- DL manuals

- Baby Lock

- Sewing Machine

- BL50A

- Instruction And Reference Manual

Baby Lock BL50A Instruction And Reference Manual

Summary of BL50A

Page 2: Congratulations On Choosing

Congratulations on choosing our machine your machine is the most advanced computerized household sewing machine. To fully enjoy all the features incorporated, we suggest that you study the manual. Please read before using this machine for safe operation 1. Be sure to keep your eye on the needle whil...

Page 3: Danger

1 important safety instructions please read these safety instructions before attempting to use the machine. Danger - to reduce the risk of electric shock: 1 always unplug the machine from the electrical outlet immediately after using, when cleaning, when making any user servicing adjustments mention...

Page 4

2 5 always keep your work area clear: • never operate the machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the build up of lint, dust, and loose cloth. • do not store objects on the foot controller. • do not use extension cords. Plug t...

Page 5: Save These Instructions.

3 9 for repair or adjustment: • if the light unit (light-emitting diode) is damaged, it must be replaced by authorized retailer. • in the event a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the operation manual to inspect and adjust the machine...

Page 6: Important

4 for users in the uk, eire, malta and cyprus only important • in the event of replacing the plug fuse, use a fuse approved by asta to bs 1362, i.E. Carrying the mark, rating as marked on plug. • always replace the fuse cover. Never use plugs with the fuse cover omitted. • if the available electrica...

Page 7: Contents

5 contents important safety instructions ............................................................................... 1 introduction ........................................................................................................................ 8 names of machine parts and their function...

Page 8

6 sewing curves ................................................................................................................................................ 48 sewing thick fabrics ......................................................................................................................

Page 9

7 operation beep ...............................................................................................................107 canceling the operation beep ...................................................................................................................... 107 index .............

Page 10: Introduction

8 introduction thank you for choosing this product. Before using this sewing machine, carefully read “important safety instructions”, and then study this manual for the correct operation of the various functions. In addition, after you have finished reading this manual, store it where it can quickly...

Page 11

9 needle and presser foot section a needle threader lever use the needle threader to thread the needle. B buttonhole lever lower the buttonhole lever when sewing buttonholes and bar tacks. C presser foot holder the presser foot is attached to the presser foot holder. D presser foot holder screw use ...

Page 12

10 operation panel the operation panel, located on the front of the sewing machine, allows you to select a stitch and specify how the stitch will be sewn. A lcd (liquid crystal display) the number of the selected stitch ( 1 ), the presser foot to be used ( 2 ), the stitch length (mm) ( 3 ), and the ...

Page 13: Accessories

11 accessories after opening the box, check that the following accessories are included. If any item is missing or damaged, contact your retailer. Included accessories the following items should also be included in the box. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10.* 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. ...

Page 14

12 optional accessories the following are available as optional accessories to be purchased separately. Memo ● to obtain optional accessories or parts, contact the nearest authorized retailer. ● all specifications are correct at the time of printing. The part codes are subject to change without noti...

Page 15: Getting Ready

13 1 1 getting ready turning the machine on/off this section explains how to turn the sewing machine on and off. Power supply precautions be sure to observe the following precautions concerning the power supply. Warning ● use only regular household electricity for the power source. Using other power...

Page 16

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 14 turning on the machine prepare the included power cord. A make sure that the sewing machine is turned off (the main power switch is set to “ ”), and then plug the power cord into ...

Page 17: Caution

15 1 preparing for upper and lower threading winding the bobbin wind the thread onto the bobbin. A turn on the sewing machine. B place the bobbin on the bobbin winder shaft so that the spring on the shaft fits into the notch in the bobbin. A notch b bobbin winder shaft spring c slide the bobbin wind...

Page 18: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 16 f slide the spool cap onto the spool pin. With the slightly rounded side of the spool cap positioned toward the left, slide the spool cap onto the spool pin as far as possible to ...

Page 19: Caution

17 1 i pull the thread to the right, pass it under the hook of the bobbin-winding thread guide, and then wind the thread counterclockwise between the discs, pulling it in as far as possible. A hook of the bobbin-winding thread guide b pretension disk j while using your left hand to hold the thread t...

Page 20: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 18 memo ● when the sewing machine is started or the handwheel is turned after winding the thread around the bobbin, the machine will make a clicking sound; this is not a malfunction....

