- DL manuals

- Bacharach

- Measuring Instruments

- HI FLOW Sampler

- Instruction

Bacharach HI FLOW Sampler Instruction

Summary of HI FLOW Sampler

Page 1

Hi flow ® sampler natural gas leak rate measurement instruction 0055-9017 operation & maintenance rev. 5 – june 2010 product leadership • training • service • reliability.

Page 2

Instruction 0055-9017 a warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in material and manufacture and will conform substantially to bacharach inc.’s applicable specifications. Bacharach’s liability and buyer’s remedy under this warrant...

Page 3: Table of Contents

Hi flow sampler contents instruction 0055-9017 i table of contents 1 introduction........................................................................................ 1 1.1 general description.................................................................................................1 1.2 ma...

Page 4

Contents hi flow sampler instruction 0055-9017 ii 4.1 view calibration dates ..........................................................................................43 4.2 gas calibration equipment setup .........................................................................43 4.3 check calibrat...

Page 5: 1 Introduction

Hi flow sampler introduction instruction 0055-9017 1 1 introduction 1.1 general description the hi flow sampler is portable, intrinsically safe, battery-powered instrument designed to determine the rate of gas leakage around various pipefittings, valve packings, and compressor seals found in natural...

Page 6: 1.2 Material

Introduction hi flow sampler instruction 0055-9017 2 the range of 0.05 to 100% gas by volume. A second identical combustibles sensor channel measures the background ch 4 level within the vicinity of the leaking component. The final element in the sampling system is a blower that exhausts the gas sam...

Page 7: 1.4 Control

Hi flow sampler introduction instruction 0055-9017 3 1.4 control unit description the control unit consists of an 8 line by 20 character lcd and the four pushbuttons. Figure 1-1. Control unit 1.5 top panel connections & controls the top panel contains the following items: scanner – bar code scanne...

Page 8

Introduction hi flow sampler instruction 0055-9017 4 notes:.

Page 9: 2 Technical Data

Hi flow sampler technical data instruction 0055-9017 5 2 technical data information displayed .......... - date and time - battery voltage - sampling flow rate in cfm - background gas concentration in ppm or % by volume - leak concentration in ppm or % by volume - leak rate in cfm - percent differen...

Page 10

Technical data hi flow sampler instruction 0055-9017 6 natural gas sensor: detection method...............Catalytic oxidation / thermal conductivity range: catalytic oxidation.........0 to 5% by volume methane thermal conductivity.....5 to 100% by volume methane accuracy............................±...

Page 11: 3 Operation

Hi flow sampler operation instruction 0055-9017 7 3 operation 3.1 operating precautions (please read) to ensure that the gas sensors are properly zeroed at startup, the hi flow sampler must be turned on in clean air (free of combustible gases or vapors). Calibrate the instrument about every 30 days ...

Page 12: 3.3

Operation hi flow sampler instruction 0055-9017 8 3.3 sampling hose & attachment connections connect the sampling hose to the instrument’s leak-gas inlet by clamping the hose to the inlet as shown in figure 3-2. Also connect the background gas sampling hose to the unit’s background inlet. Figure 3-2...

Page 13: 3.4 Grounding

Hi flow sampler operation instruction 0055-9017 9 3.4 grounding warning: to prevent the possibility of a static discharge, the hi flow sampler should be grounded while conducting a leak test. Attach the unit’s grounding clamp to the nearest earth ground. Tip: when not in use, the grounding clamp can...

Page 14: 3.5 Attachments

Operation hi flow sampler instruction 0055-9017 10 3.5 attachments a variety of attachments are available for the hi flow sampler that simplifies the task of capturing the entire gas leak. Choose the appropriate attachment for the type of component being tested from the ones listed below, and then c...

Page 15

Hi flow sampler operation instruction 0055-9017 11 3.5.3 capture bag this reusable capture bag measures 36" x 36" and can be used to completely surround a component that may have multiple leak sources, or contains a leak source that is difficult to pinpoint or reach. Attach the hi flow sampler’s mai...

