- DL manuals

- Bacharach

- Test Equipment

- Fyrite Tech 50

- Operating And Maintenance Instructions Manual

Bacharach Fyrite Tech 50 Operating And Maintenance Instructions Manual

Summary of Fyrite Tech 50

Page 1

Fyrite ® tech model 50 & 60 combustion gas analyzer instruction 0024-9428 operation & maintenance rev. 7 – may 2010 product leadership • training • service • reliability.

Page 2

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in mater ial and manufac ture and will conform substan tially to bach arach inc.’s ap plicable spec i fi ca tions. Bacharach’s li a bil i ty and buyer’s remedy under this warranty are lim i...

Page 3: Contents

Fyrite tech instruction 0024-9435 i contents ordering information ...............................................................................Iii 1.0 introduction ..................................................................................1 1.1 the fyrite tech .................................

Page 4

Fyrite tech instruction 0024-9435 ii 4.8 screen descriptions .......................................................................22 4.8.1 warm-up screens................................................................22 4.8.2 fuel screen ..............................................................

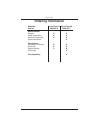

Page 5: Ordering Information

Fyrite tech instruction 0024-9435 iii model no. Part no. Fyrite tech 50 0024-8216 fyrite tech 60 0024-8217 measurements: oxygen stack temperature ambient temperature carbon monoxide calculations: combustion effi ciency excess air carbon dioxide co air free print capability* x x x x x x x x x x x x x...

Page 6

Fyrite tech instruction 0024-9435 iv notes:.

Page 7: 1.0 Introduction

Instruction 0024-9435 1 fyrite tech 1.0 introduction 1.1 the fyrite tech available in two models, the fyrite tech 50 and 60 are hand-held an a - lyz ers that are designed to calculate the ef fi cien cy of res i den tial furnaces and com bus tion appliances by measuring the stack temperature and the ...

Page 8: 1.2 Operation Overview

Instruction 0024-9435 2 fyrite tech 1.2 operation overview pressing the i/o button turns the analyzer on. Note that there is a 60 sec- ond warm-up period which must elapse before the analyzer can be used. After warm-up is complete, choose the fuel code that corresponds to the fuel being burned by th...

Page 9

Instruction 0024-9435 3 fyrite tech 2.0 technical characteristics the analyzer directly measures and displays: • flue gas o 2 content ..................................... 0.0 to 20.9% o 2 • stack temperature ....................................... 0 to 999 °f (–18 to 537 °c) • ambient temperature ....

Page 10

Instruction 0024-9435 4 fyrite tech display .......................................................4 digit, 2 line, 7-segment liquid crystal dis play front panel controls ..............................Six pushbutton switches (refer to section 3.4) accuracy: • oxygen.....................................

Page 11: 3.1 Scope

Instruction 0024-9435 5 fyrite tech 3.0 setting up the analyzer 3.1 scope before using the analyzer. . . • check batteries (section 3.2) • connect probe to analyzer (section 3.3) • check setup (section 3.5) 3.2 checking & replacing the bat ter ies install fresh batteries as described below. Check th...

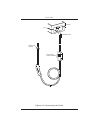

Page 12: 3.3 Connecting The Probe

Instruction 0024-9435 6 fyrite tech 3.3 connecting the probe connect the probe assembly’s fl ue-gas hose and thermocouple con nec tor to the analyzer as follows (see figure 3-2): 1. Push the fl ue gas hose onto the an a lyz er’s gas inlet fi tting. 2. Push the fl ue gas thermocouple into the t-stack...

Page 13

Instruction 0024-9435 7 fyrite tech figure 3-2. Connecting the probe t-stack gas thermocouple probe stop (optional) water trap / filter assembly.

Page 14

Instruction 0024-9435 8 fyrite tech 3.4 front panel pushbuttons note that a pushbutton may perform several functions, depending on what screen is being displayed at the time. I/o • turns analyzer on/off. There is a 60 second warm-up and a 5 second turn-off-delay period. • places the analyzer into ei...

Page 15: 3.5 Setup Mode

Instruction 0024-9435 9 fyrite tech 3.5 setup mode the analyzer is preset at the factory for the parameters shown below, but can be changed as described in their associated sec tions. Function parameter to change fuel natural gas (f1) section 4.1.2 temperature unit °f section 3.5.2 co channel auto z...

Page 16

Instruction 0024-9435 10 fyrite tech 3.5.3 co channel setup (model 60 only) the co channel setup screen is labeled “co.” 1. If not already done, enter setup per section 3.5.1. Repeatedly press enter until co channel setup screen is displayed. 2. Press the or button until the desired parameter is dis...