Page 21: Caution

19 1 e while lightly holding down bobbin with your right hand as shown, guide the thread through the slit ( 1 and 2 ). • at this time, check that the bobbin easily rotates counterclockwise. Then, pull the thread toward you to cut it with the cutter ( 3 ). A slit b cutter (cut the thread with the cut...

Page 22: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 20 threading the upper thread in this section, the procedures for installing the spool for the upper thread and threading the needle are described. A turn off the sewing machine. B r...

Page 23: Caution

21 1 a mark on handwheel e turn off the sewing machine. F swing up the spool pin, and then remove the spool cap. A spool pin b spool cap g fully insert the spool for the upper thread onto the spool pin slide the spool onto the pin so that the spool is horizontal and the thread unwinds to the front a...

Page 24

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 22 i while holding the spool with your right hand, and then pass the thread under the thread guide. A thread guide j pass the thread under the thread guide cover from the back to the...

Page 25: Caution

23 1 o while lowering the needle threader lever, hook the thread onto the guide. A needle threader b thread c guide p catch the thread on the hook as shown below. A needle threader lever q raise the needle threader lever, and then pull the end of the thread which passed through the eye of the needle...

Page 26: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 24 c raise the presser foot lever. A presser foot lever d pass the end of the thread through the presser foot, and then pull out about 5 cm (2 inches) of thread toward the rear of th...

Page 27: Caution

25 1 f thread the upper thread for the right side in the same way that the upper thread for the left side was threaded. A thread guide cover • for details, refer to step i through l of “threading the upper thread” (page 20). G without passing the thread through the needle bar thread guide, manually ...

Page 28: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 26 l start sewing. • for details on starting to sew, refer to “starting to sew” (page 42). X two lines of stitching are sewn parallel to each other. Note ● when using the twin needle...

Page 29: Replacing The Needle

27 1 replacing the needle this section provides information on sewing machine needles. Needle precautions be sure to observe the following precautions concerning the handling of the needle. Failure to observe these precautions is extremely dangerous, for example, if the needle breaks and fragments a...

Page 30: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 28 needle types and their uses the sewing machine needle that should be used depends on the fabric and thread thickness. Refer to the following table when choosing the thread and nee...

Page 31: Caution

29 1 checking the needle sewing with a bent needle is extremely dangerous since the needle may break while the machine is being operated. Before using the needle, place the flat side of the needle on a flat surface and check that the distance between the needle and the flat surface is even. A flat s...

Page 32: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 30 d loosen the needle clamp screw and remove the needle. Hold the needle with your left hand, and then turn the screwdriver counterclockwise with your right hand. A needle clamp scr...

Page 33: Replacing The Presser Foot

31 1 replacing the presser foot presser foot precautions be sure to observe the following precautions concerning the presser feet. Replacing the presser foot replace the presser foot as described below. A press (needle position button) once or twice to raise the needle. A needle position button b tu...

Page 34

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 32 e place the presser foot to be installed below the holder so that the presser foot pin is aligned with the notch in the holder. Position the presser foot so the letter indicating ...

Page 35: Caution

33 1 ■ attaching the presser foot holder a align the presser foot holder with the presser bar. A presser bar b presser foot holder b hold up the presser foot holder with your right hand, and tighten the screw. With your left hand, turn the screwdriver clockwise. Note ● if the presser foot holder is ...

Page 36: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 34 c lower the presser foot lever, insert the presser foot holder screw, and then tighten the screw with the screwdriver. A presser foot holder screw note ● when sewing with the walk...

Page 37: Useful Functions

35 1 useful functions functions useful in improving sewing efficiency are described below. Changing the needle stop position normally, the sewing machine is set to leave the needle in the fabric when sewing is stopped. Instead, the machine can be set to leave the needle raised when sewing is stopped...

Page 38

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 36 changing the initial needle position you can select whether “01 straight stitch (left needle position)” or “02 straight stitch (center needle position)” is automatically selected ...

Page 39

37 1 sewing cylindrical or large pieces when sewing cylindrical or large pieces of fabric, remove the flat bed attachment. Stitching cylindrical pieces removing the flat bed attachment makes it easier to sew cylindrical pieces such as cuffs and pant legs. A pull the flat bed attachment off to the le...

Page 40: Caution

Getting ready ——————————————————————————————————————————————————————————————————————————————————————————————————————— 38 c install the extension table. Keeping the extension table level, fully slide it into place. The lower right corner section of the extension table extends over the front section o...

