- DL manuals

- Baby Lock

- Sewing Machine

- Quest BLQ2

- Instruction And Reference Manual

Baby Lock Quest BLQ2 Instruction And Reference Manual

Summary of Quest BLQ2

Page 2: Safety Instructions

Safety instructions when using an electrical appliance, basic safety should always be followed, including the following: read all instructions before using this sewing machine. -to reduce the risk of electrical shock: 1. An appliance should never be left unattended when plugged in. 2. Always unplug ...

Page 3

For safe operation for a longer service life for repair or adjustment for additional product information and updates, visit our website at 1. Be sure to keep your eye on the needle while sewing. Do not touch the handwheel, thread take-up lever, needle or other moving parts. 2. Remember to turn off t...

Page 4

Contents contents 3 instructions safety instructions........................................................................................................................................1-2 contents ......................................................................................................

Page 5

Useful sewing tips ............................................................................................................................................47 selecting stitches...........................................................................................................................

Page 6

0 1. All purpose foot (ra) 2. Zipper foot (rb) 3. (rc) 4. Gathering foot (rd) 5. 1/4" inch quilting foot (re) 6. Quilting foot (rf) 7. Hemmer foot (rg) 8. Cording foot (rh) 9. Overcasting foot (ri) 10.Buttonhole foot (rj) 11.Satin stitch foot (rk) 12.Open toe foot (rn) 13.Darning/ embroidery foot (r...

Page 7

Principal parts of the machine 6 principal parts of the machine tension dial spool pins retractable thread guide face plate presser foot pressure dial handwheel foot control connector main power switch handle presser foot lever drop feed lever lcd screen thread cutter operation buttons selection but...

Page 8

Foot control foot control attention: consult a qualified electrician if in doubt as how to connect the machine to the power source. Unplug the power cord when the machine is not in use. The appliance must be used with the foot control c-9001 manufactured by chien hung taiwan., ltd. With the sewing m...

Page 9

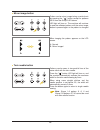

Operation buttons operation buttons the machine will start running when the start/stop button is pressed and will stop when pressed the second time. The machine will stitch slowly at the beginning of the sewing. The sewing speed can be controlled by the sewing speed controller. Start/stop button rev...

Page 10

When the group 2-b patterns 00-05, 45 and group 3-c patterns 01-02, 04, 18 are selected, the machine will immediately sew 3 locking stitches when the auto-lock button is pressed, then will automatically stop. The lcd screen will display the figure " " until the locking stitches stop. Auto-lock butto...

Page 11

Function buttons function buttons stitch width adjustment buttons when you select a stitch, the machine will auto- matically set the recommended stitch width, which will be indicated by numbers on the lcd screen. The stitch width can be regulated by pressing the stitch width adjustment buttons. Cert...

Page 12

11 stitch length adjustment button when you select a stitch the machine will automatically set the recommended stitch length which will be indicated by numbers on the lcd screen. The stitch length can be adjusted by pressing the stitch length adjustment buttons. For a shorter stitch, press the left ...

Page 13

Put the empty bobbin on the bobbin winder shaft. Push the bobbin winder switch to the left. Press the " " button to wind the bobbin. The led light will be on while the bobbin is winding. Bobbin can wind in any operation mode. 12 key lock button press the " " button to lock the function and selection...

Page 14

13 mirror imaging the pattern appears on the lcd screen. A- normal b - mirror imaged a b mirror image button pattern can be mirror imaged along a vertical axis by pressing the " " button except for patterns 30-49 from the group 2-b patterns. Led light will turn on. The machine will continue to sew t...

Page 15

Selection buttons selection buttons direct pattern selection and number buttons clear button edit button memory button direct pattern selection and number buttons direct pattern selection press the numbered button to the right of the utility pattern shown when the mode button (func) is set at the di...

Page 16

15 when combining characters or decorative patterns, press the " " button to clear or erase one character or pattern. See page 84 for details. Clear button if you wish to modify the pattern settings in the memory mode, use the stitch width "+" or "" button to select the pattern to be modified. Pres...