Page 17

Instruction 0024-9435 11 fyrite tech 1. If not already done, enter setup per section 3.5.1. Repeatedly press en ter until the fi rst time setup screen is displayed - the one with two bars over the hour digits. 2. Press the or button until the correct hour value is displayed. 3. Press en ter to move ...

Page 18

Instruction 0024-9435 12 fyrite tech 1. If not already done, enter setup per section 3.5.1. Repeatedly press en ter until the year setup screen is displayed. 2. Press the or button until the correct year is displayed. 3. Press en ter to move to next setup screen, or press i/o to exit setup. 3.5.7 se...

Page 19: 4.0 Operation

Instruction 0024-9435 13 fyrite tech 4.0 operation 4.1 performing a test 4.1.1 analyzer turn on and warm up important: the probe must be at room tem per a ture before performing the fol low ing steps. The temperature measured by the probe during warm up is the combustion-air tempera- ture used by th...

Page 20

Instruction 0024-9435 14 fyrite tech atmospheric burner or gravity vented forced air hot water tank 4.1.4 sampling point forced air furnace – when testing atmospheric burner or gravity vented, forced air heating equip ment with a clamshell or sectional heat exchanger design, test each of the exhaust...

Page 21

Instruction 0024-9435 15 fyrite tech 80% eff. Fan assist or power vented furnace/boiler 90% eff. Condensing furnace/boiler atmospheric or gravity vented boiler.

Page 22

Instruction 0024-9435 16 fyrite tech 4.1.5 performing a com bus tion effi ciency test 1. After turning on the analyzer and selecting the appropriate fuel, press the and button until the stack temperature & effi ciency screen (refer to section 4.8.7) is displayed. 2. Position the probe in the fl ue-g...

Page 23

Instruction 0024-9435 17 fyrite tech b a c h a r a c h , i n c . F y r i t e t e c h a n a l y z e r = = = = = = = = = = = = = = = = = = = = = = =.

Page 24

Instruction 0024-9435 18 fyrite tech 4.1.7 ending a combustion test warning! Burn hazard. Do not touch the probe after removing it from the stack. Allow the probe to cool before handling (about 5 minutes). 1. Remove probe from fl ue-gas stream. 2. Allow the pump to run until all combustion gases are...

Page 25: 4.3 Operating Tips

Instruction 0024-9435 19 fyrite tech 4.3 operating tips • when an analyzer is brought in from a cold vehicle, let it warm up slowly to minimize condensation. Temperatures below freezing will not dam- age the analyzer; however, bringing a cold analyzer into a warm humid environment may cause condensa...

Page 26: 4.4 Using The Backlight

Instruction 0024-9435 20 fyrite tech 4.4 using the backlight the lcd can be read in dimly-lit areas by pressing the light button. The backlight automatically turns off after 10 minutes of keyboard inactivity, but can be turned off at any time by again pressing the light button. 4.5 using the probe a...

Page 27: 4.7 Run Mode Screens

Instruction 0024-9435 21 fyrite tech 4.7 run mode screens the following diagrams show the order in which the screens are displayed by press ing the and buttons while in the run mode. Fyrite tech 60 fyrite tech 50 f1 el u f 251 92 co2 % . . Excess air f1 787 00 stack f1 eff °f % 5 . 52 ambient f1 °f ...

Page 28: 4.8 Screen Descriptions

Instruction 0024-9435 22 fyrite tech 4.8 screen descriptions 4.8.1 warm-up screens as soon as the analyzer is turned on, a series of warm-up screens are dis played. These screens show the analyzer’s model number (tech 50 or tech 60), the unit’s software revision, and fi nally the remaining warm-up t...

Page 29

Instruction 0024-9435 23 fyrite tech 4.8.3 o 2 screen (model 50 only) the o 2 display is the measured percentage of oxygen present in the fl ue- gas stream. Front panel button functions: / – scrol through run mode screens (refer to section 4.7) enter – hold for 2 seconds to display fuel screen hold ...

Page 30

Instruction 0024-9435 24 fyrite tech 4.8.5 co air free screen (model 60 only) the co air free reading is a calculation of the exact ppm con cen tra tion of car bon mon ox ide if oxygen were 0.0% in accordance with ansi standard z21.1. Front panel button functions: / – scroll through run mode screens...

Page 31

Instruction 0024-9435 25 fyrite tech 4.8.7 stack temperature & effi ciency screen the stack display is the temperature measured at the tip of the probe. The eff (effi ciency) reading is a calculation of what percentage of energy present in the fuel was converted into usable heat. Front panel button ...

