- DL manuals

- Bacharach

- Test Equipment

- HGM300

- Installation, Operation & Maintenance Instructions Manual

Bacharach HGM300 Installation, Operation & Maintenance Instructions Manual - Rdm800 - Screen Displays

Instruction 3015-4148

31

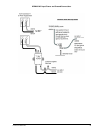

RDM800 - Screen Displays

When first powered up a splash screen appears indicating the serial number and firmware revision number.

After a brief moment the System Screen is displayed. Please refer to the Appendix for a logic diagram of all

the screen displays.

There is a 15-minute warm-up period after power is first applied. Under “HGMS”, "WARM UP" is displayed.

The green indicator on the HGM will blink during the warm-up period.

IMPORTANT:

DO NOT plug the gas-sample hose or inlet port of any zone. The monitor will perform a

vacuum test during start up and a plugged zone will give a false indication.

System Screen

Display

showing

"WARM UP"

Summary of HGM300

Page 1

Hgm300 / rdm800 refrigerant gas monitoring system instruction 3015-4148 installation / operation / maintenance rev. 5 – april 2006 inspection equipment measuring equipment 61kn product leadership • training • service • reliability.

Page 2

A instruction 3015-4148 notice: product improvements and enhancements are continuous; therefore the specifications and information contained in this document may change without notice. Bacharach, inc. Shall not be liable for errors contained herein or for incidental or consequential damages in conne...

Page 3: Table of Contents

Instruction 3015-4148 i table of contents t able of c ontents ..................................................................................................................................................... I i ntroduction ...........................................................................

Page 4: Introduction

Ii instruction 3015-4148 introduction how to use this manual thank you for investing in a bacharach hgm300 refrigerant gas monitor. This manual provides important information on how to install, operate, and service the hgm300 refrigerant monitor and rdm800 display module. Please read this manual car...

Page 5: Safety Precautions

Instruction 3015-4148 iii safety precautions ac power supply ensure the source voltage matches the voltage of the product before energizing the equipment. It is highly suggested that the hgm300 be placed on a separate circuit with ups or surge protection. • a switch or circuit-breaker shall be inclu...

Page 6: Safety Precautions (Cont.)

Iv instruction 3015-4148 safety precautions (cont.) installation category installation category ii, pollution degree ii, as defined by ul. Altitude limit 2,000 meters cleaning use a dry cloth to clean the outside of the case. Do not use soap and water . Warning statements the use of the word warning...

Page 7: Functional Overview

Instruction 3015-4148 v functional overview general description refrigerant monitors are specified to support compliance to federal, state and local safety codes governing refrigerant emissions. Avoiding significant refrigerant loss reduces equipment replacement costs, maintains equipment efficiency...

Page 8

Vi instruction 3015-4148 the hgm300 should be centrally located in the mechanical room and be readily accessible for easy visual monitoring and servicing. Air sample tubing may be run in lengths up to 500 feet . The fresh air purge line should draw from an area that does not contain any refrigerant ...

Page 9: Hgm300 Installation

Instruction 3015-4148 1 hgm300 installation hgm300 oblique photo upper & lower mounting brackets led indicators water trap upper mounting bracket led indicators standard accessories for a 4-point system 5 line-end filters (p/n 3015-3420) charcoal filter & t-bolt bracket (p/n 3015-3125) hgm300/rdm800...

Page 10: Warning

2 instruction 3015-4148 hgm300 - installation considerations locating the monitor the hgm300 should be centrally located in the facility and should be easily accessible for visual monitoring and servicing. Intake sample lines can be up to 500 feet in length, but it is important to remember that samp...

Page 11

Instruction 3015-4148 3 hgm300 - mounting instructions screw locations the hgm300 should be installed plumb and level and securely fastened to a rigid mounting surface. The enclosure utilizes keyhole mounting brackets designed for #12 pan head fasteners. Locate the four screws as shown in the diagra...

Page 12

4 instruction 3015-4148 hgm300 - connecting air lines overview individual sample lines are run from the hgm300 to each area of the facility to be monitored. Additionally, a purge line is installed to provide clean air for resetting the infrared zero baseline. An exhaust line is installed to vent res...

Page 13: Caution

Instruction 3015-4148 5 tubing considerations use ¼" outside diameter (0.040" wall) flex tubing for all air lines (p/n 3015-3235) or equivalent. The tubing should be clean and free of residual moisture or other contaminants. The tubing should be cut cleanly with a sharp knife and care should be take...