Page 17

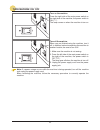

Connecting the machine to the power source connecting the machine to the power source connecting the machine before connecting the power supply, make sure that the voltage and the frequency shown on the machine is conforming to your electrical power. Place the machine on a stable table. 1. Connect t...

Page 18

Turn machine on/ off turn machine on/ off turn on the machine press the right side of the main power switch on the right side of the machine, the the lamp comes on when the machine is turn on. Power switch is on (" i ") . Turn off the machine when you are finished using the machine, turn it off. In ...

Page 19

Understanding the lcd screen understanding the lcd screen pattern tension needle position stitch length suggested presser foot and identification letters pattern alphabet sound on stitch width group mode bobbin winding sound on group mode pattern number single needle needle up position auto-stop sug...

Page 20

Memory elongation needle up position pattern stitch length suggested presser foot and identification letters mirror tension bobbin winding stitch width pattern number magnification single needle sound on auto-stop memory number pattern to edit sound on needle up position auto-stop mirror total numbe...

Page 21

Winding the bobbin winding the bobbin 1. Place the spool of thread and spool cap onto the spool pin. For smaller spools of thread, use the small spool cap. Spool cap should be close in size to the thread spool, however should not be any smaller. If the spool cap is smaller than thread spool, thread ...

Page 22

21 7. While holding the thread tail securely in one hand, push the bobbin winder switch to the left. 7 6 6. Place the thread end through one of the inner holes in the bobbin as illustrated and place the empty bobbin on the bobbin winder shaft. 5 5. Pass the thread clockwise around the bobbin winder ...

Page 23

Note: when the bobbin winder button is pushed without pushing the bobbin winder switch to the left, the following screen is displayed for a few seconds. Attention: since this machine is equipped with an independent bobbin winder the sewing speed controller does not effect the winding speed. Keep fin...

Page 24

Attention: turn power switch off ("o") before inserting or removing the bobbin. Press the needle position button to raise the needle before inserting or removing the bobbin. 1. Open the hinged cover. 2. It is important to be sure that the bobbin is turning in a clockwise direction (arrow). 3. Hold t...

Page 25

Inserting the bobbin inserting the bobbin 24 6. Hold the bobbin case by the hinged latch. Insert the bobbin case fully into the shuttle race and release the latch. 7. Close the hinged cover. 7 6 5 5. Pull the bobbin thread through the metal hook using a clockwise motion..

Page 26

Upper threading upper threading note: it is important to thread the machine correctly. Improper threading could result in several sewing problems. 6 7 8 9 10 2 1 3 4 5 25 before threading the machine, raise the needle to its highest point and raise the presser foot to release the tension discs. 1. S...

Page 27

26 3. Place the thread through the appropriate thread guide opening for the spool pin that is being used. 4. Guide the thread into the pre-tension thread guide pulling the thread through the pre- tension spring as illustrated. 5. Pull the thread downward from the thread guide. 6. Draw the thread dow...

Page 28

9. Insert the end of the thread through the eye of the needle from front to back or use the needle threader to thread the needle. ( see next page for needle threader instructions.) 10.Place the thread under the foot and pull out approximately 15 cm (6 inches) of thread to the back of the machine. 27...

Page 29

2. Pivot the needle threader into the threading position so the hook pin passes through the needle eye. 3. Pass the thread in front of the needle to catch the hook of the threader. 4. Hold the thread loosely and return the threader to its original position. The hook will turn and pull the thread thr...

Page 30

If using special threads which wind quickly off the thread spool, attach a net to the spool before using. * cut the net to match the size of the spool. Net thread spool spool pin spool cap using the net 3 1 2 29.

Page 31

1. Hold the upper thread with the left hand. Turn the handwheel towards you (counterclockwise) lowering, then raising the needle. 2. Gently pull on the upper thread to bring the bobbin thread up through the needle plate hole. The bobbin thread will come up in a loop. 3. Pull both threads to the back...

Page 32

Raise the presser foot. Remove the fabric, draw the threads to the left side of the face cover and cut using the thread cutter. The threads are cut at the proper length to start the next seam. Cutting the thread cutting the thread attention: turn power switch to off. ( when replacing the needle ! "o...