Page 32

Instruction 0024-9435 26 fyrite tech 4.8.9 sensor error screen an o 2 sensor error is displayed if the analyzer determines during the warm-up cycle that the oxygen sensor’s output is too low for it to be usable. However, in the extreme condition when the o 2 sensor has no output, a sen- sor error wi...

Page 33: Testing The Display Segments

Instruction 0024-9435 27 fyrite tech 5.0 calibration & maintenance important: fresh batteries should be installed, and the unit allowed to sta bi lize at room temperature for at least two hours before proceeding with calibration. To main tain ac- cu ra cy as listed in the technical characteristics s...

Page 34

Instruction 0024-9435 28 fyrite tech 5.2 ambient temperature calibration material required: calibrated thermometer procedure: 1. Enter the calibration mode as described in section 5.1. Observe that "ambient" is displayed at the top of the display; if not, repeatedly press enter until it appears. 2. ...

Page 35: 5.4 O

Instruction 0024-9435 29 fyrite tech 3. Set the simulator to 32 °f (0 °c). Then use the and buttons to set the dis played value to match the simulator’s value. 4. Set the simulator to 572 °f (300 °c). Then use the and but- tons to adjust the dis played value to match simulator’s value. 5. Repeat ste...

Page 36

Instruction 0024-9435 30 fyrite tech 6. After the analyzer has stabilized (2 to 3 minutes), use the and buttons to set the displayed value to 0.0%. 7. Disconnect tubing from analyzer and turn off gas fl ow. 8. Allow the pump to run until the o 2 reading returns to 20.9. If necessary, use the and but...

Page 37

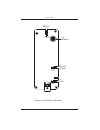

Instruction 0024-9435 31 fyrite tech leave top port open parts shown: 1. Gas cylinder 2. Regulator* 3. Tubing* 4. Tee* 5. Flowmeter* 6. Fitting, gas * contained in calibration kit figure 5-1. Calibration kit hookup 4. Do one of the following: a. End this procedure and save the new zero value by hold...

Page 38

Instruction 0024-9435 32 fyrite tech 5.6 water trap / filter maintenance the water trap / filter assembly removes water condensate from the gas sample, and also prevents soot from contaminating the internal compo- nents of the analyzer. Drain the water condensate after every test. Procedure: 1. Pull...

Page 39: Sensor Replacement

Instruction 0024-9435 33 fyrite tech o 2 sensor replacement be sure to perform all of the hecks listed in section 4.8.9 to ensure that the o 2 sensor needs to be replaced. Procedure: 1. Disassemble the analyzer as follows: a. Remove the battery cover and the batteries, uncovering one of the cover ho...

Page 40: 5.8 Co Sensor Replacement

Instruction 0024-9435 34 fyrite tech 5.8 co sensor replacement (model 60 only) be sure to perform all of the checks listed in section 4.8.9 to ensure that the co sensor needs to be replaced. Material required: • co sensor, p/n 0024-7265 • co sensor gasket, p/n 0024-1112 • #1 phillips screwdriver pro...

Page 41

Instruction 0024-9435 35 fyrite tech 5.9 pump assembly replacement material required: • co sensor, p/n 0024-7265 • #1 phillips screwdriver procedure: 1. Disassemble the analyzer as follows: a. Remove the battery cover and the batteries, uncovering one of the cover hold-down screw. B. Remove and set ...

Page 42

Instruction 0024-9435 36 fyrite tech co sensor gasket pump hold down clamp oxygen sensor & socket figure 5-3. Back case component locations.

Page 43

Instruction 0024-9435 37 fyrite tech co sensor to battery to oxygen sensor t-stack to pump (red wire) (red wire) (red wire) figure 5-4. Co sensor location.

Page 44: 6.0 Parts & Service

Instruction 0024-9435 38 fyrite tech 6.0 parts & service 6.1 replacement parts description part no. Carbon monoxide sensor (model 60 only) ...................................... 0024-7265 carbon monoxide sensor gasket (model 60 only) ..........................0024-1112 oxygen sensor w/ gasket .........

Page 45: 6.3 Service Centers

Instruction 0024-9435 39 fyrite tech 6.3 service centers replacement parts and service can be obtained by con tact ing one of the fol- low ing bacharach service centers: united states bacharach inc. 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5051 fax: 724-334-5723 email: help@myb...

Page 46: Notes:

Instruction 0024-9435 40 fyrite tech notes:.

Page 47: Notes:

Instruction 0024-9435 41 fyrite tech notes:.

Page 48

World headquarters 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com printed in u.S.A..