Page 16: 3.6

Operation hi flow sampler instruction 0055-9017 12 this tool is useful in capturing leaks in valve stems and small fittings. 3.5.6 claw tool use this tool when the leak source is spread out over a narrow area, such as a crack in a pipe, square flanges, and cylinder heads. 3.5.7 3-port background gas...

Page 17: 3.7

Hi flow sampler operation instruction 0055-9017 13 with the hi flow sampler located in an area containing clean air (no combustible gases or vapors), turn on the instrument by first pulling up the on/off switch and then moving it to its on position. Warning: turning on the instrument in air contamin...

Page 18

Operation hi flow sampler instruction 0055-9017 14 select the basic or expanded menu mode as follows: 1. From either the basic or expanded main screen, select menu > menu mode. 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 c a l i b r a t i o n s e t f l o w u n i t s m e n u m o d e [ 0 0 0 1 ] ( m ) s - - 2. Hi...

Page 19

Hi flow sampler operation instruction 0055-9017 15 3.8.1 basic main screen date and time: date displayed as mm/dd/yy, while time is displayed in a 12- hour format. The date and time are set per section 5.8. Btry(v): battery voltage flow(lpm): sample flow rate in either liters/min or cu.Ft./min. Back...

Page 20

Operation hi flow sampler instruction 0055-9017 16 3.8.2 expanded main screen date and time: date displayed as mm/dd/yy, while time is displayed in a 12- hour format. The date and time are set per section 5.8. Lat(°): latitude in degrees* lon(°): longitude in degrees* alt(ft): altitude in feet* fix(...

Page 21: 3.9

Hi flow sampler operation instruction 0055-9017 17 3.9 menu system selecting menu from either the basic or expanded main screen provides the user access to a system of submenus as shown in figures 3-4 and 3- 5. The items that are listed in the submenus depend on whether the instrument is in its basi...

Page 22: 3.10 Battery

Operation hi flow sampler instruction 0055-9017 18 3.10 battery status battery status is displayed as a single battery icon shown in the lower- left hand portion of the lcd. Since the voltage curve of the battery pack drops off rapidly towards the end of its charge, the battery status icon is useful...

Page 23

Hi flow sampler operation instruction 0055-9017 19 3.13 menu mode – basic or expanded selecting menu mode from the menu system allows the user to select whether only the most basic amount of information is displayed on the main screen (basic menu mode), or if all available information is displayed (...

Page 24

Operation hi flow sampler instruction 0055-9017 20 3.14.2 manual measurement mode 3.14.2.1 manual 2-stage mode in the manual 2-stage mode the user starts a measurement at a high flow rate, waits for a stable leak rate reading, and then manually saves the readings using the save function. The unit th...

Page 25

Hi flow sampler operation instruction 0055-9017 21 3.14.2.2 manual 1-stage mode in the manual 1-stage mode the user starts a measurement at a high flow rate and then waits for a stable leak rate reading to occur. During this time the flow rate can be changed using the speed function on the main scre...

Page 26: 3.15 Access

Operation hi flow sampler instruction 0055-9017 22 3.15 access records note: send records can only be selected if operating in the expanded menu mode. Refer to section 3.8. Selecting access records from the expanded menu system allows a user to either: 1) send all saved records to a personal compute...

Page 27

Hi flow sampler operation instruction 0055-9017 23 d. Set port settings to: - bits per second: 115200 - data bits: 8 - parity: none - stop bits: 1 - flow control: none then click ok to display hyperterminal’s main window. E. Click file > save. This creates a file with an .Ht extension using the name...

Page 28

Operation hi flow sampler instruction 0055-9017 24 3.15.2 view records view the records stored in memory on the unit’s lcd screen as follows: 1. Access the review record screen from the expanded main screen by selecting menu > access records > view records. This screen allows the user to view a shor...

Page 29

Hi flow sampler operation instruction 0055-9017 25 3.16 importing saved data into a spreadsheet test records that were downloaded to a personal computer per section 3.15.1 can be imported into spreadsheet programs that are capable of importing comma-delimited files. Note that each data record consis...

