, 10 mhz to 20 ghz, wsma(m), 50 w 560-7k50 detector, 10 mhz to 40 ghz, k(m), 50 w 560-7va50 detector, 10 mhz to 50 gh...

Page 15: Performance Specifications

Performance specifications performance specifications are provided in table 1-1. All specifications apply when cali- brated at ambient temperature after a five minute warm up. Typical values are given for ref- erence, and are not guaranteed. 1-7 chapter 1 general information cable and antenna analyz...

Page 16: 1-8

1-8 chapter 1 general information power monitor (option 5, with external detector) measurement range: –50 dbm to +16 dbm (10 nw to 40 mw) offset range: 0 db to +60 db display range: –80 dbm to 80 dbm resolution: 0.1 db, 0.1 xw measurement accuracy: ±1 db maximum for >–40 dbm and (see uncertainty cur...

Page 17: 1-9

1-9 chapter 1 general information general language support: english, spanish, french, german, chinese, japanese internal trace memory: up to 300 traces setup configurations: 10 display: standard color tft (640x480) display with variable brightness control inputs and outputs ports: rf out: type n, fe...

Page 18: Preventive Maintenance

Preventive maintenance site master preventive maintenance consists of cleaning the unit and inspecting and clean- ing the rf connectors on the instrument and all accessories. Clean the site master with a soft, lint-free cloth dampened with water or water and a mild cleaning solution. Caution: to avo...

Page 19: Annual Verification

Instacal module the anritsu instacal module can be used in place of discrete components to calibrate the site master. The instacal module can be used to perform an open, short and load (osl) or a flexcal calibration procedure. Calibration of the site master with the instacal takes approximately 45 s...

Page 21: Chapter 2

Chapter 2 functions and operations introduction this chapter provides a brief overview of the site master functions and operations, provid- ing the user with a starting point for making basic measurements. For more detailed infor- mation, refer to the specific chapters for the measurements being mad...

Page 22: 2-2

Battery charging illuminates when the battery is being charged. The indicator automatically shuts off when the battery is fully charged. External power illuminates when the site master is being powered by the external charging unit. Serial interface rs232 db9 interface to a com port on a personal co...

Page 23: Display Overview

Display overview figure 2-2 illustrates some of the key information areas of the s331d display. Chapter 2 functions and operations 2-3 title bar data points sweep time calibration status message area current menu figure 2-2. S331d display overview.

Page 24: Front Panel Overview

Front panel overview the site master menu-driven user interface is easy to use and requires little training. Hard keys on the front panel are used to initiate function-specific menus. There are four function hard keys located below the status window: mode, frequency/distance, amplitude and measure/d...

Page 25: Function Hard Keys

Function hard keys mode opens the mode selection box (below). Use the up/down arrow key to select a mode. Press the enter key to implement. Note: available mode selections will vary according to model number and options installed. Freq/dist displays the frequency or distance to fault soft key menus ...

Page 26: Keypad Hard Keys

Keypad hard keys this section contains an alphabetical listing of the site master front panel keypad controls along with a brief description of each. More detailed descriptions of the major function keys follow. The following keypad hard key functions are printed in black on the keypad keys. 0-9 the...

Page 27: 2-7

The following keypad hard key functions are printed in blue on the keypad keys. This key is used to adust the display brightness. Use the up/down arrow key and enter to adjust the brightness. Auto scale automatically scales the status window for optimum resolution in cable and antenna analyzer mode....

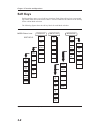

Page 28: Soft Keys

Soft keys each keypad key opens a set of soft key selections. Each of the soft keys has a correspond- ing soft key label area on the status window. The label identifies the function of the soft key for the current mode selection. The following figures show the soft key labels for each mode selection...