Page 14: Hgm300 - Interior Schematic

6 instruction 3015-4148 hgm300 - interior schematic primary filter intake manifold solenoids intake solenoid connectors power supply board main board microcontroller board infrared optical bench gas sample pump primary filter (p/n 3015-3071) intake manifold solenoids gas sample pump infrared optical...

Page 15

Instruction 3015-4148 7 ac power / rs-485 / relay connector / 4-20 madc current loop switches / fuses auxiliary ac out connector t2 (used to supply ac power to alarm devices) (overload protected by fuse f3) ac in connector t1 location of ac input line filter (240 vac units only) factory default term...

Page 16: Hgm300 - Electrical Wiring

8 instruction 3015-4148 hgm300 - electrical wiring it is highly recommended that the hgm300 be connected directly to the ac power source, preferably on its own circuit. The connection should be completed with a ul rated multi-conductor wire (14-18 awg). Locate service knockouts on exterior of enclos...

Page 17

Instruction 3015-4148 9 hgm300 ac input power and ground connections.

Page 18

10 instruction 3015-4148 hgm300 - connecting communication devices remote display module (rdm800) connection the hgm300 is connected to the rdm800 using a shielded twisted pair instrument cable. The maximum distance between the farthest away hgm300 and rdm800 is 4500 feet. Use any of the remaining s...

Page 19

Instruction 3015-4148 11 changing terminator switch settings the terminator switch is shipped from the factory in the terminated or “in” position. This is the correct setting if the hgm300 is connected as a single device, or it is the last device on the network chain. If the hgm300 is being installe...

Page 20: Multiple Hgm’S

12 instruction 3015-4148 multiple hgm’s multiple hgm300’s with rdm800 note 1: the last hgm300 or rdm800 on either end of the network must have its terminator in the “in” position, and all other units must have their terminators in the “out” position. Note 2: the total length of the rs-485 cable cann...

Page 21: Hgm300 - Pc Software

Instruction 3015-4148 13 multiple hgm300’s connected to a building management system daisy chain fashion rs-485 terminator “in” terminator terminator terminator terminator “out” “out” “out” “in” hgm300 - pc software programming the hgm300 using pc software note 1: there are two versions of pc softwa...

Page 22

14 instruction 3015-4148 7. Using the arrow keys go to edit; press enter – the edit menu drops down; select system and then press enter – the hgm location becomes highlighted. Press enter to move to the hgm tag area; use the backspace key to remove the existing tag; then enter in a new tag. Press en...

Page 23

Instruction 3015-4148 15 to save and print the hgm300 software screen, alarm log, fault log, or diagnostic screen open the software while connected to the hgm300. After the software gets the program, open the desired screen. With that screen as the active screen, press the alt and print screen keys ...

Page 24: Caution

16 instruction 3015-4148 hgm300 - current loop interfaces optional 4–20 madc outputs upon installation of the optional 4–20 madc interface board (page 7) (p/n 3015-3133), the hgm300 has the capability of providing dual 4-20 madc scrolling current loop outputs for connection to external monitoring de...

Page 25

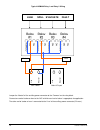

Instruction 3015-4148 17 hgm300 - connecting external alarms overview each hgm300 includes 4, form c, spdt relay contacts for the connection of external alarm devices. The relays are factory assigned to the following conditions: relay #1 leak relay #2 spill relay #3 evacuate relay #4 fault connectio...

Page 26

18 instruction 3015-4148 typical hgm300 relay 1 and relay 2 wiring jumper the ‘neutral’ of the auxiliary power connector to the ‘common’ on the relay block. Connect one end of strobe or horn to the ‘no’ of whichever level of alarm is appropriate for application. The other end of strobe or horn is co...

Page 27: Rdm800 Installation

Instruction 3015-4148 19 rdm800 installation rdm800 oblique photo upper & lower mounting brackets upper mounting bracket lower mounting bracket.

Page 28: Warning

20 instruction 3015-4148 rdm800 - installation considerations overview up to four hgm300 monitors may be connected to a single rdm800. The rdm800 can be located anywhere up to 4500 feet from the furthest hgm300. The display module should be installed out of direct sunlight in a clean area that is no...

Page 29

Instruction 3015-4148 21 rdm800 - mounting instructions screw locations the rdm800 should be installed plumb and level and securely fastened to a rigid mounting surface. The enclosure utilizes keyhole mounting brackets designed for #12 pan head fasteners. Locate the four screws as shown in the diagr...