Page 41: Sewing Basics

39 2 2 sewing basics starting to sew basic sewing operations are described below. Before operating the sewing machine, read the following precautions. Sewing procedure the basic sewing procedure is shown below. Caution ● while the machine is in operation, pay special attention to the needle. In addi...

Page 42

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 40 selecting a stitch select each stitch by using the pattern selection dial. A turn on the sewing machine. B turn the pattern selection dial to select the stitch to be sewn. Turn th...

Page 43: Caution

41 2 c press “+” or “–” side of (stitch width key) to adjust the stitch width. A stitch width key b stitch width c narrow d wide memo ● when the stitch length or stitch width is changed from the default setting, around or disappears from the lcd. When the stitch length or stitch width is reset back ...

Page 44

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 42 d while holding the end of the thread and the fabric with your left hand, turn the handwheel toward you (counterclockwise) with your right hand to lower the needle to the starting...

Page 45

43 2 b press / (start/stop button) once. A start/stop button the machine starts sewing. • if you continue pressing the / (start/ stop button) immediately after the sewing starts, the machine will sew at a slow speed. C when the end of the stitching is reached, press / (start/stop button) once. X the...

Page 46: Caution

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 44 e once you are ready to start sewing, slowly press down on the foot controller. Pressing down on the foot controller increases the sewing speed; releasing the pressure on the foot...

Page 47

45 2 c after sewing 3 to 5 stitches, press (reverse/reinforcement stitch button). Keep (reverse/reinforcement stitch button) held down until you reach the beginning of the stitching. A reverse/reinforcement stitch button while (reverse/reinforcement stitch button) is held down, reverse stitches are ...

Page 48

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 46 cutting the thread a when you wish to finish the stitching and the sewing machine is stopped, press (needle position button) once to raise the needle. A needle position button x t...

Page 49

47 2 e after reaching the end of the stitching, press the reverse/reinforcement stitch button once. A reverse/reinforcement stitch button • this step is not necessary if a stitch such as those for sewing buttonholes and bar tacks is selected where reinforcement stitches are automatically sewn. X aft...

Page 50: Useful Sewing Tips

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 48 useful sewing tips various ways to achieve better sewing results are described below. Refer to these tips when sewing. Trial sewing after a stitch is selected, the machine automat...

Page 51: Caution

49 2 ■ if thick seams are being sewn and the fabric does not feed at the beginning of stitching the fabric may not feed when thick seams are being sewn and the presser foot is not level, as shown below. In this case, use the presser foot locking pin (black button on the left side of zigzag foot “j”)...

Page 52: Caution

Sewing basics ——————————————————————————————————————————————————————————————————————————————————————————————————————— 50 sewing hook-and-loop fastener note ● before starting to sew, baste together the fabric and the hook-and-loop fastener. Make sure that the needle passes through the hook- and-loop ...

Page 53

51 2 pulling up the bobbin thread when making gathers or before free-motion quilting, first pull up the bobbin thread as described below. A insert the bobbin into the bobbin case. • refer to steps a through d of “installing the bobbin” on page 18. B pass the bobbin thread through the slot. Do not cu...

Page 54: Utility Stitches

Utility stitches ———————————————————————————————————————————————————————————————————— 52 3 utility stitches overcasting sew overcasting along the edges of cut fabric to prevent them from fraying. Six stitches are available for overcasting. The values below “auto” are set when the pattern is selected...

Page 55: Caution

53 3 sewing overcasting stitches using zigzag foot “j” a turn on the machine. B with the pattern selection dial, select , or . C attach zigzag foot “j”. • for details, refer to “replacing the presser foot” (page 31). D sew along the edge of the fabric with the needle dropping off the edge at the rig...

Page 56: Basic Stitching

Utility stitches ———————————————————————————————————————————————————————————————————— 54 basic stitching straight stitches are used for sewing plain seams. Three stitches are available for basic stitching. The values below “auto” are set when the pattern is selected. The setting can be adjusted to a...

Page 57: Blind Hem Stitching

55 3 blind hem stitching the bottoms of skirts and pants are hemmed. Two stitches are available for blind hem stitching. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any value within the range indicated below “manual”. Memo ● when stitch or is selected...

Page 58: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 56 e position the fabric with the edge of the folded hem against the guide of the presser foot, and then lower the presser foot lever. A wrong side of fabric b fold of hem c presser foot guide f press the “–” side ...