Page 33

32 changing the presser foot changing the presser foot attention: turn power switch to off ( ) when carrying out any of the following operations! "o" b a raise the presser foot bar (a). Position the presser foot holder (b) in place and attach as illustrated. Attaching the presser foot holder lower t...

Page 34

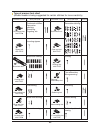

Type of presser foot chart (double needle is being suggested for certain stitches for more creativity) 33 all purpose foot with pdq zipper foot with pdq buttonhole foot cording foot with pdq overcasting foot with pdq blind hem foot with pdq hemmer foot with pdq darning/ embroidery foot gathering foo...

Page 35

Two-step presser foot lifter 1. The presser foot lever raises and lowers your presser foot. 2. When sewing several layers or thick fabrics, the presser foot can be raised a second stage for easy positioning of the work. 2 1 34.

Page 36

Precision dual-feed quilting (pdq ) ® precision dual-feed quilting (pdq ) ® the system feeds fabric from the top and bottom simultaneously to ensure matching of checked, striped or plaid fabrics. When sewing light or difficult materials such as silk or rayon fabrics, the system prevents seam puckeri...

Page 37

Pull down pdq mechanism and swing it to the rear to disengage. The push pdq mechanism up. The to disengage the pdq system raise the presser foot. 36 fabric positioning place fabric flat on top of needle plate and position the fabric under presser foot. While holding the thread tails with left hand t...

Page 38

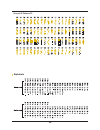

On the chart below the portion marked in gold shows a single unit of each pattern. Pattern chart pattern chart patterns 37 group 1-a patterns ( -10 direct patterns) group 2-b patterns-93 group 3-c patterns-25.

Page 39

Alphabets 38 group 4-d patterns-79.

Page 40

Matching needle/ fabric/ thread matching needle/ fabric/ thread 16 (100) needle, fabric, thread selection guide 12-14 (80-90) medium weight fabrics-cotton, satin, sailcloth, double knits, lightweight woollens. Medium weight fabrics-cotton duck, woolen, heavier knits, terrycloth, denims. Heavyweight ...

Page 41

Thread tension thread tension - basic thread tension setting: "4" - to increase the tension, turn the dial to the next number up. To reduce the tension, turn the dial to the next number down. - proper setting of tension is important to good sewing. - there is no single tension setting appropriate fo...

Page 42

For a shorter stitch, press the left side of the button "". For a longer stitch, press the right side of button "+". The stitch length can be adjusted between "0.0-5.0". Certain stitches have a limited stitch length range. Note: length & width adjusting length & width adjusting stitch width adjusti...

Page 43

Pattern balance adjustment pattern balance adjustment ifthe decorative stitch patterns, numbers or manual buttonhole stitch are uneven when you sew on a particular fabric, adjust them with the pattern adjustment dial. Use a coin to turn the dial slightly towards the "+" or "". The pattern adjustmen...

Page 44

Presser foot pressure adjustment the presser foot pressure dial is on the top of the face plate. The presser foot pressure of the machine has been preset and usually requires no particular readjustment. The foot pressure dial should be set near "1" for regular sewing. Adjust the pressure between "0"...

Page 45

Useful functions useful functions reverse stitching is used to secure the threads at the beginning and at the end of a seam. Press the reverse button and sew 4-5 stitches. The machine will sew forward when the button is released. Free-arm sewing is convenient for sewing tubular areas such as pant he...

Page 46

45 1. Take out the extension table and seven extension table feet from the packaging. Place one of the feet under one of the holes in the and tighten the top screw with the . Repeat for the remaining feet. Remove the screws from each of the feet with the large slotted screwdriver. Extension table la...

Page 47

46 with the sewing table off the machine, the feed dog adjustment lever is located at the base of the free-arm in the front of the machine. Sliding the lever to the " " (b) will lower the feed dog, for example during button sewing. If you wish to continue sewing normally, slide the lever to the " " ...

Page 48

Useful sewing tips useful sewing tips 1. Stop the sewing machine when you reach a corner. 2. Lower the needle into the fabric manually or by pressing the needle up/down button till needle is in down position. 3. Raise the presser foot. 4. Use the needle as a pivot and turn the fabric. 5. Lower the p...

