- DL manuals

- Bacharach

- Test Equipment

- FYRITE Gas Analyzer CO2 and O2 Indicators

- Instrucciones Breves Manual

Bacharach FYRITE Gas Analyzer CO2 and O2 Indicators Instrucciones Breves Manual

Summary of FYRITE Gas Analyzer CO2 and O2 Indicators

Page 1

Instruction 0011-9026 page 1 printed in u.S.A. ® registered trademarks instruction 0011-9026 fyrite ® gas analyzer co 2 and o 2 indicators operation/maintenance rev. 12 – december 2012 ® 20 16 12 8 4 %co 2 0

Page 2: Warranty

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in mater ial and manufac ture and will conform substan tially to bacharach inc.’s ap plicable specifi cations. Bacharach’s liability and buyer’s remedy under this warranty are limited to th...

Page 3: Fyrite Safety Precautions

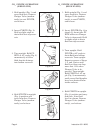

Fyrite safety precautions the operator (s) of this instrument should thoroughly familiarize themselves with the applicable safety precautions before handling or using the fyrite for gas analysis. Review figures 1a,1b, 1c and 1d on this page. Make certain to follow the steps out- lined below and read...

Page 4: Table of Contents

Table of contents 1.0 description................................................................................................................................................1 2.0 fyrite inspection before and during test ...............................................................................

Page 5: Instructions 0011-9026

Instruction 0011-9026 page 1 instructions 0011-9026 operation/maintenance bacharach fyrite models co 2 and o 2 indicators 1.0 description (refer to figure 1) the fyrite employs the well-known “orsat” method of volumetric analysis involving chemical absorption of a sample gas, such as carbon dioxide ...

Page 6

Instruction 0011-9026 page 2 (b) fyrite fluid strength to check fl uid strength. Note: when repeating procedures as outlined in section 3.0 steps 7 through 9 (absorbing and reading percent o 2 and ab- sorbing and reading percent co 2 ) and before venting fyrite to atmosphere for next sample, if the ...

Page 7

Instruction 0011-9026 page 3 hazards corrosive liquid causes burns. May cause blindness if splashed in eyes. Vapors are irritating and may be harmful. Precautions prevent contact with eyes, skin and clothing. Wear eye protection and gloves. Do not vent instrument until fl uid has drained from top we...

Page 8

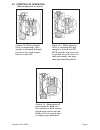

Instruction 0011-9026 page 4 co 2 fyrite operation o 2 fyrite operation (red fluid) (blue fluid) 1. Hold upright (fig. 1) and away from face. Depress plunger valve (momen- tarily) to vent fyrite, and release. 2. Invert fyrite (fig. 2). Hold at slight angle to drain fl uid into top reser- voir. 3. Tu...

Page 9

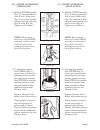

Instruction 0011-9026 page 5 figure 5 figure 5a figure 5b figure 6 co 2 fyrite operation o 2 fyrite operation (red fluid) (blue fluid) 5. Holding fyrite upright (fig. 5), loosen locknut at rear of scale. Slide scale (fig. 5a) until top of fl uid column lines up with zero line on scale (fig. 5b). Tig...

Page 10

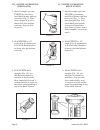

Instruction 0011-9026 page 6 7. Absorb sample gas into fyrite by inverting until fl uid drains into top reservoir (fig. 7). Then turn upright (fig. 8) to drain fl uid into bottom reservoir. Repeat this step once. 8. Hold fyrite at 45° angle (fig. 9) momentari- ly to allow fl uid droplets to drain in...

Page 11

Instruction 0011-9026 page 7 10. This step completes co 2 or o 2 fyrite gas sample analysis. A few points to re- member when reading the fyrite: (a) fyrite accuracy is within ±1/2% co 2 or o 2 compared to actual value. (b) always handle fyrite by fi ns to ensure body heat is not absorbed by fl uid. ...

Page 12

Instruction 0011-9026 page 8 3.2.1 draining fluid droplets for maximum accuracy, it is important to form the habit of follow ing a standard procedure in this operation and to use the same procedure both before adjusting scale zero and before reading percent co 2 or o 2 . 3.3 fyrite temperature the f...