Page 30

Operation hi flow sampler instruction 0055-9017 26 table 3-2. Typical spreadsheet* record# instr.Serial# date#1(mm/dd/yy) time#1(hh:mm:ss) btry#1(v) flow#1(cfm) 1 123456 01/20/03 10:15:05 4.9 9.9 2 123457 01/20/03 01:25:30 4.8 9.8 back#1(%) leak#1(%) leak#1(cfm) date#2(mm/dd/yy) time#2(hh:mm:ss) btr...

Page 31: 3.17 Access

Hi flow sampler operation instruction 0055-9017 27 3.17 access test ids note: access test ids can only be selected if operating in the expanded menu mode. Refer to section 3.8. Saved test records can be identified (e.G., location of test, type of test, name of operator, etc.) by manually entering up...

Page 32

Operation hi flow sampler instruction 0055-9017 28 3. Select the displayed test id by pressing the i/okey, and then return to the main screen by pressing esc twice. Observe that [0005] is now displayed at the bottom of the screen. 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 l e a k ( n o t a v a i l . ) s p ...

Page 33

Hi flow sampler operation instruction 0055-9017 29 5. Press the esc key twice to return to the main screen. 3.17.3 send test ids the following describes how to download the current list of test ids to a computer that is running windows ® hyperterminal as the communications program. If a different op...

Page 34

Operation hi flow sampler instruction 0055-9017 30 4. From the high flow sampler’s expanded main screen, start the download process by selecting menu > access test ids > send test ids. 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 s e l e c t t e s t i d s e d i t t e s t i d s s e n d t e s t i d s e r a s e t e...

Page 35

Hi flow sampler operation instruction 0055-9017 31 2. Select yes to erase all test id information, or select no to return to the previous screen. 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 e r a s e a l l t e s t i d s ? Y e s n o [ 0 0 0 4 ] ( a ) s - - 3. Press esc twice to return to the main screen..

Page 36

Operation hi flow sampler instruction 0055-9017 32 3.18 making a leak rate measurement before making a leak rate measurement, the user must decide whether to use . . . the basic or expanded menu mode (section 3.8) lpm or cfm for the flow rate (section 3.12) the automatic 2-stage, manual 2-stag...

Page 37

Hi flow sampler operation instruction 0055-9017 33 1 1 / 2 2 / 0 4 0 9 : 4 7 : 3 0 f l o w ( l p m ) 2 1 6 . 5 b a c k ( % ) 0 . 8 0 l e a k ( % ) 1 5 . 0 0 l e a k ( l p m ) 4 2 . 5 s p e e d ( l o h i ) [ 0 0 0 1 ] ( m ) - 1 - s a m p l e t i m e - > 0 2 : 0 0 6. In the example below, the current ...

Page 38

Operation hi flow sampler instruction 0055-9017 34 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 l e a k ( % ) 0 . 0 0 l e a k ( n o t a v a i l . ) s p e e d ( l o h i ) s a v e s t a r t [ 0 0 0 1 ] ( a ) s - - 5. The user is now asked to choose a new or different test id. Selecting yes causes the access record...

Page 39

Hi flow sampler operation instruction 0055-9017 35 7. After both measurements are complete, the values in the main screen are put on hold (as indicated by “h--” appearing at the bottom of the screen), allowing the user to make note of these values before turning off the instrument or proceeding to t...

Page 40

Operation hi flow sampler instruction 0055-9017 36 3.18.3 leak rate measurement – manual 2-stage mode note: the manual 2-stage mode can only be selected if operating in the expanded menu mode. Refer to section 3.8. 1. If not already done, place the instrument into its manual 2-stage mode. Refer to s...

Page 41

Hi flow sampler operation instruction 0055-9017 37 7. Once a stable leak measurement is obtained, highlight save and press the i/okey. Observe that the measurement is saved in memory, and that the flow rate is automatically lowered. In the example below, the measured leak concentration for measur...