Page 59: Buttonhole Stitching

57 3 buttonhole stitching buttonholes can be sewn. Five stitches are available for sewing buttonholes. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any value within the range indicated below “manual”. Stitch name pat ter n pr es se r fo ot application ...

Page 60: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 58 buttonholes with a maximum length of 30 mm (1-3/16 inches) (diameter + thickness of the button) can be sewn. Buttonholes are sewn as shown below. A reinforcement stitching the names of parts of buttonhole foot “...

Page 61

59 3 a use chalk to mark on the fabric the position and length of the buttonhole. A marks on fabric b button hole sewing b pull out the button guide plate of buttonhole foot “a”, and then insert the button that will be put through the buttonhole. ■ if the button does not fit in the button guide plat...

Page 62: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 60 h pull down the buttonhole lever as far as possible. A buttonhole lever the buttonhole lever should be positioned behind the bracket on the buttonhole foot. A buttonhole lever b bracket i gently hold the end of ...

Page 63

61 3 ■ changing the stitch width press the “+” or “–” side of the stitch width key to adjust the stitch width. A stitch width key b stitch width c narrow d wide memo ● before sewing buttonholes, check the stitch length and width by sewing a trial buttonhole on a scrap piece of fabric. ■ sewing butto...

Page 64: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 62 button sewing buttons can be sewn on with the sewing machine. Buttons with 2 or with 4 holes can be attached. A measure the distance between the holes in the button to be attached. B raise the presser foot lever...

Page 65

63 3 i start sewing. Set the sewing speed controller to the left (so that the speed will be slow). X the sewing machine automatically stops after sewing reinforcement stitches. • if additional strength is needed to secure the button, perform the button-sewing operation twice. J use scissors to cut t...

Page 66: Zipper Insertion

Utility stitches ———————————————————————————————————————————————————————————————————— 64 zipper insertion a zipper can be sewn in place. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any value within the range indicated below “manual”. There are many me...

Page 67: Caution

65 3 e align the seam with the center of the zipper, and then baste the zipper in place. A wrong side of fabric b basting stitching c zipper f with the pattern selection dial, select stitch . G attach the presser foot holder to the right side of the pin of zipper foot “i”. A right side of the pin b ...

Page 68: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 66 a turn on the machine. B attach zigzag foot “j” and sew straight stitches up to the zipper opening. • with the right sides of the fabric facing each other, sew reverse stitches after reaching the zipper opening....

Page 69: Caution

67 3 i sew the zipper to the piece of fabric with the extra 3 mm (1/8 inch), starting from the base of the zipper. J when you are about 5 cm (2 inches) from the end of the zipper, stop the sewing machine with the needle down (in the fabric), raise the presser foot lever, and then open the zipper and...

Page 70: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 68 sewing stretch fabrics and elastic tape stretch fabrics can be sewn and elastic tape can be attached. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any value within...

Page 71: Caution

69 3 c with the pattern selection dial, select stitch . D attach zigzag foot “j”. • for details, refer to “replacing the presser foot” (page 31). E sew the elastic tape to the fabric while stretching the tape so that it is the same length as the fabric. While pulling the fabric behind the presser fo...

Page 72: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 70 appliqué, patchwork and quilt stitching eight stitches are available for sewing appliqués and patchwork quilts. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any va...

Page 73

71 3 appliqué stitching a cut out the appliqué, leaving a seam allowance of between 3 and 5 mm (1/8 and 3/ 16 inch). A seam allowance b place a pattern made of thick paper on the back of the appliqué, and then fold over the seam allowance using an iron. C turn the fabric over, and then baste, glue o...

Page 74

Utility stitches ———————————————————————————————————————————————————————————————————— 72 piecing sewing together two pieces of fabric is called “piecing”. The fabric pieces should be cut with a 6.5 mm (1/4 inch) seam allowance. Sew a piecing straight stitch 6.5 mm (1/4 inch) from the right side of t...

Page 75

73 3 a insert the stem of the quilting guide into the hole at the rear of the walking foot or presser foot holder. Walking foot presser foot holder b adjust the stem of the quilting guide so that the guide aligns with the seam that has already been sewn. Note ● the optional quilting guide is availab...

Page 76: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 74 d hold the quilting foot in place with your right hand, and then tighten the presser foot holder screw using the enclosed screwdriver in your left hand. E slide the feed dog position switch, located at the rear ...

Page 77: Reinforcement Stitching

75 3 reinforcement stitching reinforce points that will be subject to strain, such as sleeve holes, inseams and pocket corners. The values below “auto” are set when the pattern is selected. The setting can be adjusted to any value within the range indicated below “manual”. Triple stretch stitching w...