Page 30: Rdm800 - Interior Schematic

22 instruction 3015-4148 rdm800 - interior schematic microcontroller board cpu reset switch main board ground stud ac power front panel chassis power supply board 120–230 vac input microcontroller board cpu reset switch main board ac in connector t3.

Page 31

Instruction 3015-4148 23 ac power rs-485 connectors terminator switches relay connector fuses 1 amp 250 vac p/n 3015-4011 terminator switches f2 f1 to monitors rs-485 to hgm300 monitors to host rs-485 to building management system relay connector ac in connector t3.

Page 32: Rdm800 - Electrical Wiring

24 instruction 3015-4148 rdm800 - electrical wiring it is highly recommended that the rdm800 be connected directly to the ac power source, preferably on its own circuit. The connection should be completed with a ul rated multi-conductor wire (14-18 awg). Locate service knockouts on exterior of enclo...

Page 33

Instruction 3015-4148 25 rdm800 ac input power and ground connections.

Page 34

26 instruction 3015-4148 rdm800 - communication connections hgm300 network the rdm800 display module is connected to the hgm300 network using a shielded twisted pair cable. The maximum distance between the rdm800 and the farthest hgm300 is 4500 feet. Use any of the remaining service knockouts to gai...

Page 35

Instruction 3015-4148 27 changing terminator switch settings the terminator switch for the rs-485 “to monitors” connector is shipped from the factory in the terminated or “in” position. This is the correct setting if the rdm800 is connected to only one hgm300, or if it is the last device on a networ...

Page 36

28 instruction 3015-4148 rdm800 - connecting external alarms overview two spdt relays are available for the connection of external alarm devices. These alarms are useful for alerting the user to global conditions anywhere on the network. Each relay can be programmed to respond to alarm, fault, or re...

Page 37: Rdm800 Operation

Instruction 3015-4148 29 rdm800 operation rdm800 exterior schematic display screen navigation buttons cursor pad led indicators led indicators display screen cursor pad navigation buttons.

Page 38: Rdm800 - Overview

30 instruction 3015-4148 rdm800 - overview the rdm800 displays comprehensive information about the hgm300 network status and enables complete programming control of all system operations. The prominent features of the display module are discussed below. Display screen the display screen is a back-li...

Page 39: Rdm800 - Screen Displays

Instruction 3015-4148 31 rdm800 - screen displays when first powered up a splash screen appears indicating the serial number and firmware revision number. After a brief moment the system screen is displayed. Please refer to the appendix for a logic diagram of all the screen displays. There is a 15-m...

Page 40: Rdm800 - System Programming

32 instruction 3015-4148 rdm800 - system programming setup parameters before working with the hgm300 network, several global parameters must be defined. Most of these are entered in the rdm setup screens or via the pc software . Parameters must also be defined for each hgm300 monitor connected to th...

Page 41: Rdm800 - Setup Programming

Instruction 3015-4148 33 rdm800 - setup programming setting the clock from the top level system screen press the key adjacent to the date/time field to go to the clock setup screen . Clock setup screen use the left/right cursor keys to move the cursor across the field to the value you wish to edit. ...

Page 42

34 instruction 3015-4148 navigating to the 1 st rdm setup screen from the top level system screen press the rdm setup key to go to rdm setup screen #1 . Rdm setup screen #1 contrast this value sets the screen brightness. 1. Press the adjacent key to adjust the setting. 2. Use the up/down cursor keys...

Page 43

Instruction 3015-4148 35 audible alarm this parameter selects the function of the rdm800’s internal audible alarm. 1. Press the adjacent key to adjust the setting. 2. Use the up/down cursor keys to select unused, monitor on, evacuate, spill, leak, fault, or alarm. 3. Press enter to accept the new en...

Page 44

36 instruction 3015-4148 navigating to the 2 nd rdm setup screen from rdm setup screen #1 press the more key to go to rdm setup screen #2 . Press the back key to return to rdm setup screen #1 . Rdm setup screen #2 setting relay parameters this setting determines the function of relays 1 and 2 mounte...

Page 45: Hgm300 - Setup Programming

Instruction 3015-4148 37 hgm300 - setup programming navigating to the 1 st and then 2 nd hgm setup screen from the system screen press the key adjacent to the target hgm300 to go to that unit’s hgm setup screen #1. Hgm setup screen #1 from hgm setup screen #1 press the setup key to go to hgm setup s...

