Bacharach Portable Combustion Analyzer Instruction

Summary of Portable Combustion Analyzer

Page 1

Portable combustion analyzer (pca) instruction 0024-9219 operation & maintenance rev. 10 – may 2010 product leadership • training • service • reliability.

Page 2

Warranty bacharach, inc. Warrants to buyer that at the time of delivery this product will be free from defects in material and manufacture and will conform substantially to bacharach inc.’s applicable specifications. Bacharach’s liability and buyer’s remedy under this warranty are limited to the rep...

Page 3: Contents

Pca contents contents 1.0 introduction ............................................................................ 1-1 1.1 the portable combustion analyzer ........................................... 1-1 1.2 displayed data ........................................................................... ...

Page 4

Contents pca 4.22 user name screens ................................................................ 4-28 4.23 saving test data .................................................................... 4-29 4.24 printing test data .................................................................. 4-30 4....

Page 5: 1.0 Introduction

Pca 1.0 introduction introduction 1.1 the portable combustion analyzer the portable combustion analyzer (pca) (figure 1-1) is a commercial grade, hand held, combustion efficiency analyzer that is designed for continuous (on demand) sampling of light industrial and residential furnaces, appliances, a...

Page 6: 1.2 Displayed Data

Introduction 1.2 displayed data pca the pca directly measures, displays, and stores the following data: • room temperature in °f or °c (primary air/ambient temperature) • flue gas oxygen content in % • flue gas temperature in °f or °c • flue gas carbon monoxide content (h 2 compensated) in ppm (for ...

Page 7

Pca 1.3 pca model configurations introduction table 1-1. Pca sensor configurations pca models standard advanced sensors installed pca part no. Pca part no. Stack temp., co nx draft model 24- model 24- air temp. & o 2 ( p) 10 8040 40 8140 x 15 8041 45 8141 x x 20 8042 50 8142 x x 25 8043 55 8143 x x...

Page 8

Introduction pca pca 30 & 60 with co and nitric oxide measurement in addition to the features of the basic pcas with co measurement, these instruments have the added capability of measuring, displaying, and saving nitric oxide (nx) content, as well as calculating a nx level that is referenced to oxy...

Page 9

Pca technical characteristics 2.0 technical characteristics the pca directly measures and displays: • oxygen content in flue gas in the range of 0.1 to 20.9 % o 2 • flue gas temperature in the range of 0 to 2192 ºf (–18 to 1200 ºc) • primary-air / ambient temperature is in the range of 0 to 999 ºf (...

Page 10

Technical characteristics pca normal operating conditions: temperature: analyzer ................... 32 to 104 ºf (0 to 40 ºc) probe tip .................. 1472 ºf (800 ºc) max. Humidity: analyzer ................... 15 to 90% relative humidity, non-condensing air pressure: analyzer ...................

Page 11

Pca technical characteristics power requirements: four aa alkaline batteries. Battery backup for the real-time clock, ram, and bias voltage for the nitric oxide sensor is provided by internal lithium batteries. Optional ac power supplies (110 vac & 230 vac) are also available. Operating time: a fres...

Page 12

Technical characteristics notes: pca 2-4 instruction 0024-9219.

Page 13: 3.0 Setting Up The Pca

Pca 3.0 setting up the pca 3.1 scope before using the pca, you must: setup • check the batteries or plug in an optional power supply (section 3.2) • connect the probe to the analyzer (section 3.3) • check the analyzer’s configuration (section 3.4) 3.2 pca power 3.2.1 checking and replacing the batte...

Page 14: 3.3 Connecting The Probe

Setup 3.2.2 using the optional power supply if an optional power supply is to be used: 1. Connect the output plug of the optional power supply to the analyzer’s power supply jack (figure 3-2). Pca 2. Plug the optional power supply into an appropriate ac wall outlet. The analyzer will now operate and...

Page 15

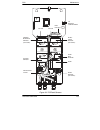

Pca setup reset button room air / primary air thermocouple (optional) power supply 110v/60hz 230v/50hz (optional) flue gas thermocouple draft hose * pressure reference port * (used in the measurement of differential pressure) flue gas hose * present only on analyzers equipped with a pressure sensor....

Page 16: 3.4 Configuring The Pca

Setup 3.4 configuring the pca pca the pca is configured at the factory for the parameters shown below. These parameters, however, can be changed by following the instructions in their associated sections. Function parameters to change, refer to . . . Fuel natural gas section 4.8 temperature ºc secti...

