- DL manuals

- Bacharach

- Test Equipment

- HGM300

- Installation & Operation Manual

Bacharach HGM300 Installation & Operation Manual - Rdm800 Wiring Schematic

8

Instruction 3015-4149

RDM800 WIRING SCHEMATIC

L N

MAIN

PWR

C NO NC C NO NC

AUXILIARY ALARM RELAYS

5 AMP, 240 VAC

USER DEFINABLE

RS-485

TO

HOST

SPECIAL NOTE: TO ESTABLISH THE RS-485 COMMUNICATION LINK WITH THE RDM800 OR WITH A BUILDING

MANAGEMENT SYSTEM, USE #18 GAGE AWG, MULTI-STRANDED, SHIELDED AND TWISTED PAIR,

INSTRUMENT CABLE. INSURE THE DRAIN WIRE IS CONNECTED TO THE GND TERMINAL AT BOTH ENDS.

RS-485

TO

MONITORS

B A GND

GND

B A GND

Summary of HGM300

Page 1

Hgm300 / rdm800 refrigerant monitoring system instruction 3015-4149 installation & operation mini manual rev. 8 – april 2006 section 1 (page 2) introduction, standard accessories and mounting specifications section 2 (page3) suggested location of hgm300/rdm800 and pickup points section 3 (page 4) hg...

Page 2: Introduction

2 instruction 3015-4149 section 1 introduction welcome – this mini manual is an introduction to the installation and operation of the hgm300/rdm800 refrigerant monitoring system. For detailed installation / operation / maintenance information, please refer to instruction 3015-4148. As you open the s...

Page 3: Mechanical Room Placement

Instruction 3015-4149 3 section 2 hgm300 / rdm800 refrigerant gas leak monitor mechanical room placement the hgm300 should be centrally located in the mechanical room and be readily accessible for easy visual monitoring and servicing. Air sample tubing may be run in lengths up to 500 feet. The fresh...

Page 4: Hgm300 Components

4 instruction 3015-4149 section 3 hgm300 components dual 4-20 madc outputs (signal out only) do not apply power! Rs-485 connector terminator switch 4–20 madc interface board (optional) factory default switch relay connector leak, spill, evac, fault ground stud ac in connector t1 location of ac input...

Page 5: Rdm800 Components

Instruction 3015-4149 5 rdm800 components terminator switches rs-485 to hgm300 monitors rs-485 to building management system relay connector ac in connector t3.

Page 6

6 instruction 3015-4149 section 4 basic hgm300/rdm800 monitor system connections most applications for the hgm300/rdm800 monitor system will consist of a single hgm300 and a single rdm800. The hgm300 should be mounted in the mechanical room and the rdm800 should be located in a control room, on an o...

Page 7: Hgm300 Wiring Schematic

Instruction 3015-4149 7 hgm300 wiring schematic gnd l n main pwr l n aux pwr main pwr bkr 1c no nc 2c no nc 3c no nc 4c no nc leak spill evacuate fault alarm relays 5 amp, 240 vdc b a gnd rs-485 optional dual loop 4-20 madc common common loop 1 zone loop 2 ppm special note: to establish the rs-485 c...

Page 8: Rdm800 Wiring Schematic

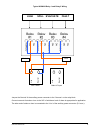

8 instruction 3015-4149 rdm800 wiring schematic l n main pwr c no nc c no nc auxiliary alarm relays 5 amp, 240 vac user definable rs-485 to host special note: to establish the rs-485 communication link with the rdm800 or with a building management system, use #18 gage awg, multi-stranded, shielded a...

Page 9

Instruction 3015-4149 9 typical hgm300 relay 1 and relay 2 wiring jumper the ‘neutral’ of the auxiliary power connector to the ‘common’ on the relay block. Connect one end of strobe or horn to the ‘no’ of whichever level of alarm is appropriate for application. The other end of strobe or horn is con...

Page 10: Multiple Hgm’S

10 instruction 3015-4149 section 5 multiple hgm’s multiple hgm300’s with rdm800 note 1: the last hgm300 or rdm800 on either end of the network must have its terminator in the “in” position, and all other units must have their terminators in the “out” position. Note 2: the total length of the rs-485 ...