Page 46

38 instruction 3015-4148 location this is the name you assign to the hgm300 to identify its location. It may have up to 12 alphanumeric characters. 1. Press the adjacent key to adjust the setting. 2. Use the left/right cursor keys to move across the entry field and the up/down cursor keys to modify ...

Page 47

Instruction 3015-4148 39 loop2 factor this sets the ppm scale factor for current loop number 2. To calculate the current output, multiply the scale factor by the ppm and add 4. For example, at the default scale factor of 0.016, a measurement of 100ppm would generate a current output of 5.6 madc. In ...

Page 48

40 instruction 3015-4148 navigating to the 3 rd hgm setup screen from hgm setup screen #2 , press the more key to go to hgm setup screen #3 . Press the back key to return to hgm setup screen #2 . Hgm setup screen #3 service timeout sets the length of time the service mode is in effect. Stops the mon...

Page 49

Instruction 3015-4148 41 rdm800 - zone setup programming navigating to the 1 st zone setup screen there are two ways to display zone setup screen #1 : • from the system screen (page 31) press the key adjacent to the hgm300 unit associated with the zone you wish to work with; press the zones key; and...

Page 50

42 instruction 3015-4148 average temperature this temperature reading may be changed to the exact temperature at the sample point for greater accuracy. The adjustment range is from –50 to +70 degrees c. 1. Press the avg temp key to adjust the temperature value. 2. Use the left/right cursor keys to m...

Page 51

Instruction 3015-4148 43 spill level this is the concentration level in ppm that will activate a spill alarm condition. 1. Press the adjacent key to adjust the value. 2. Use the up/down cursor keys to modify the setting. 3. Press enter to accept the new entry or quit to revert to the previous settin...

Page 52: General Operation

44 instruction 3015-4148 general operation functional overview normally each hgm300 will sequentially perform measurements on its active zones without user input. The total time it takes an hgm300 to complete a measurement cycle is directly proportional to the number of active zones and the physical...

Page 53

Instruction 3015-4148 45 zone hold mode a zone can be placed on hold and continuously monitored for a length of time determined by the zone hold time value (page 38). To place a zone on hold, press and hold down the key adjacent to that zone until you hear a beep. The word “holding” appears to ident...

Page 54

46 instruction 3015-4148 if the current zone screen appears normal, scroll through the displays using the next/back keys or the up/down cursor keys until you locate the affected zone. You can further investigate the status of the affected zone by pressing the adjacent key and going to that zone’s se...

Page 55

Instruction 3015-4148 47 working with the system screen the system screen provides a summary view of the entire hgm300 network. The boxes on the left side of the screen indicate the status of each hgm300 monitor including the name, the current zone, and whether fault or alarm conditions are present ...

Page 56

48 instruction 3015-4148 alarm log from the system screen press the key adjacent to the hgm300 unit that you wish to view. Hgm setup #1 screen press the alarm event log key to display the alarm log screen . Alarm log screen use the left/right and up/down cursor keys to move through the log. The alar...

Page 57

Instruction 3015-4148 49 fault conditions if a system malfunction occurs, the yellow fault led will glow. Additionally, an external alarm device may activate and an audible alarm may sound if those features have been enabled (pages 28 & 35). The faults box on the right of the screen will blink and t...

Page 58: Working With Alarms

50 instruction 3015-4148 working with alarms functional overview if the ppm level for any zone exceed its designated spill, leak, or evacuate thresholds, an alarm condition will be created. Once the hgm300 completes a measurement cycle in the affected zone the alarm condition will be indicated. At t...

Page 59

Instruction 3015-4148 51 alarm detail screen to further investigate an alarm, press the adjacent key to go to the alarm detail screen . Alarm detail screen the alarm detail screen displays more comprehensive information about the nature of the alarm including: • complete location information • refri...

Page 60

52 instruction 3015-4148 acknowledging alarms each pending alarm may require, depending upon selected alarm mode, acknowledgment before the system returns to normal operation (refer to alarm ack mode on page 38). To acknowledge an alarm, navigate to the alarm detail screen and press the ack key as p...

Page 61

Instruction 3015-4148 53 working with the trend screen overview - log interval the hgm300 retains a data log of 100 measurements for each zone. The log interval is the number of minutes from 1 to 1440 between each log point. This parameter can be changed from zone setup screen #1 (page 41). The defa...