Page 29: 2-9

Chapter 2 functions and operations 2-9 mode=dtf: softkeys: bottom top freq/dist amplitude d2 dtf aid more d1 loss cable window back prop vel page up select trace page down back bottom of list delete trace delete all traces top of list on/off resolu- tion single sweep trace math trace overlay fixed c...

Page 30: 2-10

2-10 chapter 2 functions and operations system options hour application options clock status minute self test month language english day year units gps on/off printer cal mode change date format back back back location quality reset back gps figure 2-8. Sys key menu in cable and antenna analyzer mod...

Page 31: 2-11

Freq/dist displays the frequency and distance menu depending on the measurement mode. Frequency menu the frequency and distance menu for cable and antenna analyzer measurements provides for setting sweep frequency end points when freq mode is selected. Se- lected frequency values may be changed usin...

Page 32: 2-12

Marker choosing marker in cable and antenna analyzer freq and dist mode causes the soft keys, below, to be displayed and the corresponding values to be shown in the message area. Selected frequency marker or distance marker locations may be changed using the keypad or up/down arrow key. Q m1 — selec...

Page 33: 2-13

Q m6 — selects the m6 marker parameter and opens the m6 second level menu. Q on/off — turns the selected marker on or off. Q edit — opens the selected marker parameter for data entry. Press enter when data entry is complete or escape to restore the pre- vious value. Q peak between m3 & m4 — places t...

Page 34: 2-14

Sys in cable and antenna analyzer or optional power meter mode, pressing the sys key displays the following system menu soft key selections: q system options — displays a second level of system option functions: q clock — displays a second level of functions: q hour — enter the hour (0-23) using the...

Page 35: 2-15

Q minute — enter the minute (0-59) using the up/down arrow key or the keypad. Press enter when data entry is complete or escape to restore the previous value. Q month — enter the month (1-12) using the up/down arrow key or the keypad. Press enter when data entry is complete or escape to restore the ...

Page 36: 2-16

Power monitor, external detector (option 5) selecting power monitor (external detector) from the mode menu causes the soft keys, de- scribed below, to be displayed and the corresponding values shown in the message area. Q units — toggles between dbm and watts. Q rel — turns relative mode off, if cur...

Page 37: Symbols

Symbols table 2-1 provides a listing of the symbols used as condition indicators on the lcd status window. Chapter 2 functions and operations 2-17 icon symbol site master is in hold for power conservation. To resume sweeping, press the run/hold key. When running on battery power, after 10 minutes wi...

Page 38: Self Test

Self test at turn-on, the site master runs through a series of quick checks to ensure the system is functioning properly. Note that the voltage and temperature are displayed in the lower left corner below the self test message. If the battery is low, or if the ambient temperature is not within the s...

Page 39: Error Messages

Error messages self test error messages a listing of self test error messages is provided in table 2-2. Chapter 2 functions and operations 2-19 error message description battery low battery voltage is less than 9.5 volts. Charge battery. If condition per- sists, call your anritsu service center. Ext...

Page 40: 2-20

Range error messages a listing of range error messages is provided in table 2-3. 2-20 chapter 2 functions and operations error message description range error:f1 > f2 the start (f1) frequency is greater than the stop (f2) frequency. Range error:d1 > d2 the start (d1) distance is greater than the sto...

Page 41: 2-21

Instacal error messages if the serial number of the connected instacal module does not match the serial number stored in the site master, the following message is displayed: the instacal characterization data stored in the site master is for a module different than the one currently connected. Site ...

Page 42: 2-22

High accuracy power meter (option 19) error messages the following error messages could be displayed on the site master when using the high accuracy power meter mode with power sensor psn50. If any error condition persists, contact your local anritsu service center. General error messages a listing ...

Page 43: Battery Information

Battery information charging a new battery the nimh battery supplied with the site master has already completed three charge and discharge cycles at the factory and full battery performance should be realized after your first charge. Note: use only anritsu approved batteries, adapters and chargers w...