Page 17: 4.0 Operation

Pca 4.0 operation 4.1 key pad functions operation descriptions of the key pad functions are given below. Note that most of the front panel key pad buttons perform multiple functions as determined by what screen is being displayed at the time. Turns the analyzer on and off. Note that there is a 5 sec...

Page 18

Operation 4.2 sampling hole location pca the analyzer requires that a ½" diameter sampling hole be made in the furnace stack to accommodate the probe stop on the probe and hose assembly. Locate the sampling hole downstream from the last heat exchanger, and upstream from any source of dilution, such ...

Page 19

Pca 4.3 performing a combustion test operation important! Large rapid changes in the temperature of the analyzer can affect its accuracy. This is important to know if the analyzer is stored in a cold place (such as an unheated vehicle in the winter) and then taken into a warm furnace area. For the m...

Page 20

Operation 4.3.2 installing probe in the stack pca 1. After making a sampling hole in the stack (section 4.2), and turning on the analyzer (section 4.3.1), screw the probe stop supplied with the probe and hose assembly into the sampling hole (figure 4-2). 2. Insert the probe through the hole in the p...

Page 21

Pca 4.3.3 starting a combustion test operation important! If the burner’s primary-air temperature is not the same as the room temperature, then be sure the optional room air / primary air thermocouple is installed per section 3.3. 1. With the combustion test screen (section 4.7) displayed and the pr...

Page 22

Operation caution: do not place a hot probe inside the instrument’s carrying case. Allow the probe to cool before storage. Pca 2. Loosen the thumbscrew on the probe stop; then remove the probe and probe stop from the stack. 3. If data was saved during the combustion test, you can turn off the analyz...

Page 23

Pca 4.4 differential pressure measurement operation the difference in pressure ( p) between two areas can be measured by using the pca’s two pressure ports and draft screen. By using pres- sure port 2 (–) as the reference, the pressure applied to port 1 (+) will be displayed on the draft screen as ...

Page 24: 4.5 Warm-Up Screen

Operation 4.5 warm-up screen bacharach, inc. Pca xx warmup yy where: xx = instrument model number yy = counts down from 60 seconds pca as soon as the on / off key is pressed, the instrument’s serial number and software version number are displayed for approximately 3 seconds. To continuously display...

Page 25: 4.6 Sensor Status Screen

Pca 4.6 sensor status screen bacharach, inc. Pca xx warmup 0 z where: xx = instrument model number z = sensor(s) in error operation if a problem with one or more of the sensors was detected during warmup, the sensor status screen will display an error code for those sensors at the bottom of the scre...

Page 26

Operation 4.7 combustion test screen pca models 10 thru 25, 40 thru 55 pca models 30, 35, 60, & 65 pca o2 4.0 co 12 hld o2 4.0 co 12 hld c2 9.5 cf 15 ng c2 9.5 nx 10 ng ta 68.0 ts 374 p ta 68.0 ts 374 p ef 82.6 ea 21 « s ef 82.6 ea 21 « s this screen shows: o2 ............... Oxygen content in flue ...

Page 27: 4.8 Fuel Selection Screen

Pca 4.8 fuel selection screen «natgas fuel oil #2 kerosene oil #4 propane oil #6 coal operation this screen is displayed by pressing the menu key from the combustion test screen, and is used to select the fuel being burned. To select a fuel, first use the st keys to move the cursor ( z ) in front of...

Page 28: 4.9 Draft Screens

Operation 4.9 draft screens (for pca models 15, 25, 35, 45, 55 & 65) pca the first draft screen is displayed by repeatedly pressing the menu key from the combustion test screen. To measure draft, first zero the analyzer’s pressure sensor to atmo- spheric pressure by disconnecting the draft hose from...

Page 29

Pca 4.10 memory directory screen operation ‘standard’ pca screen ‘advanced’ pca screen memory directory memory directory «m8 2/24/01 3:45pm «98 2/24/01 3:45pm m9 memory empty 99 memory empty clear memory clear memory the memory directory screen is displayed by repeatedly pressing the menu key from t...

Page 30: 4.11 Memory to Pc Screen

Operation 4.11 memory to pc screen (for ‘advanced’ pca models 40, 45, 50, 55, 60 & 65) memory to pc «transmit data clear memory pca the memory to pc screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to either transmit all stored memory locations...

