- DL manuals

- Bacharach

- Security Sensors

- MGS-150

- Installation And Operation Manual

Bacharach MGS-150 Installation And Operation Manual

Summary of MGS-150

Page 1

Gas detector installation and operation manual instruction 6309-9000 revision 4 – october 2016 product leadership • training • service • reliability.

Page 2

Mgs-150 manual 2 6309-9000 rev 4 warranty policy bacharach, inc. Warrants this instrument, excluding sensors, to be free from defects in materials and workmanship for a period of one year from the date of purchase by the original owner. The sensors have a warranty period of one year from the date of...

Page 3

Mgs-150 manual 6309-9000 rev 4 3 always include y our rma #, address, telephon e number, conta ct na me, shipping/billing informa tion and a description of the defect as you perc eiv e it. You will be conta cted with a cost estima te for expected r epa irs prior to the performa nce of a ny serv ice ...

Page 4: Table Of Contents

Mgs-150 manual 4 6309-9000 rev 4 table of contents section 1. Overview ................................................................................................... 5 1.1. General information ............................................................................................... 5 1.2....

Page 5: Section 1. Overview

Mgs-150 manual 6309-9000 rev 4 5 section 1. Overview 1.1. General information the mgs-150 is a state-of-the-art fixed gas detector which can detect a wide range of different gases. The gas sens ors can be used on a stand- alone basis or integrated into controls or b uilding management systems (bms)....

Page 6

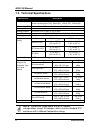

Mgs-150 manual 6 6309-9000 rev 4 1.2. Technical specifications specification description power supply 12-24 vdc, 12-24 vac 50/60 hz, 2 w max. Power consumption (12v): 60ma (ec), 153ma (sc), 136ma (ir) monitoring leds power: green led alarm: red led audible alarm buzzer, enable/disable analog outputs...

Page 7

Mgs-150 manual 6309-9000 rev 4 7 note: the haz ardous area exd gas monitor products are designed wit h individually certified e xd main housing enclosures and certified e xd remote or attached sensor enclosures. The main housing enclosure and its pcb assembly are als o e xd certified, but the final ...

Page 8

Mgs-150 manual 8 6309-9000 rev 4 section 2. Installation and wiring warni ng: explosion hazard! Do not mount the mgs in an area that may contain flammable liquids, vapors, or aerosols. Operation of any electrical equipment in such an environment constitutes a safety hazard. Caution: the mgs contains...

Page 9

Mgs-150 manual 6309-9000 rev 4 9 2.1. General placement guidelines note: the mgs-150 should be installed plumb and level and securely fastened to a rigid mounting surface. Sensors must be located within the appropriate wire lengt hs from the central control unit (if used). In all cases the sensor su...

Page 10

Mgs-150 manual 10 6309-9000 rev 4 figure 2. Ec or ir sensor components and wiring.

Page 11

Mgs-150 manual 6309-9000 rev 4 11 1 . Figure 3. Sc sensor components and wiring.

Page 12: 2.3. Machinery Rooms

Mgs-150 manual 12 6309-9000 rev 4 item description enclosure acce ss to open the standard sensor enclosure, turn the cable clamp 1/2 turn counter-clockwise to loosen the int ernal gland nut, depress the clip on top of the enclosure and open. Reverse to close. (note: for the ip66 enclosure, use the f...

Page 13

Mgs-150 manual 6309-9000 rev 4 13 consider ease of access for maintenance. The size and nature of the site will help to decide which met hod is the most appropriate to use. Locations requiring the most protection in a machinery or plant room would be around compressors, pressurized storage vessels, ...

Page 14: 2.4. Refrigerated Spaces

Mgs-150 manual 14 6309-9000 rev 4 • for racks or chillers pre-fitted with refrigerant sensors, these should be mounted so as to monitor the compressors. If extract ducts are fitted the airflow in the duct may be monitored. 2.4. Refrigerated spaces in refrigerated spaces, sensors should be located in...

Page 15

Mgs-150 manual 6309-9000 rev 4 15 2.6. Air conditioning (direct systems vrf/vrv) for compliance with e n378, at least one detector shall be installed in each occupied s pace being considered and t he loc ation of detectors shall be chosen in relation to the refrigerant and they shall be located wher...

Page 16

Mgs-150 manual 16 6309-9000 rev 4 2.7. Remote sensor head installation if you do not wish to surface mount the mgs, a brushed stainless steel faceplate is available. The remote sensor is mounted in an electrical back box 1.7 in (44 mm) deep to which the vented faceplate is fitted. Caution: to avoid ...

Page 17

Mgs-150 manual 6309-9000 rev 4 17 section 3. Housing dimensions figure 4. Mgs-150 standard housing.

Page 18

Mgs-150 manual 18 6309-9000 rev 4 figure 5. Ip66 housing with splashguard.