Page 44: 2-24

A blinking red light indicates less than 13 vdc is being supplied to the charger stand. Check that the correct ac charger adapter is connected to the charger stand. If the battery fails to charge, contact your nearest anritsu service center. Determining remaining battery life when the ac-dc adapter ...

Page 45: 2-25

Battery life the nimh battery will last longer and perform better if allowed to completely discharge before recharging. For maximum battery life, it is recommended that the nimh battery be completely discharged and recharged once every three months. The charging circuitry inside the site master is d...

Page 46: 2-26

Important battery information · the nimh battery supplied with the site master has already completed three charge and discharge cycles at the factory and full battery performance should be realized after the first charge. · recharge the battery only in the site master, or in an anritsu approved char...

Page 47: Chapter 3

Chapter 3 getting started introduction this chapter provides a brief overview of the anritsu site master. The intent of this chapter is to provide the user with a starting point for making basic cable and antenna analyzer measurements. Power on procedure the anritsu site master is capable of up to 1...

Page 48: 3-2

Cable and antenna analyzer mode selecting the frequency for the osl or flexcal calibration method the frequency range for the desired measure- ment must be set. The site master will automatically set the frequency when a particular signal standard is selected, or the frequency can be manually set us...

Page 49: 3-3

If a test port extension cable is to be used, the site master must be calibrated with the test port extension cable in place. The test port extension cable is a phase stable cable and is used as an extension cable on the test port to ensure accurate and repeatable measure- ments. This phase stable c...

Page 50: 3-4

Osl calibration procedures in cable and antenna analyzer mode, if the cal off message is displayed, or the test port cable has been changed, a new calibration is required. The following procedures detail how to perform the osl calibration. Standard osl calibration step 1. Select osl cal by pressing ...

Page 51: 3-5

Flexcal osl calibration step 8. The currently selected calibration method can be viewed by pressing the sys key, followed by the status soft key. To change the calibration method, select the sys key, followed by the application options soft key. Use the cal mode soft key to select the flexcal calibr...

Page 52: 3-6

Offset method an alternative to the termination method is to measure the return loss of a 20 db offset. This is similar to measuring an antenna that has been specified to have a 20 db return loss across the frequency of operation. A 20 db offset provides a 20 db return loss across a very wide freque...

Page 53: 3-7

Standard instacal calibration step 1. Select osl cal by pressing the sys key, followed by the application options soft key. The currently selected calibration method is indicated at the bottom of the status window. Use the cal mode soft key to select the osl calibration method. Step 2. Select the ap...

Page 54: 3-8

Auto scale the site master can automatically set the scale to the minimum and maximum values of the measurement on the y-axis of the graph. This function is particularly useful for mea- surements in swr mode. To automatically set the scale, press the auto scale key. The site master will automaticall...

Page 55: 3-9

Step 6. Using the up/down arrow key, select the cable = and press enter. Use the up/down arrow key to select the standard cable types stored in the standard site master cable lists (which cannot be edited) or choose custom , for additional ca- bles. A custom cable list can be created and uploaded us...

Page 56: All Modes

All modes save and recall a setup saving a setup saving a cable and antenna analyzer setup configuration in memory will preserve the cali- bration information. Step 1. To save the configuration in one of the available user setup locations, press save setup. There are ten locations in cable and anten...

Page 57: 3-11

Notes: more than one trace can be saved using the same alphanumeric name, as traces are stored chronologically, using the time/date stamp. Pressing the save display key will bring up the last saved trace name on the input line. Pressing the delete soft key will erase the entire trace name. To erase ...

Page 58: 3-12

Adjusting limits the site master offers two types of limits: a single horizontal limit line and segmented limits. Adjusting a single limit step 1. Press the limit key. Step 2. Press the single limit soft key. Step 3. Press the edit soft key. Step 4. Either enter the value using the numeric keypad or...