Page 78

Utility stitches ———————————————————————————————————————————————————————————————————— 76 bar tack stitching bar tacks are one type of reinforcement stitching used to strengthen points subject to strain, such as pocket corners and openings. As an example, the procedure for sewing bar tacks at pocket ...

Page 79

77 3 g pull down the buttonhole lever as far as possible. A buttonhole lever the buttonhole lever should be positioned behind the metal bracket on the buttonhole foot. A buttonhole lever b bracket h gently hold the end of the upper thread in your left hand, and then start sewing. X once sewing is co...

Page 80: Decorative Stitching

Utility stitches ———————————————————————————————————————————————————————————————————— 78 decorative stitching various decorative stitches can be sewn with this sewing machine. Stitch name pat ter n p re sse r f o o t application stitch width [mm (inch)] stitch length [mm (inch)] tw in n eedl e walk-...

Page 81

79 3 fagoting stitching across an open seam is called “fagoting”. It is used on blouses and children's clothing. This stitch is more decorative when thicker thread is used. A use an iron to fold the two pieces of fabric along their seams. B baste the two pieces of fabric, separated by about 4.0 mm (...

Page 82

Utility stitches ———————————————————————————————————————————————————————————————————— 80 c attach monogramming foot “n”. D stitch along the edge of the fabric, making sure not to sew directly on the edge of the fabric. • for better results, apply spray starch onto the fabric and press with a hot iro...

Page 83

81 3 shell tuck stitching the gathers that look like shells are called “shell tucks”. They are used to decorate trims, the front of blouses or cuffs made of thin fabrics. A fold the fabric along the bias. B turn on the machine. C select stitch , and then increase the thread tension. • for details, r...

Page 84: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 82 heirloom stitching when sewing with the wing needle, the needle holes are enlarged, creating a lace-like decorative stitch. This is used to decorate hems and tablecloths on thin or medium weight fabrics in addit...

Page 85

83 3 d with the right side of the fabric facing up, sew along the right edge of the frayed section. E turn the fabric around to sew the opposite side. F sew along the other edge of the frayed section so that it looks like the previous stitching. ■ drawnwork (example 2) a pull out several threads fro...

Page 86: Caution

Utility stitches ———————————————————————————————————————————————————————————————————— 84 using the side cutter (optional) by using the optional side cutter, overcasting stitching can be sewn while the edge of the fabric is cut off. The values below “auto” are set when the pattern is selected. The se...

Page 87: Caution

85 3 f position the side cutter so that the side cutter pin is aligned with the notch in the presser foot holder, and then slowly lower the presser foot lever. A notch in presser foot holder b pin x the side cutter is attached. G raise the presser foot lever to check that the side cutter is securely...

Page 88: Appendix

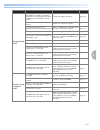

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 86 4 appendix stitch settings applications, stitch lengths and widths and whether the twin needle can be used are listed for utility stitches in the following table. Utility stitches...

Page 89

87 4 overcasting stitch g preventing fraying in thick fabrics and fab- rics that fray easily 5.0 (3/16) 3.5–5.0 (1/8–3/16) 2.5 (3/32) 1.0–4.0 (1/16–3/16) no no reinforcement j overcasting on stretch fabrics 5.0 (3/16) 0.0–7.0 (0–1/4) 2.5 (3/32) 0.5–4.0 (1/32–3/16) yes (j) no reinforcement blind hem ...

Page 90

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 88 fagoting stitch j fagoting, smocking and decorative stitch- ing 5.0 (3/16) 2.5-7.0 (3/32-1/4) 2.5 (3/32) 1.0-4.0 (1/16-3/16) yes (j) no reinforcement ladder stitch j decorative st...

Page 91

89 4 buttonhole stitch a keyhole buttonholes for thick or furry fabrics 7.0 (1/4) 3.0–7.0 (1/8-1/4) 0.5 (1/32) 0.3–1.0 (1/64-1/16) no no automatic reinforcement bar tack stitch a reinforcing openings and areas where the seam easily comes loose 2.0 (1/16) 1.0–3.0 (1/16-1/8) 0.4 (1/64) 0.3–1.0 (1/64-1...

Page 92: Maintenance

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 90 maintenance simple sewing machine maintenance operations are described below. Restrictions on oiling in order to prevent damaging this machine, it must not be oiled by the user. T...