Page 11

Instruction 3015-4149 11 multiple hgm’s connected to a building management system daisy chain fashion rs-485 terminator “in” terminator terminator terminator terminator “out” “out” “out” “in” hgm300 unit 1 node 1 hgm300 unit 2 node 2 hgm300 unit 3 node 3 hgm300 unit 4 node 4 building management syst...

Page 12

12 instruction 3015-4149 section 6 powering up the monitoring system (warm up time is 15 minutes) start up checkpoints: • all buttons on rdm800 “chirp” when pressed. (contact the factory if they do not “chirp”) • do not plug the gas-sample inlets of any unused zones. During start up the software wil...

Page 13

Instruction 3015-4149 13 section 7 programming the hgm300 using the rdm800 1. From the system screen on the rdm800, press the button adjacent to “zones”. Then press the button adjacent to zone 1 to display its zone setup screen #1. 2. Press button adjacent to “location”. Then using the keypad left/r...

Page 14

14 instruction 3015-4149 10. Press the “leak level” button. Use left/right keys to move across and up/down keys to readjust leak alarm ppm level to desired ppm level. 11. Press the “spill level” button. Repeat as in step 10. Note: the spill level must be greater than or equal to the leak level. 12. ...

Page 15

Instruction 3015-4149 15 section 8 programming the hgm300 using pc software note 1: there are two versions of pc software. Use version 1.0 with hgm300 units with v1.0 unit firmware, which were built june 2001 or before (as indicated by a serial number that starts with af01 or lower). Use version 1.5...

Page 16: Usb Type Laptops

16 instruction 3015-4149 saving an hgm300 program to a disk or drive go to file, path, and change the drive letter to the drive where the program is to be saved. Give the program a name, such as a:\hgm300 or c:\my documents\hgm300; press enter; go to save setup and press enter again. Type in the fil...

Page 17: Responding to Alarms

Instruction 3015-4149 17 section 9 responding to alarms to respond to an alarm from the system screen, press the button adjacent to the blinking alarms field. This will take you to the alarm summary screen. The alarm summary screen displays a list of all alarm conditions across the network. Each box...

Page 18

18 instruction 3015-4149 the alarm detail screen provides the following three navigation keys at the bottom of the display: ack acknowledges the alarm as described in the next section quit returns you to the alarm summary screen setup takes you to the zone setup screen, which enables you to review t...

Page 19

Instruction 3015-4149 19 section 10 log interval and trend screen the hgm300 retains a data log of 100 measurements per zone. The stored measurements are displayed on the trend screen starting on the left and moving to the right. The log interval setting is a useful tool to determine what is occurri...

Page 20

20 instruction 3015-4149 section 11 working with the fault screen from the system screen press the button adjacent to faults. This takes you to the fault screen. The information displayed on this screen is broken onto two categories – critical faults and non critical faults. Critical faults • no flo...

Page 21: Viewing The Fault Log

Instruction 3015-4149 21 • pressure sensor – manifold pressure is outside normal operating range (or sensor has failed). Check the diagnostic screen record all data. Call the factory with this information for further instructions. • loop fault – this would be displayed only if the dual 4-20 madc opt...

Page 22: Diagnostic Screen Overview

22 instruction 3015-4149 section 12 working with the diagnostic screen the diagnostic screen displays reference values for use by repair technicians. From the top level zone screen press the system key to go to the system screen. Press the diagnostic key to view the reference values. Diagnostic scre...

Page 23

Instruction 3015-4149 23 line 8: zero temperature – this line contains the sensor and enclosure temperature measured and stored during the last purge cycle in degrees c. Line 9: bench temperature – this is the current ir sensor temperature in degrees c as well as the raw voltage coming from the temp...

Page 24: Monitor Assistance

24 instruction 3015-4149 section 13 whom to contact for refrigerant gas leak monitor assistance phone number: 800-850-0044 fax number: 678-423-2479 e-mail: peter pape – peterp@bacharach-inc.Com bacharach, inc. – help@bacharach-inc.Com mailing address: bacharach, inc. 621 hunt valley circle new kensi...