- DL manuals

- Bacharach

- Measuring Instruments

- Gas Pup

- Instruction

Bacharach Gas Pup Instruction

Summary of Gas Pup

Page 1

Gas pup ® natural gas & pressure detection instruction 55-9002 operation & maintenance rev. 1 – december 2003 product leadership • training • service • reliability.

Page 2: Warranty

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in material and manufacture and will conform substantially to bacharach inc.’s applicable specifications. Bacharach’s liability and buyer’s remedy under this warranty are limited to the rep...

Page 3: Contents

I gas pup instruction 55-9002 contents contents safety information ....................................................................... Iii introduction ..................................................................................... 1 general description .......................................

Page 4

Ii gas pup instruction 55-9002 contents calibration ..................................................................................... 22 gas calibration equipment setup ....................................................... 22 gas calibration procedure .............................................

Page 5: Safety

Safety safety is essential in the use and maintenance of bacharach equipment. Therefore this manual and any marking on the instrument provide important safety information concerning the operation, care, and mainte- nance of this instrument. All operating and maintenance personnel should read and und...

Page 6: Notes:

Notes: iv instruction 55-9002 gas pup safety.

Page 7: Introduction

Instruction 55-9002 1 gas pup introduction introduction general description the bacharach gas pup (figure 1) is a natural gas detection instru- ment designed for general leak detection, barholing operations, regulator pressure checks, and line pressure integrity operations. It offers measurement of ...

Page 8: Components

Gas pup 2 instruction 55-9002 introduction components natural gas detection the instrument’s ppm and lo% ranges use a catalytic-bead detection circuit, which is the most widely accepted method of detecting combus- tible gases. The hi% range uses the thermal-conductivity method of detection, which is...

Page 9: Control Panel Description

Instruction 55-9002 3 gas pup control panel description two pushbutton controls and a large lcd are conveniently located at the top of the instrument. The backlit lcd provides highly readable indica- tions of natural gas or pressure in any lighting condition ranging from direct sunlight to total dar...

Page 10: Gas and Pressure Fittings

Gas pup 4 instruction 55-9002 • bar graph window: provides a real time moving display of the natural gas concentration to give a better ‘feel’ of when the gas level has reached a peak. The bar graph is active only in the ppm and hi% ranges. • range window: identifies the range in which the instrumen...

Page 11: Technical Characteristics

Instruction 55-9002 5 gas pup technical characteristics measurement ranges: natural gas ........................... Ppm: 0 to 2500 ppm lo%: 0.2 to 5.0% volume gas hi%: 0 to 100% volume gas pressure: high .................................... 0 to 99 psig low ...................................... ±9....

Page 12: Operation

Gas pup 6 instruction 55-9002 operation operating precautions (please read) to ensure that the gas sensor is properly zeroed at startup, the gas pup must be turned on in fresh air (free of combustible gases or vapors). Before using the pup to detect gas, ‘bump test’ the instrument by apply- ing a kn...

Page 13: Battery Installation

Instruction 55-9002 7 gas pup operation battery installation warning: explosion hazard: • to reduce the risk of igniting a flammable atmosphere, batteries must only be changed in an area known to be non-flammable. • to maintain agency approval, use only the following types of ‘aa’ alkaline batteries...

Page 14: Turning On The Gas Pup

Gas pup 8 instruction 55-9002 turning on the gas pup important! To assure that all detectors are properly zeroed, the gas pup must be turned on in a gas-free environment (no combustibles), and that no pressure is being applied to the instrument’s pressure port. It is also recommended that the probe ...

Page 15

Instruction 55-9002 9 gas pup figure 5. Turning on the gas pup operation battery voltage mode display range flashing display / auto start sequence ppm gas display lcd segment test uer (version) software version.

Page 16: Turning Off The Gas Pup

Gas pup 10 instruction 55-9002 turning off the gas pup pushing and holding down the key initiates the instrument’s turn-off sequence. At first the battery voltage is displayed, followed in about 1 second by the letters “off” scrolling across the screen. The screen will go blank shortly after all thr...

Page 17: Backlighting

Instruction 55-9002 11 gas pup backlighting backlighting of the lcd allows a user to see the display in darkened areas. Be aware that backlighting causes a higher battery drain and should only be used when needed. To conserve battery life, the backlight is automatically disabled when the battery vol...

Page 18: Auto-Ranging

Gas pup 12 instruction 55-9002 after checking for gas, allow the instrument to sample fresh air until the lcd shows a very low ppm reading. This will help prolong sensor life by purging the sensor chamber of combustible gas. Auto-ranging the gas pup incorporates an auto-ranging function that automat...

Page 19: Ppm Range

Instruction 55-9002 13 gas pup ppm range after the gas pup has been turned on, it will default to its ppm range, showing nothing or some portion of a bar graph display. The range window will show a pointer to the “ppm” flag for range defini- tion. Any low levels of gas will be shown by a moving bar ...

Page 20: Hi% (High Percent) Range

Gas pup 14 instruction 55-9002 hi% (high percent) range if the gas concentration goes above the upper limit of the lo% range (greater than 5.0%), automatic changeover to the hi% range occurs. The instrument goes through a 5 second stabilization time period after this range change occurs, with the di...

Page 21

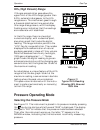

Instruction 55-9002 15 gas pup figure 12. Selecting the pressure operating mode during startup operation important! Ensure that the instrument’s pressure port is open to the atmosphere during startup, otherwise incorrect pressure readings may result. Before making a pressure measurement, tubing must...