Page 31

Pca operation data is transmitted to a computer in ascii comma-delimited format, which can be captured as a text file and then opened in most commer- cially available spreadsheet programs. Note that each data record con- sists of 20 fields, some of which may be blank for different tests and pca mode...

Page 32

Operation pca table 4-1. Comma-delimited fields field data name or value label in column headings 1 instrument serial number sn 2 id line 1 (up to 16 characters) id1 3 id line 2 (up to 16 characters) id2 4 id line 3 (up to 16 characters) id3 5 time of test (hh:mm:ss) time 6 date of test (dd.Mm.Yyyy)...

Page 33: 4.12 Id Setup Screens

Pca 4.12 id setup screens (for ‘advanced’ pca models 40, 45, 50, 55, 60 & 65) setup «id #1 id #2 id #3 operation this initial id setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to edit three lines of customer information (e.G., the custo...

Page 34

Operation pca press enter to save the selected character and advance to the next posi- tion. If you make a mistake, press enter until the cursor is over the incorrect character and make your correction by again using the st keys. After all the desired characters have been selected, press the run key...

Page 35

Pca 4.13 temperature setup screen setup temperature unit «°c °f operation the temperature setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to setup the analyzer to display temperature in either °c or °f. To select the temperature unit-of-...

Page 36

Operation 4.14 draft unit setup screen (for pca models 15, 25, 35, 45, 55 & 65) setup draft unit mb pa «wc pca the draft unit setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to setup the analyzer to display draft in either millibars (mb)...

Page 37: 4.15 O

Pca 4.15 o 2 reference setup screen (for ‘advanced’ pca models 50, 55, 60 and 65) setup o2 reference 0% operation the o 2 reference setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to select the o 2 reference level that the analyzer will ...

Page 38

Operation 4.16 language setup screen setup language «eng esp fra pca the language setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to select the language displayed on the analyzer. The languages available for selection include english (en...

Page 39

Pca 4.17 display mode setup screen (for pca models 30, 35, 60 & 65) setup display «co nx cf nf operation the display setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to select whether the combustion test screen will display the measured v...

Page 40

Operation 4.18 time / date setup screen setup «time 03:12:45 pm date 02/24/01 pca the time/date setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to enter the cur- rent time and date as follows: use the st keys to move the cursor ( z ) in ...

Page 41: 4.19 Printer Setup Screen

Pca 4.19 printer setup screen setup «ir - hp printer ir - irda rs232 operation the printer setup screen is displayed by repeatedly pressing the menu key from the combustion test screen. Use this screen to choose the type of connection and printer being used. Ir-hp: infrared connection to a printer m...

Page 42: Password Screen

Operation 4.20 calibration / maintenance password screen pca pca models 10 thru 35 pca models 40 thru 65 calibration maintenance «password xxx «password xxx where: xxx = password number the calibration / maintenance password screen is displayed by repeat- edly pressing the menu key from the combusti...

Page 43: 4.21 Maintenance Screen

Pca 4.21 maintenance screen (for pca models 40, 45, 50, 55, 60 & 65) maintenance «calibration user name operation the maintenance screen is displayed after entering the correct password in the maintenance password screen. Use this screen to either enter the analyzer’s calibration menu screen or user...

Page 44: 4.22 User Name Screens

Operation 4.22 user name screens (for pca models 40, 45, 50, 55, 60 & 65) user name «line 1 line 2 line 3 pca this initial user name screen is displayed after selecting user name from the maintenance screen. Use this screen to either enter or edit three lines of user-name information. Each user-name...

Page 45: 4.23 Saving Test Data

Pca operation press enter to save the selected character and advance to the next posi- tion. If you make a mistake, press enter until the cursor is over the wrong character and make your correction by again using the st keys. After all the desired characters have been selected, press run to save the...

Page 46: 4.24 Printing Test Data

Operation 4.24 printing test data pca o2 4.0 co 12 hld draft c2 9.5 nx 15 ng draft – 0.25 wc ta 68.0 ts 374 «p hot spot 374 °f «p ef 82.6 ea 21 s s before printing, ensure that the correct connection and printer has been selected per section 4.19. The print function is available in either the combus...

Page 47

Pca operation when using a serial printer: 1. First connect the analyzer to the printer using the optional rs-232 cable (see figure 4-6). 2. Set the printer’s communication parameters to 9600 baud, 8 data bits, 1 stop bit, no parity, and no handshaking. 3. Use the st keys to move the cursor ( z ) in...