Page 13

Instruction 0011-9026 page 9 figure 12. When plunger valve is depressed, a gas sample is pumped through top reservoir with center bore is sealed off. Figure 13. When plunger valve is released, the gas sample is locked into fy- rite and the top reservoir is opened to center bore so that gas sample ca...

Page 14

Instruction 0011-9026 page 10 to make a test with the fyrite, the metal sampling tube at one end of sampling assembly hose is inserted into the gas to be analyzed. The rubber connector plug at the other end of the rubber hose is then fi rmly pressed down on the spring-loaded valve of the instrument ...

Page 15

Instruction 0011-9026 page 11 fyrite co 2 refi ll fl uid may develop a white insoluble precipitate upon aging. The precipitate does not affect fl uid performance in any way, but if present, should be fi ltered out to prevent adherence to internal surfaces of the fyrite. To fi lter, place a clean pie...

Page 16

Instruction 0011-9026 page 12 0-7.6% co 2 or o 2 co 2 tests of controlled atmospheres in fruit, vegetable, and meat storage rooms. Oxygen determination in fl ammable gases. Oxygen tests to check atmospheres made inert with nitrogen (silos, fuel tanks, etc.) 0-20% co 2 or 0-21% o 2 flue gas combustio...

Page 17

Instruction 0011-9026 page 13 excess combustion air is heated and carries some of this heat to the fl ue where it is wasted. The fyrite co 2 analyzer is used to adjust combustion excess air to a mini- mum (maximum co 2 ), which will permit clean effi cient combustion. Calculation of combustion effi ...

Page 18

Instruction 0011-9026 page 14 proper o 2 content for any fuel fi red is the lowest o 2 value that will ensure complete, clean combustion with adequate safety margin for variations in fuel, draft, atmospher- ic conditions, and mechanical wear. Consult manufacturer of heating equipment or local author...

Page 19

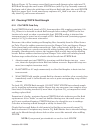

Instruction 0011-9026 page 15 figure 15. Relation between oxygen, co 2 and excess air in fl ue gases for natural gas and fuel oil. Theoretical excess air curve percent excess air stoichiometric mix figure 16. Co 2 measurements alone do not determine combustion air setting when fi ring gaseous fuels..

Page 20

Instruction 0011-9026 page 16 as a rule of thumb, background gases/vapors may be present in con centrations up to 1/2% by volume (5000 ppm) before they present a signifi cant interference problem to the co 2 or o 2 fyrite (20/21% ranges). An exception exists with the action of ammonia on oxygen fyri...

Page 21

Instruction 0011-9026 page 17 figure 17. Checking co 2 of gas designed furnace (sampling tube inserted through draft diverter; fl ue gas temperature test can be made at same point). 5.7 general fyrite applications it is only possible to specify a few general rules for such applications. Where possib...

Page 22

Instruction 0011-9026 page 18 the gas concentration read on the fyrite is directly dependent upon the mass of air in the sample. The aspirator bulb used in the fyrite is a constant-volume pump, not a constant-mass pump. Altitude, therefore, affects the fyrite reading due to the air’s density changin...

Page 23

Instruction 0011-9026 page 19 refer to figure 19. To remove excess fl uid, insert small diameter glass tube into fy- rite fl uid through the small center fyrite bore (with top cap assembly removed). Seal open end of glass tube with fi nger and dip out fl uid with glass tube until fyrite fl uid is at...

Page 24

Instruction 0011-9026 page 20 ® 20 16 12 8 4 %co 2 0 20 16 12 8 4 %co 2 0 ® 20 16 12 8 4 0 ® %co 2 top gasket top cap/ plunger valve assembly oval head screws top cap ring with gasket 20 16 12 8 4 %o 2 0 ® figure 18. Increasing fyrite fl uid to proper level. Figure 19. Decreasing fyrite fl uid to pr...

Page 25

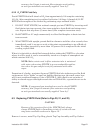

Instruction 0011-9026 page 21 accuracy don’t forget to saturate fi lter saturator wool packing as such gas standards are usually supplied “bone dry”. 6.2.2 o 2 fyrite fluid only fresh fyrite fl uid will absorb all o 2 from approximately 100 samples containing 10% o 2 . After completing test (as outl...