Page 42

Operation hi flow sampler instruction 0055-9017 38 3.18.4 leak rate measurement – manual 1-stage mode note: the manual 1-stage mode can only be selected if operating in the expanded menu mode. Refer to section 3.8. 1. If not already done, place the instrument into its manual 1-stage mode. Refer to s...

Page 43

Hi flow sampler operation instruction 0055-9017 39 1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0 f l o w ( l p m ) 0 . 0 b a c k ( % ) 0 . 0 0 l e a k ( % ) 0 . 0 0 l e a k ( l p m ) 0 . 0 s p e e d ( l o h i ) [ 0 0 0 1 ] ( m ) - 1 - speed bar 7. Once a stable leak measurement is obtained, all current readings c...

Page 44: 3.19 Message

Operation hi flow sampler instruction 0055-9017 40 3.19 message line various messages will appear at the bottom of the lcd that describe what functions are currently being performed or errors that have been detected. The following list describes the meaning of these messages. Note that detailed expl...

Page 45: 3.20 Gps

Hi flow sampler operation instruction 0055-9017 41 check zeroing bypassed error – the esc key was pressed during start up, thus bypassing the normal sensor-zeroing process. Refer to section 6.2. Check leak rate difference error–the calculated leak rate difference between measurements #1 and #2 durin...

Page 46: 3.21 Barcode

Operation hi flow sampler instruction 0055-9017 42 the gps data is saved along with all other measured and calculated values at the conclusion of an automatic test, or when save is selected during a manual test. 3.21 barcode scanner data note: barcode scanning can only be performed ifoperating in th...

Page 47: 4 Calibration

Hi flow sampler calibration instruction 0055-9017 43 4 calibration it is recommended that the hi flow sampler be calibrated by your nearest bacharach service center every 30 days. Calibration, however, can be performed in the field if your facility has the necessary equipment and qualified personnel...

Page 48: 4.3

Calibration hi flow sampler instruction 0055-9017 44 figure 4-1. Calibration equipment setup 4.3 check calibration procedure this procedure checks the calibration of both the leak-gas sensor and the background-gas sensor using 2.5% ch 4 . After setting up the calibration equipment as described in se...

Page 49: 4.4

Hi flow sampler calibration instruction 0055-9017 45 5. Disconnect the hose from the background inlet port and connect it to the gas inlet port. 6. Again wait several minutes for the gas reading to stabilize. At this time the gas concentration shown on the display should match the concentration stam...

Page 50

Calibration hi flow sampler instruction 0055-9017 46 5. Apply the appropriate level of calibration gas from the calibration equipment to the instrument’s gas or background inlet port. (in the example above, apply 2.5% ch 4 to the background port.) then press the i/okey to start the calibration pr...

Page 51: 4.5

Hi flow sampler calibration instruction 0055-9017 47 4.5 calibration amplifier gain check use this procedure to display the gain values of the calibration amplifier circuits in hexadecimal. This procedure is useful to service technicians for troubleshooting purposes. 1. From the main screen select m...

Page 52

Calibration hi flow sampler instruction 0055-9017 48 notes:.

Page 53: 5 Maintenance

Hi flow sampler maintenance instruction 0055-9017 49 5 maintenance routine maintenance of the hi flow sampler consists of the following: charging the battery pack replacing the internal filters replacing the gas sensors verifying flow rate setting the time and date resetting the micropro...

Page 54: 5.2

Maintenance hi flow sampler instruction 0055-9017 50 5.2 charging the battery pack warning: explosion hazard!Do not charge the battery pack in an unsafe atmosphere. 1. Unplug battery pack from the instrument’s power cord; then remove battery pack from backpack. 2. Interconnect the supplied power sup...

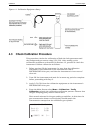

Page 55: 5.3

Hi flow sampler maintenance instruction 0055-9017 51 5.3 removing the cover when instructed to do maintenance inside the instrument, remove its protective cover as follows: 1. Do the following before removing the instrument from the backpack: - disconnect battery pack - unscrew metal-cage diffuser f...

Page 56: 5.4

Maintenance hi flow sampler instruction 0055-9017 52 5.4 replacing the internal filters three internal filters protect the instrument from being contaminated by dust and dirt. Replace these filters when they look contaminated. A good indication that a filter needs replaced is when the instrument’s g...