Page 49

Selecting stitches selecting stitches 48 using the selection buttons ten of the most frequently used utility stitches can quickly be selected with the selection buttons. Select the desired stitch from those shown on the stitch pattern plate. When the sewing machine is turned on, the straight stitch ...

Page 50

Basic stitching basic stitching straight stitches and needle position zigzag stitches changing the needle position this setting can be applied only to patterns 1-4 from group 1-a, group 2-b patterns 00-05, 27-29, group 3-c patterns 00-02, 04, 18 and group 4-d pattern 50. The pre-set position is "4.0...

Page 51

Stretch stitch stretch stitches assure you of a stitch that is strong and flexible and will give with the fabric without breaking. The flexibility of the straight stretch stitch makes it ideal for seaming heavy, knit or easy to ravel fabrics. These stitches can also be used as a bold, decorative top...

Page 52

1. Fold the fabric as illustrated with the wrong side facing up. 2. Attach the blind hem foot. Place the fabric under the foot. Turn the handwheel towards you by hand until the needle swings fully to the left. It should just pierce the fold of the fabric. If it does not, adjust the stitch width or g...

Page 53

Using the overcasting foot 1. Change the presser foot to the overcasting foot. 2. Sew the fabric with the fabric edge against the guide of the overcasting foot. Attention: the overcasting foot should be used to sew with group 2-b patterns 06 and 09 only and do not set the stitch width narrower than ...

Page 54

1. Baste the zipper opening on the garment. 2. Press open the seam allowance. Place the zipper face down on the seam allowance with the teeth against the seam line. Baste the zipper tape. 3. Attach the zipper foot. Attach the left side of the presser foot pin to the presser foot holder when sewing t...

Page 55

1. Baste the zipper opening on the garment. 2. Fold the garment back to the left seam allowance. Turn under the right seam allowance to form a 3mm (1/8 inch) fold. 3. Attach the zipper foot. Attach the left side of the presser foot pin to the presser foot holder when sewing the right side of the zip...

Page 56

1. Select the pattern 43 from the group 2-b patterns to get the button sewing stitch. Change the presser foot to the button sewing foot "rc" and lower feed dogs. 2.5~4.5 button sewing button sewing 1 2. Position the fabric under the foot. Place the button in the desired position, lower the presser f...

Page 57

Note: before sewing a buttonhole on your project, practice on a scrap piece of the same type of fabric. Buttonhole stitching buttonhole stitching 1. Mark the position of the buttonholes on the fabric. The maximum buttonhole length is 3cm (1 3/16 inch). (total of diameter + thickness of button.) 2. A...

Page 58

3. Select the buttonhole stitch. Adjust the stitch width and the stitch length to the desired width and density. Position the fabric under the presser foot with the front end of the buttonhole mark aligned with the center line on the buttonhole foot. 4. Pull the buttonhole lever all the way down and...

Page 59

30 31 32 33 34 35 36 37 38 39 6. Buttonholes are sewn from the front of the presser foot to the back, as shown. 7. Raise the presser foot and cut thread. To restart the same buttonhole at the beginning, raise the presser foot to return to the starting position. After sewing the buttonholes, raise th...

Page 60

8. Cut the center of the buttonhole being careful not to cut any buttonhole stitches on either side. Use a pin as a stopper at the bartack to prevent the stitching from being cut. 8 when sewing buttonholes on stretch fabric, hook gimp thread under the buttonhole foot. 1. Attach the buttonhole foot a...

Page 61

1. Select pattern 44 from the group 2-b patterns to get the bar tack stitch. Change the presser foot to the buttonhole foot. Bar tack stitch bar tack stitch 1.0~3.0 0.4~1.0 2. Extend the button guide plate and set to the desire bartack length. Adjust the stitch width and stitch length to personalize...

Page 62

1. Select pattern 45 from the group 2-b patterns to get the bar tack stitch. The stitch width and stitch length can be . Change to the satin stitch presser foot "rk". Adjusted 2. Position the needle at the top edge of the pocket opening. 3. Press the start/stop button or push on the foot control to ...

Page 63

Eyelet stitch eyelet stitch 1. Select pattern 40 or 41 from group 2-b patterns to get the eyelet stitch. Attach the satin stitch presser foot "rk". 2. Press the "" or "+" stitch width adjustment button to select the eyelet size. Size of eyelet. A. 8.0mm (5/16 inch). B. 7.0mm (1/4 inch). C. 6.0mm (1...