Page 26

Instruction 0011-9026 page 22 drain old fl uid from fyrite and rinse all parts in clean, lukewarm water. Note: fyrite fl uid is corrosive to skin, clothing, some met- als, and painted or lacquered surfaces. Dispose of these fl uids in accordance with local, state and federal laws. If draining into a...

Page 27

Instruction 0011-9026 page 23 20 16 12 8 4 %co 2 0 2 0 1 6 1 2 8 4 % co 2 0 ® 20 16 12 8 4 %co 2 0 ® gasket body top cap assembly top gasket used in 7%, 20% & 21% models only ® 20 16 12 8 4 %co 2 0 figure 21a. Alternate fi lling meth- od. Invert fyrite (with bottle in place) to upright position. Fig...

Page 28

Instruction 0011-9026 page 24 mine replacement parts necessary for repair, or drain instrument and return if factory service or repair is desired. 6.5 cleaning fyrite use only soapy lukewarm water if cleaning is required (lukewarm water is usually suffi cient). Note: use of gasoline, naptha, carbon ...

Page 29

Instruction 0011-9026 page 25 figure 25a. Replacement diaphragm properly installed. Figure 25. Locating bezel rubber gaskets. Figure 26. Fyrite sampling assembly; locating inlet/outlet check valves. 2 0 1 6 1 2 8 4 % co 2 0 ® lettering bottom cap (recess).

Page 30

Instruction 0011-9026 page 26 with fi nger and squeeze aspirator bulb (figure 27). Bulb should remain fi rm. If bulb collapses, check bulb and hose to connector tip for cracks or other source of leakage. Replace defective parts. If there are no apparent leaks in the sampling assembly, replace inlet ...

Page 31

Instruction 0011-9026 page 27 aspirator bulb should remain firm when squeezed rubber connector tip (hold finger here) check for bulb inflation after squeezing sampling tube end (hold finger here) figure 27. Testing sampling assembly (outlet side) for leaks. Figure 28. Testing sampling assembly (inle...

Page 32

Instruction 0011-9026 page 28 figure 30. Wrapping replacement filter material. Figure 31. Wet filter material then squeeze out excess water. Figure 32. Installing wetted filter material into saturator tube..

Page 33

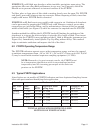

Instruction 0011-9026 page 29 part # description qty-rq’d 11-0102 bezel 4 11-0188 oval head screw 8 11-0110 bezel screw 4 11-0109 top cap ring gasket (optional, part of 11-0136) 1 11-0105 scale screw 1 02-3690 scale screw nut 1 11-0021 diaphragm 1 11-0126 bottom cap 1 11-0132 top cap 1 11-0019 valve...

Page 34

Instruction 0011-9026 page 30 7.1 fyrite illustrated parts figure 33. Fyrite parts breakout. 11-0019 11-0026 11-0188 11-0188 11-0102 11-0136 11-0109 11-0132 11-0062 05-5169 05-5155 11-0102 11-0143 (7%, 20%, and 21% models only) 11-0110 11-0110 11-0020 11-0140 11-0154 05-5134 11-0105 02-3690 05-5134 ...

Page 35

Instruction 0011-9026 page 31 0011-0106 0011-0118 0011-0118 0011-0122 (0011-0180 + 0011-0130) 0011-0119 0011-0138 0011-0138 0011-0120 0011-0152 7.2 parts list for fyrite sampling assemblies standard sampling assembly part no. 11-7029 gases saturated with water vapor (combustion products). Dry gases ...

Page 36

Instruction 0011-9026 page 32 current former part # list # description # req'd 11-0152 10-0019 connector tip with tube 1 11-0156 10-0029 rubber tubing, 10' length 1 11-0118 10-0020 rubber tubing, 6" length 2 11-0165 10-0030 filter tube, aluminum 1 19-5004 19-9004 gas collecting bladder with orifi ce...

Page 37

Instruction 0011-9026 page 33 notes.

Page 38

Instruction 0011-9026 page 34 notes.

Page 39

Instruction 0011-9026 page 35 notes.

Page 40

Instruction 0011-9026 page 36 bacharach, inc. 621 hunt valley circle, new kensington, pa 15068 phone: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 web: www.Mybacharach.Com • e-mail: help@mybacharach.Com.