Page 59: 3-13

Notes: the site master does not allow overlapping limit segments of the same type. That is, two upper limit segments cannot overlap and two lower limit segments cannot overlap. The site master also does not allow vertical limit segments. A limit segment in which the start and end frequencies are the...

Page 60: Printing

Printing printing is accomplished by selecting an available printer and pressing the print key as de- scribed below. Refer to the particular printer operating manual for specific printer settings. Printing a screen step 1. Obtain the desired measurement display. Step 2. Press the sys key and the sys...

Page 61: 3-15

Using the soft carrying case the soft carrying case has been designed such that the strap can be unsnapped to allow the case to be easily oriented horizontally; thus allowing the anritsu controls to be more easily accessed (figure 3-5). Chapter 3 getting started 3-15 figure 3-5. Using the site maste...

Page 63: Chapter 4

Chapter 4 cable and antenna analyzer measurements introduction this chapter provides a description of cable and antenna analyzer measurements, including line sweeping fundamentals and line sweeping measurement procedures, available when the site master is in frequency or dtf mode. Line sweep fundame...

Page 64: 4-2

The performance of a transmission feed line system may be affected by excessive signal re- flection and cable loss. Signal reflection occurs when the rf signal reflects back due to an impedance mismatch or change in impedance caused by excessive kinking or bending of the transmission line. Cable los...

Page 65: 4-3

Cw mode/rf immunity cw mode can be used to maximize sweep speeds of both frequency and dtf measure- ments. With cw on, sweep times can be twice as fast as with cw off. However, making measurements with cw on will reduce the instrument’s immunity to interfering signals. In a controlled environment, t...

Page 66: 4-4

Procedure step 1. Press the mode key. Step 2. Select freq-return loss using the up/down arrow key and press enter. Step 3. Set the start and stop frequencies, automatically by selecting a signal standard or manually using the f1 and f2 soft keys, as described on page 3-2. Step 4. Calibrate the site ...

Page 67: 4-5

Cable loss measurement the transmission feed line insertion loss test verifies the signal attenuation level of the ca- ble system in reference to the specification. This test can be conducted with the site master in freq–cable loss mode. Required equipment q site master model s331d q precision open/...

Page 68: 4-6

Figure 4-3 is an example of a typical transmission line cable loss measurement trace using a standard calibration. 4-6 chapter 4 cable & antenna measurements figure 4-3. Typical transmission line cable loss trace.

Page 69: 4-7

Distance-to-fault (dtf) transmission line test the distance-to-fault transmission line test verifies the performance of the transmission line assembly and its components and identifies the fault locations in the transmission line system. This test determines the return loss value of each connector p...

Page 70: 4-8

Figure 4-4 shows an example of a typical dtf return loss measurement trace using a flexcal calibration. In the above example: q marker m1 marks the first connector, the end of the site master phase stable test port extension cable. Q marker m2 marks the first jumper cable. Q marker m3 marks the end ...

Page 71: 4-9

Increasing the data points increases the sweep time and increases the accuracy of the mea- surement. Cw mode on or off can also affect sweep speed (see cw mode, page 4-3 for details). Antenna subsystem return loss test antenna subsystem return loss measurement verifies the performance of the transmi...

Page 72: 4-10

The following trace is an example of an antenna return loss measurement trace using a flexcal calibration.. Calculate the threshold value and compare the recorded lowest return loss to the calcu- lated threshold value. Maximum return loss = ( ) ( ) − − + 20 1 1 log vswr vswr notes: vswr is the anten...

Page 73: Chapter 5

Chapter 5 power monitor mode introduction the site master with option 5 installed can be used for making power measurements with broadband rf detectors, such as the 10 mhz to 20 ghz anritsu 560-7n50b. See the table of available rf detectors on page 1-3. The power monitor displays the measured power ...

Page 74: 5-2

Displaying relative power step 9. With the desired base power level input to the site master, press the rel soft key. The message area will show rel: on and the power reading will indicate 100%. Step 10. Press the units soft key to display power in dbm. Since rel is on, the power reading will be in ...