Page 22: High Pressure Mode

Gas pup 16 instruction 55-9002 high pressure mode caution: maximum over pressure without damage is 150 psig. The high-pressure mode measures pressure in the range of 0 to 99 psig. Enter this mode by first selecting the pressure mode during startup as previously described. The instru- ment will defau...

Page 23

Instruction 55-9002 17 gas pup figure 14. Pressure proving a system using the delta pressure mode to piping system being tested pressure fitting hi% lo% ppm ® range natural gas reading attach a hand pump or air compressor and pump up piping system to desired pressure (not to exceed 99 psig) with ins...

Page 24

Gas pup 18 instruction 55-9002 operation using the probe’s filter chamber the standard 10" probe supplied with the gas pup has a built-in filter chamber that can hold either a foam filter element, or a charcoal filter pack. Install and use these filters as follows: foam filter element – particulate ...

Page 25

Instruction 55-9002 19 gas pup the petroleum absorbing property of the activated charcoal filter is used to detect petroleum based gases and vapors in the following way: 1. With a standard foam filter installed in the probe’s filter chamber, take a gas sample and note the display indication. 2. Remo...

Page 26: Water/filter Trap

Gas pup 20 instruction 55-9002 operation water/filter trap the optional water/filter trap accessory is recommended to be used in conjunction with the 30" barholing probe; thus preventing water from being drawn into the instrument when the probe is inserted into a hole filled with water. The water tr...

Page 27: Error Messages

Instruction 55-9002 21 gas pup error messages 2.3.0. 2.3.1. 2.3.2. 2.4.2. 2.4.8. 2.5.1. 2.5.2. F p cal meaning stable level of calibration gas was not detected within 50 seconds during calibration. Calibration gas was not detected during calibration. Gain increase since last calibration was greater ...

Page 28: Calibration

Gas pup 22 instruction 55-9002 calibration calibration it is recommended that the gas pup be calibrated by your nearest bacharach service center. Calibration, however, can be performed in the field if your facility has the necessary equipment and qualified personnel to perform the procedures describ...

Page 29: Gas Calibration Procedure

Instruction 55-9002 23 gas pup gas calibration procedure the gas pup has an auto-calibration feature that ensures proper calibra- tion of the instrument. After setting up the calibration equipment as previously described, proceed with the calibration procedure as follows: 1. Before turning on the in...

Page 30

Gas pup 24 instruction 55-9002 calibration note: if zero air is being applied at this time, remove it before proceeding to step 5. 5. While a steady “ac” is being displayed, apply calibration gas by simply connecting the tubing from the calibration equipment to the pup’s gas-inlet fitting. The on-de...

Page 31

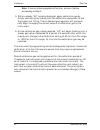

Instruction 55-9002 25 gas pup figure 19. Performing a lo% calibration steady display apply 2.5% gas now flashing display flashing display remove gas fashing display during calibration calibration.

Page 32

Gas pup 26 instruction 55-9002 calibration figure 20. Performing a hi% calibration steady display apply 100% gas now remove gas flashing display flashing display flashing display flashing display during calibration.

Page 33: Pressure Sensor Check

Instruction 55-9002 27 gas pup pressure sensor check the pressure sensor does not require calibration, but it is recommended that the sensor be checked for accuracy on a periodic basis and to assure that it is still operational. To check the pressure sensor, the following equipment is recommended: •...

Page 34: Maintenance

Gas pup 28 instruction 55-9002 maintenance maintenance batteries the battery voltage is monitored by the instrument’s microprocessor, and can be checked by momentarily pressing the key. Refer back to the previous section battery voltage check. Battery replacement is recommended when the voltage at s...

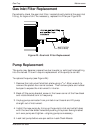

Page 35: Gas Inlet Filter Replacement

Instruction 55-9002 29 gas pup maintenance gas inlet filter replacement periodically check the gas inlet filter, located directly behind the gas-inlet fitting, for signs of dirt. As necessary, replace this filter per figure 23. Pump replacement the pump may become inoperative due to water or solid p...

Page 36: Leak Check Basics

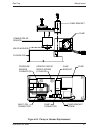

Gas pup 30 instruction 55-9002 combustibles sensor replacement if the instrument cannot be calibrated in either range, the combustibles sensor must be replaced with a new unit. To replace the sensor (see figure 24): 1. Remove the instrument’s bottom plate by using a 5 / 64 " allen wrench to remove t...

Page 37

Instruction 55-9002 31 gas pup maintenance figure 24. Pump or sensor replacement flow block combustibles sensor wave washer printed circuit board screw (3 places) pump bracket screw pump bracket pump multi-pin connector pump connector pressure sensor connector pump bracket pump.

Page 38: Parts & Service

Gas pup 32 instruction 55-9002 parts & service parts & service replacement parts gas pup instrument kit: includes instrument, 10" gas probe, coiled gas tubing with quick-connect fittings, 2 inlet filters, 3 batteries, and a pocket size pressure & gas conversion card. ...... 55-8000 battery cover ass...

Page 39: Accessories

Instruction 55-9002 33 gas pup accessories barhole probe assemblies: 30" polycarbonate probe ............................................................... 55-3001 30" aluminum probe ..................................................................3474-1210 cap, vinyl tip (for polycarbonage probe ...

Page 40: Service Centers

Gas pup 34 instruction 55-9002 service centers service and replacement parts can be obtained by contacting a bacharach service center at the following locations: parts & service united states california 7281 garden grove blvd., suite h garden grove, ca 92841 phone: 714-895-0050 fax: 714-895-7950 ema...

Page 41

Instruction 55-9002 35 gas pup.

Page 44

World headquarters 621 hunt valley circle, new kensington, pa 15068-7974 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Bacharach-inc.Com • e-mail: help@bacharach-inc.Com printed in u.S.A..