Page 93: Caution

91 4 g use the enclosed cleaning brush or a vacuum cleaner to remove any lint and dust from the race and its surrounding area. A cleaning brush b race • do not apply oil to the race or bobbin case. H insert the bobbin case so that the s mark on the bobbin case aligns with the z mark on machine as sh...

Page 94

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 92 d return the needle plate to its original position, and then tighten the screws with the disc- shaped screwdriver. Note ● align the two screw holes on the needle plate with the tw...

Page 95: Troubleshooting

93 4 troubleshooting if the machine stops operating correctly, check the following possible problems before requesting service. If the problem persists, contact your authorized baby lock retailer. Frequent troubleshooting topics detailed causes and remedies for common troubleshooting topics are desc...

Page 96

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 94 d while holding the bobbin in place with your finger, pass the thread through the slit in the needle plate. • hold down the bobbin with your right hand, and then pull the end of t...

Page 97

95 4 d raise the presser foot using the presser foot lever. A presser foot lever • if the presser foot is not raised, the sewing machine cannot be threaded correctly. E press (needle position button) once or twice to raise the needle. A needle position button • if the needle is not correctly raised,...

Page 98

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 96 incorrect thread tension ■ symptoms • symptom 1: the lower thread is visible from the upper side of the fabric. • symptom 2: the upper thread appears as a straight line on the upp...

Page 99

97 4 fabric is caught in the machine and cannot be removed if the fabric is caught in the sewing machine and cannot be removed, the thread may have become tangled under the needle plate. Follow the procedure described below to remove the fabric from the machine. If the operation could not be complet...

Page 100

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 98 j use the enclosed disc-shaped screwdriver to loosen the two screws on the needle plate. Note ● be careful not to drop the removed screws in the machine. K slightly lift up the ne...

Page 101: Caution

99 4 q attach the needle plate cover according to steps i in “cleaning the race” on page 90. R check the condition of the needle, and then install it. If the needle is in a poor condition, for example, if it is bent, be sure to install a new needle. • refer to “checking the needle” on page 29 and “r...

Page 102: Caution

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 100 g correctly thread the machine. • for details on threading the machine, refer to “threading the upper thread” on page 20. Note ● the thread may have become tangled as a result of...

Page 103

101 4 c slide the bobbin winder shaft to the left, and then remove the bobbin from the shaft. D hold the thread end with your left hand, and wind off the thread clockwise near the bobbin with your right hand as shown below. E wind the bobbin again. Note ● make sure that the thread passes under the p...

Page 104

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 102 list of symptoms symptom probable cause remedy reference the sewing machine does not operate. The plug of the power cord is not inserted into an electrical outlet. Insert the plu...

Page 105

103 4 the upper thread breaks. The upper thread was incorrectly threaded (for example, the spool is incorrectly installed or the thread has come out of the needle bar thread guide). Correct the upper threading. Page 20 there are knots or tangles in the thread. Remove any knots or tangles. – the sele...

Page 106

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 104 the thread tension is incorrect. The upper thread is incorrectly installed. Correct the upper threading. Page 20 the bobbin thread is incorrectly installed. Correct the bobbin th...

Page 107

105 4 the thread does not pass through the eye of the needle. The needle was not raised. Press (needle position button) once or twice to raise the needle. Page 20 the needle is incorrectly installed. Correctly install the needle. Page 29 the stitch is not sewn correctly. The appropriate presser foot...

Page 108: Error Messages

Appendix ———————————————————————————————————————————————————————————————————————————————————————————————————————————— 106 error messages if the sewing machine is incorrectly operated or if the sewing machine malfunctions, an error message appears in the lcd. The message can be cleared by pressing an...

Page 109: Operation Beep

107 4 operation beep each time a key is pressed or an incorrect operation is performed, a beep is sounded. ■ for a correct operation one beep is sounded. ■ if an incorrect operation is performed two or four beeps are sounded. ■ if the machine locks up, for example, because the thread is tangled the ...

Page 110: Index

108 index numerics 1/4 inch quilting foot......................................................12 1/4 inch quilting foot with guide ....................................12 a accessory bag.................................................................11 adjustable zipper/piping foot ...................

Page 111

109 sewing machine needles ................................................27 sewing speed controller.............................................9 , 17 sewing stretch fabrics .....................................................49 sewing thick fabrics...................................................

Page 112

English 885-v15 printed in china xf7113-001.