Page 64

2mm 1. Select pattern 46, 47 or 48 from group 2-b patterns to get the darning stitch. Change the presser foot to the buttonhole foot "rj". 2. Baste the upper fabric and the reinforcement fabric together. Select the width of the pattern by using the stitch width button. Lower the presser foot over th...

Page 65

6. Pass the upper thread down through the hole in the presser foot. Pull down the buttonhole lever and position it behind the bracket on the buttonhole foot. Gently hold the end of the upper thread in your left hand, and then start sewing. Note: when you start to sew darning pattern before the butto...

Page 66

1. Fold the edge of the fabric over about 3mm (1/8 inch), then fold it over again 3mm (1/8 inch) for about 5cm (2 inches) along the edge of the fabric. 2. Insert the needle into the fold by rotating the handwheel toward you, and lower the presser foot. Sew several stitches and raise the presser foot...

Page 67

Quilting quilting 66 sew a 1/4" seam allowance. Red lines mark 1/4" and 1/8" pivot points in front of and behind the needle. Sew with edge of fabric at the edge of the 1/4" quilting foot "re". To pivot 1/4" from end of fabric; when fabric edge reaches the first red mark on foot stop sewing with need...

Page 68

Place the two pieces of fabric with the right sides together and sew with the straight stitch. Open the seam allowances and press it flat. On the right side of the joined pieces of fabric place the center of the presser foot on the seam line and sew over the seam with decorative stitching. Decorativ...

Page 69

Note: free motion darning is accomplished with the feed dog in the lowered position. Movement of the fabric is controlled by the operator; therefore it is necessary to coor- dinate sewing speed and the movement of fabric. Remove the presser foot holder, and attach the darning foot to the presser foo...

Page 70

Free motion embroidery mark the design to be embroidered on the fabric with wash-out marker. Place fabric and stabilizer in an embroidery hoop. Raise the needle to its highest position and slide the hoop under the needle. Lower the presser foot lever. Hold the needle thread in the left hand; turn th...

Page 71

Use the edge/quilting guide to sew parallel stitches that are equally spaced. Insert the bar of the edge/quilting guide into the slot at the rear of the presser foot holder as illustrated. Adjust the bar of the edge/quilting guide to the width from the needle that you desire. Sew the first row of st...

Page 72

Mark the design on the fabric. Insert the cord in the center groove of the cording foot from the right side opening. Pull the cord about 5cm (2 inches) behind the foot. The grooves under the foot will hold the length of the cord in place while the stitches are being form over the cord. Select the st...

Page 73

1. Separate the folded edges of the fabric pieces with a gap of 4mm (1/8 inch) and baste them onto a piece of thin paper or water-soluble stabilizer sheet. 2. Align the center of the presser foot with the center of the two pieces of fabric and begin sewing. 3. After sewing, remove the paper. Fagotin...

Page 74

Gather one layer of fabric or gather one layer and attach it to a flat fabric piece at the same time using the gathering foot. This foot gathers light to medium weight fabrics particularly well. It is usually necessary to use other sewing techniques to gather heavier fabrics. 1. Remove the presser f...

Page 75

Look closely at the gathering foot to see a slot on the bottom. When using the slot, you can gather the bottom layer of the fabric while attaching it to a flat top layer, such as the waistband on a dress bodice. 1. Remove the presser foot holder and attach gathering foot. 2. Place the fabric to be g...

Page 76

See stitch reference chart on page 93 for stitch length and stitch width ranges. Use the satin stitch foot for satin stitching and sewing decorative stitches. This foot has a full indentation on the underside to allowed easy sewing over the thickness of the stitches form by closely spaced zigzag sti...

Page 77

1. Place the fabric right sides together and sew along the edge. 2. Cut the fabric along the seam leaving an allowance of 3mm (1/8 inch) for seaming. Notch the allowance. 3. Turn the fabric over and push out the curved seam to the surface and press flat with iron. 1. Place the fabric wrong sides tog...