Page 57

Hi flow sampler maintenance instruction 0055-9017 53 5.4.2 leak-gas sensor filter the leak-gas sensor filter is located inside the flow block of the leak-gas sensor assembly. See figure 5-4. Equipment required: medium phillips head screwdriver replacement filter (p/n 0055-0045) procedure: 1. Rem...

Page 58: 5.5

Maintenance hi flow sampler instruction 0055-9017 54 5.5 gas sensor replacement replace a gas sensor when it fails to calibrate per section 4 calibration. The gas sensors are located inside their associated flow blocks of the leak-gas and background-gas sensor assemblies. See figure 5-5. Figure 5-5....

Page 59: 5.6 Pump

Hi flow sampler maintenance instruction 0055-9017 55 5.6 pump replacement the pump located in either the leak-gas or background-gas sensor assembly (see figure 5-5) may become inoperative due to water or solid particles getting into the valves. This will require replacement of the pump to correct. E...

Page 60: 5.7

Maintenance hi flow sampler instruction 0055-9017 56 5.7 flow rate verification this procedure verifies the instrument’s ability to provide sufficient airflow to capture the entire gas leak, and to verify the accuracy of the instrument’s calculated flow rate by using the optional external flow meter...

Page 61

Hi flow sampler maintenance instruction 0055-9017 57 figure 5-8. Flow rate validation graph 5. With a fully charged battery pack, the measured flow rate should be greater than 9 cfm. If not, perform the following (see figures 5-9 and 5-10): clean the gas sample inlet screen. ensure that the exha...

Page 62

Maintenance hi flow sampler instruction 0055-9017 58 figure 5-9. Gas flow system.

Page 63: 5.8

Hi flow sampler maintenance instruction 0055-9017 59 figure 5-10. Plumbing diagram 5.8 setting date and time the following describes how to set the date and time as displayed on the hi flow sampler’s lcd using a personal computer that is running windows ® hyperterminal as the communications program....

Page 64: 5.9 Resetting

Maintenance hi flow sampler instruction 0055-9017 60 - if hyperterminal has never been run in association with the hi flow sampler, then a new hyperterminal connection needs to be made as follows: a. Select start > run. In the run box type “hypertrm.Exe” and click ok. The new connection dialog box s...

Page 65: 6 Troubleshooting

Hi flow sampler troubleshooting instruction 0055-9017 61 6 troubleshooting 6.1 instrument repair it is recommended that field repair of the hi flow sampler be limited to: cleaning gas-inlet screen replacing internal filters replacing sensors replacing sensor assembly pump simple checks of ...

Page 66

Troubleshooting hi flow sampler instruction 0055-9017 62 table 6-1. Troubleshooting guide (cont.) instrument won’t respond when a control unit key is pressed. Microprocessor needs reset. Disconnect battery pack for several seconds. Low flow rate reading with fully charged battery. Flow path obstruct...

Page 67: 6.3

Hi flow sampler troubleshooting instruction 0055-9017 63 table 6-1. Troubleshooting guide (cont.) “check background offset” message appears at bottom of display. The background-gas sensor did not zero properly during start-up. Switch off instrument and restart in an area with clean air. Replace sens...

Page 68

Troubleshooting hi flow sampler instruction 0055-9017 64 notes:.

Page 69: 7 Parts & Service

Hi flow sampler parts & service instruction 0055-9017 65 7 parts & service 7.1 replacement parts complete hi flow sampler assembly ...................................... 0055-8020 standard attachments: 3-port background gas sampler ....................................... 0055-0271 bellows tool ........

Page 70: 7.3 Service

Parts & service hi flow sampler instruction 0055-9017 66 7.3 service centers united states bacharach sales/service center 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5051 fax: 724-334-5723 email: help@mybacharach.Com canada bacharach of canada, inc. 20 amber st. Unit #7 markham, o...

Page 72

Headquarters: 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 1-800-736-4666 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com printed in u.S.A..