Page 48: 4.25 Clear Memory Screen

Operation 4.25 clear memory screen clear memory c «e pca the clear memory screen is accessed from either the memory directory screen (section 4.10) or the memory to pc screen (section 4.11). To clear all memory locations, use the st keys to move the cursor ( z ) in front of the clear (c) function, a...

Page 49: 5.0 Calibration

Pca 5.0 calibration calibration note: bacharach recommends that the pca be calibrated by your nearest bacharach service center. Calibration, however, can be performed in the field if your facility has the necessary equipment and qualified personnel to perform the procedures described in the sections...

Page 50: 5.2 Calibration Fixtures

Calibration 5.2 calibration fixtures pca a gas and a draft fixture will be required to perform the various calibra- tion procedures described in this manual. Material required: • calibration kit (refer to section 8.2) • calibration gas cylinder (refer to section 8.2) • bellows • micromanometer proce...

Page 51: 5.3 Calibrate Menu Screen

Pca 5.3 calibrate menu screen «ts-zero calibrate ts-span nx ta-zero co ta-span draft calibration the calibrate menu screen is displayed after entering either the correct password in the calibration password screen for ‘standard’ pcas, or the maintenance password screen and selecting calibration from...

Page 52: 5.4 Calibrate Ts-Zero

Calibration 5.4 calibrate ts-zero material required: • thermocouple simulator (k-type) range: 0 to 600 °f accuracy: ±0.5 °f procedure: pca 1. With the analyzer turned off, first plug the simulator’s k-type connec- tor into the t-stack jack (figure 3-2); then turn on the analyzer and wait for its war...

Page 53: 5.5 Calibrate Ts-Span

Pca 5.5 calibrate ts-span material required: • thermocouple simulator (k-type) range: 0 to 600 °f accuracy: ±0.5 °f procedure: calibration 1. With the analyzer turned off, first plug the simulator’s k-type connec- tor into the t-stack jack (figure 3-2); then turn on the analyzer and wait for its war...

Page 54: 5.6 Calibrate Ta-Zero

Calibration 5.6 calibrate ta-zero material required: • thermocouple simulator (k-type) range: 0 to 600 °f accuracy: ±0.5 °f procedure: pca 1. With the analyzer turned off, first plug the simulator’s k-type connec- tor into the t-air jack (figure 3-2); then turn on the analyzer and wait for its warm-...

Page 55: 5.7 Calibrate Ta-Span

Pca 5.7 calibrate ta-span material required: • thermocouple simulator (k-type) range: 0 to 600 °f accuracy: ±0.5 °f procedure: calibration 1. With the analyzer turned off, first plug the simulator’s k-type connec- tor into the t-air jack (figure 3-2); then turn on the analyzer and wait for its warm-...

Page 56: 5.8 Calibrate

Calibration 5.8 calibrate nx (for pca models 30, 35, 60 & 65) pca the nitric oxide sensor needs to be spanned at regular intervals to determine if the analyzer still meets its accuracy specification. Because of the toxicity of nitric oxide gas, however, unless your facility has the necessary gas cyl...

Page 57: 5.9 Calibrate Co

Pca 5.9 calibrate co (for pca models 20, 25, 30, 35, 50, 55, 60 & 65) material required: • calibration gas fixture (section 5.2) • gas cylinder, 500 ppm co in air (refer to section 8.2) • gas cylinder, co (1000 ppm) and h 2 (1000 ppm) in nitrogen (refer to section 8.2) procedure: calibration 1. Ente...

Page 58

Calibration pca 7. Turn off the flow of co calibration-gas; then remove the calibration- gas cylinder from the calibration fixture. 8. Attach a co/h 2 calibration-gas cylinder to the calibration fixture; then adjust the regulator of the calibration fixture for a flowmeter reading of approximately 2 ...

Page 59: 5.10 Calibrate Draft

Pca 5.10 calibrate draft (for pca models 15, 25, 35, 45, 55 & 65) material required: calibration • calibration fixture (section 5-2) • bellows (adjustable) • micromanometer range: ±8 in. H 2 o column (±20 mb) accuracy: ±0.01 in. H 2 o column (±0.025 mb) procedure: important! In step 1, do not connec...

Page 60

Calibration pca notes: 5-12 instruction 0024-9219.