Page 19: Figure 7. Exd Housing

Mgs-150 manual 6309-9000 rev 4 19 figure 6. Ip66airflow duct mount housing figure 7. Exd housing units = mm.

Page 20

Mgs-150 manual 20 6309-9000 rev 4 for dimensions and mounting locations , see figure 5. Figure 8. Ip66 housing with remote sensor head note: for the exd remote sensor head and 16.4 ft (5 m) cable, the thread varies based on the model. 9.8 feet (3 meters) typical.

Page 21

Mgs-150 manual 6309-9000 rev 4 21 section 4. Operation and stabilization on powering up, the mgs-150 will sense for the pres ence of gas after an initial warm-up delay of 5 minutes. The green led will flash at 1 second intervals during the warm-up. In an alarm condition: • green led stays on and the...

Page 22: 5.1. Overview

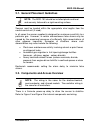

Mgs-150 manual 22 6309-9000 rev 4 section 5. Configurations 5.1. Overview function description time delay a vailable on the audible alarm and relay to avoid false alarms. This is set with jumpers. The default delay is 0 minutes. You may wish to set to 15 minutes during start up. See figure 2 and fig...

Page 23: 6.1. Introduction

Mgs-150 manual 6309-9000 rev 4 23 section 6. Functional tests and calibration 6.1. Introduction to comply with t he requirements of en378 and t he e uropean f-gas regulation, sensors must be tested annually. However, local regulations may specify the nature and frequency of this test. Caution: check...

Page 24

Mgs-150 manual 24 6309-9000 rev 4 important: failure to t est or calibrate t he unit in accordance with applicable instructions and with industry guidelines may result in serious injury or death. The manufacturer is not liable for any loss, injury, or damage arising from improper testing, incorrect ...

Page 25: 6.2. Bump Testing

Mgs-150 manual 6309-9000 rev 4 25 bump test exposing the sensor to a gas and observing its response to the gas. The objective is to establish if the sensor is reacting to the gas and all the sensor outputs are working correctly. There are two types of bump test. Quantified: a known concentration of ...

Page 26

Mgs-150 manual 26 6309-9000 rev 4 note: prior to carrying out a bump test, check and adjust the zero setting as described in the calibration section. Note: p rocedures for bump test and calibration vary depending on the sensor technology used and the gas in question. The mgs is available in three se...

Page 27

Mgs-150 manual 6309-9000 rev 4 27 figure 9. Gas cylinder and test hardware gas ampoules are convenient and inexpensive alternatives to using gas cylinders for bump testing. Step bump testing usi ng ga s ampoule s 1 make sure that both the ampoules and the calibration beaker are clean and dry. 2 unsc...

Page 28

Mgs-150 manual 28 6309-9000 rev 4 step bump testing usi ng ga s ampoule s 7 tighten the wing-nut screw onto the ampoule until it shatters allowing the gas to diffus e in the beaker. It should be left in place for approximately 5 min. 8 the voltage output will increase. This confirms that the sensor ...

Page 29

Mgs-150 manual 6309-9000 rev 4 29 6.4. Calculating calibration voltage sensor out puts are linear. As long as you have a gas cylinder of known concentration you can calibrate to any desired range. Example: for a sensor range of 0-1000 ppm and a cylinder of t he target gas at 800 ppm: ??????? = ?????...

Page 30

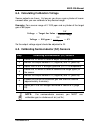

Mgs-150 manual 30 6309-9000 rev 4 6.6. Calibrating electrochemical (ec) sensors there are two adjustments required: zero and s pan. They are monitored at 0v and vs using a 0-5v scale. If the sensor range is 0-1000 ppm, then 5v=1000 ppm. Step calibrating electrochemical (ec) sensors 1 locate pot vr20...

Page 31

Mgs-150 manual 6309-9000 rev 4 31 section 7. Troubleshooting symptom possible cause(s) green and red light off • check power supply. Check wiring. • mgs-150 was possibly damaged in transit. Check by installing another mgs-150 to confirm the fault. Red light on, green led off (indicates a fault) • se...

Page 32

Mgs-150 manual 32 6309-9000 rev 4 the technical documentation file required by this directive is maintained at the corporate headquarters of bacharach, inc. Note: the directives or harmonized standards to which this product has been evaluated may have changed. Bacharach, inc. However continues to ma...

Page 33

Mgs-150 manual 6309-9000 rev 4 33.

Page 34

Mgs-150 manual 34 6309-9000 rev 4.

Page 35

Mgs-150 manual 6309-9000 rev 4 35.

Page 36

Mgs-150 manual 36 6309-9000 rev 4 www.Mybacharach.Com ● help@mybacharach.Com bacharach world headquarters - usa 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5000 • toll free: 1-800-736-4666 • fax: 724-334-5001 murco ltd – a bacharach company 114a george’s street low er dun laoghair...