Page 78

R a 1. Use the all purpose foot to sew straight lines 1cm (3/8 inch) apart, across the area to be smocked. 2. Knot the threads at the beginning of the stitch- ing. Pull the bobbin threads and distribute the gathers evenly. Secure the threads at end of the stitching. 3. Reduce the tension, if necessa...

Page 79

The twin needle 2.0~6.0 the twin needle 1 78 * twin needle is not included with the machine. R a with a twin needle, you can sew two parallel lines of the same stitch using two different threads; however make sure that the two threads are of the same weight and quality for balanced stitching. The ne...

Page 80

4. Be sure to thread each needle thread path separately. 5. Select a stitch pattern. Except patterns 27-49 from group 2-b, other patterns can be used with a twin needle. Press the twin needle button, the led light will turn on, and the machine automatically reduces the maximum width for twin needle ...

Page 81

Elongation elongation 2.5~8.0 0.3~1.0 1. The stitch can be elongated up to five times its normal length by pressing the elongation button. 1 func 3 2 2. The elongation icon appears on the lcd screen with the elongated image of the selected pattern. 3. Press the elongation button to lengthen the patt...

Page 82

Mirror image mirror image 1. Press func and group 4-d, then select pattern 11. 1 2 3. The lcd screen icon for mirror imaging of the pattern appears. 2. Press the mirror image button. Note: - patterns 30-49 from group 2-b patterns cannot be mirror imaged. - mirror imaged patterns can also be combined...

Page 83

Memory function memory function note: - multiple patterns selecting from groups 2-b, 3-c, 4-d, 5-a, 6- can be combined and sewn together. - direct patterns, group 2-b patterns 27-49 and group 3-c pattern 00 cannot be entered into memory. - 20 patterns can be combined in each of the 8 memory pockets....

Page 84

83 6 7 6. Press the desired pattern number. (e.G. 82) (upper left corner of lcd shows the number of the memory opened- e.G. M2.) 8 7. The selected pattern displays on the lcd screen and the cursor moves to the second position. 8. Repeat step 5~7 for more patterns to be stored in the memory. Note: di...

Page 85

84 editing patterns 1. Press the " " button and the number of the memory you wish to edit. Press the stitch width adjustment button to move the cursor to the pattern you wish to edit. 2. Press the " " button to edit the pattern. The stitch length, stitch width, elongation, mirror imaging and auto-lo...

Page 86

85 1. Press the " " button to enter the memory mode and then input the number of the memory when the cursor start flashing. 2. Input the number of the memory you wish to recall or sew. (e.G. 2) recalling and sewing the memorized pattern 1 2 5. The cursor on the lcd screen will move along with the se...

Page 87

Warning functions warning functions warning animation message display presser foot is not lowered the start/stop button or reverse button was pressed while the presser foot was in the "up" position. Lower presser foot lever. Bh lever is not lowered the buttonhole or darning stitch was selected and t...

Page 88

Attention: if the thread gets jammed inside the bobbin area stopping the needle from moving and you continue pressing the foot control, the security switch will stop the machine completely. Turn off the machine, clean all thread and lint from the bobbin area. Rethread the machine completely; turn on...

Page 89

3 88 2. You can select the mode by pressing the stitch width "+" or "" button. Select desired mode sound on " "or sound off " ". On off 1 2 1. You can mute the beeping sound in normal operation. Press and hold the " " button and turn on the power switch. Beeping sound 3. Press the " " button after ...

Page 90

Attention: disconnect the power cord from the wall socket before cleaning the lcd screen and sewing machine surface, otherwise injury or electrical shock may result. If the front panel is dirty, wipe it gently with a soft, dry cloth. Do not use any organic solvents or detergents. If the surface of t...

Page 91

2. Open the hinged cover. 3. Remove the bobbin. 4. Remove the needle, presser foot, and presser foot holder. Remove the screws holding the needle plate and remove the needle plate. 5. Clean the hook race, feed dog and bobbin case with a brush. Also clean them, using a soft, dry cloth. 6. Apply a dro...

Page 92

Before calling for service, check the following items. If the problem still persists, contact the place of purchase or your nearest authorized baby lock retailer. Trouble shooting trouble shooting problem cause correction upper thread breaks lower thread breaks skipped stitches needle breaks loose s...