Page 61: 6.0 Maintenance

Pca 6.0 maintenance 6.1 routine maintenance maintenance routine maintenance of the analyzer consists of: replacing the batteries, cleaning the probe, draining the water trap, replacing the water trap filter, and performing periodic calibration checks to ensure that the analyzer is providing accurate...

Page 62: 6.2 Disassembly

Maintenance 6.2 disassembly pca perform the following when a maintenance procedure calls for removing the case, printed circuit board, pump, or sensors: 1. Remove the batteries (section 3.2.1) 2. Place the analyzer face down on a work surface, then remove the unit’s four rear-case screws. 3. Careful...

Page 63

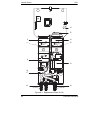

Pca maintenance co pcb nx pcb bias battery fuse to battery compartment carbon monoxide sensor (optional) nitric oxide sensor (optional) oxygen sensor – + red pump mtg. Screws pump black particulate filter draft sensor (optional) figure 6-2. Pcb and sensors instruction 0024-9219 6-3.

Page 64: 6.3 Cleaning The Probe

Maintenance 6.3 cleaning the probe pca the probe tube and the probe body will become dirty under normal use (the water trap’s filter element should prevent soot from reaching the analyzer’s internal components). If the probe assembly is not kept clean, it could become clogged and restrict the flow o...

Page 65

Pca maintenance 6.4 water trap/filter assembly maintenance the water trap / filter assembly removes water condensate from the gas sample, and also prevents soot from contaminating the internal compo- nents of the analyzer. Drain the water condensate after every use. Procedure: 1. Pull off the end-ca...

Page 66

Maintenance 6.5 replacing the particulate filter pca the internal particulate filter (figure 6-2) prevents small dust and dirt particles from entering and damaging the pump. Depending on your environmental conditions, it is recommended to change the particulate filter and fitting approximately every...

Page 67

Pca 6.6 replacing the oxygen sensor maintenance replace the oxygen sensor when it has expired (when the analyzer’s automatic o 2 calibration fails and the unit displays the message “o2- sensor error”). Note: a "o2-sensor error" displayed in the sensor status screen does not necessarily mean that the...

Page 68

Maintenance 6.7 replacing the nitric oxide sensor (for pca models 30, 35, 60 & 65) replace the nitric oxide sensor when it has expired (can no longer be calibrated). Note: a "nx-sensor error" displayed in the sensor status screen does not necessarily mean that the sensor has expired. Before replacin...

Page 69

Pca 6.7.2 replacing the nitric oxide sensor bias battery maintenance a single lithium battery, located on the nitric oxide printed circuit board (see figure 6-2), applies a constant bias voltage to the nitric oxide sensor even while the instrument is turned off. This battery has a life expectancy of...

Page 70

Maintenance pca 6.8 replacing the carbon monoxide sensor (for pca models 20, 25, 30, 35, 50, 55, 60 & 65) replace the carbon monoxide sensor when it has expired (can no longer be calibrated). Note: a "co-sensor error" displayed in the sensor status screen does not necessarily mean that the sensor ha...

Page 71

Pca maintenance 6.8.1 replacing the carbon monoxide sensor filter to increase the life of the carbon monoxide sensor, it is recommended its red filter be replaced once a year . Procedure: 1. Remove the carbon monoxide sensor per section 6.8. 2. Pry the red filter from the carbon monoxide sensor and ...

Page 72

Maintenance 6.9 replacing the pump assembly replace the pump assembly if it is found to be defective. Equipment required: • 1 / 8 " flat blade screw driver • no. 1 phillips screw driver • pump assembly (refer to section 8.1) procedure: pca 1. Remove the analyzer’s rear case and lay it aside (refer t...

Page 73: 7.0 Troubleshooting

Pca 7.0 troubleshooting 7.1 analyzer repair troubleshooting it is recommended that field repair of the pca be limited to: • simple checks of the printed circuit boards • replacing the probe assembly • replacing the filter element in the water trap / filter assembly • replacing the particulate filter...

Page 74: 7.2 Error

Troubleshooting 7.2 error codes pca if one of the following messages or symbols is displayed, refer to section 7.3 troubleshooting guide for information on how to correct the error. O2 - sensor error o 2 sensor not connected, or is expired, or was exposed to combustion gases during warmup. Co - sens...

Page 75: 7.3 Troubleshooting Guide

Pca 7.3 troubleshooting guide troubleshooting the following table lists the most common analyzer faults, causes and remedies. For help with any problem not discussed here, please contact the nearest bacharach service center per section 8.3. Table 7-1. Troubleshooting guide fault probable cause & rem...