Page 62: Working With System Faults

54 instruction 3015-4148 working with system faults functional overview if a system malfunction occurs, the hgm300 will detect the problem and cause its yellow fault led to glow. Additionally, an external alarm device may activate and an audible alarm may sound if those features have been enabled (p...

Page 63

Instruction 3015-4148 55 critical faults • no flow on zone – go to the system screen (page 31) and press the zones key. The zone screen will display a “no flow” message in each individual zone affected. Check for a blockage in the air sample line or at the line end filter. Once the blockage has been...

Page 64

56 instruction 3015-4148 clearing system faults if the fault condition is associated with an hgm300, the monitor will return to normal operation soon after the problem is corrected. At that time the yellow led will turn off and any external alarms connected to the monitor’s alarm relays will also tu...

Page 65

Instruction 3015-4148 57 working with the calibration screen overview the calibration screen is used to adjust the calibration factor for each refrigerant gas. It is also used to program the instrument for new gasses. Important: changing information on cal factors will void the factory calibration. ...

Page 66

58 instruction 3015-4148 calibration procedure the cal factor is determined by sampling a known dilution of the type of refrigerant gas to be sampled. The sample must be prepared to less than half the desired accuracy, and the concentration must be corrected for ambient temperature and pressure at t...

Page 67

Instruction 3015-4148 59 programming new gasses as new refrigerants come into use the hgm300 allows the addition of these new gases to its on-board refrigerant gas library. At the end of the gas library list are five place-holders for adding new gases. They are labeled “new gas1 – new gas5.” from th...

Page 68

60 instruction 3015-4148 working with the diagnostic screen overview the diagnostic screen displays reference values for use by repair technicians for troubleshooting purposes. Navigating to the diagnostic screen display the system screen (page 31); press the key adjacent to the target hgm300 unit t...

Page 69

Instruction 3015-4148 61 line 7: ppm – parts per million is the volume concentration referenced to standard temperature and pressure and is computed from lines 5, 8 and 13. There are two figures given. The first (annotated by a b) is the actual ppm at the ir bench. The second is a ppm reading normal...

Page 70: Service Mode

62 instruction 3015-4148 service mode when activated, the service mode will disable a specific hgm300 unit for a specified length of time. The default is 60 minutes. This time interval can be changed as described under the heading service timeout on page 40. Important: note that while in the service...

Page 71: Appendix

Instruction 3015-4148 63 appendix.

Page 72: Hgm300 / Rdm800 Maintenance

64 instruction 3015-4148 hgm300 / rdm800 maintenance warning - always remove ac input power to the monitor before working inside the instrument. Caution - when working inside the instrument be very careful not to dislodge any electrical wiring or pneumatic tubing. The hgm300 contains sensitive elect...

Page 73: Optional Accessories

Instruction 3015-4148 65 optional accessories intake manifolds up to three additional intake manifolds (p/n 3015-3419 & 3015-3411) can be installed in the hgm300 to increase the total capacity to 16 zones. Each manifold requires a sample line end filter for each of the 4 zones. Please follow the ins...

Page 74: Rdm800 - Logic Diagram

66 instruction 3015-4148 rdm800 - logic diagram.

Page 75

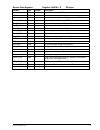

Instruction 3015-4148 67 table of recommended alarm settings refrigerant leak ppm spill ppm evacuate ppm r11 100 300 500 r12 100 300 500 r22 100 300 500 r23 100 300 500 r113 100 300 500 r114 100 300 500 r123 15 25 35 r124 100 300 500 r134a 100 300 500 r401a 100 300 500 r402a 100 300 500 r402b 100 30...

Page 76

68 instruction 3015-4148 rs-485 communication protocol overview the following instructions are intended as a guide for integrating the hgm300 network into a building management system. If you are unfamiliar with complex systems of this type, it is recommended that you contact bacharach for technical...

Page 77: Hgm300 Modbus Rtu Operation

Instruction 3015-4148 69 hgm300 modbus rtu operation overview the hgm-300 and rdm800 are equipped to communicate with other equipment using the modbus rtu protocol. Using this communication channel a modbus master device may communicate with up to 15 hgm300s on a communications network, exchanging m...

Page 78

70 instruction 3015-4148 notes on network topologies hgm300s may be connected directly to the modbus network or they may be connected to the network through an rdm800. In either case, each hgm300 must have a unique node id. Up to 15 hgm300s can be connected directly to the modbus network. If hgm300s...