Page 75: Chapter 6

Chapter 6 high accuracy power meter introduction anritsu's high accuracy power meter (option 19) enables high accuracy, rms measurements for both cw and digitally modulated signals such as cdma/ev-do, gsm/edge, and wcdma/hsdpa. This option requires either the psn50 or ma24104a power sensors. The psn...

Page 76: Power Measurement

Zeroing the sensor the zero feature improves low-level accuracy by removing measured system noise. Cal factors correct both efficiency and mismatch loss. The frequency information must be en- tered to obtain the correct calibration factor. Using attenuators when necessary, attenuators should be used...

Page 77: 6-3

Zero and cal step 6. Press the freq/dist key. Step 7. To enter the frequency manually using the number keys, select the center soft key. To select a known signal standard, press the signal standard soft key and use the up/down arrow key to select the desired standard. The cal factors will be derived...

Page 78: 6-4

Displaying relative power step 21. Press the amplitude key. Step 22. With the desired base power level input to the sensor, press the rel soft key. The message area will show relative on and the power reading will show 0 db and 100%. If measuring a 10 dbm signal with the rel key selected, a drop to ...

Page 79: Chapter 7

Chapter 7 handheld software tools introduction this chapter provides a description of the anritsu handheld software tools (hhst) program. Handheld software tools is a windows 95/98/nt4/2000/me/xp/vista program for transferring measured traces, along with markers and limit lines, to the pc display. T...

Page 80: System Requirements

System requirements the handheld software tools program will run on most any computer running windows 95/98/nt4/2000/me/xp/vista. Minimum requirements and recommendations are: q intel pentium 100 mhz microprocessor (pentium ii 350 mhz or better recom- mended) q 16 mb of ram (64 mb or above recommend...

Page 81: 7-3

Communication port setting the handheld software tools communicates with the instrument through a standard serial com port on the pc. Set the baud rate of the com port to 115200. Step1. Select start, programs and select software tools. Step2. When the program has loaded, select settings, communicati...

Page 82: 7-4

Interface cable installation communication between the instrument and the pc is accomplished over a null modem se- rial cable provided with the instrument (anritsu part number 800-441, and optional usb to serial adapter, part number 551-1691, if required). Step1. Install the null modem serial interf...

Page 83: 7-5

Using handheld software tools select start, programs and select software tools. Downloading traces traces that can be downloaded from the instrument are grouped by the date on which they were saved. They are further organized in chronological order for each date, with the oldest trace at the top of ...

Page 84: 7-6

Plot properties after downloading, certain plot properties and information can be modified. Select the plot properties or plot information icon. Plot properties that can be changed include: graph titles display mode scale/limit markers misc. (plot display parameters) graph titles after downloading t...

Page 85: 7-7

Misc. The miscellaneous tab allows adjustment of the plot/limit line width, the setting of the plot footer, and the date format. Plot/limit line width can be used when preparing reports for the carrier, ser- vice providers, and network operators where the trace data must be visible and legible for d...

Page 86: 7-8

To copy a metafile: step1. Select the trace to be copied with the mouse cursor. Step2. Select edit and then copy. The file will copied to the clipboard, or select file and then export to a windows metafile. Step3. Open the target application (microsoft word, etc.). Step4. Select edit and then paste....

Page 87: 7-9

Cable list a custom cable list can be created in software tools and uploaded to the site master. Some standard 1000 mhz, 2000 mhz, and 2500 mhz cables are stored in the site master and are listed in appendix a of this user’s guide. The cable list contains vital information such as propagation veloci...

Page 88: 7-10

To convert from frequency domain to distance to fault, follow these steps: step1. Capture a plot or load a previously saved plot. Step2. Click the distance-to-fault button on the toolbar (or choose distance-to-fault from the tools menu). A dialog will open allowing you to specify the cable pa- ramet...