Page 76

Troubleshooting pca table 7-1. Troubleshooting guide (cont.) fault probable cause & remedy nx-sensor error code appears in the sensor status screen. Co-sensor error code appears in the sensor status screen. Draft-sensor error code appears in the sensor status screen. T-stack or t-air sensor error co...

Page 77

Pca troubleshooting table 7-1. Troubleshooting guide (cont.) fault probable cause & remedy “****” appears in one or more value fields. “- - - -” appears in one or more value fields of the combustion test screen. “xxxx” appears in one or more value fields. Analyzer won’t respond when a panel key is p...

Page 78

Troubleshooting table 7-1. Troubleshooting guide (cont.) pca fault probable cause & remedy backlight will not turn on. Batteries do not last 10 hours. Erratic combustion test screen values. Analyzer will not calibrate prop- erly. Backlight led burned out. Return to bacharach for repair. Cold tempera...

Page 79: 8.0 Parts & Service

Pca 8.0 parts & service 8.1 replacement parts parts & service item description part no. (figure 8-1) 1 battery cover 0024-0784 2 screw, case housing 0501-3824 3 screw, pump mounting 0501-3822 8 oxygen sensor 0024-0788 9 carbon monoxide sensor 0024-0789 10 nitric oxide sensor 0024-0881 11 carbon mono...

Page 80: 8.2 Accessories

Parts & service 8.2 accessories pca description part no. Standard accessories: battery, “aa” alkaline 0204-0004 complete probe and hose assembly (gas & draft) 0024-3004 instruction manual 0024-9219 plastic carrying case 0024-1078 optional accessories: ambient thermocouple, 10 ft. K-type 0104-1797 am...

Page 81

Pca parts & service figure 8-1. Replacement parts (1 of 3) instruction 0024-9219 8-3.

Page 82

Parts & service pca fuse 14 15 9 10 11 12 8 – + 13 red black 16 17 18 19 figure 8-1. Replacement parts (2 of 3) 8-4 instruction 0024-9219.

Page 83

Pca parts & service / ! ( * figure 8-1. Replacement parts (3 of 3) instruction 0024-9219 8-5.

Page 84: 8.3 Service Centers

Parts & service 8.3 service centers pca united states bacharach, inc. 621 hunt valley circle new kensington, pa 15068 phone: 724-334-5051 fax: 724-334-5723 email: help@bacharach-inc.Com canada bacharach of canada, inc. 20 amber st. Unit #7 markham, ontario l3r sp4 canada phone: 905-470-8985 fax: 905...

Page 85: Appendix A

Pca appendix a display screen translations english french spanish warm up screen appendix a bacharach, inc. Bacharach, inc. Bacharach, inc. Pca nn pca nn pca nn warmup nn echauffement nn calentamiento nn sensor status screen (errors) no errors detected pas d d'erreur relevee no error detectado low b...

Page 86

Appendix a english french spanish saving memory screen saving memory garde location salvando en memoria location nn memoire nn localizacion nn memory directory screen memory directory liste memoire directorio mem memory empty memoire vide memoria vacia clear memory effacer memoire borrar memoria dra...

Page 87

Pca english french spanish time/date setup screen setup programme setup time heure hora date date fecha printer setup screen setup printer programme printer setup printer ir - hp ir - hp ir - hp ir - irda ir - irda ir - irda rs232 rs232 rs232 maintenance password screen maintenance maintenance mante...

Page 88

Appendix a english french spanish pca calibrate ta-span screen calibrate ta-span calibrer ta portee calibrar ta-span measured mesuree medido applied appliquee aplicado bad calibration entry erreur d'etalonnage calibracion-incorrecta calibrate nx screen calibrate nx calibrer nx calibrar nx measured m...

Page 89

Pca appendix b appendix b – printout translations english french spanish combustion test data [line 1: user name] [line 2: user name] [line 3: user name] bacharach, inc. Pca 65 sn: xxxxxx ==================== id1: [optional data] id2: [optional data] id3: [optional data] time 04:27:35 pm date 02/24/...

Page 90

Appendix b pca notes: b-2 instruction 0024-9219.

Page 91

World headquarters 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 800-736-4666 website: www.Mybacharach.Com • e-mail: help@mybacharach.Com printed in u.S.A..