Page 79

Instruction 3015-4148 71 summary of registers register name number type description system data 0x0010h r/w hgm system setup data status 0x0011h r/w operating summary of faults, alarms and status zone data 0x12xxh r/w setup data for up to 16 zones (xx defines zone number) cal data 0x0014h r/w cal fa...

Page 80

72 instruction 3015-4148 system data register register 0x0010h r/w 54 bytes variable type length description type ui 2 bytes indicates eepprom has been initialized if value = 300 do not modify rev float 4 bytes firmware rev level do not modify sn ui 2 bytes firmware serial number do not modify node ...

Page 81

Instruction 3015-4148 73 status register register 0x0011h r/w 10 bytes variable type length description mode uc 1 byte defines operating mode of hgm-300. 0 = normal mode; 1 = zone_hold mode; 2 = diagnostic mode; 3 = service mode. Do not modify (use zone hold register or service mode register to chan...

Page 82

74 instruction 3015-4148 zone data register 0x12xxh r/w 78 bytes each zone for an hgm300 has a separate zone data structure that is 78 bytes long. The zone number is the low order byte in the register address (i.E., zone 1 data register = 0x1201h) variable type length description location c 13 bytes...

Page 83

Instruction 3015-4148 75 notes on alarms and alarm acknowledge the hgm300 can be operated in two different alarm acknowledge modes, auto and manual (set via the alarm_ack_mode variable in the system data register). For purposes of this discussion, the term “alarm” refers to a hgm300 state where the ...

Page 84

76 instruction 3015-4148 cal data register register 0x0014h r/w 174 bytes variable type length description factor float 132 bytes 33 element array containing cal factors for each of the 33 gases. Order of cal factor is defined in note 1 under zone data curve uc 3 bytes existing master curve to use f...

Page 85

Instruction 3015-4148 77 sensor data register register 0x0016h r 82 bytes variable type length description pressure float 4 manifold pressure is psia p_volts float 4 pressure sensor output voltage vacuum_p float 4 pressure with all value closed and pump on in psia ambient_p float 4 absolute ambient ...

Page 86

78 instruction 3015-4148 release zone hold register register 0x0017h w 10 bytes variable type length description rel_hold * * see description of status register hold zone register register 0x0018h w 10 bytes variable type length description zone_hold * * see description of status register notes conc...

Page 87

Instruction 3015-4148 79 fault log register register 0x1900, 0x1901h r 302 bytes these registers contain the 20 most recent fault events, the time they occurred, and a pointer to the most recent event. The data is split into 2 registers. The first register contains 200 bytes and the second register ...

Page 88

80 instruction 3015-4148 service mode register register 0x001bh w 10 bytes variable type length description rel_svc_mode * * see description of status register release service mode register register 0x001ch w 10 bytes variable type length description ent svc_mode * * see description of status regist...

Page 89

Instruction 3015-4148 81 ppm register register 0x001eh r 32 bytes variable type length description ppm ui 32 bytes 16 unsigned integers that represent the ppm values for each hgm300 zone note: 16 values are returned independent of the number of actual zones installed in the unit. The master device i...

Page 90: Warranty and Service

82 instruction 3015-4148 warranty and service warranty subject to the terms herein, seller warrants the original equipment cataloged or manufactured by the seller and furnished hereunder is free from defects in material and workmanship, and will be of the kind and quality designated or described on ...

Page 91

Instruction 3015-4148 83 to return equipment to the factory for repair a return authorization (ra) number should be requested from the factory. Normal factory repair time is approximately two (2) weeks, unless special provisions have been pre-negotiated prior to the issuance of an ra number. Equipme...

Page 92: Hgm300 - Specifications

84 instruction 3015-4148 hgm300 - specifications product type: multiple refrigerant gas and multiple area monitoring system for low level continuous monitoring of cfc, hcfc and hfc refrigerant gasses used in most commercial refrigeration systems. System design supports compliance to the refrigerant ...

Page 93: Rdm800 - Specifications

Instruction 3015-4148 85 rdm800 - specifications product description: the rdm800 remote display module provides remote programming, interrogation and display functionality to support the hgm3000 refrigerant gas monitor. The system design supports compliance to the refrigerant monitoring requirements...

Page 94

Headquarters: 621 hunt valley circle, new kensington, pa 15068 website: www.Bacharach-inc.Com • e-mail: help@bacharach-inc.Com printed in u.S.A. ® registered trademark of bacharach inc..