Page 93

Seam puckering patterns are distorted 1.The needle thread tension is too tight. 2.The needle thread is not threaded correctly. 3.The needle is too heavy for the fabric being sewn. 4.The stitch length is too long for the fabric. 5.The presser foot pressure is not correctly adjusted. 1.The correct pre...

Page 94

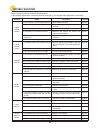

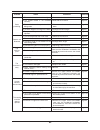

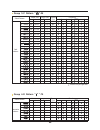

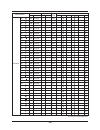

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 4.0 8.0 4.0 4.0 4.0 4.0 3.5 6.0 6.0 6.0 6.0 6.0 6.0 6.0 6.0 4.0 3.0 3.0 3.0 4.0 6.0 6.0 0.0~8.0 0.0~8.0 0.0~8.0 0.0~8.0 0.0~8.0 1.0~7.0 0.0~8.0 1.0~8.0 2.5~8.0 4.0~8.0 2.5~8.0 2.5~8.0 2.5~8.0 2.5~8.0 2.5~8.0 2.5~8.0 2.5~6.0 2.5~8.0 2....

Page 95

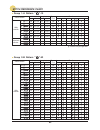

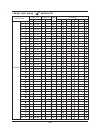

Functions presser foot stitch pattern auto manual auto manual auto-lock elongation mirror twin needle reverse width (mm) length (mm) memory presser foot 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 6.0 4.0 4.0 6.0 4.0 4.0 ...

Page 96

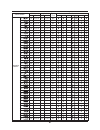

63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 7.0 7.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3.0~8.0 3....

Page 97

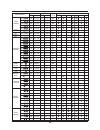

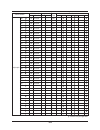

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 4.0 4.0 7.8 6.0 1.8 2.5 2.5 2.0 3.0 3.0 2.0 6.0 6.0 6.0 8.0 8.0 8.0 8.0 4.0 8.0 5.0 5.0 8.0 7.0 7.0 0.0~8.0 0.0~8.0 0.0~8.0 4.5~8.0 0.0~8.0 2.0~8.0 2.0~8.0 1.5~8.0 2.0~8.0 2.0~8.0 2.0~8.0 2.5~8.0 3.5~8.0 2.5~8.0 3.5~8.0 3.5~8...

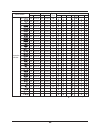

Page 98

07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0 7.0 8.0 8.0 8.0 7.0 8.0 8.0 8.0 7.0 7.0 7.0 7.0 7.0 8.0 5.0 3.5~8.0 3.5~8...

Page 99

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 5.0 8.0 4.0 7.0 7.0 7.0 7.0 8.0 8.0 7.0 8.0 7.0 7.0 7.0 8.0 7.0 8.0 8.0 8.0 8.0 7.0 7.0 8.0 8.0 7.0 8.0 5.0 7.0 7.0 8.0 8.0 3.5~8.0 3.5~8.0 0.0~8.0 3.5~8.0 3.5~8.0 3.0~8.0 3.0~8.0 5.0~8.0 5.0~8.0 5.0~8.0 5.0...

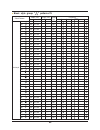

Page 100

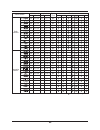

Functions presser foot stitch pattern auto manual auto manual auto-lock elongation mirror twin needle reverse width (mm) length (mm) memory presser foot block style 99 block style group " " patterns-78 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33...

Page 101

Functions presser foot stitch pattern auto manual auto manual auto-lock elongation mirror twin needle reverse width (mm) length (mm) memory presser foot block style 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 8.0 8.0 8.0 8.0 8....

Page 102

Script style 101 script style group " " patterns-78 functions presser foot stitch pattern auto manual auto manual auto-lock elongation mirror twin needle reverse width (mm) length (mm) memory presser foot 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32...

Page 103

Script style functions presser foot stitch pattern auto manual auto manual auto-lock elongation mirror twin needle reverse width (mm) length (mm) memory presser foot 102 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 8.0 8.0 8.0 8...

Page 104

021r1a0101(c)( ) may/08 baby lock ( ) blq2 rt.