Page 89: 7-11

Signal standards editor the signal standards editor is a software application for viewing, editing and creating sig- nal standards files. Select a signal standard entry from the list to make it active. The signal standards editor can: · create new signal standards files · view and edit the signal st...

Page 90: 7-12

Retrieving signal standards files connection manager must be connected to a test unit before retrieving a signal standards file. An active connection is indicated in the status bar at the bottom right corner of the ap- plication window. To retrieve a signal standards file, select retreive signal sta...

Page 91: Chapter 8

Chapter 8 master software tools introduction this chapter provides an introduction to the anritsu master software tools (mst) program. Users of the legacy handheld software tools (hhst) program are strongly encouraged to migrate to new mst platform. This new platform has numerous productivity advant...

Page 92: 8-2

· language editor – this utility allows you to add new or modify existing language tables. Languages available for selection are english, french, german, spanish, italian, japanese, chinese and korean. All of these languages except for english can be edited. Up to two more custom languages can be lo...

Page 93: 8-3

Note: new firmware is not compatible with master software tools version 1.25 or older. Insure that you have maximum functionality by updating your master software tools to the latest version. Chapter 8 handheld software tools 8-3 figure 8-4. Dat file conversion tool used to convert existing spa and ...

Page 94: 8-4

Minimum system requirements · microsoft windows 2000 (service pack 4 or above), windows xp (service pack 2 or above), or windows vista · microsoft .Net framework, version 2.0 · intel pentium 233 mhz microprocessor (pentium iii 350 mhz or better recommenced) · 128 mb of available ram (256 mb or above...

Page 95: Appendix A

Appendix a windowing introduction the freq/dist menu (page 2-11) provides for setting the cable loss and relative propa- gation velocity of the coaxial cable. The window key opens a menu of fft windowing types for the dtf calculation. The theoretical requirement for inverse fft is for the data to ex...

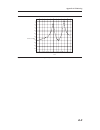

Page 96: A-2

A-2 appendix a windowing d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 f e e t 3 5 4 0 4 5 5 0 5 5 6 0 - 5 - 1 0 - 1 5 - 2 0 - 2 5 - 3 0 - 3 5 - 4 0 - 4 5 - 5 0 r e t u r n l o s s ( d b ) figure a-2. Nominal side lobe windowing example d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 f e e...

Page 97: A-3

A-3 appendix a windowing d i s t a n c e t o f a u l t 5 1 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5 5 0 5 5 6 0 f e e t - 5 - 1 0 - 1 5 - 2 0 - 2 5 - 3 0 - 3 5 - 4 0 - 4 5 - 5 0 r e t u r n l o s s ( d b ) figure a-4. Minimum side lobe windowing example.

Page 99: Index

Index a accessories . . . . . . . . . . . . . . 1-2, 1-4 b battery . . . . . . . . . . . . . . . . . . 2-23 brightness. . . . . . . . . . . . . . . . . 3-13 c cable loss . . . . . . . . . . . . . . . 4-2, 4-5 calibration . . . . . . . . . . . . . . 1-10, 3-2 case . . . . . . . . . . . . . . . . . . ...

Page 100: Index-2

R resolution . . . . . . . . . . . . . . . . . 4-8 return loss . . . . . . . . . . . . . . . 4-2, 4-9 rs232. . . . . . . . . . . . . . . . . 2-2, 7-4 s scale . . . . . . . . . . . . . . . . . . . . 3-8 self test . . . . . . 2-14 - 2-15, 2-18, 2-24, 3-1 serial interface . . . . . . . . . . . . . . . ...

Page 101

Anritsu company 490 jarvis drive morgan hill, ca 95037-2809 p/n: 10000-00000 revision: prelim printed: june 2009.

Page 102

Anritsu company 490 jarvis drive morgan hill, ca 95037-2809 usa http://www.Anritsu.Com/ anritsu company prints on recycled paper with vegetable soybean oil ink.